JP5252231B2 - Female terminal - Google Patents

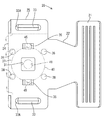

Female terminal Download PDFInfo

- Publication number

- JP5252231B2 JP5252231B2 JP2009274489A JP2009274489A JP5252231B2 JP 5252231 B2 JP5252231 B2 JP 5252231B2 JP 2009274489 A JP2009274489 A JP 2009274489A JP 2009274489 A JP2009274489 A JP 2009274489A JP 5252231 B2 JP5252231 B2 JP 5252231B2

- Authority

- JP

- Japan

- Prior art keywords

- tab

- spring

- female terminal

- spring member

- disc spring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Coupling Device And Connection With Printed Circuit (AREA)

Description

本発明は、雌端子に関する。 The present invention relates to a female terminal.

例えば、大電流回路のワイヤハーネスの接続に用いられる雌端子として、特許文献1に記載されたものが知られている。この雌端子は、相手の雄端子のタブが挿入される角筒状の接続部を備え、この接続部の例えば底面上に、略山形に曲げ形成された板ばねを備えて別体として形成されたばね部材が装着された構造となっている。そして、雌雄の端子金具を接続するべく雄端子のタブが接続部内に挿入されると、タブは板ばねを弾性変位させつつ押し込まれ、所定位置まで挿入されると、板ばねの復元弾力を受けてタブが接続部の天井面に押圧され、雌雄の端子金具間が電気的に接続されるようになっている。 For example, what was described in patent document 1 is known as a female terminal used for the connection of the wire harness of a large current circuit. This female terminal includes a rectangular tube-like connecting portion into which a tab of a mating male terminal is inserted, and is formed as a separate body including a leaf spring bent into a substantially mountain shape, for example, on the bottom surface of this connecting portion. A structure in which a spring member is mounted. When the tab of the male terminal is inserted into the connecting portion to connect the male and female terminal fittings, the tab is pushed in while elastically displacing the leaf spring. When the tab is inserted to a predetermined position, it receives the restoring elasticity of the leaf spring. Thus, the tab is pressed against the ceiling surface of the connecting portion so that the male and female terminal fittings are electrically connected.

上記従来技術では、タブを接続部の天井面に弾性接触させるべくばね部材として板ばねを用いていたのであるが、この板ばねは、ばね特性すなわち荷重−変位(撓み)特性が、図15の特性線iに示すように線形特性となる。

一方、従来技術におけるばね部材(板ばね)は、接続部とは別体に形成されて後から組み付けられるのであるから、組み付けの誤差等により板ばねの頂部と接続部の天井面との間の空間、すなわちタブの挿入空間の高さ寸法にばらつきが出やすい。また、雄端子のタブが板材を2枚重ねて形成されている場合等には、タブの厚さもばらつく可能性がある。

In the above prior art, a leaf spring is used as a spring member in order to bring the tab into elastic contact with the ceiling surface of the connection portion. This leaf spring has a spring characteristic, that is, a load-displacement (flexure) characteristic. As shown by the characteristic line i, the linear characteristic is obtained.

On the other hand, since the spring member (leaf spring) in the prior art is formed separately from the connecting portion and is assembled later, there is an error in assembling between the top of the leaf spring and the ceiling surface of the connecting portion. Variations in the height of the space, that is, the insertion space of the tab, are likely to occur. In addition, when the tab of the male terminal is formed by stacking two plate materials, the thickness of the tab may vary.

