JP4093964B2 - 抵抗炉 - Google Patents

抵抗炉 Download PDFInfo

- Publication number

- JP4093964B2 JP4093964B2 JP2003562552A JP2003562552A JP4093964B2 JP 4093964 B2 JP4093964 B2 JP 4093964B2 JP 2003562552 A JP2003562552 A JP 2003562552A JP 2003562552 A JP2003562552 A JP 2003562552A JP 4093964 B2 JP4093964 B2 JP 4093964B2

- Authority

- JP

- Japan

- Prior art keywords

- resistance furnace

- heating element

- annular

- heating

- annular collar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000010438 heat treatment Methods 0.000 claims abstract description 116

- 238000001816 cooling Methods 0.000 claims description 33

- 239000012494 Quartz wool Substances 0.000 claims description 9

- 239000000110 cooling liquid Substances 0.000 claims description 6

- 229910052751 metal Inorganic materials 0.000 claims description 5

- 239000002184 metal Substances 0.000 claims description 5

- 230000001681 protective effect Effects 0.000 claims description 5

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 4

- 239000002826 coolant Substances 0.000 claims description 4

- 229910052802 copper Inorganic materials 0.000 claims description 4

- 239000010949 copper Substances 0.000 claims description 4

- 229910000881 Cu alloy Inorganic materials 0.000 claims description 3

- 238000011010 flushing procedure Methods 0.000 claims description 3

- 229910004298 SiO 2 Inorganic materials 0.000 claims 1

- 239000007789 gas Substances 0.000 description 44

- 238000009826 distribution Methods 0.000 description 25

- 238000000265 homogenisation Methods 0.000 description 10

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 9

- 239000000463 material Substances 0.000 description 8

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 6

- 229910002804 graphite Inorganic materials 0.000 description 6

- 239000010439 graphite Substances 0.000 description 6

- 239000000498 cooling water Substances 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 239000002470 thermal conductor Substances 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000009529 body temperature measurement Methods 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000003486 chemical etching Methods 0.000 description 1

- 238000005660 chlorination reaction Methods 0.000 description 1

- 239000003245 coal Substances 0.000 description 1

- 229910052681 coesite Inorganic materials 0.000 description 1

- 229910052906 cristobalite Inorganic materials 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 229910021397 glassy carbon Inorganic materials 0.000 description 1

- 230000006698 induction Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 239000013307 optical fiber Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 229910052682 stishovite Inorganic materials 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- 229910052905 tridymite Inorganic materials 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D11/00—Arrangement of elements for electric heating in or on furnaces

- F27D11/02—Ohmic resistance heating

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67098—Apparatus for thermal treatment

- H01L21/67109—Apparatus for thermal treatment mainly by convection

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B23/00—Re-forming shaped glass

- C03B23/04—Re-forming tubes or rods

- C03B23/043—Heating devices specially adapted for re-forming tubes or rods in general, e.g. burners

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B37/00—Manufacture or treatment of flakes, fibres, or filaments from softened glass, minerals, or slags

- C03B37/01—Manufacture of glass fibres or filaments

- C03B37/012—Manufacture of preforms for drawing fibres or filaments

- C03B37/01205—Manufacture of preforms for drawing fibres or filaments starting from tubes, rods, fibres or filaments

- C03B37/01225—Means for changing or stabilising the shape, e.g. diameter, of tubes or rods in general, e.g. collapsing

- C03B37/01257—Heating devices therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B17/00—Furnaces of a kind not covered by any of groups F27B1/00 - F27B15/00

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D21/00—Arrangement of monitoring devices; Arrangement of safety devices

- F27D21/0014—Devices for monitoring temperature

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B3/00—Ohmic-resistance heating

- H05B3/62—Heating elements specially adapted for furnaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B9/00—Furnaces through which the charge is moved mechanically, e.g. of tunnel type; Similar furnaces in which the charge moves by gravity

- F27B9/28—Furnaces through which the charge is moved mechanically, e.g. of tunnel type; Similar furnaces in which the charge moves by gravity for treating continuous lengths of work

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D9/00—Cooling of furnaces or of charges therein

- F27D2009/0002—Cooling of furnaces

- F27D2009/0045—Cooling of furnaces the cooling medium passing a block, e.g. metallic

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D19/00—Arrangements of controlling devices

- F27D2019/0006—Monitoring the characteristics (composition, quantities, temperature, pressure) of at least one of the gases of the kiln atmosphere and using it as a controlling value

- F27D2019/0025—Monitoring the temperature of a part or of an element of the furnace structure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D99/00—Subject matter not provided for in other groups of this subclass

- F27D99/0001—Heating elements or systems

- F27D99/0006—Electric heating elements or system

- F27D2099/0008—Resistor heating

- F27D2099/001—Resistor heating the container being the resistor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D7/00—Forming, maintaining or circulating atmospheres in heating chambers

- F27D7/02—Supplying steam, vapour, gases or liquids

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D7/00—Forming, maintaining or circulating atmospheres in heating chambers

- F27D7/06—Forming or maintaining special atmospheres or vacuum within heating chambers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D99/00—Subject matter not provided for in other groups of this subclass

- F27D99/0073—Seals

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Computer Hardware Design (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Physics & Mathematics (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Resistance Heating (AREA)

- Furnace Details (AREA)

- Non-Adjustable Resistors (AREA)

- Electronic Switches (AREA)

Description

えば、正確なばね定数を有するばねを具備し、それによって均一なバイアスを再現可能でありチェック可能なやり方で設定することができる。

献する。

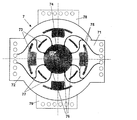

される加熱電流が、方向矢印75によって表される等しい長さの8つの電流路に分岐され、それによって内側穴77aの区域の「好ましい供給点」76にガイドされ、それとともに環状鍔部が接触チューブ5上に載置される(図1参照)ように配列される。2つの電極端子71、72および貫通穴73の分布およびサイズのおかげで、加熱電流は、図2にしたがって合計8つの好ましい供給点76(「8点供給」)にわたって環状鍔部7に分布される。1つの「好ましい供給点」のみを備えた環状鍔部の実施形態と比較すると、これは、結果として、内側穴77aの区域でより均一な電流密度分布になり、したがって、接触チューブ5の、したがって加熱チューブ2の区域における電流密度の均質的な水平分布になる。

Claims (18)

- 上部側と下部側とによって画成されかつ炉チャンバを囲繞するシェル表面を具備し垂直に配向された長手方向軸を有する管状加熱要素を具備する抵抗炉であって、前記管状加熱要素は少なくとも2つの供給端子に接続され、それによって加熱電流が、電力供給点で前記加熱要素内に導入され、前記供給端子は、前記上部側(11)の領域に囲繞上部環状鍔部(7)と前記下部側(12)の領域に囲繞下部環状鍔部(8)とを具備することを特徴とする抵抗炉。

- 前記環状鍔部(7、8)の各々は、前記加熱電流を供給するための電極端子(71)を具備し、前記長手方向に見たとき、前記上部環状鍔部(7)の前記電極端子(71)は、前記下部環状鍔部(8)の前記電極端子に対して円周方向にずれていることを特徴とする請求項1に記載の抵抗炉。

- 前記環状鍔部(7、8)の各々には、円周方向に前記環状鍔部(7、8)のまわりに均一に分布される少なくとも2つの電極端子(71、72)が設けられていることを特徴とする請求項1または2に記載の抵抗炉。

- 金属から作られる前記環状鍔部(7、8)に貫通穴を設け、前記供給された加熱電流を少なくとも4つの電流路(77)に分岐するために前記環状鍔部(7、8)に金属からなる導電性の高い領域と貫通穴を有する導電性の低い領域(73)とを形成し、かつ該電流路(77)は前記加熱要素(2、5、6)の円周にわたって均一に分布される電力供給点(76)へ通じていることを特徴とする請求項1〜3のいずれか1項に記載の抵抗炉。

- 前記上部環状鍔部(7)の前記電力供給点(76)は前記下部環状鍔部(8)の前記電力供給点に対して円周方向にずれていることを特徴とする請求項4に記載の抵抗炉。

- 前記環状鍔部(7、8)は、前記加熱要素(2、5、6)の円錐状接続領域に整合する接続円錐を具備することを特徴とする請求項1〜5のいずれか1項に記載の抵抗炉。

- 前記接続円錐が内側円錐とされかつ前記加熱要素(2、5、6)の前記接続領域が外側円錐とされ、前記環状鍔部(7、8)の内側円錐が前記加熱要素(2、5、6)の前記外側円錐に嵌合されるようにしたことを特徴とする請求項6に記載の抵抗炉。

- 前記環状鍔部(7、8)は、第1の冷却液入口(27)が設けられた第1の囲繞冷却チャネル(10)を有することを特徴とする請求項1〜7のいずれか1項に記載の抵抗炉。

- 前記環状鍔部(7、8)には、前記第1の冷却チャネル(10)の隣にかつ空間的にはそれから分離して、第2の冷却液入口(28)を含む第2の囲繞冷却チャネル(9)が設けられ、前記第2の入口(28)は、円周方向に見たときに、前記第1の入口(27)に向かい合っている前記環状鍔部(7、8)の側部に配列されていることを特徴とする請求項8に記載の抵抗炉。

- 前記環状鍔部(7、8)は、銅または銅合金から構成されることを特徴とする請求項1〜9のいずれか1項に記載の抵抗炉。

- 前記加熱要素(2、5、6)は、加熱チューブ(2)を具備し、これは、前側に接続する少なくとも1つの接触チューブ(5、6)によって両側に延在し、前記環状鍔部(7、8)の各々は前記接触チューブ(5、6)上に載置され、前記加熱チューブ(2)の壁厚が前記接触チューブ(5、6)の壁厚よりも薄いことを特徴とする請求項1〜10のいずれか1項に記載の抵抗炉。

- 複数のクランプ要素(13)を具備するクランプ手段が設けられ、それによって、前記接触チューブ(5、6)、前記加熱チューブ(2)および前記環状鍔部(7、8)が互いに対して軸方向にクランプされることを特徴とする請求項11に記載の抵抗炉。

- 前記加熱要素(2、5、6)の円周にわたって均一に分布される少なくとも4本のテンションロッドが、クランプ要素(13)として設けられることを特徴とする請求項12に記載の抵抗炉。

- 等しい圧力損失の複数の二次ライン(20)内で、少なくとも1つの分岐ステージ(82)に分岐されるガス入口(19)を具備するガスフラッシング用の手段が設けられ、前記二次ライン(20)は、エンベロープ円形にわたって均一に分布され前記炉チャンバ(4)内に方向づけられる複数のガス出口(86)で終端することを特徴とする請求項1〜13のいずれか1項に記載の抵抗炉。

- 前記ガス出口(86)は、前記上部環状鍔部(7)の上に配列され、少なくとも2つの別個の円形セグメント(89)から構成されるフラッシュリング(18)に形成され、前記二次ライン(20)は各々が前記円形セグメント(89)の1つで終端することを特徴とする請求項14に記載の抵抗炉。

- 前記加熱要素(2、5、6)は温度制御可能な保護ジャケット(21)によって囲繞され、その外側壁はそれに着脱自在に取り付けられた冷却プレート(29)を有しその中を冷却液体が流れていることを特徴とする請求項1〜15のいずれか1項に記載の抵抗炉。

- 前記加熱要素(2、5、6)の内部は石英ウール(26)によって外部に封止されていることを特徴とする請求項1〜16のいずれか1項に記載の抵抗炉。

- 前記石英ウール(26)は合成されたSiO2から構成されることを特徴とする請求項17に記載の抵抗炉。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP2002/000663 WO2003062727A1 (de) | 2002-01-24 | 2002-01-24 | Widerstandsofen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005515399A JP2005515399A (ja) | 2005-05-26 |

| JP4093964B2 true JP4093964B2 (ja) | 2008-06-04 |

Family

ID=27589042

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003562552A Expired - Fee Related JP4093964B2 (ja) | 2002-01-24 | 2002-01-24 | 抵抗炉 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US7006552B2 (ja) |

| EP (1) | EP1468233B1 (ja) |

| JP (1) | JP4093964B2 (ja) |

| KR (1) | KR100837747B1 (ja) |

| CN (1) | CN100371670C (ja) |

| AT (1) | ATE503161T1 (ja) |

| DE (1) | DE50214980D1 (ja) |

| TW (1) | TW200302672A (ja) |

| WO (1) | WO2003062727A1 (ja) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101228406B (zh) * | 2005-07-22 | 2011-01-26 | 西门子公司 | 用于确定电弧炉中的至少一个状态参数的方法和电弧炉 |

| FR2910777B1 (fr) * | 2006-12-21 | 2013-07-19 | Revtech | Procede de traitement thermique de materiaux pulverulents |

| DE102010025236A1 (de) * | 2010-02-18 | 2011-08-18 | SMS Siemag AG, 40237 | Elektrodentragarm eines schmelzmetallurgischen Ofens |

| EP3158284B1 (en) * | 2014-06-17 | 2022-03-16 | Heraeus Quartz North America LLC | Apparatus and method for heating and measuring of transparent cylindrical articles |

| CN104596280A (zh) * | 2014-12-25 | 2015-05-06 | 贵州永兴科技有限公司 | 一种具有报警和人脸识别功能的信息化万用电炉 |

| CN104596263A (zh) * | 2014-12-25 | 2015-05-06 | 贵州永兴科技有限公司 | 一种具有计数和指纹识别功能的信息化万用电炉 |

| CN104596273A (zh) * | 2014-12-25 | 2015-05-06 | 贵州永兴科技有限公司 | 一种具有计数和人脸识别功能的自开启式万用电炉开关 |

| CN104596265A (zh) * | 2014-12-25 | 2015-05-06 | 贵州永兴科技有限公司 | 一种具有报警和人脸识别功能的信息化万用电炉 |

| CN104596264A (zh) * | 2014-12-25 | 2015-05-06 | 贵州永兴科技有限公司 | 一种具有计数和指纹识别功能的信息化万用电炉 |

| KR102043876B1 (ko) * | 2016-02-09 | 2019-11-12 | 가부시키가이샤 코쿠사이 엘렉트릭 | 기판 처리 장치 및 반도체 장치의 제조 방법 |

| CN109553276B (zh) * | 2017-09-26 | 2021-10-29 | 东旭光电科技股份有限公司 | 铂金通道电加热设备和方法 |

| US11459626B2 (en) * | 2018-08-10 | 2022-10-04 | American Iron And Steel Institute | Flash ironmaking drop tube furnace system |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US715509A (en) * | 1902-03-28 | 1902-12-09 | George Westinghouse | End support and circuit-terminal for carbon-tube furnaces. |

| US1023309A (en) * | 1911-08-11 | 1912-04-16 | Hugo Helberger | Electrical resistance furnace. |

| FR500555A (fr) | 1918-06-14 | 1920-03-17 | Morgan Crucible Co | Perfectionnements aux fours électriques |

| US2121744A (en) | 1933-10-20 | 1938-06-21 | Norton Co | Electric furnace |

| US3139474A (en) | 1959-12-21 | 1964-06-30 | Chrysler Corp | High temperature furnace for treating refractory materials with metals and intermetallic compounds |

| US3170018A (en) * | 1960-05-03 | 1965-02-16 | Nuclear Technical Service Corp | High temperature furnace |

| US4549345A (en) | 1981-11-19 | 1985-10-29 | Wilsey Harvey J | Method of making a graphite zig-zag picket heater |

| CN85202601U (zh) * | 1985-06-27 | 1986-04-23 | 关东冶金工业株式会社 | 石墨筒加热炉 |

| US4703556A (en) | 1985-11-12 | 1987-11-03 | Ultra Carbon Corporation | Method of making a segmented heater system |

| CN2059437U (zh) * | 1989-03-27 | 1990-07-18 | 胡其达 | 电阻拉管炉 |

| JP3388306B2 (ja) | 1996-02-01 | 2003-03-17 | 株式会社ニッカトー | 電気炉 |

-

2002

- 2002-01-24 JP JP2003562552A patent/JP4093964B2/ja not_active Expired - Fee Related

- 2002-01-24 CN CNB028275527A patent/CN100371670C/zh not_active Expired - Lifetime

- 2002-01-24 AT AT02722031T patent/ATE503161T1/de active

- 2002-01-24 KR KR1020047011156A patent/KR100837747B1/ko not_active IP Right Cessation

- 2002-01-24 EP EP02722031A patent/EP1468233B1/de not_active Expired - Lifetime

- 2002-01-24 WO PCT/EP2002/000663 patent/WO2003062727A1/de active Application Filing

- 2002-01-24 DE DE50214980T patent/DE50214980D1/de not_active Expired - Lifetime

- 2002-01-24 US US10/502,485 patent/US7006552B2/en not_active Expired - Lifetime

-

2003

- 2003-01-21 TW TW092101261A patent/TW200302672A/zh unknown

Also Published As

| Publication number | Publication date |

|---|---|

| JP2005515399A (ja) | 2005-05-26 |

| CN100371670C (zh) | 2008-02-27 |

| KR100837747B1 (ko) | 2008-06-13 |

| US7006552B2 (en) | 2006-02-28 |

| ATE503161T1 (de) | 2011-04-15 |

| KR20040077742A (ko) | 2004-09-06 |

| US20050069015A1 (en) | 2005-03-31 |

| WO2003062727A1 (de) | 2003-07-31 |

| EP1468233B1 (de) | 2011-03-23 |

| TW200302672A (en) | 2003-08-01 |

| CN1618000A (zh) | 2005-05-18 |

| EP1468233A1 (de) | 2004-10-20 |

| DE50214980D1 (de) | 2011-05-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4093964B2 (ja) | 抵抗炉 | |

| US7173219B2 (en) | Ceramic heaters | |

| JP2007300057A (ja) | 二重温度帯を有する静電チャックをもつ基板支持体 | |

| JPH06294785A (ja) | 気体移送管の取付け装置 | |

| CN103347639A (zh) | 用于弧光焊接设备的气体冷却焊枪 | |

| US20090188906A1 (en) | High-temperature tube furnace for pyrolysis | |

| JP7401654B2 (ja) | 均一性が改善される半導体処理装置 | |

| CA2011153C (en) | Furnace and process for optical fiber drawing | |

| JPH06227822A (ja) | ガラス素地流出装置 | |

| US3205343A (en) | Blackbody source | |

| US5184894A (en) | Method of using an immersible air cooled thermocouple | |

| JPH0718446A (ja) | 熱処理装置 | |

| JP2009253061A (ja) | 基板支持部材 | |

| CN100493265C (zh) | 供给电流到管式炉的方法 | |

| JP5686467B2 (ja) | 基板処理装置及び半導体装置の製造方法 | |

| JP5655304B2 (ja) | 光ファイバ線引き炉および光ファイバ線引き方法 | |

| US3377418A (en) | Small diameter fluid cooled arc-rotating electrode | |

| JP5348447B2 (ja) | セルの特性評価装置 | |

| CN113874548A (zh) | 用于改良基板处理的基板底座 | |

| JPH08102445A (ja) | ウエハ加熱装置及びこれに用いる半導体製造用熱処理ウエハボート | |

| JPH06227837A (ja) | 光ファイバ紡糸用加熱炉 | |

| JP6829087B2 (ja) | 試料保持具 | |

| US3580977A (en) | Quick-change field coil assembly for use in an electrode having a fluid-cooled arcing surface | |

| CN116669237A (zh) | 一种用于光伏半导体的加热装置以及可温度补偿的扩散炉 | |

| JP5329037B2 (ja) | 酸素ポンプ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071116 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080201 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080227 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080304 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110314 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4093964 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110314 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120314 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120314 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130314 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130314 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140314 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |