KR102124380B1 - 세라믹스 적층체, 세라믹스 절연 기판, 및 세라믹스 적층체의 제조 방법 - Google Patents

세라믹스 적층체, 세라믹스 절연 기판, 및 세라믹스 적층체의 제조 방법 Download PDFInfo

- Publication number

- KR102124380B1 KR102124380B1 KR1020187023122A KR20187023122A KR102124380B1 KR 102124380 B1 KR102124380 B1 KR 102124380B1 KR 1020187023122 A KR1020187023122 A KR 1020187023122A KR 20187023122 A KR20187023122 A KR 20187023122A KR 102124380 B1 KR102124380 B1 KR 102124380B1

- Authority

- KR

- South Korea

- Prior art keywords

- phase

- zirconia

- particles

- ceramics

- alumina

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000919 ceramic Substances 0.000 title claims abstract description 344

- 239000000758 substrate Substances 0.000 title claims abstract description 96

- 238000000034 method Methods 0.000 title claims abstract description 69

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 27

- 239000002245 particle Substances 0.000 claims abstract description 318

- 239000002131 composite material Substances 0.000 claims abstract description 135

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 claims description 354

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims description 113

- 239000002994 raw material Substances 0.000 claims description 104

- 239000000843 powder Substances 0.000 claims description 77

- 239000000443 aerosol Substances 0.000 claims description 65

- 239000010949 copper Substances 0.000 claims description 60

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 55

- 229910052802 copper Inorganic materials 0.000 claims description 55

- 239000013078 crystal Substances 0.000 claims description 27

- 229910052782 aluminium Inorganic materials 0.000 claims description 19

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 19

- RKTYLMNFRDHKIL-UHFFFAOYSA-N copper;5,10,15,20-tetraphenylporphyrin-22,24-diide Chemical compound [Cu+2].C1=CC(C(=C2C=CC([N-]2)=C(C=2C=CC=CC=2)C=2C=CC(N=2)=C(C=2C=CC=CC=2)C2=CC=C3[N-]2)C=2C=CC=CC=2)=NC1=C3C1=CC=CC=C1 RKTYLMNFRDHKIL-UHFFFAOYSA-N 0.000 claims description 15

- 230000005484 gravity Effects 0.000 claims description 11

- 239000011148 porous material Substances 0.000 claims description 10

- 229910052727 yttrium Inorganic materials 0.000 claims description 9

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 claims description 9

- 238000010030 laminating Methods 0.000 claims 1

- 230000017525 heat dissipation Effects 0.000 abstract description 17

- 238000009413 insulation Methods 0.000 abstract description 13

- 208000025599 Heat Stress disease Diseases 0.000 abstract description 3

- 230000035882 stress Effects 0.000 description 37

- 230000000052 comparative effect Effects 0.000 description 31

- 238000000151 deposition Methods 0.000 description 24

- 239000007789 gas Substances 0.000 description 23

- 230000015572 biosynthetic process Effects 0.000 description 20

- 230000000694 effects Effects 0.000 description 18

- 230000008646 thermal stress Effects 0.000 description 18

- 239000000463 material Substances 0.000 description 17

- 230000015556 catabolic process Effects 0.000 description 16

- 229910052751 metal Inorganic materials 0.000 description 16

- 239000002184 metal Substances 0.000 description 16

- 230000005684 electric field Effects 0.000 description 15

- RUDFQVOCFDJEEF-UHFFFAOYSA-N yttrium(III) oxide Inorganic materials [O-2].[O-2].[O-2].[Y+3].[Y+3] RUDFQVOCFDJEEF-UHFFFAOYSA-N 0.000 description 14

- 238000005245 sintering Methods 0.000 description 13

- 230000008569 process Effects 0.000 description 12

- 239000003381 stabilizer Substances 0.000 description 11

- 238000004458 analytical method Methods 0.000 description 10

- 230000008021 deposition Effects 0.000 description 10

- 239000011812 mixed powder Substances 0.000 description 10

- 239000000203 mixture Substances 0.000 description 10

- 238000002156 mixing Methods 0.000 description 9

- 239000011347 resin Substances 0.000 description 9

- 229920005989 resin Polymers 0.000 description 9

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 8

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 8

- CPLXHLVBOLITMK-UHFFFAOYSA-N Magnesium oxide Chemical compound [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 8

- 229910001873 dinitrogen Inorganic materials 0.000 description 8

- 230000007246 mechanism Effects 0.000 description 8

- 239000012528 membrane Substances 0.000 description 8

- 239000004065 semiconductor Substances 0.000 description 8

- 230000009466 transformation Effects 0.000 description 8

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 7

- 230000001133 acceleration Effects 0.000 description 7

- 229910052684 Cerium Inorganic materials 0.000 description 6

- GWXLDORMOJMVQZ-UHFFFAOYSA-N cerium Chemical compound [Ce] GWXLDORMOJMVQZ-UHFFFAOYSA-N 0.000 description 6

- 239000010987 cubic zirconia Substances 0.000 description 6

- 238000011156 evaluation Methods 0.000 description 6

- 230000002401 inhibitory effect Effects 0.000 description 6

- 239000011159 matrix material Substances 0.000 description 6

- 238000005507 spraying Methods 0.000 description 6

- 238000002441 X-ray diffraction Methods 0.000 description 5

- 230000008859 change Effects 0.000 description 5

- 239000006185 dispersion Substances 0.000 description 5

- 238000009826 distribution Methods 0.000 description 5

- 239000012535 impurity Substances 0.000 description 5

- 238000005498 polishing Methods 0.000 description 5

- 229910052581 Si3N4 Inorganic materials 0.000 description 4

- 238000007545 Vickers hardness test Methods 0.000 description 4

- CETPSERCERDGAM-UHFFFAOYSA-N ceric oxide Chemical compound O=[Ce]=O CETPSERCERDGAM-UHFFFAOYSA-N 0.000 description 4

- 229910000422 cerium(IV) oxide Inorganic materials 0.000 description 4

- 230000006378 damage Effects 0.000 description 4

- 238000005304 joining Methods 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- 238000005096 rolling process Methods 0.000 description 4

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 4

- ODINCKMPIJJUCX-UHFFFAOYSA-N Calcium oxide Chemical compound [Ca]=O ODINCKMPIJJUCX-UHFFFAOYSA-N 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 3

- 238000005299 abrasion Methods 0.000 description 3

- 238000005219 brazing Methods 0.000 description 3

- 239000000292 calcium oxide Substances 0.000 description 3

- 235000012255 calcium oxide Nutrition 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 3

- 239000013065 commercial product Substances 0.000 description 3

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 238000007606 doctor blade method Methods 0.000 description 3

- 239000001307 helium Substances 0.000 description 3

- 229910052734 helium Inorganic materials 0.000 description 3

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 3

- 238000010191 image analysis Methods 0.000 description 3

- 238000004898 kneading Methods 0.000 description 3

- 239000000395 magnesium oxide Substances 0.000 description 3

- 150000002739 metals Chemical class 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000011164 primary particle Substances 0.000 description 3

- 230000000087 stabilizing effect Effects 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 238000007751 thermal spraying Methods 0.000 description 3

- 239000011800 void material Substances 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 2

- UQSXHKLRYXJYBZ-UHFFFAOYSA-N Iron oxide Chemical compound [Fe]=O UQSXHKLRYXJYBZ-UHFFFAOYSA-N 0.000 description 2

- 241000282341 Mustela putorius furo Species 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- 230000033228 biological regulation Effects 0.000 description 2

- 229910052791 calcium Inorganic materials 0.000 description 2

- 239000011575 calcium Substances 0.000 description 2

- 238000005056 compaction Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 229910003460 diamond Inorganic materials 0.000 description 2

- 239000010432 diamond Substances 0.000 description 2

- 238000010292 electrical insulation Methods 0.000 description 2

- 230000005611 electricity Effects 0.000 description 2

- 238000010304 firing Methods 0.000 description 2

- 230000007062 hydrolysis Effects 0.000 description 2

- 238000006460 hydrolysis reaction Methods 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 238000007373 indentation Methods 0.000 description 2

- 238000002065 inelastic X-ray scattering Methods 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 238000003475 lamination Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 229910002077 partially stabilized zirconia Inorganic materials 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 230000002250 progressing effect Effects 0.000 description 2

- 238000010298 pulverizing process Methods 0.000 description 2

- 229910052761 rare earth metal Inorganic materials 0.000 description 2

- 230000003252 repetitive effect Effects 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- PIGFYZPCRLYGLF-UHFFFAOYSA-N Aluminum nitride Chemical compound [Al]#N PIGFYZPCRLYGLF-UHFFFAOYSA-N 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- 229910017945 Cu—Ti Inorganic materials 0.000 description 1

- 229910002601 GaN Inorganic materials 0.000 description 1

- JMASRVWKEDWRBT-UHFFFAOYSA-N Gallium nitride Chemical compound [Ga]#N JMASRVWKEDWRBT-UHFFFAOYSA-N 0.000 description 1

- 206010053759 Growth retardation Diseases 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 229910017309 Mo—Mn Inorganic materials 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 239000004809 Teflon Substances 0.000 description 1

- 229920006362 Teflon® Polymers 0.000 description 1

- 229910010413 TiO 2 Inorganic materials 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000009770 conventional sintering Methods 0.000 description 1

- PMHQVHHXPFUNSP-UHFFFAOYSA-M copper(1+);methylsulfanylmethane;bromide Chemical compound Br[Cu].CSC PMHQVHHXPFUNSP-UHFFFAOYSA-M 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 230000001186 cumulative effect Effects 0.000 description 1

- 238000000280 densification Methods 0.000 description 1

- 238000002149 energy-dispersive X-ray emission spectroscopy Methods 0.000 description 1

- 238000009661 fatigue test Methods 0.000 description 1

- 238000007429 general method Methods 0.000 description 1

- 238000007542 hardness measurement Methods 0.000 description 1

- 238000003384 imaging method Methods 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 229910000734 martensite Inorganic materials 0.000 description 1

- 239000008204 material by function Substances 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 238000010338 mechanical breakdown Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- 230000000877 morphologic effect Effects 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 230000000644 propagated effect Effects 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- KKCBUQHMOMHUOY-UHFFFAOYSA-N sodium oxide Chemical compound [O-2].[Na+].[Na+] KKCBUQHMOMHUOY-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 229910002076 stabilized zirconia Inorganic materials 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C24/00—Coating starting from inorganic powder

- C23C24/02—Coating starting from inorganic powder by application of pressure only

- C23C24/04—Impact or kinetic deposition of particles

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/12—Mountings, e.g. non-detachable insulating substrates

- H01L23/14—Mountings, e.g. non-detachable insulating substrates characterised by the material or its electrical properties

- H01L23/15—Ceramic or glass substrates

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Laminated Bodies (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Abstract

Description

도 2는, 제2 상 입자를 타원으로 보고 판단하여 상당 타원을 도시하는 개략도이다.

도 3은, 배향각의 설명에 제공되는 개략도이다.

도 4는, 실시예 1에서 제작한 본 발명의 세라믹스 적층체에 있어서, 복합 세라믹스층과 기재의 접합면에 대하여 직교하는 임의의 단면을, 전계 방사형 주사 전자 현미경으로 관찰하였을 때의 반사 전자상이다.

도 5는, 실시예 3에서 제작한 본 발명의 세라믹스 적층체에 있어서, 복합 세라믹스층과 기재의 접합면에 대하여 직교하는 임의의 단면을, 전계 방사형 주사 전자 현미경으로 관찰하였을 때의 2차 전자상이다.

2: 알루미나상(제1 상)

3: 지르코니아상(제2 상 입자)

4: 공극

Claims (12)

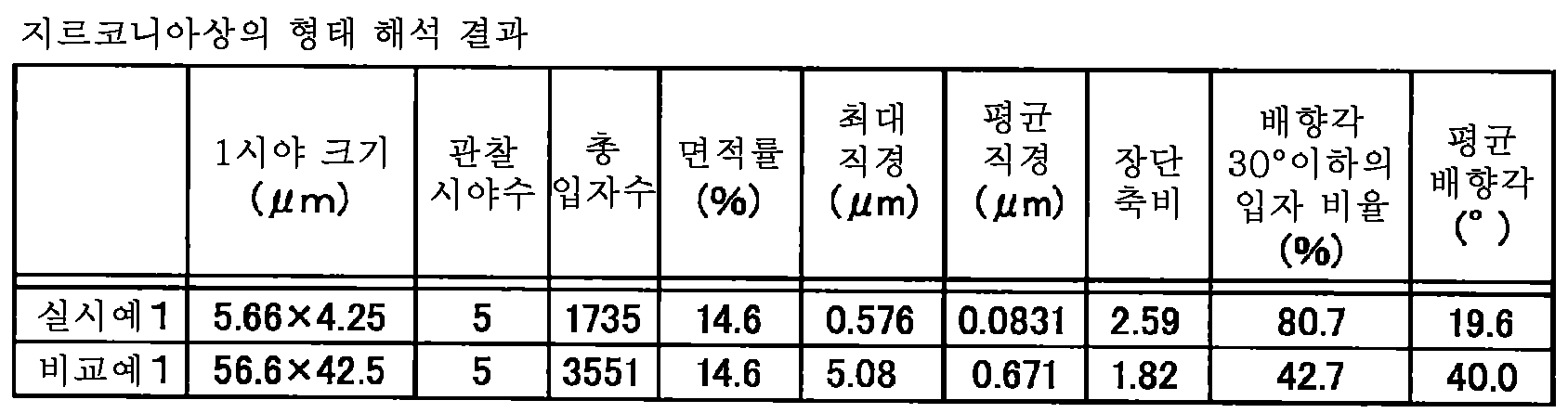

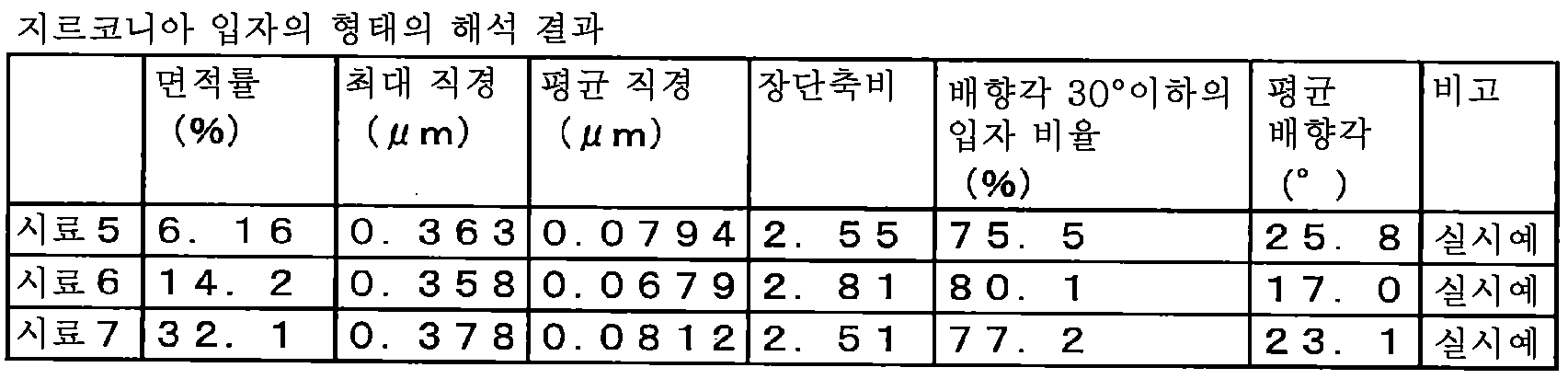

- 기재층의 일부 혹은 전체면에, 알루미나상과 지르코니아상을 포함하여 이루어지는 복합 세라믹스층이 피복된 세라믹스 적층체이며,

상기 복합 세라믹스층과 상기 기재층의 접합면에 대하여 직교하는 임의의 단면에 있어서, 상기 알루미나상 또는 상기 지르코니아상 중 어느 것으로 이루어지는 제1 상 내에, 해당 제1 상보다 총 면적률이 작은 다른 쪽의 상기 지르코니아상 또는 상기 알루미나상으로 이루어지는 제2 상 입자가 분산된 조직을 갖고,

상기 단면 내에 있어서 원 상당 직경이 0.01㎛ 이상인 상기 제2 상 입자와 공극을 계측하였을 때,

상기 제2 상 입자의 원 상당 직경의 최댓값이 5㎛ 이하이고,

상기 제2 상 입자의 원 상당 직경의 평균값이 0.02㎛ 이상 0.3㎛ 이하로 이루어지고,

또한, 상기 제2 상 입자를 타원으로 보고 판단하였을 때의 상당 타원의 긴 직경을 짧은 직경으로 나눈 값의 평균값이 2 이상 10 이하이고,

공극의 면적률이 5% 이하인 것을 특징으로 하는 세라믹스 적층체. - 제1항에 있어서, 상기 제2 상 입자의 무게 중심에 가장 거리가 가까운 상기 접합면의 면 방향과, 상기 제2 상 입자의 상당 타원 긴 직경의 방향이 이루는 각이 -90°내지 90°의 각도로 표현되고, 그 각도의 절댓값을 상기 제2 상 입자의 배향각이라고 하였을 때,

임의의 상기 단면에서는, 60% 이상의 수의 상기 제2 상 입자가 30°이하의 상기 배향각을 갖고 있으며,

또한 상기 배향각의 총합을 상기 제2 상 입자의 총 입자수로 나눈 평균 배향각이 5°이상 35°이하인 것을 특징으로 하는 세라믹스 적층체. - 제1항 또는 제2항에 있어서, 상기 기재층은 구리 또는 알루미늄을 주체로 하고,

상기 복합 세라믹스층은, 상기 기재층과 수직 방향의 두께가 5㎛ 이상 200㎛ 이하인 것을 특징으로 하는 세라믹스 적층체. - 제1항 또는 제2항에 있어서, 상기 제1 상이 알루미나상이고, 상기 제2 상이 지르코니아상인 것을 특징으로 하는 세라믹스 적층체.

- 제1항 또는 제2항에 있어서, 상기 지르코니아상이 적어도 정방정을 함유하고, 이트륨의 함유량이 0.1질량% 이하인 것을 특징으로 하는 세라믹스 적층체.

- 제1항 또는 제2항에 기재된 세라믹스 적층체로 이루어지는 것을 특징으로 하는 세라믹스 절연 기판.

- 제6항에 있어서, 상기 기재층이 구리 또는 알루미늄이며, 상기 복합 세라믹스층을 사이에 두고 반대면에 구리 또는 알루미늄 회로가 형성되어 있는, 세라믹스 절연 기판.

- 제7항에 있어서, 상기 기재층의 두께가 0.5mm 초과이며, 상기 회로의 두께의 2배 이상인, 세라믹스 절연 기판.

- 제1항에 기재된 세라믹스 적층체의 제조 방법이며, 알루미나 원료 입자와 지르코니아 원료 입자를 기체와 혼합하고, 상기 알루미나 원료 입자와 상기 지르코니아 원료 입자를 상기 기체와 함께 기재층의 표면을 향하여 분사하여 충돌시킴으로써, 상기 기재층의 표면에 복합 세라믹스층을 적층하는 것을 특징으로 하는 세라믹스 적층체의 제조 방법.

- 제9항에 있어서, 상기 알루미나 원료 입자와 상기 기체를 혼합하여 하나의 에어로졸을 생성하고, 상기 지르코니아 원료 입자와 상기 기체를 혼합하여 다른 에어로졸을 생성하고,

상기 하나의 에어로졸과 상기 다른 에어로졸을 상기 기재층의 표면을 향하여 분사하는 것을 특징으로 하는 세라믹스 적층체의 제조 방법. - 제9항에 있어서, 상기 알루미나 원료 입자 및 상기 지르코니아 원료 입자를 혼합한 혼합 원료 분말에, 상기 기체를 혼합시켜 에어로졸을 생성하고, 상기 에어로졸을 상기 기재층의 표면을 향하여 분사하는 것을 특징으로 하는 세라믹스 적층체의 제조 방법.

- 제9항 내지 제11항 중 어느 한 항에 있어서, 상기 지르코니아 원료가 전융 분말인, 세라믹스 적층체의 제조 방법.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JPJP-P-2016-030501 | 2016-02-19 | ||

| JP2016030501 | 2016-02-19 | ||

| PCT/JP2017/006004 WO2017142090A1 (ja) | 2016-02-19 | 2017-02-17 | セラミックス積層体、セラミックス絶縁基板、及びセラミックス積層体の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180100429A KR20180100429A (ko) | 2018-09-10 |

| KR102124380B1 true KR102124380B1 (ko) | 2020-06-19 |

Family

ID=59625248

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187023122A Active KR102124380B1 (ko) | 2016-02-19 | 2017-02-17 | 세라믹스 적층체, 세라믹스 절연 기판, 및 세라믹스 적층체의 제조 방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US10889899B2 (ko) |

| EP (1) | EP3418428B1 (ko) |

| JP (1) | JP6477968B2 (ko) |

| KR (1) | KR102124380B1 (ko) |

| CN (1) | CN108603294B (ko) |

| TW (1) | TWI632059B (ko) |

| WO (1) | WO2017142090A1 (ko) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2018168035A (ja) * | 2017-03-30 | 2018-11-01 | Toto株式会社 | ジルコニア構造物 |

| KR20200128119A (ko) * | 2018-04-03 | 2020-11-11 | 닛폰세이테츠 가부시키가이샤 | 복합 세라믹스 적층체, 및 제조 방법 |

| JP7206716B2 (ja) * | 2018-09-07 | 2023-01-18 | トヨタ自動車株式会社 | 蒸発器及びその製造方法、並びに蒸発器を有するループ型ヒートパイプ |

| CN112335334B (zh) * | 2018-09-11 | 2022-12-09 | 京瓷株式会社 | 加热器以及具备该加热器的加热用具 |

| EP3648156B1 (en) | 2018-11-02 | 2025-06-04 | Infineon Technologies AG | Semiconductor substrate |

| CN114026956A (zh) * | 2019-07-01 | 2022-02-08 | 日本碍子株式会社 | 带轴的陶瓷加热器 |

| CN110473778B (zh) * | 2019-08-17 | 2021-10-15 | 哈尔滨工业大学 | 一种利用等离子体活化直接键合氧化锆和三氧化二铝的方法 |

| JP7339538B2 (ja) * | 2020-01-15 | 2023-09-06 | 日本製鉄株式会社 | 金属セラミックス積層体 |

| TWI806482B (zh) * | 2022-03-10 | 2023-06-21 | 誠創科技股份有限公司 | 陶瓷基板及其製造方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009050251A2 (en) | 2007-10-16 | 2009-04-23 | Hkpb Scientific Limited | Surface coating processes and uses of same |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4331825B2 (ja) * | 1999-05-31 | 2009-09-16 | 京セラ株式会社 | 高強度アルミナ質焼結体の製造方法 |

| JP2002004029A (ja) | 2000-06-16 | 2002-01-09 | Fuji Kihan:Kk | 酸化物分散メッキ被膜による浸炭防止方法及び前記酸化物分散メッキ被膜 |

| JP3784341B2 (ja) | 2001-04-03 | 2006-06-07 | 独立行政法人産業技術総合研究所 | 回路基板とその作製方法 |

| JP4955192B2 (ja) * | 2001-08-02 | 2012-06-20 | スリーエム イノベイティブ プロパティズ カンパニー | ガラス−セラミック |

| JP3937952B2 (ja) | 2002-07-15 | 2007-06-27 | 東陶機器株式会社 | 放熱回路基板とその作製方法 |

| JP4784150B2 (ja) | 2004-11-10 | 2011-10-05 | 富士電機株式会社 | 半導体装置および、半導体装置の製造方法 |

| JP2008196012A (ja) | 2007-02-13 | 2008-08-28 | Ntn Corp | エアロゾル発生装置 |

| JP2009179847A (ja) | 2008-01-30 | 2009-08-13 | Hitachi Cable Ltd | 炭素被覆材の製造方法及び炭素被覆材 |

| JP2010232580A (ja) | 2009-03-30 | 2010-10-14 | Brother Ind Ltd | 圧電素子 |

| JP5842457B2 (ja) | 2011-01-24 | 2016-01-13 | 富士通株式会社 | ヒートスプレッダ及びその製造方法、半導体装置、電子装置 |

| JP2013032265A (ja) | 2011-07-01 | 2013-02-14 | Maruwa Co Ltd | 半導体装置用アルミナジルコニア焼結基板及びその製造方法 |

| JP5879141B2 (ja) * | 2012-02-03 | 2016-03-08 | スタンレー電気株式会社 | ハードコート層を備えた物品およびその製造方法 |

| US9212099B2 (en) | 2012-02-22 | 2015-12-15 | Applied Materials, Inc. | Heat treated ceramic substrate having ceramic coating and heat treatment for coated ceramics |

| US20130288037A1 (en) | 2012-04-27 | 2013-10-31 | Applied Materials, Inc. | Plasma spray coating process enhancement for critical chamber components |

| US9343289B2 (en) * | 2012-07-27 | 2016-05-17 | Applied Materials, Inc. | Chemistry compatible coating material for advanced device on-wafer particle performance |

| US9708713B2 (en) * | 2013-05-24 | 2017-07-18 | Applied Materials, Inc. | Aerosol deposition coating for semiconductor chamber components |

| JP6203942B2 (ja) * | 2014-04-04 | 2017-09-27 | シャープ株式会社 | 発光装置用基板の製造方法、発光装置の製造方法、及び照明装置の製造方法 |

-

2017

- 2017-02-17 CN CN201780011306.9A patent/CN108603294B/zh active Active

- 2017-02-17 EP EP17753344.5A patent/EP3418428B1/en active Active

- 2017-02-17 WO PCT/JP2017/006004 patent/WO2017142090A1/ja active Application Filing

- 2017-02-17 TW TW106105335A patent/TWI632059B/zh active

- 2017-02-17 KR KR1020187023122A patent/KR102124380B1/ko active Active

- 2017-02-17 JP JP2018500239A patent/JP6477968B2/ja active Active

- 2017-02-17 US US15/999,792 patent/US10889899B2/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009050251A2 (en) | 2007-10-16 | 2009-04-23 | Hkpb Scientific Limited | Surface coating processes and uses of same |

| US20100211158A1 (en) * | 2007-10-16 | 2010-08-19 | Hkpb Scientific Limited | Surface coating processes and uses of same |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108603294A (zh) | 2018-09-28 |

| WO2017142090A1 (ja) | 2017-08-24 |

| US20200071836A1 (en) | 2020-03-05 |

| JP6477968B2 (ja) | 2019-03-06 |

| US10889899B2 (en) | 2021-01-12 |

| TWI632059B (zh) | 2018-08-11 |

| JPWO2017142090A1 (ja) | 2019-01-10 |

| EP3418428A4 (en) | 2020-01-15 |

| KR20180100429A (ko) | 2018-09-10 |

| EP3418428B1 (en) | 2023-05-17 |

| EP3418428A1 (en) | 2018-12-26 |

| TW201731688A (zh) | 2017-09-16 |

| CN108603294B (zh) | 2020-05-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102124380B1 (ko) | 세라믹스 적층체, 세라믹스 절연 기판, 및 세라믹스 적층체의 제조 방법 | |

| KR101975633B1 (ko) | 금속-세라믹스 접합 기판 및 그 제조 방법 | |

| KR102239069B1 (ko) | 세라믹스 적층체 | |

| US9293384B2 (en) | Silicon nitride substrate, circuit substrate and electronic device using the same | |

| KR102274971B1 (ko) | 구리-세라믹 복합재 | |

| JP5440947B2 (ja) | 窒化珪素基板の製造方法及び窒化珪素基板並びにそれを使用した回路基板 | |

| CN114787105A (zh) | 板状的氮化硅质烧结体及其制造方法 | |

| KR102206422B1 (ko) | 구리/세라믹 복합체 | |

| KR102222223B1 (ko) | 구리-세라믹 복합체 | |

| KR102274969B1 (ko) | 구리-세라믹 복합재 | |

| KR20180111938A (ko) | 구리-세라믹 복합체 | |

| WO2019194240A1 (ja) | 複合セラミックス積層体、及び製造方法 | |

| KR102206421B1 (ko) | 구리-세라믹 복합재 | |

| JP2002029850A (ja) | 窒化ケイ素焼結体とその製造方法 | |

| JP3562042B2 (ja) | セラミックス基板及びその製造方法 | |

| JP2023140101A (ja) | 複合セラミックス材料および接合体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0105 | International application |

Patent event date: 20180810 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20200122 Patent event code: PE09021S01D |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

Patent event code: PE07011S01D Comment text: Decision to Grant Registration Patent event date: 20200408 |

|

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 20200612 Patent event code: PR07011E01D |

|

| PR1002 | Payment of registration fee |

Payment date: 20200615 End annual number: 3 Start annual number: 1 |

|

| PG1601 | Publication of registration | ||

| PR1001 | Payment of annual fee |

Payment date: 20230523 Start annual number: 4 End annual number: 4 |

|

| PR1001 | Payment of annual fee |

Payment date: 20240521 Start annual number: 5 End annual number: 5 |