JP5425508B2 - モーターケーブル装置、及び、モーターケーブル装置のケーブル本体製造方法 - Google Patents

モーターケーブル装置、及び、モーターケーブル装置のケーブル本体製造方法 Download PDFInfo

- Publication number

- JP5425508B2 JP5425508B2 JP2009082055A JP2009082055A JP5425508B2 JP 5425508 B2 JP5425508 B2 JP 5425508B2 JP 2009082055 A JP2009082055 A JP 2009082055A JP 2009082055 A JP2009082055 A JP 2009082055A JP 5425508 B2 JP5425508 B2 JP 5425508B2

- Authority

- JP

- Japan

- Prior art keywords

- cable

- motor

- inverter

- cables

- vibration

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 9

- 230000001681 protective effect Effects 0.000 claims description 16

- 239000011347 resin Substances 0.000 claims description 13

- 229920005989 resin Polymers 0.000 claims description 13

- 238000004804 winding Methods 0.000 claims description 11

- 239000006096 absorbing agent Substances 0.000 claims description 3

- 238000003825 pressing Methods 0.000 claims description 3

- 230000001012 protector Effects 0.000 description 25

- 238000010521 absorption reaction Methods 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 238000000034 method Methods 0.000 description 5

- 230000035939 shock Effects 0.000 description 5

- QTBSBXVTEAMEQO-UHFFFAOYSA-M Acetate Chemical compound CC([O-])=O QTBSBXVTEAMEQO-UHFFFAOYSA-M 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 230000006866 deterioration Effects 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 238000009954 braiding Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- NJPPVKZQTLUDBO-UHFFFAOYSA-N novaluron Chemical compound C1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1F NJPPVKZQTLUDBO-UHFFFAOYSA-N 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/02—Details

- H02G3/04—Protective tubing or conduits, e.g. cable ladders or cable troughs

- H02G3/0437—Channels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L3/00—Electric devices on electrically-propelled vehicles for safety purposes; Monitoring operating variables, e.g. speed, deceleration or energy consumption

- B60L3/0007—Measures or means for preventing or attenuating collisions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L3/00—Electric devices on electrically-propelled vehicles for safety purposes; Monitoring operating variables, e.g. speed, deceleration or energy consumption

- B60L3/0023—Detecting, eliminating, remedying or compensating for drive train abnormalities, e.g. failures within the drive train

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L50/00—Electric propulsion with power supplied within the vehicle

- B60L50/50—Electric propulsion with power supplied within the vehicle using propulsion power supplied by batteries or fuel cells

- B60L50/51—Electric propulsion with power supplied within the vehicle using propulsion power supplied by batteries or fuel cells characterised by AC-motors

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G11/00—Arrangements of electric cables or lines between relatively-movable parts

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K11/00—Structural association of dynamo-electric machines with electric components or with devices for shielding, monitoring or protection

- H02K11/30—Structural association with control circuits or drive circuits

- H02K11/33—Drive circuits, e.g. power electronics

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K5/00—Casings; Enclosures; Supports

- H02K5/04—Casings or enclosures characterised by the shape, form or construction thereof

- H02K5/22—Auxiliary parts of casings not covered by groups H02K5/06-H02K5/20, e.g. shaped to form connection boxes or terminal boxes

- H02K5/225—Terminal boxes or connection arrangements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2270/00—Problem solutions or means not otherwise provided for

- B60L2270/10—Emission reduction

- B60L2270/14—Emission reduction of noise

- B60L2270/145—Structure borne vibrations

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K5/00—Casings; Enclosures; Supports

- H02K5/24—Casings; Enclosures; Supports specially adapted for suppression or reduction of noise or vibrations

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/64—Electric machine technologies in electromobility

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49117—Conductor or circuit manufacturing

- Y10T29/49194—Assembling elongated conductors, e.g., splicing, etc.

