JP7630759B2 - Resin composition, compound (Z), substrate (i), optical filter and use thereof - Google Patents

Resin composition, compound (Z), substrate (i), optical filter and use thereof Download PDFInfo

- Publication number

- JP7630759B2 JP7630759B2 JP2021018596A JP2021018596A JP7630759B2 JP 7630759 B2 JP7630759 B2 JP 7630759B2 JP 2021018596 A JP2021018596 A JP 2021018596A JP 2021018596 A JP2021018596 A JP 2021018596A JP 7630759 B2 JP7630759 B2 JP 7630759B2

- Authority

- JP

- Japan

- Prior art keywords

- group

- compound

- substrate

- atom

- optical filter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 150000001875 compounds Chemical class 0.000 title claims description 402

- 239000000758 substrate Substances 0.000 title claims description 210

- 230000003287 optical effect Effects 0.000 title claims description 133

- 239000011342 resin composition Substances 0.000 title claims description 28

- 229920005989 resin Polymers 0.000 claims description 233

- 239000011347 resin Substances 0.000 claims description 233

- YMWUJEATGCHHMB-UHFFFAOYSA-N Dichloromethane Chemical compound ClCCl YMWUJEATGCHHMB-UHFFFAOYSA-N 0.000 claims description 210

- 125000004432 carbon atom Chemical group C* 0.000 claims description 88

- 238000002834 transmittance Methods 0.000 claims description 69

- 238000010521 absorption reaction Methods 0.000 claims description 63

- -1 polyparaphenylene Polymers 0.000 claims description 52

- 125000001424 substituent group Chemical group 0.000 claims description 46

- 125000002723 alicyclic group Chemical group 0.000 claims description 43

- 125000004435 hydrogen atom Chemical group [H]* 0.000 claims description 40

- 229910052727 yttrium Inorganic materials 0.000 claims description 35

- 239000011521 glass Substances 0.000 claims description 31

- 125000004430 oxygen atom Chemical group O* 0.000 claims description 30

- 125000002887 hydroxy group Chemical group [H]O* 0.000 claims description 29

- 229910052757 nitrogen Inorganic materials 0.000 claims description 29

- 229910052717 sulfur Chemical group 0.000 claims description 29

- 125000004434 sulfur atom Chemical group 0.000 claims description 29

- 238000003384 imaging method Methods 0.000 claims description 27

- 125000005843 halogen group Chemical group 0.000 claims description 26

- 125000002029 aromatic hydrocarbon group Chemical group 0.000 claims description 25

- 125000004433 nitrogen atom Chemical group N* 0.000 claims description 23

- 125000001072 heteroaryl group Chemical group 0.000 claims description 18

- 238000000411 transmission spectrum Methods 0.000 claims description 18

- 125000001931 aliphatic group Chemical group 0.000 claims description 15

- 239000004642 Polyimide Substances 0.000 claims description 12

- 229910052799 carbon Inorganic materials 0.000 claims description 12

- 229920001721 polyimide Polymers 0.000 claims description 12

- 125000004093 cyano group Chemical group *C#N 0.000 claims description 11

- 125000000449 nitro group Chemical group [O-][N+](*)=O 0.000 claims description 11

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 claims description 10

- 238000000862 absorption spectrum Methods 0.000 claims description 9

- 150000001450 anions Chemical class 0.000 claims description 9

- 229920000642 polymer Polymers 0.000 claims description 8

- 125000002252 acyl group Chemical group 0.000 claims description 6

- 125000004453 alkoxycarbonyl group Chemical group 0.000 claims description 6

- 125000003118 aryl group Chemical group 0.000 claims description 6

- 150000001768 cations Chemical class 0.000 claims description 6

- 125000000623 heterocyclic group Chemical group 0.000 claims description 6

- 238000001228 spectrum Methods 0.000 claims description 6

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 claims description 6

- 239000004593 Epoxy Substances 0.000 claims description 5

- BUGBHKTXTAQXES-UHFFFAOYSA-N Selenium Chemical group [Se] BUGBHKTXTAQXES-UHFFFAOYSA-N 0.000 claims description 5

- 125000003368 amide group Chemical group 0.000 claims description 5

- 125000002467 phosphate group Chemical group [H]OP(=O)(O[H])O[*] 0.000 claims description 5

- 229910052711 selenium Inorganic materials 0.000 claims description 5

- 125000003808 silyl group Chemical group [H][Si]([H])([H])[*] 0.000 claims description 5

- 125000000020 sulfo group Chemical group O=S(=O)([*])O[H] 0.000 claims description 5

- 229910052714 tellurium Inorganic materials 0.000 claims description 5

- PORWMNRCUJJQNO-UHFFFAOYSA-N tellurium atom Chemical group [Te] PORWMNRCUJJQNO-UHFFFAOYSA-N 0.000 claims description 5

- 125000004122 cyclic group Chemical group 0.000 claims description 4

- 239000004417 polycarbonate Substances 0.000 claims description 4

- 229920002554 vinyl polymer Polymers 0.000 claims description 4

- 239000004962 Polyamide-imide Substances 0.000 claims description 3

- 239000004695 Polyether sulfone Substances 0.000 claims description 3

- 229920000265 Polyparaphenylene Polymers 0.000 claims description 3

- 239000004721 Polyphenylene oxide Substances 0.000 claims description 3

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 claims description 3

- 150000001336 alkenes Chemical class 0.000 claims description 3

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 claims description 3

- 229920002492 poly(sulfone) Polymers 0.000 claims description 3

- 229920002647 polyamide Polymers 0.000 claims description 3

- 229920002312 polyamide-imide Polymers 0.000 claims description 3

- 229920001230 polyarylate Polymers 0.000 claims description 3

- 229920000515 polycarbonate Polymers 0.000 claims description 3

- 229920001225 polyester resin Polymers 0.000 claims description 3

- 229920000570 polyether Polymers 0.000 claims description 3

- 229920006393 polyether sulfone Polymers 0.000 claims description 3

- 239000011112 polyethylene naphthalate Substances 0.000 claims description 3

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 claims description 2

- 125000001183 hydrocarbyl group Chemical group 0.000 claims 1

- 239000010410 layer Substances 0.000 description 281

- 239000010408 film Substances 0.000 description 157

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 132

- 239000000203 mixture Substances 0.000 description 101

- 239000000243 solution Substances 0.000 description 83

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 79

- 230000009102 absorption Effects 0.000 description 62

- 230000015572 biosynthetic process Effects 0.000 description 57

- 238000003786 synthesis reaction Methods 0.000 description 57

- 239000002904 solvent Substances 0.000 description 56

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 51

- 229910010413 TiO 2 Inorganic materials 0.000 description 44

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 39

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 35

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 33

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 33

- 239000012074 organic phase Substances 0.000 description 33

- CSNNHWWHGAXBCP-UHFFFAOYSA-L Magnesium sulfate Chemical compound [Mg+2].[O-][S+2]([O-])([O-])[O-] CSNNHWWHGAXBCP-UHFFFAOYSA-L 0.000 description 32

- 239000007787 solid Substances 0.000 description 31

- 239000000463 material Substances 0.000 description 30

- WFDIJRYMOXRFFG-UHFFFAOYSA-N Acetic anhydride Chemical compound CC(=O)OC(C)=O WFDIJRYMOXRFFG-UHFFFAOYSA-N 0.000 description 27

- 239000011248 coating agent Substances 0.000 description 26

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 24

- 238000005160 1H NMR spectroscopy Methods 0.000 description 23

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 23

- 238000004458 analytical method Methods 0.000 description 23

- 238000000034 method Methods 0.000 description 23

- 238000006243 chemical reaction Methods 0.000 description 22

- 238000013461 design Methods 0.000 description 22

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 21

- 238000002835 absorbance Methods 0.000 description 21

- 238000000576 coating method Methods 0.000 description 20

- 238000000465 moulding Methods 0.000 description 17

- 238000001816 cooling Methods 0.000 description 16

- 229910052943 magnesium sulfate Inorganic materials 0.000 description 16

- 235000019341 magnesium sulphate Nutrition 0.000 description 16

- 230000003595 spectral effect Effects 0.000 description 16

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 15

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 15

- 238000004895 liquid chromatography mass spectrometry Methods 0.000 description 15

- 239000000377 silicon dioxide Substances 0.000 description 15

- VLTRZXGMWDSKGL-UHFFFAOYSA-N perchloric acid Chemical compound OCl(=O)(=O)=O VLTRZXGMWDSKGL-UHFFFAOYSA-N 0.000 description 12

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 12

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 11

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 11

- 239000000706 filtrate Substances 0.000 description 11

- 238000001914 filtration Methods 0.000 description 11

- 239000007788 liquid Substances 0.000 description 11

- PBKBURVPAHHUIK-AVUWLFEKSA-N phenyl-[(e)-3-phenyliminoprop-1-enyl]azanium;chloride Chemical compound Cl.C=1C=CC=CC=1N\C=C\C=NC1=CC=CC=C1 PBKBURVPAHHUIK-AVUWLFEKSA-N 0.000 description 11

- 235000002597 Solanum melongena Nutrition 0.000 description 10

- 239000008346 aqueous phase Substances 0.000 description 10

- 239000000975 dye Substances 0.000 description 10

- 230000000694 effects Effects 0.000 description 10

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 10

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 9

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 9

- 238000001035 drying Methods 0.000 description 9

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 9

- 238000010438 heat treatment Methods 0.000 description 9

- 229910052744 lithium Inorganic materials 0.000 description 9

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 9

- 239000003960 organic solvent Substances 0.000 description 9

- 238000003756 stirring Methods 0.000 description 9

- 239000012790 adhesive layer Substances 0.000 description 8

- 230000005540 biological transmission Effects 0.000 description 8

- 239000003795 chemical substances by application Substances 0.000 description 8

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 8

- 125000004108 n-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 8

- 238000000151 deposition Methods 0.000 description 7

- 230000008021 deposition Effects 0.000 description 7

- VXWPONVCMVLXBW-UHFFFAOYSA-M magnesium;carbanide;iodide Chemical compound [CH3-].[Mg+2].[I-] VXWPONVCMVLXBW-UHFFFAOYSA-M 0.000 description 7