そうすると、タブが挿入空間に挿入された場合の板ばねの変位(撓み)にばらつきができ、接触荷重及び挿入力が敏感に変化することになる。上記した図15の特性線iを参照すると、仮に最適の接触形態として、タブの挿入に伴う板ばねの変位がx(mm)で、そのときの接触荷重がX(N)となるように設定されている場合において、板ばねの変位にばらつきができ、例えば変位が少なくて、極端にはx1程度に留まると、接触荷重がX1程度に小さくなり、このことはタブの挿入時の抵抗は小さくなるものの、電気的信頼性が低くなる。逆に、変位が大きくて、x2程度になると、接触荷重がX2程度と大きくなり、電気的信頼性は高くなるものの、タブの挿入時の抵抗が大きくなって作業性が悪くなり、また板ばねに対して無理な荷重が掛かることになるため、板ばねにへたり(劣化)が生じやすいという問題があった。 If it does so, dispersion | variation in the displacement (deflection) of a leaf | plate spring when a tab is inserted in insertion space can be varied, and a contact load and insertion force will change sensitively. Referring to the characteristic line i in FIG. 15 described above, as an optimum contact form, the displacement of the leaf spring accompanying the insertion of the tab is set to x (mm), and the contact load at that time is set to X (N). In this case, the displacement of the leaf spring can vary. For example, if the displacement is small and stays extremely about x1, the contact load decreases to about X1, which means that the resistance when the tab is inserted is small. However, electrical reliability is lowered. On the other hand, if the displacement is large and about x2, the contact load increases to about X2 and the electrical reliability increases, but the resistance when inserting the tab increases and the workability deteriorates. For this reason, an unreasonable load is applied to the leaf spring, and there is a problem that the leaf spring is likely to sag (deteriorate).

さらにこの種の雌端子では、相手の雄端子のタブが捻回されて接続部内に挿入された場合には内部のばね部材が過度に撓んで塑性変形し、適正な接触圧が得られなくなるおそれもあるため、その防止対策も併せて希求されるところである。

本発明は上記のような事情に基づいて完成されたものであって、その目的は、相手の雄端子と接続される場合において、良好な接続作業性を得た上で高い電気的信頼性を得ることができる雌端子を提供するところにある。

Further, in this type of female terminal, when the tab of the mating male terminal is twisted and inserted into the connecting portion, the internal spring member may be excessively bent and plastically deformed, and an appropriate contact pressure may not be obtained. Therefore, prevention measures are also in demand.

The present invention has been completed on the basis of the above circumstances, and its purpose is to achieve high electrical reliability after obtaining good connection workability when connected to a male terminal of a counterpart. It is in providing a female terminal that can be obtained.

本発明の雌端子は、相手の雄端子のタブが挿入される角筒状の接続部と、この接続部の一内面に装着されたばね部材であって、上面が膨出した円形の周縁を有する形状をなし、前記タブの挿入に伴い弾性変位し挿入完了後は復元弾力により前記タブを前記接続部の反対側の内面に接触させるように機能し、かつ荷重−変位特性に関して変位範囲の途中においてばね定数が0に近くなる領域を持った非線形特性を有するものと、前記接続部における前記一内面に設けられ、挿入された前記タブが捻回された場合に同タブに当接して捻回量を規制する突部と、が具備されたところに特徴を有する。 The female terminal of the present invention is a rectangular tube-like connecting portion into which a tab of a mating male terminal is inserted, and a spring member mounted on one inner surface of the connecting portion, and has a circular periphery with the upper surface bulging. It has a shape, elastically displaces with the insertion of the tab, and after the insertion is completed, it functions to bring the tab into contact with the inner surface on the opposite side of the connecting portion by restoring elasticity, and in the middle of the displacement range with respect to load-displacement characteristics A non-linear characteristic having a region in which the spring constant is close to 0 and a twist amount that is provided on the inner surface of the connecting portion and abuts on the inserted tab when the inserted tab is twisted. And a projecting portion that regulates the pressure.

上記構成によれば、相手の雄端子のタブが接続部内に挿入される際、ばね部材の変位が変わっても荷重変化がほとんどない領域を得ることができる。そのため、ばね部材の変位のばらつきによらず、適正な接触圧が得られて高い電気的信頼性を得ることができ、併せて適度の挿入抵抗を受けることとなって良好な接続作業性を得ることができる。また、タブが捻回して挿入された場合に突部に当たることで捻回量が規制され、その結果ばね部材が過度に撓み変位して塑性変形することが防止され、適正な接触圧を得ることができる。 According to the said structure, when the tab of the other male terminal is inserted in a connection part, even if the displacement of a spring member changes, the area | region where there is almost no load change can be obtained. Therefore, regardless of variations in the displacement of the spring member, an appropriate contact pressure can be obtained and high electrical reliability can be obtained, and at the same time, an appropriate insertion resistance can be obtained to obtain good connection workability. be able to. In addition, when the tab is twisted and inserted, the amount of twisting is regulated by hitting the protrusion, and as a result, the spring member is prevented from being excessively bent and displaced to be plastically deformed, thereby obtaining an appropriate contact pressure. Can do.