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Mechanical Engineering (AREA)

- Sustainable Energy (AREA)

- Sustainable Development (AREA)

- Transportation (AREA)

- Life Sciences & Earth Sciences (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Motor Or Generator Frames (AREA)

- Details Of Indoor Wiring (AREA)

Description

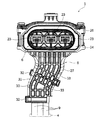

2…インバータ

3…モーターケーブル装置

4…ケーブル本体

5…モーター側接続部

6…インバータ側接続部

7…モーター側プロテクタ

8…インバータ側プロテクタ(樹脂部品)

9…ケーブル

10…編組

11…保護部材

12…テープ巻き

13…治具

14…略平面

15…挟持部

16…支柱

17…台座

18、23…端子金具

19、24…ハウジング

20、25…アース部

21、26…金属シェル

22、32…固定部

27…プロテクタ本体

28…カバー

29…固定端部

30…振れ吸収部

31…並列支持部

33…リブ

Claims (4)

- 複数本のケーブルを含むケーブル本体と、該ケーブル本体の一端に設けられるモーター側接続部と、前記ケーブル本体の他端に設けられるインバータ側接続部とを備えて、モーターとインバータとを電気的に接続するモーターケーブル装置において、

前記ケーブル本体に前記モーター又は外部からの振動や衝撃を伝えて振れが生じるように前記ケーブル本体を形成するにあたり、

前記ケーブル本体は、

前記複数本のケーブルの他に、筒状の編組と、シート状の保護部材と、を備え、且つ、前記複数本のケーブルを一列に並列配置するとともに、この並列配置した前記複数本のケーブルの外側を前記編組にて一括して覆い、さらに、該編組の外側に前記保護部材を巻き付けテープ巻きで固定してなる

ことを特徴とするモーターケーブル装置。 - 請求項1に記載のモーターケーブル装置において、

樹脂部品を更に備え、該樹脂部品を、前記インバータに直接的又は間接的に固定される固定端部と、該固定端部に連成され前記インバータ側接続部近傍の前記ケーブル本体を支持して該ケーブル本体に生じる振れを吸収する振れ吸収部とを有する構成とする

ことを特徴とするモーターケーブル装置。 - 請求項2に記載のモーターケーブル装置において、

前記振れ吸収部は、前記インバータ側接続部近傍の前記複数本のケーブルを一列に並べて支持する並列支持部を有する

ことを特徴とするモーターケーブル装置。 - モーターとインバータとを電気的に接続するモーターケーブル装置のケーブル本体製造方法において、

筒状の編組に複数本のケーブルを挿入し、前記編組内で前記複数本のケーブルを一列に並列配置する第一工程と、

前記編組の外側にシート状の保護部材を巻き付ける第二工程と、

前記保護部材の巻き付けにより生じる一対の略平面を押さえ付けて前記並列配置の状態を保ちつつ前記保護部材にテープ巻きを施す第三工程と、

を含む

ことを特徴とするモーターケーブル装置のケーブル本体製造方法。

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009082055A JP5425508B2 (ja) | 2009-03-30 | 2009-03-30 | モーターケーブル装置、及び、モーターケーブル装置のケーブル本体製造方法 |

| DE102010002040A DE102010002040B4 (de) | 2009-03-30 | 2010-02-17 | Motorkabelanordnung und Verfahren zum Herstellen einer Motorkabelanordnung |

| US12/659,466 US8395047B2 (en) | 2009-03-30 | 2010-03-10 | Motor cable assembly and method of manufacturing cable main body of the same |

| CN2010101493544A CN101854039B (zh) | 2009-03-30 | 2010-03-25 | 马达电缆组件 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009082055A JP5425508B2 (ja) | 2009-03-30 | 2009-03-30 | モーターケーブル装置、及び、モーターケーブル装置のケーブル本体製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010239678A JP2010239678A (ja) | 2010-10-21 |

| JP5425508B2 true JP5425508B2 (ja) | 2014-02-26 |

Family

ID=42675159

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009082055A Active JP5425508B2 (ja) | 2009-03-30 | 2009-03-30 | モーターケーブル装置、及び、モーターケーブル装置のケーブル本体製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US8395047B2 (ja) |

| JP (1) | JP5425508B2 (ja) |

| CN (1) | CN101854039B (ja) |

| DE (1) | DE102010002040B4 (ja) |

Families Citing this family (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5624805B2 (ja) * | 2010-06-10 | 2014-11-12 | 矢崎総業株式会社 | シールド端末接続構造及び方法 |

| JP5750264B2 (ja) * | 2010-12-28 | 2015-07-15 | 矢崎総業株式会社 | ハーネス用プロテクタ |

| JP5270702B2 (ja) * | 2011-02-14 | 2013-08-21 | トヨタ自動車株式会社 | 車両用機器搭載構造 |

| JP5626047B2 (ja) * | 2011-03-15 | 2014-11-19 | 住友電装株式会社 | 機器用コネクタ |

| JP5751875B2 (ja) * | 2011-03-22 | 2015-07-22 | 矢崎総業株式会社 | シールドコネクタ |

| US9605408B2 (en) | 2011-05-16 | 2017-03-28 | Hitachi Construction Machinery Co., Ltd. | Construction machine |

| JP5878740B2 (ja) * | 2011-06-02 | 2016-03-08 | 矢崎総業株式会社 | シールドコネクタ付き電線及びシールドコネクタ付き電線の製造方法 |

| JP5525488B2 (ja) * | 2011-06-24 | 2014-06-18 | 日立建機株式会社 | 旋回式建設機械 |

| JP5844572B2 (ja) | 2011-08-08 | 2016-01-20 | 矢崎総業株式会社 | ワイヤハーネス止水構造及びワイヤハーネス |

| JP5826615B2 (ja) * | 2011-11-24 | 2015-12-02 | 矢崎総業株式会社 | シールド接続ユニット |

| EP2685565B1 (en) * | 2012-07-10 | 2016-09-07 | Rolls-Royce plc | Electrical connectors |

| JP6158539B2 (ja) * | 2013-03-01 | 2017-07-05 | 矢崎総業株式会社 | 電線の分岐構造 |

| DE102013215859A1 (de) * | 2013-08-12 | 2015-02-12 | Zf Friedrichshafen Ag | Elektromechanischer Stellantrieb |

| JP5931813B2 (ja) * | 2013-08-19 | 2016-06-08 | トヨタ自動車株式会社 | 車両用のケーブルユニット |

| US9762043B2 (en) * | 2013-09-03 | 2017-09-12 | Marmon Utility Llc | Impact-absorbing wire and cable fixture, system, and related methods |

| JP5965373B2 (ja) * | 2013-09-20 | 2016-08-03 | 株式会社豊田自動織機 | コネクタ |

| CA2930068C (en) * | 2013-11-13 | 2021-08-24 | Baumuller Nurnberg Gmbh | Electromotive drive system |

| JP6144632B2 (ja) * | 2014-01-10 | 2017-06-07 | トヨタ自動車株式会社 | ケーブル配索構造 |

| JP2015216774A (ja) * | 2014-05-11 | 2015-12-03 | 山洋電気株式会社 | ケーブル固定台 |

| JP6352872B2 (ja) * | 2015-01-07 | 2018-07-04 | トヨタ自動車株式会社 | シールド電線接続構造 |

| DE102015206274A1 (de) * | 2015-04-08 | 2016-10-13 | Zf Friedrichshafen Ag | Aktiver Wankstabilisator eines Kraftfahrzeuges und Verfahren zur Montage |

| US10114092B2 (en) * | 2015-08-07 | 2018-10-30 | General Electric Company | Connection system and method |

| JP6205397B2 (ja) * | 2015-10-28 | 2017-09-27 | 住友電装株式会社 | シールドコネクタ |

| US10311997B2 (en) | 2016-01-29 | 2019-06-04 | Yazaki Corporation | Wire harness and method for routing wire harness |

| CN107396529B (zh) * | 2016-05-17 | 2020-03-20 | 天津远度科技有限公司 | Fpc绕线方法、承载装置以及云台 |

| GB2546168A (en) * | 2016-12-15 | 2017-07-12 | Daimler Ag | Shield protection device for a shield of a high voltage cable of a motor vehicle, motor vehicle and a method for operating a shield protection device |

| US11431220B2 (en) * | 2018-10-22 | 2022-08-30 | Nidec Corporation | Motor assembly including inverter case and wiring harness |

| JP7321752B2 (ja) * | 2018-10-22 | 2023-08-07 | ニデック株式会社 | モータユニット |

| DE102019200388A1 (de) * | 2019-01-15 | 2019-03-07 | Carl Zeiss Smt Gmbh | Schutzvorrichtung für Leitungen in einer Projektionsbelichtungsanlage für die Halbleiterlithographie |

| US12021321B2 (en) * | 2019-02-08 | 2024-06-25 | Gkn Automotive Limited | Connector assembly for inverter busbar and drive unit |

| FR3126267A1 (fr) | 2021-08-19 | 2023-02-24 | Psa Automobiles Sa | Connecteur de faisceau electrique pour vehicule |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5349133A (en) * | 1992-10-19 | 1994-09-20 | Electronic Development, Inc. | Magnetic and electric field shield |

| US5537742A (en) * | 1995-05-22 | 1996-07-23 | General Signal Corporation | Method for joining multiple conductor cables |

| US5710851A (en) * | 1995-11-06 | 1998-01-20 | Amphenol Corporation | Strain relief system for a fiber optic connector |

| JP4081889B2 (ja) * | 1998-11-11 | 2008-04-30 | 日産自動車株式会社 | 電動車両の強電ハーネス配索構造 |

| JP4562161B2 (ja) * | 2001-05-23 | 2010-10-13 | 株式会社オートネットワーク技術研究所 | コネクタ |

| JP3716985B2 (ja) * | 2002-11-05 | 2005-11-16 | 株式会社椿本チエイン | ケーブル類支持案内装置 |

| JP3997208B2 (ja) * | 2004-02-17 | 2007-10-24 | トヨタ自動車株式会社 | コネクタの固定構造 |

| JP2006086091A (ja) * | 2004-09-17 | 2006-03-30 | Sumitomo Wiring Syst Ltd | コネクタ |

| JP2006156051A (ja) * | 2004-11-26 | 2006-06-15 | Yazaki Corp | 高圧用ワイヤーハーネス |

| US7247795B2 (en) * | 2004-12-06 | 2007-07-24 | Hitachi Cable. Ltd. | Shield wire, housing connected with same, connecting method thereof and shield wire unit |

| US7645157B2 (en) | 2005-03-15 | 2010-01-12 | Toyota Jidosha Kabushiki Kaisha | Connector |

| JP2007074848A (ja) * | 2005-09-08 | 2007-03-22 | Toyota Motor Corp | 車両駆動用モータの配線接続構造 |

| JP2008253017A (ja) | 2007-03-29 | 2008-10-16 | Toyota Motor Corp | ケーブル固定具 |

| JP5314871B2 (ja) | 2007-09-28 | 2013-10-16 | カーツ株式会社 | 刈払機の接続分離構造 |

| JP5425507B2 (ja) * | 2009-03-30 | 2014-02-26 | 矢崎総業株式会社 | モーターケーブル装置、及び、モーターケーブル装置に用いる樹脂部品 |

-

2009

- 2009-03-30 JP JP2009082055A patent/JP5425508B2/ja active Active

-

2010

- 2010-02-17 DE DE102010002040A patent/DE102010002040B4/de active Active

- 2010-03-10 US US12/659,466 patent/US8395047B2/en active Active

- 2010-03-25 CN CN2010101493544A patent/CN101854039B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN101854039A (zh) | 2010-10-06 |

| DE102010002040B4 (de) | 2012-05-03 |

| US20100243321A1 (en) | 2010-09-30 |

| CN101854039B (zh) | 2013-07-31 |

| US8395047B2 (en) | 2013-03-12 |

| DE102010002040A1 (de) | 2010-10-07 |

| JP2010239678A (ja) | 2010-10-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5425508B2 (ja) | モーターケーブル装置、及び、モーターケーブル装置のケーブル本体製造方法 | |

| JP5425507B2 (ja) | モーターケーブル装置、及び、モーターケーブル装置に用いる樹脂部品 | |

| US8253021B2 (en) | Motor cable device | |

| JP2015198042A (ja) | 配線部材 | |

| WO2011096426A1 (ja) | ワイヤハーネス | |

| JP2007221897A (ja) | コルゲートチューブの固定構造 | |

| JP6252538B2 (ja) | 外装部材付配線モジュール | |

| CN109390091B (zh) | 具有包围电线的屏蔽部件的线束 | |

| JP5607412B2 (ja) | ワイヤハーネス | |

| JP2017055570A (ja) | 導電路とシールド部材とのズレ防止構造、及びワイヤハーネス | |

| JP6174628B2 (ja) | ワイヤーハーネス及び電線保持部材 | |

| JP2020089160A (ja) | 電線固定構造、電気接続箱、及びワイヤハーネス | |

| JP6239882B2 (ja) | ワイヤハーネス | |

| JP5835893B2 (ja) | ワイヤハーネス | |

| JP6971525B2 (ja) | ワイヤーハーネスの配索構造 | |

| JP4950515B2 (ja) | シールド導電路 | |

| JP7367832B2 (ja) | 電気接続箱 | |

| JP6595860B2 (ja) | 電線束 | |

| WO2013190724A1 (ja) | ワイヤーハーネス外装体及びワイヤーハーネス保護構造 | |

| KR200478835Y1 (ko) | 이중 고정 그로멧 | |

| JP2012119192A (ja) | ワイヤハーネス | |

| JP5763428B2 (ja) | ケーブル分岐部の保護具 | |

| JP2009240104A (ja) | 回転電機 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120130 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130529 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130604 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130711 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130722 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20131119 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20131127 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5425508 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |