Disclosure of Invention

The invention aims to provide an adjustable rotary manipulator which can rotate the manipulator, so that woven bags clamped by the manipulator can be turned together, and the woven bags can be conveniently carried and stacked by people.

The invention discloses an adjustable rotary manipulator, which adopts the technical scheme that:

the utility model provides a rotatory manipulator with adjustable, includes connecting seat, slewing mechanism and two sets of fixture, slewing mechanism is including rotating motor, synchronizing wheel, rotation axis and hold-in range, rotation axis one end sets up in the connecting seat, the rotation axis passes through the bearing and rotates with the connecting seat to be connected, the rotation axis other end extends to the connecting seat below, the synchronizing wheel is fixed in the rotation axis other end, it is fixed in connecting seat one side to rotate the motor, the synchronizing wheel passes through synchronous belt drive with the rotation motor and is connected, the synchronizing wheel below is equipped with the fixing base, the fixing base internal fixation is equipped with the optical axis, the optical axis runs through in the fixing base both sides, the fixing base is located the optical axis middle part.

Preferably, the number of the optical axes is at least two, and two ends of each optical axis are fixedly connected with the clamping mechanism respectively.

As preferred scheme, fixture includes baffle, cylinder, dwang, clamping jaw and fixed block, the fixed block sets up in the baffle top, the baffle passes through fixed block and optical axis fixed connection, the cylinder sets up to be close to fixing base one side in the baffle, the cylinder rotates with the baffle to be connected, the output shaft of cylinder is towards the baffle opposite side, the output shaft of cylinder passes through the connecting block to be connected with the dwang, connecting block one end and dwang fixed connection, the connecting block other end rotates with the output shaft of cylinder to be connected, the dwang is fixed in the baffle top through the dead lever, the dwang rotates with the dead lever to be connected, the clamping jaw becomes L type structure, clamping jaw upper end and dwang fixed connection, the clamping jaw lower extreme is located the.

As preferred scheme, carry out fixed connection through the adjusting lever between clamping jaw and the dwang, adjusting lever one end and dwang fixed connection, the waist shape hole has been seted up on the surface that the clamping jaw is close to dwang one end, the clamping jaw passes waist shape hole and adjusting lever fixed connection through the fastener.

Preferably, the number of the clamping jaws is several.

As the preferred scheme, the number of the cylinders is two, and the cylinders are respectively arranged at the two ends of the baffle.

Preferably, a sensor for detecting the product is arranged on one side, close to the fixed seat, of the baffle.

The adjustable rotary manipulator disclosed by the invention has the beneficial effects that: the rotating motor of the rotating mechanism is arranged on one side of the connecting seat, the synchronous wheel is transmitted to rotate together through the rotating motor and the synchronous belt, the synchronous wheel is fixedly connected with the rotating shaft, one end of the rotating shaft is rotatably connected with the connecting column, the rotating shaft also rotates together, the fixing seat fixed below the rotating shaft is driven by the rotating shaft to rotate together, and the fixing seat is fixed on the clamping mechanisms on two sides of the fixing seat through the optical axis and rotates along with the fixing seat. In the production process, snatch the braided bag of production through fixture, the rethread rotates the motor and drives the rotation axis and rotate, makes fixture also rotate to adjust the angular direction of braided bag, the people of being convenient for carry and stack better.

Detailed Description

The invention will be further elucidated and described with reference to the embodiments and drawings of the specification:

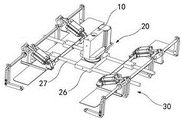

referring to fig. 1 and 2, an adjustable rotary manipulator includes a connecting seat 10, a rotating mechanism 20, and two sets of clamping mechanisms 30.

Slewing mechanism 20 is including rotating motor 21, synchronizing wheel 22, rotation axis 23 and hold-in range 24, rotation axis 23 one end sets up in connecting seat 10, rotation axis 23 passes through bearing 25 and is connected with connecting seat 10 rotation, the rotation axis 23 other end extends to connecting seat 10 below, synchronizing wheel 22 is fixed in the rotation axis 23 other end, it is fixed in connecting seat 10 one side to rotate motor 21, synchronizing wheel 22 passes through the drive with rotating motor 21 and is connected with hold-in range 24, synchronizing wheel 22 below is equipped with fixing base 26, the fixing base 26 internal fixation is equipped with optical axis 27, optical axis 27 runs through in fixing base 26 both sides, fixing base 26 is located optical axis 27 middle part, fixture 30 sets up respectively in optical axis 27 both.

The rotating motor 21 of the rotating mechanism 20 is disposed on one side of the connecting seat 10, the synchronizing wheel 22 is transmitted to rotate together through the rotating motor 21 and the synchronous belt 24, the synchronizing wheel 22 is fixedly connected with the rotating shaft 23, one end of the rotating shaft 23 is rotatably connected with the connecting column, so that the rotating shaft 23 also rotates together, the fixing seat 26 fixed below the rotating shaft 23 is driven by the rotating shaft 23 to rotate together with the fixing seat 26, and the clamping mechanisms 30 fixed on two sides of the fixing seat 26 through the optical axis 27 rotate along with the fixing seat 26.

In process of production, snatch the braided bag of production through fixture 30, rethread rotates motor 21 and drives rotation axis 23 and rotate, makes fixture 30 also rotate to adjust the angle direction of braided bag, the people of being convenient for carry and stack better.

The number of the optical axes 27 is at least two, and both ends of the optical axis 27 are respectively fixedly connected with the clamping mechanism 30, so that the clamping mechanism 30 can be more stably fixed on the optical axis 27, and the clamping mechanism 30 can be supported with enough supporting force.

Referring to fig. 3, the clamping mechanism 30 includes a baffle 31, a cylinder 32, a rotating rod 33, a clamping jaw 34 and a fixing block 35, the fixing block 35 is disposed above the baffle 31, the baffle 31 is fixedly connected to the optical axis 27 through the fixing block 35, the cylinder 32 is disposed on one side of the baffle 31 close to the fixing base 26, the cylinder 32 is rotatably connected to the baffle 31, an output shaft of the cylinder 32 faces the other side of the baffle 31, an output shaft of the cylinder 32 is connected to the rotating rod 33 through a connecting block 36, one end of the connecting block 36 is fixedly connected to the rotating rod 33, the other end of the connecting block 36 is rotatably connected to an output shaft of the cylinder 32, the rotating rod 33 is fixed above the baffle 31 through a fixing rod 37, the rotating rod 33 is rotatably connected to the fixing rod 37, the clamping jaw 34.

The output shaft through cylinder 32 is kept away from fixing base 26 one side towards baffle 31 and is promoted, makes dwang 33 go towards the baffle 31 outside on dead lever 37 and rotates to drive clamping jaw 34 and rotate towards baffle 31 and be close to fixing base 26 one side, carry out the centre gripping fixedly with the braided bag through clamping jaw 34 and baffle 31. On the contrary, when the output shaft of the cylinder 32 is contracted towards the side of the baffle 31 close to the fixed seat 26, the woven bag clamped by the clamping jaws 34 is loosened, and the purpose of carrying is achieved.

And the baffle 31 can be adjusted on the optical axis 27 through the fixing block 35, so that the distance between the two clamping mechanisms 30 can be adjusted, and the purpose of clamping woven bags with different sizes is met.

In the above scheme, the clamping jaw 34 is fixedly connected with the rotating rod 33 through the adjusting rod 38, one end of the adjusting rod 38 is fixedly connected with the rotating rod 33, the surface of the clamping jaw 34 close to one end of the rotating rod 33 is provided with the kidney-shaped hole 341, and the clamping jaw 34 passes through the kidney-shaped hole 341 through a fastener and is fixedly connected with the adjusting rod 38.

The position of the clamping jaw 34 on the adjusting rod 38 can be adjusted through the waist-shaped hole 341 on the clamping jaw 34, so that the distance between the other end of the clamping jaw 34 and the baffle plate 31 is changed, and the clamping jaw is used for clamping woven bags with different stacking thicknesses.

Above-mentioned clamping jaw 34 quantity is a plurality of, improves the power of grabbing of clamping jaw 34 when snatching the braided bag, ensures that the braided bag can be more firm when snatching.

And the cylinder 32 is two in quantity, and the cylinder 32 sets up respectively in baffle 31 both ends, and the skew can be avoided taking place at dwang 33 both ends, utilizes two cylinders 32 to drive dwang 33 both ends simultaneously and rotates, makes clamping jaw 34 on the dwang 33 carry out the centre gripping in step.

Be equipped with the sensor 39 that is used for detecting the product on baffle 31 is close to fixing base 26 one side, utilize sensor 39 can detect fixture 30 whether when carrying out the centre gripping, the accuracy is located the top of braided bag to after fixture 30 loosens, the condition that the braided bag can drop smoothly.

The invention provides an adjustable rotary manipulator, wherein a rotating motor of a rotating mechanism is arranged on one side of a connecting seat, a synchronous wheel is transmitted to rotate together through the rotating motor and a synchronous belt, the synchronous wheel is fixedly connected with a rotating shaft, one end of the rotating shaft is rotatably connected with a connecting column, so that the rotating shaft also rotates together, a fixed seat fixed below the rotating shaft is driven by the rotating shaft to rotate together, and the fixed seat is fixed on two sides of the fixed seat through clamping mechanisms fixed on two sides of the fixed seat through an optical axis and rotates along with the fixed seat. In the production process, snatch the braided bag of production through fixture, the rethread rotates the motor and drives the rotation axis and rotate, makes fixture also rotate to adjust the angular direction of braided bag, the people of being convenient for carry and stack better.

Finally, it should be noted that the above embodiments are only used for illustrating the technical solutions of the present invention, and not for limiting the protection scope of the present invention, although the present invention is described in detail with reference to the preferred embodiments, it should be understood by those skilled in the art that modifications or equivalent substitutions can be made on the technical solutions of the present invention without departing from the spirit and scope of the technical solutions of the present invention.