また、以下のような構成としてもよい。

(1)前記接続部の前記一内面には方形状をなす前記ばね部材の装着面が設けられ、同装着面の隅部であって前記ばね部材の周縁の側方に前記突部が設けられている。捻回規制用の突部がデッドスペースに設けられているから、接続部自体の大型化を招くことなく対応できる。

The following configuration may also be used.

(1) A mounting surface of the spring member having a square shape is provided on the one inner surface of the connection portion, and the protrusion is provided at a corner of the mounting surface and on a side of the peripheral edge of the spring member. ing. Since the protrusion for twisting restriction is provided in the dead space, it is possible to cope without causing an increase in size of the connection part itself.

(2)前記装着面の四隅に前記突部が設けられている。タブが先上がりまたは先下がりに振れる縦捻回と、軸線回りに回動する横捻回とのすべての捻回動作に対応してその捻回量を規制することができる。 (2) The protrusions are provided at the four corners of the mounting surface. The amount of twist can be regulated in correspondence with all the twisting operations of the vertical twisting in which the tab swings up and down and the horizontal twisting that rotates around the axis.

(3)前記ばね部材の周縁には一対の位置決め突部が180度間隔を開けて形成されているとともに、前記接続部における前記ばね部材の前記装着面と隣り合って互いに対向する両内面には、前記位置決め突部が嵌る位置決め凹部が形成されている。接続部を組み立てる途中で、ばね部材の両位置決め突部が、接続部の対応する内面の位置決め凹部に嵌められることで、接続部の装着面上における皿ばねの位置決めができる。 (3) A pair of positioning protrusions are formed on the peripheral edge of the spring member with an interval of 180 degrees, and the inner surfaces of the connecting portion adjacent to the mounting surface of the spring member and facing each other are A positioning recess into which the positioning protrusion is fitted is formed. In the middle of assembling the connecting portion, the positioning protrusions of the spring member are fitted into the positioning recesses on the corresponding inner surface of the connecting portion, so that the disc spring can be positioned on the mounting surface of the connecting portion.

本発明の雌端子によれば、相手の雄端子と接続される場合において、良好な接続作業性を得た上で高い電気的信頼性を得ることができる。 According to the female terminal of the present invention, high electrical reliability can be obtained after obtaining good connection workability in the case of being connected to the counterpart male terminal.

以下、本発明の実施形態を添付図面に基づいて説明する。

<実施形態1>

本発明の実施形態1を図1ないし図11によって説明する。

先に相手の雄端子10を説明すると、雄端子10は、図8に示すように、銅合金等の導電性に優れた比較的厚肉の金属板をプレス加工することによって形成され、電線Wの芯線Waの端末にかしめ圧着されるバレル部11の前方に、連結部12を介してタブ13が形成された形状である。タブ13の先端は、ガイド用に先細りの形状となっている。

Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

<Embodiment 1>

A first embodiment of the present invention will be described with reference to FIGS.

First, the mating

雌端子20は、同じく銅合金等の導電性に優れた比較的厚肉の金属板をプレス加工することによって形成されており、電線Wの芯線Waの端末にかしめ圧着されるバレル部21の前方に、連結部22を介して雄端子10のタブ13と接続される接続部25が形成された形状である。

接続部25は、図1の展開図に示すように、横長の方形状をなす板部24が、折曲線s,tでそれぞれ直角曲げされることにより、底面部26の左右両側縁に側面部27が立ち上がり形成され、さらに各側面部27の上縁から天面部28が互いに突き合うように突出形成されることにより、全体として前後方向に開口したやや扁平な角筒状に形成されている。より具体的には、接続部25内の空間の横幅寸法は、雄端子10のタブ13の横幅よりも少し大きく、また高さ寸法は、タブ13の厚さの1.2〜1.3倍程度である。なお、両天面部28の突き合わせ端縁の間には、所定の隙間29が開けられている。

The

As shown in the development view of FIG. 1, the connecting

接続部25の底面部26における中央部には方形のランス孔31が形成されており、当該雌端子20がハウジング(図示せず)の対応するキャビティ内に挿入された場合に、同キャビティ内に設けられた樹脂ランスがランス孔31に嵌って弾性的に係止することにより、当該雌端子20が抜け止めされるようになっている。

一方、各天面部28の内面には、前後方向を向いた突条からなる接点部33が、叩き出しにより形成されている。接点部33の前端部には、ガイド用にテーパ部33Aが形成されている。

A

On the other hand, on the inner surface of each

上記した接続部25の底面部26上には、当該接続部25に挿入されたタブ13を、上記した接点部33に向けて弾性的に押圧するべくばね部材である皿ばね40が装着されている。

皿ばね40は、ステンレス鋼板、銅合金板等の比較的薄肉の金属板をプレス加工することにより、中央部に円形孔41が開口された円錐斜面状に形成されている。より詳細には、斜面の傾斜角度が6度程度で、かつ内周縁42の直径が外周縁43の直径の1/4程度の比較的低い自由高さを有しており、この実施形態では、外周縁43の直径が接続部25内の空間の横幅よりも少し大きく、かつ接続部25の底面部26から接点部33までの高さの40%程度の自由高さを有している。

On the

The

皿ばね40の外周縁43における180度の角度間隔を開けた位置には、一対の位置決め突片45が水平姿勢で互いに反対方向を向いて突出形成されている。一方、接続部25の左右の側面部27には、奥行の中央部でかつ下縁の位置に、上記した位置決め突片45が嵌合される位置決め孔35が貫通形成されている。この位置決め孔35は、その高さ並びに間口が、位置決め突片45の厚さ並びに横幅よりも大きく形成され、特に間口については、内面側に向けて次第に大きくなるように形成されている。これは、皿ばね40における位置決め突片45が突設された部分の外周縁43を、自然状態さらには後記するように弾縮されて拡径した場合も含めてこれを逃がすためである。

A pair of

言い換えると、接続部25の底面部26上には、横幅が、同底面部26の横幅に等しく、すなわち皿ばね40の自然状態の外周縁43の直径より少し小さい寸法で、また奥行が、皿ばね40の自然状態の外周縁43の直径よりも少し大きい寸法の長方形をなす皿ばね40の装着面37が設けられている。

そして、その装着面37の四隅の位置で、かつ自然状態の皿ばね40の外周縁43から若干の隙間を持って離間した位置に、突部38が裏面からの叩き出しによって形成されている。上記の隙間は、皿ばね40が正規に扁平に弾縮された場合に、その外周縁43が突部38と干渉しない程度の寸法である。突部38は、例えば球形の一部をなすような形状であって、その高さは、同じく皿ばね40が正規に扁平に弾縮された場合における高さよりも少し低い程度である。

In other words, on the

And the

皿ばね40を装着する場合は、図1に示すように、雌端子20を製造する途中の接続部25が組み立てられる前の工程において、底面部26に設定された装着面37の中心に、外周縁43を下に向け、かつ両位置決め突片45を位置決め孔35に合わせた姿勢で載せられる。続いて既述したように、板部24が曲げられて接続部25が形成されると、皿ばね40は、その外周縁43が装着面37上に当てられ、また左右の位置決め突片45が側面部27の位置決め孔35に嵌ってずれ止めされた状態で、接続部25内に装着される。これに伴い、自由状態の皿ばね40の内周縁42(頂面)と接点部33との間に、タブ13の挿入空間Sが構成され、この挿入空間Sの高さ寸法が、タブ13の厚さよりも所定だけ小さくなるように設定されている。

When the

続いて、本実施形態の作動を説明する。

雌雄の端子金具20,10が接続される際には、図8に示すように、雄端子10のタブ13が対応する雌端子20の接続部25内に前方から挿入される。挿入されたタブ13は、接点部33の前端のテーパ部33Aあるいは皿ばね40の前側の斜面で案内されて、皿ばね40の頂面と接点部33の間の挿入空間Sへと導かれ、途中から皿ばね40を扁平に弾縮しつつ押し込まれる。図9に示すように、タブ13が所定位置まで挿入されると、扁平に弾縮された皿ばね40の復元弾力によって、タブ13が接続部25の両天面部28に形成された接点部33に押し付けられ、雌雄の端子金具20,10間が電気的に接続されることになる。

Next, the operation of this embodiment will be described.

