0% found this document useful (0 votes)

483 views2 pagesVacuum Manhole Test of New Sanitary Sewer Manholes

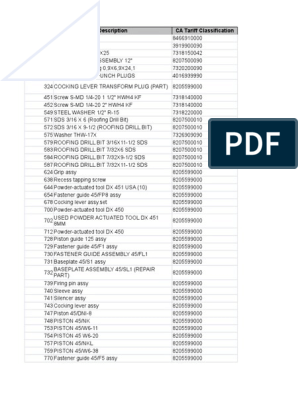

The document describes vacuum testing procedures for new sanitary sewer manholes. It provides an example inspection report showing manhole test results with manhole numbers, sizes, depths, required minimum test times, starting vacuum levels, ending vacuum levels, and pass/fail results. The testing procedures specify plugging pipe openings, creating a seal between the vacuum base and manhole, drawing a vacuum to 10 inches Hg, and ensuring the vacuum drop is less than 1 inch during the required test period which varies based on manhole diameter and depth.

Uploaded by

Mahmoud GaberCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

483 views2 pagesVacuum Manhole Test of New Sanitary Sewer Manholes

The document describes vacuum testing procedures for new sanitary sewer manholes. It provides an example inspection report showing manhole test results with manhole numbers, sizes, depths, required minimum test times, starting vacuum levels, ending vacuum levels, and pass/fail results. The testing procedures specify plugging pipe openings, creating a seal between the vacuum base and manhole, drawing a vacuum to 10 inches Hg, and ensuring the vacuum drop is less than 1 inch during the required test period which varies based on manhole diameter and depth.

Uploaded by

Mahmoud GaberCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 2