- 125000004123 n-propyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])* 0.000 description 7

- 239000003505 polymerization initiator Substances 0.000 description 7

- 238000010992 reflux Methods 0.000 description 7

- 238000010898 silica gel chromatography Methods 0.000 description 7

- 238000000967 suction filtration Methods 0.000 description 7

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 7

- 238000012360 testing method Methods 0.000 description 7

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 6

- 125000001797 benzyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C([H])([H])* 0.000 description 6

- 238000001723 curing Methods 0.000 description 6

- 230000009477 glass transition Effects 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 239000011148 porous material Substances 0.000 description 6

- 238000002360 preparation method Methods 0.000 description 6

- 239000000047 product Substances 0.000 description 6

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 5

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 5

- KEAYESYHFKHZAL-UHFFFAOYSA-N Sodium Chemical compound [Na] KEAYESYHFKHZAL-UHFFFAOYSA-N 0.000 description 5

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 description 5

- DKGAVHZHDRPRBM-UHFFFAOYSA-N Tert-Butanol Chemical compound CC(C)(C)O DKGAVHZHDRPRBM-UHFFFAOYSA-N 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 5

- 238000005520 cutting process Methods 0.000 description 5

- 230000007547 defect Effects 0.000 description 5

- 239000006185 dispersion Substances 0.000 description 5

- HHEIMYAXCOIQCJ-UHFFFAOYSA-N ethyl 2,2-dimethylpropanoate Chemical compound CCOC(=O)C(C)(C)C HHEIMYAXCOIQCJ-UHFFFAOYSA-N 0.000 description 5

- 238000005227 gel permeation chromatography Methods 0.000 description 5

- 230000014759 maintenance of location Effects 0.000 description 5

- 239000012188 paraffin wax Substances 0.000 description 5

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 5

- 125000002914 sec-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 5

- 230000035945 sensitivity Effects 0.000 description 5

- 239000012312 sodium hydride Substances 0.000 description 5

- 229910000104 sodium hydride Inorganic materials 0.000 description 5

- 229910052938 sodium sulfate Inorganic materials 0.000 description 5

- 235000011152 sodium sulphate Nutrition 0.000 description 5

- 238000003828 vacuum filtration Methods 0.000 description 5

- YEJRWHAVMIAJKC-UHFFFAOYSA-N 4-Butyrolactone Chemical compound O=C1CCCO1 YEJRWHAVMIAJKC-UHFFFAOYSA-N 0.000 description 4

- FXHOOIRPVKKKFG-UHFFFAOYSA-N N,N-Dimethylacetamide Chemical compound CN(C)C(C)=O FXHOOIRPVKKKFG-UHFFFAOYSA-N 0.000 description 4

- WETWJCDKMRHUPV-UHFFFAOYSA-N acetyl chloride Chemical compound CC(Cl)=O WETWJCDKMRHUPV-UHFFFAOYSA-N 0.000 description 4

- 239000012346 acetyl chloride Substances 0.000 description 4

- 229910052801 chlorine Inorganic materials 0.000 description 4

- 125000001309 chloro group Chemical group Cl* 0.000 description 4

- 125000000113 cyclohexyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 4

- 229910052731 fluorine Inorganic materials 0.000 description 4

- 125000001153 fluoro group Chemical group F* 0.000 description 4

- 150000002430 hydrocarbons Chemical group 0.000 description 4

- 239000012528 membrane Substances 0.000 description 4

- 125000000956 methoxy group Chemical group [H]C([H])([H])O* 0.000 description 4

- IEQIEDJGQAUEQZ-UHFFFAOYSA-N phthalocyanine Chemical compound N1C(N=C2C3=CC=CC=C3C(N=C3C4=CC=CC=C4C(=N4)N3)=N2)=C(C=CC=C2)C2=C1N=C1C2=CC=CC=C2C4=N1 IEQIEDJGQAUEQZ-UHFFFAOYSA-N 0.000 description 4

- BWHMMNNQKKPAPP-UHFFFAOYSA-L potassium carbonate Chemical compound [K+].[K+].[O-]C([O-])=O BWHMMNNQKKPAPP-UHFFFAOYSA-L 0.000 description 4

- 239000002356 single layer Substances 0.000 description 4

- 239000006097 ultraviolet radiation absorber Substances 0.000 description 4

- 238000007740 vapor deposition Methods 0.000 description 4

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- WKBOTKDWSSQWDR-UHFFFAOYSA-N Bromine atom Chemical group [Br] WKBOTKDWSSQWDR-UHFFFAOYSA-N 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- YLQBMQCUIZJEEH-UHFFFAOYSA-N Furan Chemical compound C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 3

- SIKJAQJRHWYJAI-UHFFFAOYSA-N Indole Chemical compound C1=CC=C2NC=CC2=C1 SIKJAQJRHWYJAI-UHFFFAOYSA-N 0.000 description 3

- 239000004793 Polystyrene Substances 0.000 description 3

- ZMANZCXQSJIPKH-UHFFFAOYSA-N Triethylamine Chemical compound CCN(CC)CC ZMANZCXQSJIPKH-UHFFFAOYSA-N 0.000 description 3

- BGYHLZZASRKEJE-UHFFFAOYSA-N [3-[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxy]-2,2-bis[3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoyloxymethyl]propyl] 3-(3,5-ditert-butyl-4-hydroxyphenyl)propanoate Chemical compound CC(C)(C)C1=C(O)C(C(C)(C)C)=CC(CCC(=O)OCC(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)(COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)COC(=O)CCC=2C=C(C(O)=C(C=2)C(C)(C)C)C(C)(C)C)=C1 BGYHLZZASRKEJE-UHFFFAOYSA-N 0.000 description 3

- 239000006096 absorbing agent Substances 0.000 description 3

- MIBQYWIOHFTKHD-UHFFFAOYSA-N adamantane-1-carbonyl chloride Chemical compound C1C(C2)CC3CC2CC1(C(=O)Cl)C3 MIBQYWIOHFTKHD-UHFFFAOYSA-N 0.000 description 3

- 239000000654 additive Substances 0.000 description 3

- 239000003963 antioxidant agent Substances 0.000 description 3

- 235000006708 antioxidants Nutrition 0.000 description 3

- 239000002216 antistatic agent Substances 0.000 description 3

- 230000000903 blocking effect Effects 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 238000011156 evaluation Methods 0.000 description 3

- RKJUIXBNRJVNHR-UHFFFAOYSA-N indolenine Natural products C1=CC=C2CC=NC2=C1 RKJUIXBNRJVNHR-UHFFFAOYSA-N 0.000 description 3

- 238000010030 laminating Methods 0.000 description 3

- 239000000155 melt Substances 0.000 description 3

- NFHFRUOZVGFOOS-UHFFFAOYSA-N palladium;triphenylphosphane Chemical compound [Pd].C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1 NFHFRUOZVGFOOS-UHFFFAOYSA-N 0.000 description 3

- 125000000951 phenoxy group Chemical group [H]C1=C([H])C([H])=C(O*)C([H])=C1[H] 0.000 description 3

- 229920002223 polystyrene Polymers 0.000 description 3

- LLHKCFNBLRBOGN-UHFFFAOYSA-N propylene glycol methyl ether acetate Chemical compound COCC(C)OC(C)=O LLHKCFNBLRBOGN-UHFFFAOYSA-N 0.000 description 3

- 239000013557 residual solvent Substances 0.000 description 3

- 238000000926 separation method Methods 0.000 description 3

- 238000004528 spin coating Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 239000010409 thin film Substances 0.000 description 3

- 125000002023 trifluoromethyl group Chemical group FC(F)(F)* 0.000 description 3

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 description 3

- QNODIIQQMGDSEF-UHFFFAOYSA-N (1-hydroxycyclohexyl)-phenylmethanone Chemical compound C=1C=CC=CC=1C(=O)C1(O)CCCCC1 QNODIIQQMGDSEF-UHFFFAOYSA-N 0.000 description 2

- KOFLVDBWRHFSAB-UHFFFAOYSA-N 1,2,4,5-tetrahydro-1-(phenylmethyl)-5,9b(1',2')-benzeno-9bh-benz(g)indol-3(3ah)-one Chemical compound C1C(C=2C3=CC=CC=2)C2=CC=CC=C2C23C1C(=O)CN2CC1=CC=CC=C1 KOFLVDBWRHFSAB-UHFFFAOYSA-N 0.000 description 2

- RFFLAFLAYFXFSW-UHFFFAOYSA-N 1,2-dichlorobenzene Chemical compound ClC1=CC=CC=C1Cl RFFLAFLAYFXFSW-UHFFFAOYSA-N 0.000 description 2

- KBPLFHHGFOOTCA-UHFFFAOYSA-N 1-Octanol Chemical compound CCCCCCCCO KBPLFHHGFOOTCA-UHFFFAOYSA-N 0.000 description 2

- FCEHBMOGCRZNNI-UHFFFAOYSA-N 1-benzothiophene Chemical compound C1=CC=C2SC=CC2=C1 FCEHBMOGCRZNNI-UHFFFAOYSA-N 0.000 description 2

- LIKMAJRDDDTEIG-UHFFFAOYSA-N 1-hexene Chemical compound CCCCC=C LIKMAJRDDDTEIG-UHFFFAOYSA-N 0.000 description 2

- 239000012956 1-hydroxycyclohexylphenyl-ketone Substances 0.000 description 2

- PGDIJTMOHORACQ-UHFFFAOYSA-N 9-prop-2-enoyloxynonyl prop-2-enoate Chemical compound C=CC(=O)OCCCCCCCCCOC(=O)C=C PGDIJTMOHORACQ-UHFFFAOYSA-N 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 2

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 2

- 239000005977 Ethylene Substances 0.000 description 2

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 2

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 2

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 2

- YNAVUWVOSKDBBP-UHFFFAOYSA-N Morpholine Chemical compound C1COCCN1 YNAVUWVOSKDBBP-UHFFFAOYSA-N 0.000 description 2

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 2

- KAESVJOAVNADME-UHFFFAOYSA-N Pyrrole Chemical compound C=1C=CNC=1 KAESVJOAVNADME-UHFFFAOYSA-N 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- YTPLMLYBLZKORZ-UHFFFAOYSA-N Thiophene Chemical compound C=1C=CSC=1 YTPLMLYBLZKORZ-UHFFFAOYSA-N 0.000 description 2

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 2

- BDAHDQGVJHDLHQ-UHFFFAOYSA-N [2-(1-hydroxycyclohexyl)phenyl]-phenylmethanone Chemical compound C=1C=CC=C(C(=O)C=2C=CC=CC=2)C=1C1(O)CCCCC1 BDAHDQGVJHDLHQ-UHFFFAOYSA-N 0.000 description 2

- MPIAGWXWVAHQBB-UHFFFAOYSA-N [3-prop-2-enoyloxy-2-[[3-prop-2-enoyloxy-2,2-bis(prop-2-enoyloxymethyl)propoxy]methyl]-2-(prop-2-enoyloxymethyl)propyl] prop-2-enoate Chemical compound C=CC(=O)OCC(COC(=O)C=C)(COC(=O)C=C)COCC(COC(=O)C=C)(COC(=O)C=C)COC(=O)C=C MPIAGWXWVAHQBB-UHFFFAOYSA-N 0.000 description 2

- 125000005073 adamantyl group Chemical group C12(CC3CC(CC(C1)C3)C2)* 0.000 description 2

- 230000002411 adverse Effects 0.000 description 2

- 125000003277 amino group Chemical group 0.000 description 2

- 230000003078 antioxidant effect Effects 0.000 description 2

- 150000004945 aromatic hydrocarbons Chemical class 0.000 description 2

- 125000003354 benzotriazolyl group Chemical class N1N=NC2=C1C=CC=C2* 0.000 description 2

- 230000008033 biological extinction Effects 0.000 description 2

- MQDJYUACMFCOFT-UHFFFAOYSA-N bis[2-(1-hydroxycyclohexyl)phenyl]methanone Chemical compound C=1C=CC=C(C(=O)C=2C(=CC=CC=2)C2(O)CCCCC2)C=1C1(O)CCCCC1 MQDJYUACMFCOFT-UHFFFAOYSA-N 0.000 description 2

- UORVGPXVDQYIDP-UHFFFAOYSA-N borane Chemical compound B UORVGPXVDQYIDP-UHFFFAOYSA-N 0.000 description 2

- QHIWVLPBUQWDMQ-UHFFFAOYSA-N butyl prop-2-enoate;methyl 2-methylprop-2-enoate;prop-2-enoic acid Chemical compound OC(=O)C=C.COC(=O)C(C)=C.CCCCOC(=O)C=C QHIWVLPBUQWDMQ-UHFFFAOYSA-N 0.000 description 2

- 238000004440 column chromatography Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 238000012937 correction Methods 0.000 description 2

- NLCKLZIHJQEMCU-UHFFFAOYSA-N cyano prop-2-enoate Chemical class C=CC(=O)OC#N NLCKLZIHJQEMCU-UHFFFAOYSA-N 0.000 description 2

- JHIVVAPYMSGYDF-UHFFFAOYSA-N cyclohexanone Chemical compound O=C1CCCCC1 JHIVVAPYMSGYDF-UHFFFAOYSA-N 0.000 description 2

- 125000001559 cyclopropyl group Chemical group [H]C1([H])C([H])([H])C1([H])* 0.000 description 2

- 125000004186 cyclopropylmethyl group Chemical group [H]C([H])(*)C1([H])C([H])([H])C1([H])[H] 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 125000001028 difluoromethyl group Chemical group [H]C(F)(F)* 0.000 description 2

- 125000002147 dimethylamino group Chemical group [H]C([H])([H])N(*)C([H])([H])[H] 0.000 description 2

- 125000005982 diphenylmethyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C([H])(*)C1=C([H])C([H])=C([H])C([H])=C1[H] 0.000 description 2

- 238000010894 electron beam technology Methods 0.000 description 2

- 150000002148 esters Chemical class 0.000 description 2

- LZCLXQDLBQLTDK-UHFFFAOYSA-N ethyl 2-hydroxypropanoate Chemical compound CCOC(=O)C(C)O LZCLXQDLBQLTDK-UHFFFAOYSA-N 0.000 description 2

- UHESRSKEBRADOO-UHFFFAOYSA-N ethyl carbamate;prop-2-enoic acid Chemical compound OC(=O)C=C.CCOC(N)=O UHESRSKEBRADOO-UHFFFAOYSA-N 0.000 description 2

- WDAXFOBOLVPGLV-UHFFFAOYSA-N ethyl isobutyrate Chemical compound CCOC(=O)C(C)C WDAXFOBOLVPGLV-UHFFFAOYSA-N 0.000 description 2

- 150000002212 flavone derivatives Chemical class 0.000 description 2

- VOZRXNHHFUQHIL-UHFFFAOYSA-N glycidyl methacrylate Chemical compound CC(=C)C(=O)OCC1CO1 VOZRXNHHFUQHIL-UHFFFAOYSA-N 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 150000002475 indoles Chemical class 0.000 description 2

- 239000003999 initiator Substances 0.000 description 2

- 150000002576 ketones Chemical class 0.000 description 2

- MRELNEQAGSRDBK-UHFFFAOYSA-N lanthanum(3+);oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[La+3].[La+3] MRELNEQAGSRDBK-UHFFFAOYSA-N 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- OTLDLKLSNZMTTA-UHFFFAOYSA-N octahydro-1h-4,7-methanoindene-1,5-diyldimethanol Chemical compound C1C2C3C(CO)CCC3C1C(CO)C2 OTLDLKLSNZMTTA-UHFFFAOYSA-N 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 238000005457 optimization Methods 0.000 description 2

- CTSLXHKWHWQRSH-UHFFFAOYSA-N oxalyl chloride Chemical compound ClC(=O)C(Cl)=O CTSLXHKWHWQRSH-UHFFFAOYSA-N 0.000 description 2

- 239000008188 pellet Substances 0.000 description 2

- HXITXNWTGFUOAU-UHFFFAOYSA-N phenylboronic acid Chemical compound OB(O)C1=CC=CC=C1 HXITXNWTGFUOAU-UHFFFAOYSA-N 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 229910000027 potassium carbonate Inorganic materials 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- KCTAWXVAICEBSD-UHFFFAOYSA-N prop-2-enoyloxy prop-2-eneperoxoate Chemical compound C=CC(=O)OOOC(=O)C=C KCTAWXVAICEBSD-UHFFFAOYSA-N 0.000 description 2

- 238000011084 recovery Methods 0.000 description 2

- 238000007151 ring opening polymerisation reaction Methods 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000012719 thermal polymerization Methods 0.000 description 2

- 229920001187 thermosetting polymer Polymers 0.000 description 2

- ITMCEJHCFYSIIV-UHFFFAOYSA-N triflic acid Chemical compound OS(=O)(=O)C(F)(F)F ITMCEJHCFYSIIV-UHFFFAOYSA-N 0.000 description 2

- BPSIOYPQMFLKFR-UHFFFAOYSA-N trimethoxy-[3-(oxiran-2-ylmethoxy)propyl]silane Chemical compound CO[Si](OC)(OC)CCCOCC1CO1 BPSIOYPQMFLKFR-UHFFFAOYSA-N 0.000 description 2

- 238000005406 washing Methods 0.000 description 2

- OLZBVTCFCPEPLI-UHFFFAOYSA-N (3-anilino-2-chloroprop-2-enylidene)-phenylazanium;chloride Chemical compound Cl.C=1C=CC=CC=1N=CC(Cl)=CNC1=CC=CC=C1 OLZBVTCFCPEPLI-UHFFFAOYSA-N 0.000 description 1

- LIPRQQHINVWJCH-UHFFFAOYSA-N 1-ethoxypropan-2-yl acetate Chemical compound CCOCC(C)OC(C)=O LIPRQQHINVWJCH-UHFFFAOYSA-N 0.000 description 1

- STPXIOFWKOIYHX-UHFFFAOYSA-N 1-methylcyclohexane-1-carbonyl chloride Chemical compound ClC(=O)C1(C)CCCCC1 STPXIOFWKOIYHX-UHFFFAOYSA-N 0.000 description 1

- GTDXPJJHRWOFDI-UHFFFAOYSA-N 1-methylcyclopropane-1-carbonyl chloride Chemical compound ClC(=O)C1(C)CC1 GTDXPJJHRWOFDI-UHFFFAOYSA-N 0.000 description 1

- 125000001637 1-naphthyl group Chemical group [H]C1=C([H])C([H])=C2C(*)=C([H])C([H])=C([H])C2=C1[H] 0.000 description 1

- 125000006017 1-propenyl group Chemical group 0.000 description 1

- BNBRIFIJRKJGEI-UHFFFAOYSA-N 2,6-difluorobenzonitrile Chemical compound FC1=CC=CC(F)=C1C#N BNBRIFIJRKJGEI-UHFFFAOYSA-N 0.000 description 1

- XNWFRZJHXBZDAG-UHFFFAOYSA-N 2-METHOXYETHANOL Chemical compound COCCO XNWFRZJHXBZDAG-UHFFFAOYSA-N 0.000 description 1

- RILZRCJGXSFXNE-UHFFFAOYSA-N 2-[4-(trifluoromethoxy)phenyl]ethanol Chemical compound OCCC1=CC=C(OC(F)(F)F)C=C1 RILZRCJGXSFXNE-UHFFFAOYSA-N 0.000 description 1

- 125000006020 2-methyl-1-propenyl group Chemical group 0.000 description 1

- 125000001622 2-naphthyl group Chemical group [H]C1=C([H])C([H])=C2C([H])=C(*)C([H])=C([H])C2=C1[H] 0.000 description 1

- 125000006024 2-pentenyl group Chemical group 0.000 description 1

- 125000003903 2-propenyl group Chemical group [H]C([*])([H])C([H])=C([H])[H] 0.000 description 1

- LJMPOXUWPWEILS-UHFFFAOYSA-N 3a,4,4a,7a,8,8a-hexahydrofuro[3,4-f][2]benzofuran-1,3,5,7-tetrone Chemical compound C1C2C(=O)OC(=O)C2CC2C(=O)OC(=O)C21 LJMPOXUWPWEILS-UHFFFAOYSA-N 0.000 description 1

- HESXPOICBNWMPI-UHFFFAOYSA-N 4-[2-[4-[2-(4-aminophenyl)propan-2-yl]phenyl]propan-2-yl]aniline Chemical compound C=1C=C(C(C)(C)C=2C=CC(N)=CC=2)C=CC=1C(C)(C)C1=CC=C(N)C=C1 HESXPOICBNWMPI-UHFFFAOYSA-N 0.000 description 1

- HYDATEKARGDBKU-UHFFFAOYSA-N 4-[4-[4-(4-aminophenoxy)phenyl]phenoxy]aniline Chemical group C1=CC(N)=CC=C1OC1=CC=C(C=2C=CC(OC=3C=CC(N)=CC=3)=CC=2)C=C1 HYDATEKARGDBKU-UHFFFAOYSA-N 0.000 description 1

- YWFPGFJLYRKYJZ-UHFFFAOYSA-N 9,9-bis(4-hydroxyphenyl)fluorene Chemical compound C1=CC(O)=CC=C1C1(C=2C=CC(O)=CC=2)C2=CC=CC=C2C2=CC=CC=C21 YWFPGFJLYRKYJZ-UHFFFAOYSA-N 0.000 description 1

- CPELXLSAUQHCOX-UHFFFAOYSA-M Bromide Chemical compound [Br-] CPELXLSAUQHCOX-UHFFFAOYSA-M 0.000 description 1

- DKPFZGUDAPQIHT-UHFFFAOYSA-N Butyl acetate Natural products CCCCOC(C)=O DKPFZGUDAPQIHT-UHFFFAOYSA-N 0.000 description 1

- NLZUEZXRPGMBCV-UHFFFAOYSA-N Butylhydroxytoluene Chemical compound CC1=CC(C(C)(C)C)=C(O)C(C(C)(C)C)=C1 NLZUEZXRPGMBCV-UHFFFAOYSA-N 0.000 description 1

- VEXZGXHMUGYJMC-UHFFFAOYSA-M Chloride anion Chemical compound [Cl-] VEXZGXHMUGYJMC-UHFFFAOYSA-M 0.000 description 1

- ZAFNJMIOTHYJRJ-UHFFFAOYSA-N Diisopropyl ether Chemical compound CC(C)OC(C)C ZAFNJMIOTHYJRJ-UHFFFAOYSA-N 0.000 description 1

- NTIZESTWPVYFNL-UHFFFAOYSA-N Methyl isobutyl ketone Chemical compound CC(C)CC(C)=O NTIZESTWPVYFNL-UHFFFAOYSA-N 0.000 description 1

- UIHCLUNTQKBZGK-UHFFFAOYSA-N Methyl isobutyl ketone Natural products CCC(C)C(C)=O UIHCLUNTQKBZGK-UHFFFAOYSA-N 0.000 description 1

- 238000005481 NMR spectroscopy Methods 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- GAMYVSCDDLXAQW-AOIWZFSPSA-N Thermopsosid Natural products O(C)c1c(O)ccc(C=2Oc3c(c(O)cc(O[C@H]4[C@H](O)[C@@H](O)[C@H](O)[C@H](CO)O4)c3)C(=O)C=2)c1 GAMYVSCDDLXAQW-AOIWZFSPSA-N 0.000 description 1

- 238000003848 UV Light-Curing Methods 0.000 description 1

- 230000006750 UV protection Effects 0.000 description 1

- 239000005083 Zinc sulfide Substances 0.000 description 1

- RUFZJUYWZZUTJE-UHFFFAOYSA-J [F-].[F-].[F-].[F-].F.F.[Na+].[Al+3] Chemical compound [F-].[F-].[F-].[F-].F.F.[Na+].[Al+3] RUFZJUYWZZUTJE-UHFFFAOYSA-J 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 125000000738 acetamido group Chemical group [H]C([H])([H])C(=O)N([H])[*] 0.000 description 1

- 125000002777 acetyl group Chemical group [H]C([H])([H])C(*)=O 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 125000003342 alkenyl group Chemical group 0.000 description 1

- 125000000217 alkyl group Chemical group 0.000 description 1

- 125000000304 alkynyl group Chemical group 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 150000001408 amides Chemical class 0.000 description 1

- 125000002490 anilino group Chemical group [H]N(*)C1=C([H])C([H])=C([H])C([H])=C1[H] 0.000 description 1

- 150000001454 anthracenes Chemical class 0.000 description 1

- 125000002178 anthracenyl group Chemical group C1(=CC=CC2=CC3=CC=CC=C3C=C12)* 0.000 description 1

- 230000003667 anti-reflective effect Effects 0.000 description 1

- 239000002518 antifoaming agent Substances 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 239000004760 aramid Substances 0.000 description 1

- 229920003235 aromatic polyamide Polymers 0.000 description 1

- RFRXIWQYSOIBDI-UHFFFAOYSA-N benzarone Chemical compound CCC=1OC2=CC=CC=C2C=1C(=O)C1=CC=C(O)C=C1 RFRXIWQYSOIBDI-UHFFFAOYSA-N 0.000 description 1

- 125000003236 benzoyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C(*)=O 0.000 description 1

- 238000000071 blow moulding Methods 0.000 description 1

- 229910000085 borane Inorganic materials 0.000 description 1

- 229940006460 bromide ion Drugs 0.000 description 1

- 125000004369 butenyl group Chemical group C(=CCC)* 0.000 description 1

- 125000004106 butoxy group Chemical group [*]OC([H])([H])C([H])([H])C(C([H])([H])[H])([H])[H] 0.000 description 1

- 235000010354 butylated hydroxytoluene Nutrition 0.000 description 1

- 125000004744 butyloxycarbonyl group Chemical group 0.000 description 1

- 125000000480 butynyl group Chemical group [*]C#CC([H])([H])C([H])([H])[H] 0.000 description 1

- 125000004063 butyryl group Chemical group O=C([*])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 229910000420 cerium oxide Inorganic materials 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000003851 corona treatment Methods 0.000 description 1

- 125000002592 cumenyl group Chemical group C1(=C(C=CC=C1)*)C(C)C 0.000 description 1

- 125000000753 cycloalkyl group Chemical group 0.000 description 1

- 125000001995 cyclobutyl group Chemical group [H]C1([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 1

- 125000000582 cycloheptyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 125000002933 cyclohexyloxy group Chemical group C1(CCCCC1)O* 0.000 description 1

- 125000000640 cyclooctyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C([H])([H])C1([H])[H] 0.000 description 1

- 125000001511 cyclopentyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 1

- 125000002704 decyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000004915 dibutylamino group Chemical group C(CCC)N(CCCC)* 0.000 description 1

- 125000001664 diethylamino group Chemical group [H]C([H])([H])C([H])([H])N(*)C([H])([H])C([H])([H])[H] 0.000 description 1

- 229940028356 diethylene glycol monobutyl ether Drugs 0.000 description 1

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 230000005684 electric field Effects 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- 125000001301 ethoxy group Chemical group [H]C([H])([H])C([H])([H])O* 0.000 description 1

- 125000003754 ethoxycarbonyl group Chemical group C(=O)(OCC)* 0.000 description 1

- 229940116333 ethyl lactate Drugs 0.000 description 1

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 229930003944 flavone Natural products 0.000 description 1

- 235000011949 flavones Nutrition 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 125000006343 heptafluoro propyl group Chemical group 0.000 description 1

- 150000002391 heterocyclic compounds Chemical class 0.000 description 1

- FUZZWVXGSFPDMH-UHFFFAOYSA-N hexanoic acid Chemical compound CCCCCC(O)=O FUZZWVXGSFPDMH-UHFFFAOYSA-N 0.000 description 1

- 125000006038 hexenyl group Chemical group 0.000 description 1

- 125000004051 hexyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000003707 hexyloxy group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])O* 0.000 description 1

- 125000005980 hexynyl group Chemical group 0.000 description 1

- 238000005984 hydrogenation reaction Methods 0.000 description 1

- 239000005457 ice water Substances 0.000 description 1

- 125000005462 imide group Chemical group 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 229910003437 indium oxide Inorganic materials 0.000 description 1

- PJXISJQVUVHSOJ-UHFFFAOYSA-N indium(iii) oxide Chemical compound [O-2].[O-2].[O-2].[In+3].[In+3] PJXISJQVUVHSOJ-UHFFFAOYSA-N 0.000 description 1

- PZOUSPYUWWUPPK-UHFFFAOYSA-N indole Natural products CC1=CC=CC2=C1C=CN2 PZOUSPYUWWUPPK-UHFFFAOYSA-N 0.000 description 1

- 238000002329 infrared spectrum Methods 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- XMBWDFGMSWQBCA-UHFFFAOYSA-M iodide Chemical compound [I-] XMBWDFGMSWQBCA-UHFFFAOYSA-M 0.000 description 1

- 229940006461 iodide ion Drugs 0.000 description 1

- 238000007733 ion plating Methods 0.000 description 1

- 238000000869 ion-assisted deposition Methods 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 125000003253 isopropoxy group Chemical group [H]C([H])([H])C([H])(O*)C([H])([H])[H] 0.000 description 1

- 125000005928 isopropyloxycarbonyl group Chemical group [H]C([H])([H])C([H])(OC(*)=O)C([H])([H])[H] 0.000 description 1

- 238000004898 kneading Methods 0.000 description 1

- ORUIBWPALBXDOA-UHFFFAOYSA-L magnesium fluoride Chemical compound [F-].[F-].[Mg+2] ORUIBWPALBXDOA-UHFFFAOYSA-L 0.000 description 1

- 229910001635 magnesium fluoride Inorganic materials 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 125000001160 methoxycarbonyl group Chemical group [H]C([H])([H])OC(*)=O 0.000 description 1

- 125000004184 methoxymethyl group Chemical group [H]C([H])([H])OC([H])([H])* 0.000 description 1

- XTXCFTMJPRXBBC-UHFFFAOYSA-N methyl 4,4-dimethyl-3-oxopentanoate Chemical compound COC(=O)CC(=O)C(C)(C)C XTXCFTMJPRXBBC-UHFFFAOYSA-N 0.000 description 1

- UMCSHTKHXAMMQM-UHFFFAOYSA-N methyl 4-methyltetracyclo[6.2.1.13,6.02,7]dodec-9-ene-4-carboxylate Chemical compound C1C(C23)C=CC1C3C1CC2CC1(C)C(=O)OC UMCSHTKHXAMMQM-UHFFFAOYSA-N 0.000 description 1

- 125000006431 methyl cyclopropyl group Chemical group 0.000 description 1

- YULMNMJFAZWLLN-UHFFFAOYSA-N methylenecyclohexane Chemical compound C=C1CCCCC1 YULMNMJFAZWLLN-UHFFFAOYSA-N 0.000 description 1

- WPHGSKGZRAQSGP-UHFFFAOYSA-N methylenecyclohexane Natural products C1CCCC2CC21 WPHGSKGZRAQSGP-UHFFFAOYSA-N 0.000 description 1

- 125000002816 methylsulfanyl group Chemical group [H]C([H])([H])S[*] 0.000 description 1

- 239000011259 mixed solution Substances 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 125000006126 n-butyl sulfonyl group Chemical group 0.000 description 1

- 125000001280 n-hexyl group Chemical group C(CCCCC)* 0.000 description 1

- 125000000740 n-pentyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- LKKPNUDVOYAOBB-UHFFFAOYSA-N naphthalocyanine Chemical compound N1C(N=C2C3=CC4=CC=CC=C4C=C3C(N=C3C4=CC5=CC=CC=C5C=C4C(=N4)N3)=N2)=C(C=C2C(C=CC=C2)=C2)C2=C1N=C1C2=CC3=CC=CC=C3C=C2C4=N1 LKKPNUDVOYAOBB-UHFFFAOYSA-N 0.000 description 1

- 230000004297 night vision Effects 0.000 description 1

- ZKATWMILCYLAPD-UHFFFAOYSA-N niobium pentoxide Inorganic materials O=[Nb](=O)O[Nb](=O)=O ZKATWMILCYLAPD-UHFFFAOYSA-N 0.000 description 1

- URLJKFSTXLNXLG-UHFFFAOYSA-N niobium(5+);oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[O-2].[O-2].[Nb+5].[Nb+5] URLJKFSTXLNXLG-UHFFFAOYSA-N 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 125000001400 nonyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- UMRZSTCPUPJPOJ-KNVOCYPGSA-N norbornane Chemical group C1C[C@H]2CC[C@@H]1C2 UMRZSTCPUPJPOJ-KNVOCYPGSA-N 0.000 description 1

- 125000002347 octyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000005447 octyloxy group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])O* 0.000 description 1

- 239000012788 optical film Substances 0.000 description 1

- 239000012044 organic layer Substances 0.000 description 1

- BMMGVYCKOGBVEV-UHFFFAOYSA-N oxo(oxoceriooxy)cerium Chemical compound [Ce]=O.O=[Ce]=O BMMGVYCKOGBVEV-UHFFFAOYSA-N 0.000 description 1

- SIWVEOZUMHYXCS-UHFFFAOYSA-N oxo(oxoyttriooxy)yttrium Chemical compound O=[Y]O[Y]=O SIWVEOZUMHYXCS-UHFFFAOYSA-N 0.000 description 1

- JCGNDDUYTRNOFT-UHFFFAOYSA-N oxolane-2,4-dione Chemical compound O=C1COC(=O)C1 JCGNDDUYTRNOFT-UHFFFAOYSA-N 0.000 description 1

- BPUBBGLMJRNUCC-UHFFFAOYSA-N oxygen(2-);tantalum(5+) Chemical compound [O-2].[O-2].[O-2].[O-2].[O-2].[Ta+5].[Ta+5] BPUBBGLMJRNUCC-UHFFFAOYSA-N 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 125000006340 pentafluoro ethyl group Chemical group FC(F)(F)C(F)(F)* 0.000 description 1

- 125000004115 pentoxy group Chemical group [*]OC([H])([H])C([H])([H])C([H])([H])C(C([H])([H])[H])([H])[H] 0.000 description 1

- 125000001147 pentyl group Chemical group C(CCCC)* 0.000 description 1

- VLTRZXGMWDSKGL-UHFFFAOYSA-M perchlorate Inorganic materials [O-]Cl(=O)(=O)=O VLTRZXGMWDSKGL-UHFFFAOYSA-M 0.000 description 1

- 125000002080 perylenyl group Chemical group C1(=CC=C2C=CC=C3C4=CC=CC5=CC=CC(C1=C23)=C45)* 0.000 description 1

- CSHWQDPOILHKBI-UHFFFAOYSA-N peryrene Natural products C1=CC(C2=CC=CC=3C2=C2C=CC=3)=C3C2=CC=CC3=C1 CSHWQDPOILHKBI-UHFFFAOYSA-N 0.000 description 1

- 125000005561 phenanthryl group Chemical group 0.000 description 1

- 125000003356 phenylsulfanyl group Chemical group [*]SC1=C([H])C([H])=C([H])C([H])=C1[H] 0.000 description 1

- 238000009832 plasma treatment Methods 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 230000010287 polarization Effects 0.000 description 1

- 125000003367 polycyclic group Chemical group 0.000 description 1

- 229920006267 polyester film Polymers 0.000 description 1

- 239000002685 polymerization catalyst Substances 0.000 description 1

- 229920005672 polyolefin resin Polymers 0.000 description 1

- 150000004032 porphyrins Chemical class 0.000 description 1

- 125000001501 propionyl group Chemical group O=C([*])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000002572 propoxy group Chemical group [*]OC([H])([H])C(C([H])([H])[H])([H])[H] 0.000 description 1

- 125000004742 propyloxycarbonyl group Chemical group 0.000 description 1

- 125000002568 propynyl group Chemical group [*]C#CC([H])([H])[H] 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 238000001226 reprecipitation Methods 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 235000012239 silicon dioxide Nutrition 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 238000001308 synthesis method Methods 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- PBCFLUZVCVVTBY-UHFFFAOYSA-N tantalum pentoxide Inorganic materials O=[Ta](=O)O[Ta](=O)=O PBCFLUZVCVVTBY-UHFFFAOYSA-N 0.000 description 1

- ANRHNWWPFJCPAZ-UHFFFAOYSA-M thionine Chemical compound [Cl-].C1=CC(N)=CC2=[S+]C3=CC(N)=CC=C3N=C21 ANRHNWWPFJCPAZ-UHFFFAOYSA-M 0.000 description 1

- 229930192474 thiophene Natural products 0.000 description 1

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 description 1

- 229910001887 tin oxide Inorganic materials 0.000 description 1

- 125000003944 tolyl group Chemical group 0.000 description 1

- 150000003918 triazines Chemical class 0.000 description 1

- 125000003866 trichloromethyl group Chemical group ClC(Cl)(Cl)* 0.000 description 1

- VOITXYVAKOUIBA-UHFFFAOYSA-N triethylaluminium Chemical compound CC[Al](CC)CC VOITXYVAKOUIBA-UHFFFAOYSA-N 0.000 description 1

- BYMUNNMMXKDFEZ-UHFFFAOYSA-K trifluorolanthanum Chemical compound F[La](F)F BYMUNNMMXKDFEZ-UHFFFAOYSA-K 0.000 description 1

- KPGXUAIFQMJJFB-UHFFFAOYSA-H tungsten hexachloride Chemical class Cl[W](Cl)(Cl)(Cl)(Cl)Cl KPGXUAIFQMJJFB-UHFFFAOYSA-H 0.000 description 1

- 238000001771 vacuum deposition Methods 0.000 description 1

- VHBFFQKBGNRLFZ-UHFFFAOYSA-N vitamin p Natural products O1C2=CC=CC=C2C(=O)C=C1C1=CC=CC=C1 VHBFFQKBGNRLFZ-UHFFFAOYSA-N 0.000 description 1

- 239000003643 water by type Substances 0.000 description 1

- 239000008096 xylene Substances 0.000 description 1

- 125000005023 xylyl group Chemical group 0.000 description 1

- 239000011787 zinc oxide Substances 0.000 description 1

- 229910052984 zinc sulfide Inorganic materials 0.000 description 1

- DRDVZXDWVBGGMH-UHFFFAOYSA-N zinc;sulfide Chemical compound [S-2].[Zn+2] DRDVZXDWVBGGMH-UHFFFAOYSA-N 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/0008—Organic ingredients according to more than one of the "one dot" groups of C08K5/01 - C08K5/59

- C08K5/0041—Optical brightening agents, organic pigments

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L35/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a carboxyl radical, and containing at least one other carboxyl radical in the molecule, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Compositions of derivatives of such polymers

- C08L35/02—Homopolymers or copolymers of esters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/10651—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer comprising colorants, e.g. dyes or pigments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/20—Layered products comprising a layer of synthetic resin characterised by the use of special additives using fillers, pigments, thixotroping agents

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D311/00—Heterocyclic compounds containing six-membered rings having one oxygen atom as the only hetero atom, condensed with other rings

- C07D311/02—Heterocyclic compounds containing six-membered rings having one oxygen atom as the only hetero atom, condensed with other rings ortho- or peri-condensed with carbocyclic rings or ring systems

- C07D311/04—Benzo[b]pyrans, not hydrogenated in the carbocyclic ring

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D311/00—Heterocyclic compounds containing six-membered rings having one oxygen atom as the only hetero atom, condensed with other rings

- C07D311/02—Heterocyclic compounds containing six-membered rings having one oxygen atom as the only hetero atom, condensed with other rings ortho- or peri-condensed with carbocyclic rings or ring systems

- C07D311/78—Ring systems having three or more relevant rings

- C07D311/80—Dibenzopyrans; Hydrogenated dibenzopyrans

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D403/00—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00

- C07D403/02—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00 containing two hetero rings

- C07D403/06—Heterocyclic compounds containing two or more hetero rings, having nitrogen atoms as the only ring hetero atoms, not provided for by group C07D401/00 containing two hetero rings linked by a carbon chain containing only aliphatic carbon atoms

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/15—Heterocyclic compounds having oxygen in the ring

- C08K5/151—Heterocyclic compounds having oxygen in the ring having one oxygen atom in the ring

- C08K5/1535—Five-membered rings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/15—Heterocyclic compounds having oxygen in the ring

- C08K5/151—Heterocyclic compounds having oxygen in the ring having one oxygen atom in the ring

- C08K5/1545—Six-membered rings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/16—Nitrogen-containing compounds

- C08K5/34—Heterocyclic compounds having nitrogen in the ring

- C08K5/3412—Heterocyclic compounds having nitrogen in the ring having one nitrogen atom in the ring

- C08K5/3415—Five-membered rings

- C08K5/3417—Five-membered rings condensed with carbocyclic rings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/16—Nitrogen-containing compounds

- C08K5/34—Heterocyclic compounds having nitrogen in the ring

- C08K5/3412—Heterocyclic compounds having nitrogen in the ring having one nitrogen atom in the ring

- C08K5/3432—Six-membered rings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/36—Sulfur-, selenium-, or tellurium-containing compounds

- C08K5/45—Heterocyclic compounds having sulfur in the ring

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L45/00—Compositions of homopolymers or copolymers of compounds having no unsaturated aliphatic radicals in side chain, and having one or more carbon-to-carbon double bonds in a carbocyclic or in a heterocyclic ring system; Compositions of derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L71/00—Compositions of polyethers obtained by reactions forming an ether link in the main chain; Compositions of derivatives of such polymers

- C08L71/08—Polyethers derived from hydroxy compounds or from their metallic derivatives

- C08L71/10—Polyethers derived from hydroxy compounds or from their metallic derivatives from phenols

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L79/00—Compositions of macromolecular compounds obtained by reactions forming in the main chain of the macromolecule a linkage containing nitrogen with or without oxygen or carbon only, not provided for in groups C08L61/00 - C08L77/00

- C08L79/04—Polycondensates having nitrogen-containing heterocyclic rings in the main chain; Polyhydrazides; Polyamide acids or similar polyimide precursors

- C08L79/08—Polyimides; Polyester-imides; Polyamide-imides; Polyamide acids or similar polyimide precursors

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/20—Filters

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/20—Filters

- G02B5/208—Filters for use with infrared or ultraviolet radiation, e.g. for separating visible light from infrared and/or ultraviolet radiation

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- General Physics & Mathematics (AREA)

- Toxicology (AREA)

- Optical Filters (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Pyrane Compounds (AREA)

- Laminated Bodies (AREA)

- Photometry And Measurement Of Optical Pulse Characteristics (AREA)

Description

本発明は、樹脂組成物、化合物(Z)、基材(i)、光学フィルター、ならびに、該光学フィルターを用いた固体撮像装置および光学センサー装置に関する。 The present invention relates to a resin composition, a compound (Z), a substrate (i), an optical filter, and a solid-state imaging device and an optical sensor device using the optical filter.

ビデオカメラ、デジタルスチルカメラ、カメラ機能付き携帯電話などの固体撮像装置には、カラー画像の固体撮像素子であるCCDやCMOSイメージセンサーが使用されている。これら固体撮像素子では、その受光部において人間の目では感知できない近赤外線に感度を有するシリコンフォトダイオード等が使用されている。また、光学センサー装置でも、シリコンフォトダイオード等が使用されている。例えば、固体撮像素子では、人間の目で見て自然な色合いにさせる視感度補正を行うことが必要であり、特定の波長領域の光線を選択的に透過もしくはカットする光学フィルター(例えば、近赤外線カットフィルター)を用いることが多い。 Solid-state imaging devices such as video cameras, digital still cameras, and mobile phones with camera functions use CCD and CMOS image sensors, which are solid-state imaging elements for color images. These solid-state imaging elements use silicon photodiodes and the like that are sensitive to near-infrared light, which cannot be detected by the human eye, in their light receiving sections. Silicon photodiodes and the like are also used in optical sensor devices. For example, solid-state imaging elements require visibility correction to make colors appear natural to the human eye, and optical filters (e.g., near-infrared cut filters) that selectively transmit or cut light in a specific wavelength range are often used.

このような近赤外線カットフィルターとしては、従来から、各種方法で製造されたものが使用されている。例えば、基材として樹脂を用い、樹脂中に近赤外線吸収色素を含有させた近赤外線カットフィルターが知られている(例えば特許文献1参照)。しかしながら、特許文献1に記載された近赤外線カットフィルターは、近赤外線吸収特性が必ずしも充分ではない場合があった。 Such near-infrared cut filters have been manufactured by various methods. For example, a near-infrared cut filter is known that uses a resin as a base material and contains a near-infrared absorbing dye in the resin (see, for example, Patent Document 1). However, the near-infrared cut filter described in Patent Document 1 does not necessarily have sufficient near-infrared absorption characteristics.

前記近赤外線吸収色素としては、従来、ポリメチン系、スクアリリウム系、ポルフィリン系、ジチオール金属錯体系、フタロシアニン系、ジイモニウム系などの色素が使用されているが、中でもポリメチン系、スクアリリウム系等の色素は、熱に対して十分な耐性を有することから多用されている。 As the near-infrared absorbing dye, polymethine-based, squarylium-based, porphyrin-based, dithiol metal complex-based, phthalocyanine-based, diimonium-based, and other dyes have been used to date, with polymethine-based and squarylium-based dyes being particularly popular due to their sufficient resistance to heat.

しかしながら、従来用いられてきたこれらの色素は、

吸収極大波長が長波長域にあるため、波長700~750nm付近、または、波長720~900nm付近に吸収極大を有する化合物が求められていた点、

可視光域の吸光度に対する赤外線域の吸光度の比が小さい点、

耐光性(耐久性)が十分ではない点、

の少なくともいずれかの点で、改良の余地があった。

However, these dyes that have been used conventionally have the following characteristics:

Since the absorption maximum wavelength is in the long wavelength region, a compound having an absorption maximum in the vicinity of 700 to 750 nm or 720 to 900 nm has been required.

The ratio of absorbance in the infrared range to absorbance in the visible range is small.

The light resistance (durability) is insufficient,

There was room for improvement in at least one of the above points.

また、従来の近赤外線カットフィルターは、該フィルター由来の反射光がフレアやゴーストなどとして、カメラ画像などの画像に悪影響を与えることがあり、特に、近赤外線カットフィルターの反射帯域と、センサーが光電変換可能な波長帯域とが重なった場合、前記悪影響がより顕著になる場合がある。 In addition, conventional near-infrared cut filters can have adverse effects on images such as camera images due to the reflected light from the filter appearing as flare or ghosting. In particular, when the reflection band of the near-infrared cut filter overlaps with the wavelength band that the sensor can convert photoelectrically, the adverse effects can become more pronounced.

本発明は以上のことに鑑みてなされたものであり、波長700~750nm付近、または、波長720~900nm付近に吸収極大を有し、可視光域の吸光度に対する赤外線域の吸光度の比が大きく、耐光性(耐久性)に優れる樹脂組成物を提供することを目的とする。 The present invention has been made in consideration of the above, and aims to provide a resin composition that has an absorption maximum in the wavelength range of about 700 to 750 nm or about 720 to 900 nm, has a large ratio of absorbance in the infrared range to absorbance in the visible light range, and has excellent light resistance (durability).

本発明者らは、前記課題を解決するために鋭意検討した結果、下記構成例によれば、前記課題を解決できることを見出し、本発明を完成するに至った。本発明の構成例を以下に示す。

なお、本発明において、数値範囲を表す「A~B」等の記載は、「A以上、B以下」と同義であり、AおよびBをその数値範囲内に含む。また、本発明において、波長A~Bnmとは、波長Anm以上、波長Bnm以下の波長領域における波長分解能1nmにおける特性を表す。

As a result of intensive research into solving the above problems, the present inventors have found that the above problems can be solved by the following configuration examples, and have thus completed the present invention.

In the present invention, the expression "A to B" or the like expressing a numerical range is synonymous with "A or more, B or less", and includes A and B in the numerical range. In addition, in the present invention, a wavelength of A to B nm represents characteristics at a wavelength resolution of 1 nm in a wavelength region of A nm or more and B nm or less.

[1] 樹脂と、下記式(I)で表される化合物(Z)とを含有する樹脂組成物。

Cn+An- (I)

[式(I)中、Cn+は下記式(II)で表される一価のカチオンであり、An-は一価のアニオンである。]

[1] A resin composition containing a resin and a compound (Z) represented by the following formula (I):

Cn + An - (I)

[In formula (I), Cn + is a monovalent cation represented by the following formula (II), and An − is a monovalent anion.]

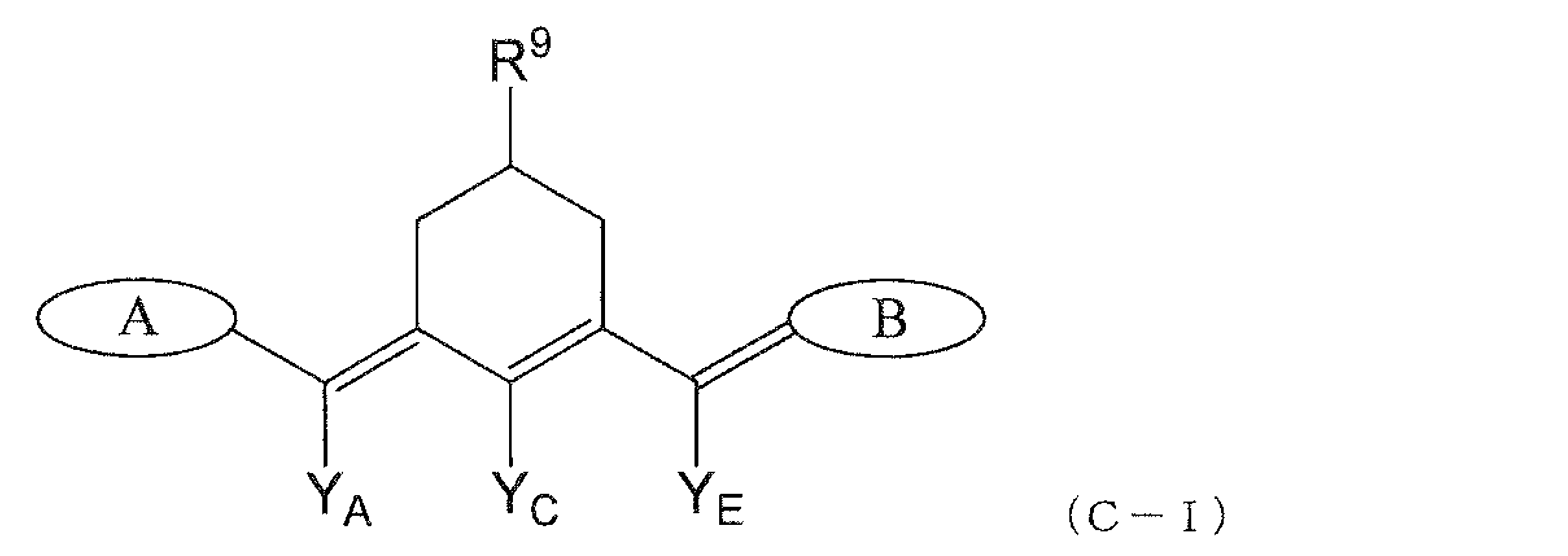

ユニットAは、下記式(A-I)~(A-III)のいずれかであり、

ユニットBは、下記式(B-I)~(B-III)のいずれかであり、

YA~YEはそれぞれ独立に、水素原子、ハロゲン原子、水酸基、カルボキシ基、ニトロ基、-NRgRh基、アミド基、イミド基、シアノ基、シリル基、-Q1、-N=N-Q1、-S-Q2、-SSQ2、または、-SO2Q3であり、

YAとYC、YBとYD、YCとYEは互いに結合して、炭素数6~14の芳香族炭化水素基、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含んでもよい4~7員の脂環基、または、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含む、炭素数3~14の複素芳香族基を形成していてもよく、これらの芳香族炭化水素基、脂環基および複素芳香族基は、水酸基、炭素数1~9の脂肪族炭化水素基またはハロゲン原子を有してもよく、また該脂環基は、=Oを有していてもよく、

YAと下記式(A-III)におけるR1またはR5、YEと下記式(B-III)におけるR5またはR1は、互いに結合して、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含んでもよい4~7員の脂環基を形成してもよく、

RgおよびRhはそれぞれ独立に、水素原子、-C(O)Ri基または下記La~Lhのいずれかであり、Q1は独立に、下記La~Lhのいずれかであり、Q2は独立に、水素原子または下記La~Lhのいずれかであり、Q3は、水酸基または下記La~Lhのいずれかであり、Riは下記La~Lhのいずれかである。]

Unit A is any one of the following formulas (AI) to (A-III):

The unit B is represented by any one of the following formulas (BI) to (B-III):

Y A to Y E each independently represent a hydrogen atom, a halogen atom, a hydroxyl group, a carboxy group, a nitro group, a -NR g R h group, an amide group, an imido group, a cyano group, a silyl group, -Q 1 , -N═N-Q 1 , -S-Q 2 , -SSQ 2 , or -SO 2 Q 3 ;

Y and Y , Y and Y , and Y and Y may be bonded to each other to form an aromatic hydrocarbon group having 6 to 14 carbon atoms, a 4- to 7-membered alicyclic group which may contain at least one nitrogen atom, oxygen atom or sulfur atom, or a heteroaromatic group having 3 to 14 carbon atoms and containing at least one nitrogen atom, oxygen atom or sulfur atom, and these aromatic hydrocarbon groups, alicyclic groups and heteroaromatic groups may have a hydroxyl group, an aliphatic hydrocarbon group having 1 to 9 carbon atoms or a halogen atom, and the alicyclic group may have =O,

Y A and R 1 or R 5 in the following formula (A-III), and Y E and R 5 or R 1 in the following formula (B-III) may be bonded to each other to form a 4- to 7-membered alicyclic group which may contain at least one nitrogen atom, oxygen atom or sulfur atom,

R g and R h are each independently a hydrogen atom, a -C(O)R i group, or any one of L a to L h described below, Q 1 is independently any one of L a to L h described below, Q 2 is independently a hydrogen atom or any one of L a to L h described below, Q 3 is a hydroxyl group or any one of L a to L h described below, and R i is any one of L a to L h described below.]

式(B-I)~(B-III)中の=**は、前記式(II)のYEが結合する炭素と二重結合することを示し、

式(A-I)~(B-III)中、

Xは独立に、酸素原子、硫黄原子、セレン原子、テルル原子または-NR8-であり、

R1~R6はそれぞれ独立に、水素原子、ハロゲン原子、スルホ基、水酸基、シアノ基、ニトロ基、カルボキシ基、リン酸基、-NRgRh基、-SRi基、-SO2Ri基、-OSO2Ri基、-C(O)Ri基または下記La~Lhのいずれかであり、

隣接するR1~R6は互いに結合して、炭素数6~14の芳香族炭化水素基、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含んでもよい4~7員の脂環基、または、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含む、炭素数3~14の複素芳香族基を形成していてもよく、これらの芳香族炭化水素基、脂環基および複素芳香族基は、水酸基、炭素数1~9の脂肪族炭化水素基またはハロゲン原子を有してもよく、また該脂環基は、=Oを有していてもよく、

R8は独立に、水素原子、ハロゲン原子、-C(O)Ri基、下記La~Lhのいずれかであり、

RgおよびRhはそれぞれ独立に、水素原子、-C(O)Ri基または下記La~Lhのいずれかであり、

Riは独立に、下記La~Lhのいずれかであり、

(La):炭素数1~15の脂肪族炭化水素基

(Lb):炭素数1~15のハロゲン置換アルキル基

(Lc):置換基Kを有してもよい炭素数3~14の脂環式炭化水素基

(Ld):置換基Kを有してもよい炭素数6~14の芳香族炭化水素基

(Le):置換基Kを有してもよい炭素数3~14の複素環基

(Lf):-OR(Rは置換基Lを有してもよい炭素数1~12の炭化水素基)

(Lg):置換基Lを有してもよい炭素数1~9のアシル基

(Lh):置換基Lを有してもよい炭素数1~9のアルコキシカルボニル基

前記置換基Kは、前記La~Lbより選ばれる少なくとも一種であり、前記置換基Lは、前記La~Lfより選ばれる少なくとも一種である。]

In formulae (BI) to (B-III), =** indicates that the carbon atom to which Y in formula (II) is bonded forms a double bond.

In formulas (AI) to (B-III),

X is independently an oxygen atom, a sulfur atom, a selenium atom, a tellurium atom or --NR 8 --;

R 1 to R 6 each independently represent a hydrogen atom, a halogen atom, a sulfo group, a hydroxyl group, a cyano group, a nitro group, a carboxy group, a phosphate group, a -NR g R h group, a -SR i group, a -SO 2 R i group, a -OSO 2 R i group, a -C(O)R i group, or any of the following L a to L h ,

adjacent R 1 to R 6 may be bonded to each other to form an aromatic hydrocarbon group having 6 to 14 carbon atoms, a 4- to 7-membered alicyclic group which may contain at least one nitrogen atom, oxygen atom or sulfur atom, or a heteroaromatic group having 3 to 14 carbon atoms and containing at least one nitrogen atom, oxygen atom or sulfur atom, these aromatic hydrocarbon groups, alicyclic groups and heteroaromatic groups may have a hydroxyl group, an aliphatic hydrocarbon group having 1 to 9 carbon atoms or a halogen atom, and the alicyclic group may have =O,

R 8 is independently a hydrogen atom, a halogen atom, a —C(O)R i group, or any one of L a to L h below,

R g and R h each independently represent a hydrogen atom, a —C(O)R i group, or any one of L a to L h below,

R i is independently any one of L a to L h below,

(L a ): an aliphatic hydrocarbon group having 1 to 15 carbon atoms; (L b ): a halogen-substituted alkyl group having 1 to 15 carbon atoms; (L c ): an alicyclic hydrocarbon group having 3 to 14 carbon atoms which may have a substituent K; (L d ): an aromatic hydrocarbon group having 6 to 14 carbon atoms which may have a substituent K; (L e ): a heterocyclic group having 3 to 14 carbon atoms which may have a substituent K; (L f ): -OR (R is a hydrocarbon group having 1 to 12 carbon atoms which may have a substituent L).

(L g ): an acyl group having 1 to 9 carbon atoms which may have a substituent L; (L h ): an alkoxycarbonyl group having 1 to 9 carbon atoms which may have a substituent L; the substituent K is at least one selected from the above L a to L b , and the substituent L is at least one selected from the above L a to L f .

[2] 前記化合物(Z)が下記要件(A)を満たす、[1]に記載の樹脂組成物。

要件(A):前記化合物(Z)をジクロロメタンに溶解させた溶液を用いて測定される透過スペクトル(但し、該透過スペクトルは、吸収極大波長における透過率が10%となるスペクトルである。)において、波長430~580nmにおける透過率の平均値が93%以上である

[2] The resin composition according to [1], wherein the compound (Z) satisfies the following requirement (A):

Requirement (A): In a transmission spectrum measured using a solution in which the compound (Z) is dissolved in dichloromethane (wherein the transmission spectrum is a spectrum in which the transmittance at the absorption maximum wavelength is 10%), the average transmittance at wavelengths of 430 to 580 nm is 93% or more.

[3] 前記R1~R6の少なくとも1つが前記La、LcまたはLdである、[1]または[2]に記載の樹脂組成物。 [3] The resin composition according to [1] or [2], wherein at least one of R 1 to R 6 is L a , L c or L d .

[4] 前記化合物(Z)が下記要件(B-1)を満たす、[1]~[3]のいずれかに記載の樹脂組成物。

要件(B-1):前記化合物(Z)をジクロロメタンに溶解させた溶液を用いて測定される吸収スペクトルにおいて、波長720~900nmの範囲に極大値を有する

[4] The resin composition according to any one of [1] to [3], wherein the compound (Z) satisfies the following requirement (B-1):

Requirement (B-1): The compound (Z) has a maximum value in the wavelength range of 720 to 900 nm in an absorption spectrum measured using a solution obtained by dissolving the compound (Z) in dichloromethane.

[5] 前記化合物(Z)が下記要件(B-2)を満たす、[1]~[3]のいずれかに記載の樹脂組成物。

要件(B-2):前記化合物(Z)をジクロロメタンに溶解させた溶液を用いて測定される吸収スペクトルにおいて、波長700~750nmの範囲に極大値を有する

[5] The resin composition according to any one of [1] to [3], wherein the compound (Z) satisfies the following requirement (B-2):

Requirement (B-2): In the absorption spectrum measured using a solution in which the compound (Z) is dissolved in dichloromethane, the maximum value is in the wavelength range of 700 to 750 nm.

[6] 前記樹脂が、環状(ポリ)オレフィン系樹脂、芳香族ポリエーテル系樹脂、ポリイミド系樹脂、ポリエステル系樹脂、ポリカーボネート系樹脂、ポリアミド系樹脂、ポリアリレート系樹脂、ポリサルホン系樹脂、ポリエーテルサルホン系樹脂、ポリパラフェニレン系樹脂、ポリアミドイミド系樹脂、ポリエチレンナフタレート系樹脂、フッ素化芳香族ポリマー系樹脂、(変性)アクリル系樹脂、エポキシ系樹脂、アリルエステル系硬化型樹脂、シルセスキオキサン系紫外線硬化型樹脂、アクリル系紫外線硬化型樹脂およびビニル系紫外線硬化型樹脂からなる群より選ばれる少なくとも1種の樹脂である、[1]~[5]のいずれかに記載の樹脂組成物。 [6] The resin composition according to any one of [1] to [5], wherein the resin is at least one resin selected from the group consisting of cyclic (poly)olefin-based resins, aromatic polyether-based resins, polyimide-based resins, polyester-based resins, polycarbonate-based resins, polyamide-based resins, polyarylate-based resins, polysulfone-based resins, polyethersulfone-based resins, polyparaphenylene-based resins, polyamideimide-based resins, polyethylene naphthalate-based resins, fluorinated aromatic polymer-based resins, (modified) acrylic-based resins, epoxy-based resins, allyl ester-based curable resins, silsesquioxane-based ultraviolet-curable resins, acrylic-based ultraviolet-curable resins, and vinyl-based ultraviolet-curable resins.

[7] [1]~[6]のいずれかに記載の樹脂組成物から形成された化合物(Z)を含有する基材(i)。 [7] A substrate (i) containing a compound (Z) formed from a resin composition according to any one of [1] to [6].

[8] 前記基材(i)が、

前記化合物(Z)を含有する樹脂層からなる基材、

2層以上の樹脂層を含む基材であって、該2層以上の樹脂層のうち少なくとも1つが前記化合物(Z)を含有する樹脂層である基材、または、

ガラス支持体と前記化合物(Z)を含有する樹脂層とを含む基材である、

[7]に記載の基材(i)。

[8] The substrate (i)

A substrate comprising a resin layer containing the compound (Z);

A substrate comprising two or more resin layers, at least one of which is a resin layer containing the compound (Z), or

A substrate comprising a glass support and a resin layer containing the compound (Z),

The substrate (i) according to [7].

[9] [7]または[8]に記載の基材(i)と、誘電体多層膜とを有する、光学フィルター。

[10] 固体撮像装置用である、[9]に記載の光学フィルター。

[11] 光学センサー装置用である、[9]に記載の光学フィルター。

[9] An optical filter comprising the substrate (i) according to [7] or [8] and a dielectric multilayer film.

[10] The optical filter according to [9], which is for use in a solid-state imaging device.

[11] The optical filter according to [9], which is for use in an optical sensor device.

[12] [9]に記載の光学フィルターを具備する固体撮像装置。

[13] [9]に記載の光学フィルターを具備する光学センサー装置。

[12] A solid-state imaging device comprising the optical filter according to [9].

[13] An optical sensor device comprising the optical filter according to [9].

[14] 下記式(III)で表される化合物(Z)。

Cn+An- (III)

[式(III)中、Cn+は下記式(IV)で表される一価のカチオンであり、An-は一価のアニオンである。]

[14] A compound (Z) represented by the following formula (III):

Cn + An - (III)

[In formula (III), Cn + is a monovalent cation represented by the following formula (IV), and An − is a monovalent anion.]

ユニットAは、下記式(A-I)~(A-III)のいずれかであり、

ユニットBは、下記式(B-I)~(B-III)のいずれかであり、

YA~YEはそれぞれ独立に、水素原子、ハロゲン原子、水酸基、カルボキシ基、ニトロ基、-NRgRh基、アミド基、イミド基、シアノ基、シリル基、-Q1、-N=N-Q1、-S-Q2、-SSQ2、または、-SO2Q3であり、

YAとYC、YBとYD、YCとYEは互いに結合して、炭素数6~14の芳香族炭化水素基、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含んでもよい4~7員の脂環基、または、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含む、炭素数3~14の複素芳香族基を形成していてもよく、これらの芳香族炭化水素基、脂環基および複素芳香族基は、水酸基、炭素数1~9の脂肪族炭化水素基またはハロゲン原子を有してもよく、また該脂環基は、=Oを有していてもよく、

YAと下記式(A-III)におけるR1またはR5、YEと下記式(B-III)におけるR5またはR1は、互いに結合して、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含んでもよい4~7員の脂環基を形成してもよく、

RgおよびRhはそれぞれ独立に、水素原子、-C(O)Ri基または下記La~Lhのいずれかであり、Q1は独立に、下記La~Lhのいずれかであり、Q2は独立に、水素原子または下記La~Lhのいずれかであり、Q3は、水酸基または下記La~Lhのいずれかであり、Riは下記La~Lhのいずれかである。]

Unit A is any one of the following formulas (AI) to (A-III):

The unit B is represented by any one of the following formulas (BI) to (B-III):

Y A to Y E each independently represent a hydrogen atom, a halogen atom, a hydroxyl group, a carboxy group, a nitro group, a -NR g R h group, an amide group, an imido group, a cyano group, a silyl group, -Q 1 , -N═N-Q 1 , -S-Q 2 , -SSQ 2 , or -SO 2 Q 3 ;

Y and Y , Y and Y , and Y and Y may be bonded to each other to form an aromatic hydrocarbon group having 6 to 14 carbon atoms, a 4- to 7-membered alicyclic group which may contain at least one nitrogen atom, oxygen atom or sulfur atom, or a heteroaromatic group having 3 to 14 carbon atoms and containing at least one nitrogen atom, oxygen atom or sulfur atom, and these aromatic hydrocarbon groups, alicyclic groups and heteroaromatic groups may have a hydroxyl group, an aliphatic hydrocarbon group having 1 to 9 carbon atoms or a halogen atom, and the alicyclic group may have =O,

Y A and R 1 or R 5 in the following formula (A-III), and Y E and R 5 or R 1 in the following formula (B-III) may be bonded to each other to form a 4- to 7-membered alicyclic group which may contain at least one nitrogen atom, oxygen atom or sulfur atom,

R g and R h are each independently a hydrogen atom, a -C(O)R i group, or any one of L a to L h described below, Q 1 is independently any one of L a to L h described below, Q 2 is independently a hydrogen atom or any one of L a to L h described below, Q 3 is a hydroxyl group or any one of L a to L h described below, and R i is any one of L a to L h described below.]

式(B-I)~(B-III)中の=**は、前記式(II)のYEが結合する炭素と二重結合することを示し、

式(A-I)~(B-III)中、

Xは独立に、酸素原子、硫黄原子、セレン原子、テルル原子または-NR8-であり、

R1~R6はそれぞれ独立に、水素原子、ハロゲン原子、スルホ基、水酸基、シアノ基、ニトロ基、カルボキシ基、リン酸基、-NRgRh基、-SRi基、-SO2Ri基、-OSO2Ri基、-C(O)Ri基または下記La~Lhのいずれかであり、

隣接するR1~R6は互いに結合して、炭素数6~14の芳香族炭化水素基、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含んでもよい4~7員の脂環基、または、窒素原子、酸素原子もしくは硫黄原子を少なくとも一つ含む、炭素数3~14の複素芳香族基を形成していてもよく、これらの芳香族炭化水素基、脂環基および複素芳香族基は、水酸基、炭素数1~9の脂肪族炭化水素基またはハロゲン原子を有してもよく、また該脂環基は、=Oを有していてもよく、

R8は独立に、水素原子、ハロゲン原子、-C(O)Ri基、下記La~Lhのいずれかであり、

RgおよびRhはそれぞれ独立に、水素原子、-C(O)Ri基または下記La~Lhのいずれかであり、

Riは独立に、下記La~Lhのいずれかであり、

(La):炭素数1~15の脂肪族炭化水素基

(Lb):炭素数1~15のハロゲン置換アルキル基

(Lc):置換基Kを有してもよい炭素数3~14の脂環式炭化水素基

(Ld):置換基Kを有してもよい炭素数6~14の芳香族炭化水素基

(Le):置換基Kを有してもよい炭素数3~14の複素環基

(Lf):-OR(Rは置換基Lを有してもよい炭素数1~12の炭化水素基)

(Lg):置換基Lを有してもよい炭素数1~9のアシル基

(Lh):置換基Lを有してもよい炭素数1~9のアルコキシカルボニル基

前記置換基Kは、前記La~Lbより選ばれる少なくとも一種であり、前記置換基Lは、前記La~Lfより選ばれる少なくとも一種である。]

In formulae (BI) to (B-III), =** indicates that the carbon atom to which Y in formula (II) is bonded forms a double bond.

In formulas (AI) to (B-III),

X is independently an oxygen atom, a sulfur atom, a selenium atom, a tellurium atom or --NR 8 --;