When the male and female

上記のようにタブ13を接点部33に向けて弾性的に押圧するべくばね部材に皿ばね40を用いた場合は、タブ13の挿入に伴う皿ばね40のばね特性すなわち荷重−変位(撓み)特性は、図11の特性線Iに示すように、変位範囲の途中においてばね定数が0に近くなる領域aを持った非線形特性を示す。

したがって、最適の接触荷重A(N)を得るために皿ばね40の変位を設定するに際し、上記したばね定数が0に近い範囲の中間位置であるa0(mm)に設定しておけば、皿ばね40の変位が、上記したばね定数が0に近い範囲a内、すなわち変位がa1(mm)〜a2(mm)の領域内でばらつく限りは、ほぼ最適の接触荷重A(N)を得ることができる。

そのため、製造誤差等に起因して、雄端子10のタブ13を雌端子20の接続部25に挿入した場合の皿ばね40の変位にばらつきが出た場合でも、適正な接触圧が得られて高い電気的信頼性を得ることができ、併せて適度の挿入抵抗を受けることとなって良好な接続作業性を得ることができる。

When the

Accordingly, when setting the displacement of the

Therefore, an appropriate contact pressure can be obtained even when the

ここで、雄端子10のタブ13が、雌端子20の接続部25内に挿入される際、図9に示すように、タブ13が先下がりの姿勢(符号13a)あるいは先上がりの姿勢(符号13b)で挿入される場合がある。先下がりに振れた場合は、タブ13aの先端側が奥側の左右の突部38に当たり、一方、先上がりに振れた場合は、タブ13bの先端から基端側に寄った位置が手前側の左右の突部38に当たることで、それ以上の振れ(縦捻回)が規制され、結果、皿ばね40が過度に撓み変形することが防止される。

Here, when the

また、図10に示すように、タブ13が軸線を中心として正面から見た時計回り方向に回動した姿勢(符号13c)、あるいは反時計回り方向に回動した姿勢(符号13d)で挿入されると、タブ13cの右側縁が正面から見た右側の前後の突部38に当たり、あるいはタブ13dの左側縁が左側の前後の突部38に当たることで、それ以上の回動(横捻回)が規制され、同様に皿ばね40が過度に撓み変形することが防止される。

Also, as shown in FIG. 10, the

このように、装着面37の四隅に突部38を配設したことにより、タブ13が先上がりまたは先下がりに振れる縦捻回と、軸線回りに回動する横捻回とのすべての捻回動作に対応してその捻回量を規制することができる。そのため、皿ばね40が過度に撓み変位して塑性変形することが防止され、もって適正な接触圧を得ることができる。

また装着面37の四隅は、言わば円形の皿ばね40を装着するに当たってのデッドスペースとなることから、接続部25の大型化を招くことなく、対応することができる。

Thus, by providing the

Further, the four corners of the mounting

<実施形態2>

図12は実施形態2を示す。実施形態2では、タブ13を接点部33に向けて弾性的に押圧するべく皿ばねに変更が加えられている。

実施形態2の皿ばね50は、上記実施形態1に示した皿ばね40を2枚、外周縁43同士を突き合わせて結合してなる直列皿ばね50となっている。具体的には、2枚の皿ばね40が、位置決め突片45を整合させた状態で外周縁43同士が重ねられ、適宜の角度間隔を開けた複数箇所でスポット溶接することによって結合されている。

<Embodiment 2>

FIG. 12 shows a second embodiment. In the second embodiment, the disc spring is changed to elastically press the

The

実施形態1の皿ばね40に代わって、直列皿ばね50を用いた場合における、タブ13の挿入に伴う直列皿ばね50のばね特性すなわち荷重−変位特性も、図11の特性線IIに示すように非線形特性を示す。直列皿ばね50は、単一の皿ばね40と比べて変位が大きく取れる利点があり、その結果、直列皿ばね50の荷重−変位特性は、実施形態1の皿ばね40の同特性と比べると、ばね定数が全体として小さくなることに加え、ばね定数が0に近くなる領域bが広くなった非線形特性となる。

したがって、最適の接触荷重A(N)を得るために直列皿ばね50の変位を設定するに際し、上記したばね定数が0に近い範囲の中間位置であるb0(mm)に設定しておけば、より広範囲にわたる変位のばらつきを吸収して、最適の接触荷重A(N)を得ることができる。

When the

Therefore, when setting the displacement of the

また、直列皿ばね50の装着面37の四隅に同様に突部38を形成することによって、タブ13の縦捻回と横捻回とのすべての捻回動作に対応してその捻回量を規制し、直列皿ばね50が過度に撓み変位することを防止できる。

Further, by similarly forming

<実施形態3>

荷重−変位特性に関し、変位範囲の途中においてばね定数が0に近くなる領域を持った非線形特性を有するばね部材としては、皿ばねの他に、図13に示すように、球面の一部をなすように膨出形成されたドーム型ばね60が挙げられる。

このようなドーム型ばね60を使用した場合でも、その装着面の四隅に同様に突部38を形成することによって、タブ13の縦捻回と横捻回とのすべての捻回動作に対応してその捻回量を規制し、ドーム型ばね60が過度に撓み変位することを防止できる。

<Embodiment 3>

Regarding the load-displacement characteristic, as a spring member having a non-linear characteristic having a region in which the spring constant is close to 0 in the middle of the displacement range, as shown in FIG. A dome-shaped

Even when such a dome-shaped

<実施形態4>

図14は、本発明の実施形態4を示す。この実施形態4の雌端子20Aでは、実施形態1に示した雌端子20と比べて、接続部25Aの長さが若干大きく形成されていて、同接続部25Aの底面部26Aには、実施形態1と同じ大きさの皿ばね40が装着される位置の前後両側に、ほぼ全幅に亘る突条39がそれぞれ叩き出しにより形成されている。

<Embodiment 4>

FIG. 14 shows a fourth embodiment of the present invention. In the

実施形態4の雌端子20Aにおいて、雄端子10のタブ13が接続部25A内に挿入される際、タブ13が先下がりの姿勢、あるいは先上がりの姿勢に振れて挿入された場合は、タブ13の先端側が奥側の突条39に当たり、あるいはタブ13の先端から基端側に寄った位置が手前側の突条39に当たることで、それ以上の振れ(縦捻回)が規制され、結果、皿ばね40が過度に撓み変形することが防止される。

In the

また、タブ13が軸線を中心として時計回り方向または反時計回り方向に回動した姿勢で挿入されると、タブ13の右側縁が前後の突条39の右端部に当たり、あるいはタブ13の左側縁が前後の突条39の左端部に当たることで、それ以上の回動(横捻回)が規制され、同様に皿ばね40が過度に撓み変形することが防止される。

Further, when the

<他の実施形態>

本発明は上記記述及び図面によって説明した実施形態に限定されるものではなく、例えば次のような実施形態も本発明の技術的範囲に含まれる。

(1)実施形態1では、皿ばねの装着面の四隅に突部を設けた場合を例示したが、相手の雄端子におけるタブの挿入方向の条件等によって、タブの捻回方向が限定されている場合には、突部について、前後いずれか一方の左右2箇所に設けたり、左右いずれか一方の前後2箇所に設けるといったように、配設箇所を制限するようにしてもよい。

(2)突部の形状については、実施形態1に例示した球形の一部をなす形状に限らず、角錐形、角錐台等、任意の形状に形成してもよい。

<Other embodiments>

The present invention is not limited to the embodiments described with reference to the above description and drawings. For example, the following embodiments are also included in the technical scope of the present invention.

(1) In Embodiment 1, the case where the protrusions are provided at the four corners of the mounting surface of the disc spring is illustrated, but the twisting direction of the tab is limited depending on the conditions of the tab insertion direction in the other male terminal. In the case where the protrusions are provided, the locations of the protrusions may be limited such that the protrusions are provided at the left and right two locations on either the front and rear sides, or at the left and right two locations on the left and right sides.

(2) The shape of the protrusion is not limited to the shape that forms part of the sphere illustrated in the first embodiment, and may be formed in an arbitrary shape such as a pyramid or a truncated pyramid.

(3)皿ばねに対してより大きな接触荷重を望むような場合には、複数枚の皿ばねを同じ向きで重ねた並列皿ばねを適用してもよい。

(4)上記実施形態で示した荷重−変位特性に関する非線形特性はあくまでも一例であって、皿ばねの素材、形状等を適宜に変更することによって、用途に応じた非線形特性を得ることができる。

(3) When a larger contact load is desired for the disc spring, a parallel disc spring in which a plurality of disc springs are stacked in the same direction may be applied.

(4) The non-linear characteristic regarding the load-displacement characteristic shown in the above embodiment is merely an example, and the non-linear characteristic corresponding to the application can be obtained by appropriately changing the material, shape, etc. of the disc spring.

10…雄端子

13…タブ

20,20A…雌端子

25,25A…接続部

26,26A…底面部

27…側面部

28…天面部

33…接点部

35…位置決め孔(位置決め凹部)

37…装着面

38…突部

39…突条(突部)

40…皿ばね(ばね部材)

43…外周縁(周縁)

45…位置決め突片(位置決め突部)

50…直列皿ばね(ばね部材)

60…ドーム型ばね(ばね部材)

DESCRIPTION OF

37 ... Mounting

40 ... Belleville spring (spring member)

43 ... outer periphery (periphery)

45 ... Positioning protrusion (positioning protrusion)

50 ... Series disc spring (spring member)

60 ... Dome-shaped spring (spring member)

Claims (4)

この接続部の一内面に装着されたばね部材であって、上面が膨出した円形の周縁を有する形状をなし、前記タブの挿入に伴い弾性変位し挿入完了後は復元弾力により前記タブを前記接続部の反対側の内面に接触させるように機能し、かつ荷重−変位特性に関して変位範囲の途中においてばね定数が0に近くなる領域を持った非線形特性を有するものと、

前記接続部における前記一内面に設けられ、挿入された前記タブが捻回された場合に同タブに当接して捻回量を規制する突部と、

が具備されたことを特徴とする雌端子。 A rectangular tube-like connection part into which the tab of the mating male terminal is inserted;

A spring member attached to one inner surface of the connection portion, having a shape having a circular peripheral edge whose upper surface bulges, and is elastically displaced with the insertion of the tab, and after the insertion is completed, the tab is connected by the restoring elasticity. And a non-linear characteristic that has a region in which the spring constant is close to zero in the middle of the displacement range with respect to the load-displacement characteristic,

A protrusion that is provided on the inner surface of the connecting portion and that abuts against the tab when the inserted tab is twisted, and regulates the amount of twist;

A female terminal characterized by comprising:

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009274489A JP5252231B2 (en) | 2009-12-02 | 2009-12-02 | Female terminal |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009274489A JP5252231B2 (en) | 2009-12-02 | 2009-12-02 | Female terminal |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2011119100A JP2011119100A (en) | 2011-06-16 |

| JP5252231B2 true JP5252231B2 (en) | 2013-07-31 |

Family

ID=44284214

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009274489A Expired - Fee Related JP5252231B2 (en) | 2009-12-02 | 2009-12-02 | Female terminal |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5252231B2 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2013099995A1 (en) * | 2011-12-28 | 2015-05-11 | 日本発條株式会社 | connector |

| WO2015125682A1 (en) | 2014-02-18 | 2015-08-27 | 矢崎総業株式会社 | Connection terminal |

| JP6301722B2 (en) * | 2014-04-23 | 2018-03-28 | 矢崎総業株式会社 | Contact connection structure |

| JP2015210870A (en) * | 2014-04-24 | 2015-11-24 | 矢崎総業株式会社 | Contact connection structure |

| JP6301717B2 (en) * | 2014-04-18 | 2018-03-28 | 矢崎総業株式会社 | Contact connection structure |

| JP6301724B2 (en) * | 2014-04-25 | 2018-03-28 | 矢崎総業株式会社 | Contact connection structure |

| JP6301723B2 (en) * | 2014-04-23 | 2018-03-28 | 矢崎総業株式会社 | Contact connection structure |

| JP2015210862A (en) * | 2014-04-24 | 2015-11-24 | 矢崎総業株式会社 | Contact connection structure |

| WO2015159946A1 (en) * | 2014-04-18 | 2015-10-22 | 矢崎総業株式会社 | Contact-connection structure |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6060881U (en) * | 1983-10-01 | 1985-04-27 | 東洋ハーネス株式会社 | Terminal for connector housing |

| JP2546255Y2 (en) * | 1992-07-08 | 1997-08-27 | 矢崎総業株式会社 | Female terminal fitting |

| JP3529026B2 (en) * | 1998-04-15 | 2004-05-24 | 矢崎総業株式会社 | Female terminal |

| JP3473899B2 (en) * | 1999-05-11 | 2003-12-08 | 矢崎総業株式会社 | Female terminal |

| JP4080411B2 (en) * | 2003-10-17 | 2008-04-23 | 矢崎総業株式会社 | Assembly method of connection terminal for flat circuit body |

| JP2005353524A (en) * | 2004-06-14 | 2005-12-22 | Yazaki Corp | Connection terminal |

| JP2006012740A (en) * | 2004-06-29 | 2006-01-12 | Sumitomo Wiring Syst Ltd | Female side terminal fitting |

| JP3992024B2 (en) * | 2004-06-29 | 2007-10-17 | 住友電装株式会社 | Female terminal fitting |

| JP4678341B2 (en) * | 2006-06-21 | 2011-04-27 | 住友電装株式会社 | Female terminal bracket |

| JP2009259490A (en) * | 2008-04-14 | 2009-11-05 | Sumitomo Wiring Syst Ltd | Terminal metal fitting |

| WO2010098157A1 (en) * | 2009-02-25 | 2010-09-02 | 住友電装株式会社 | Terminal fitting and terminal fitting connecting structure |

| JP2011070843A (en) * | 2009-09-24 | 2011-04-07 | Yazaki Corp | Female side terminal fitting |

-

2009

- 2009-12-02 JP JP2009274489A patent/JP5252231B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2011119100A (en) | 2011-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5252231B2 (en) | Female terminal | |

| JP5815352B2 (en) | Female terminal | |

| CN202855982U (en) | Socket terminal and socket terminal connector | |

| KR101927869B1 (en) | Receptacle contact | |

| JP5630655B2 (en) | Multi-contact type terminal fitting | |

| JP4575494B2 (en) | Press-fit pin | |

| US7833039B2 (en) | Electrical connector and conducting terminal used therein | |

| JP6084898B2 (en) | Connecting terminal | |

| JP4889027B2 (en) | Connection structure between flexible board and terminal bracket | |

| JP2009231226A (en) | Right angle connector | |

| JP5208265B2 (en) | Female terminal | |

| JP5720526B2 (en) | Terminal fitting | |

| JP6091055B2 (en) | Connectors and connector assemblies | |

| JP2018045929A (en) | Contact terminal | |

| TWI616032B (en) | Crimp connector | |

| JP2015210941A (en) | Contact connection structure | |

| JP7435362B2 (en) | Terminal fittings and chain terminals | |

| JP2015210948A (en) | Contact connection structure | |

| JP5552450B2 (en) | Aluminum body connection structure and connector | |

| JP5151936B2 (en) | Terminal fitting and manufacturing method thereof | |

| JP5773553B1 (en) | Terminal fitting | |

| JP6116339B2 (en) | Plate terminal | |

| KR101608375B1 (en) | Female terminal having bead part | |

| JP2009238505A (en) | Female terminal | |

| WO2018037601A1 (en) | Terminal connection structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120326 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130314 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130321 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130403 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160426 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |