JP6898510B2 - 積層ガラスペインのための熱可塑性フィルム - Google Patents

積層ガラスペインのための熱可塑性フィルム Download PDFInfo

- Publication number

- JP6898510B2 JP6898510B2 JP2020502266A JP2020502266A JP6898510B2 JP 6898510 B2 JP6898510 B2 JP 6898510B2 JP 2020502266 A JP2020502266 A JP 2020502266A JP 2020502266 A JP2020502266 A JP 2020502266A JP 6898510 B2 JP6898510 B2 JP 6898510B2

- Authority

- JP

- Japan

- Prior art keywords

- thermoplastic film

- region

- glass pane

- laminated glass

- area

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229920001169 thermoplastic Polymers 0.000 title claims description 103

- 239000004416 thermosoftening plastic Substances 0.000 title claims description 98

- 239000005340 laminated glass Substances 0.000 title claims description 65

- 239000011521 glass Substances 0.000 claims description 60

- 238000000034 method Methods 0.000 claims description 28

- 230000002093 peripheral effect Effects 0.000 claims description 22

- 238000004519 manufacturing process Methods 0.000 claims description 13

- 230000001603 reducing effect Effects 0.000 claims description 5

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims 1

- 239000000463 material Substances 0.000 description 17

- 230000003287 optical effect Effects 0.000 description 9

- 230000007704 transition Effects 0.000 description 9

- 230000007547 defect Effects 0.000 description 6

- 230000000873 masking effect Effects 0.000 description 6

- 229920002037 poly(vinyl butyral) polymer Polymers 0.000 description 6

- 229920000642 polymer Polymers 0.000 description 6

- 230000005540 biological transmission Effects 0.000 description 5

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 5

- 230000006835 compression Effects 0.000 description 4

- 238000007906 compression Methods 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 230000003247 decreasing effect Effects 0.000 description 3

- 238000001125 extrusion Methods 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- -1 polyethylene terephthalate Polymers 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 239000004698 Polyethylene Substances 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 238000010030 laminating Methods 0.000 description 2

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 2

- 239000004417 polycarbonate Substances 0.000 description 2

- 229920000515 polycarbonate Polymers 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 239000004926 polymethyl methacrylate Substances 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 238000004088 simulation Methods 0.000 description 2

- 239000005361 soda-lime glass Substances 0.000 description 2

- 239000012815 thermoplastic material Substances 0.000 description 2

- 239000004925 Acrylic resin Substances 0.000 description 1

- 239000004812 Fluorinated ethylene propylene Substances 0.000 description 1

- 229930182556 Polyacetal Natural products 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000005354 aluminosilicate glass Substances 0.000 description 1

- 238000011074 autoclave method Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000002457 bidirectional effect Effects 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 239000005388 borosilicate glass Substances 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 210000003298 dental enamel Anatomy 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- HQQADJVZYDDRJT-UHFFFAOYSA-N ethene;prop-1-ene Chemical group C=C.CC=C HQQADJVZYDDRJT-UHFFFAOYSA-N 0.000 description 1

- 229920000840 ethylene tetrafluoroethylene copolymer Polymers 0.000 description 1

- 239000005038 ethylene vinyl acetate Substances 0.000 description 1

- 239000005357 flat glass Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 230000008447 perception Effects 0.000 description 1

- 229920009441 perflouroethylene propylene Polymers 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920006324 polyoxymethylene Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000009993 protective function Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

- 238000001429 visible spectrum Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/10559—Shape of the cross-section

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/10559—Shape of the cross-section

- B32B17/10568—Shape of the cross-section varying in thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10009—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets

- B32B17/10036—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets comprising two outer glass sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/10761—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer containing vinyl acetal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10807—Making laminated safety glass or glazing; Apparatus therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10807—Making laminated safety glass or glazing; Apparatus therefor

- B32B17/10889—Making laminated safety glass or glazing; Apparatus therefor shaping the sheets, e.g. by using a mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60J—WINDOWS, WINDSCREENS, NON-FIXED ROOFS, DOORS, OR SIMILAR DEVICES FOR VEHICLES; REMOVABLE EXTERNAL PROTECTIVE COVERINGS SPECIALLY ADAPTED FOR VEHICLES

- B60J1/00—Windows; Windscreens; Accessories therefor

- B60J1/001—Double glazing for vehicles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/10—Properties of the layers or laminate having particular acoustical properties

- B32B2307/102—Insulating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2315/00—Other materials containing non-metallic inorganic compounds not provided for in groups B32B2311/00 - B32B2313/04

- B32B2315/08—Glass

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/006—Transparent parts other than made from inorganic glass, e.g. polycarbonate glazings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2605/00—Vehicles

- B32B2605/08—Cars

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B27/00—Optical systems or apparatus not provided for by any of the groups G02B1/00 - G02B26/00, G02B30/00

- G02B27/01—Head-up displays

- G02B27/0101—Head-up displays characterised by optical features

- G02B2027/0118—Head-up displays characterised by optical features comprising devices for improving the contrast of the display / brillance control visibility

- G02B2027/012—Head-up displays characterised by optical features comprising devices for improving the contrast of the display / brillance control visibility comprising devices for attenuating parasitic image effects

- G02B2027/0121—Parasitic image effect attenuation by suitable positioning of the parasitic images

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B27/00—Optical systems or apparatus not provided for by any of the groups G02B1/00 - G02B26/00, G02B30/00

- G02B27/01—Head-up displays

- G02B27/0101—Head-up displays characterised by optical features

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Joining Of Glass To Other Materials (AREA)

- Laminated Bodies (AREA)

- Instrument Panels (AREA)

Description

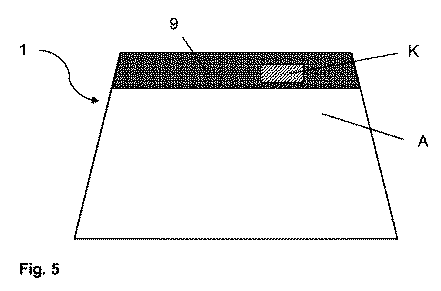

GS2 ガラス層2、ガラスペイン2

F 熱可塑性フィルム

K 規定領域

A 周囲領域

g1 第一の境界領域

g2 第二の境界領域

h1 加工前の熱可塑性フィルムの厚さ、周囲領域Aにおける熱可塑性フィルムの厚さ

h2 規定領域における熱可塑性フィルムの厚さ

h2max 規定領域における熱可塑性フィルムの最大厚さ

S 対称面、鏡面

1 ガラスペイン

2 目

3 光源、HUDプロジェクター

4 一定の厚さを有する熱可塑性フィルム、加工前の熱可塑性フィルム

5 HUD装置

6 カメラ装置

7 カメラ

8 レーザー

9 マスキングプリント

10 熱可塑性フィルムの表面

10.1 熱可塑性フィルムの第一の面

10.2 熱可塑性フィルムの第二の面

11 走査線

Claims (16)

- 積層ガラスペイン(1)のための中間層として適している熱可塑性フィルム(F)であって、少なくとも以下を含む熱可塑性フィルム(F):

− カメラウィンドウ又はHUD(ヘッドアップディスプレイ)領域のために提供される、0でないくさび角度を有している規定領域(K)、及び

− 前記規定領域(K)のすべての側を取り囲んでいる領域であって、前記熱可塑性フィルムが実質的に一定の厚さ(h1)を有している周囲領域(A)、

ここで、前記熱可塑性フィルムの前記規定領域(K)における最大厚さ(h2max)が、前記周囲領域(A)における厚さ(h1)よりも小さい。 - 前記規定領域(K)が、変化するくさび角度を有している、請求項1に記載の熱可塑性フィルム(F)。

- 前記周囲領域(A)における、前記熱可塑性フィルムの厚さ(h1)が、50μm〜2000μm、好ましくは300μm〜850μm、特に好ましくは380μm〜760μmである、請求項1又は2に記載の熱可塑性フィルム(F)。

- 前記熱可塑性フィルム(F)が、実質的にPVBでできている、請求項1〜3のいずれか一項に記載の熱可塑性フィルム(F)。

- 前記熱可塑性フィルム(F)が、ノイズ低減効果を有する、請求項1〜4のいずれか一項に記載の熱可塑性フィルム(F)。

- 前記規定領域(K)が、2000mm2〜200,000mm2の面積にわたって延在しており、好ましくは、HUD領域のためには、10,000mm2〜200,000mm2の面積にわたって、かつカメラウィンドウのためには、2000mm2〜10,000mm2の面積にわたって延在している、請求項1〜5のいずれか一項に記載の熱可塑性フィルム(F)。

- 前記熱可塑性フィルム(F)が、第一の面(10.1)及び反対側の第二の面(10.2)を有しており、これらの平面が、前記周囲領域(A)において、互いに平行に配置されており、かつ前記熱可塑性フィルムが、前記規定領域(K)において、前記周囲領域の前記第一の面(10.1)及び前記第二の面(10.2)の前記平面に対して平行に、これらの平面間の中央に配置された鏡面/対称面(S)を有している、請求項1〜6のいずれか一項に記載の熱可塑性フィルム(F)。

- 以下を含む、積層ガラスペインのための中間層として適している熱可塑性フィルム(F)の製造方法:

− 一定の厚さ(4)を有する熱可塑性フィルムを提供すること、

− 少なくとも一つの規定領域(K)において、レーザー(8)を使って、熱可塑性ポリマーを除去すること、

ここで、前記熱可塑性フィルム(F)は、0でないくさび角度を有している少なくとも一つの規定領域(K)、及び前記熱可塑性フィルム(F)が実質的に一定の厚さ(h1)を有している周囲領域(A)を含み、

前記熱可塑性フィルムの前記規定領域(K)における最大厚さ(h2max)は、前記周囲領域(A)における厚さ(h1)よりも小さい。 - 前記規定領域(K)における前記くさび角度が変化する、請求項8に記載の方法。

- 最初に、一定の厚さ(4)を有する前記熱可塑性フィルムの第一の面(10.1)を、前記規定領域(K)においてレーザー(8)で処理し、かつその後、前記熱可塑性フィルムの第二の面(10.2)を、同じ前記規定領域(K)においてレーザー(8)で処理する、請求項8又は9に記載の方法。

- 前記除去の深さが、0.10mm〜0.30mm、好ましくは0.15mm〜0.25mmである、請求項8〜10のいずれか一項に記載の方法。

- 第一のガラス層(GS1)、第二のガラス層(GS2)、及び請求項1〜7のいずれか一項に記載の熱可塑性フィルム(F)を少なくとも含み、前記熱可塑性フィルム(F)が、前記第一のガラス層(GS1)と、前記第二のガラス層(GS2)との間に配置されている、積層ガラスペイン(1)。

- 以下の工程を含む、積層ガラスペイン(1)を製造する方法:

− 第一のガラスペイン(GS1)を提供すること、

− 第二のガラスペイン(GS2)を提供すること、

− 第一のガラスペイン(GS1)上に、請求項1〜7のいずれか一項に記載の熱可塑性フィルム(F)を設置すること、

− 前記熱可塑性フィルム(F)上に、第二のガラスペイン(GS2)を設置すること、及び

− 第二のガラスペイン(GS2)を、前記熱可塑性フィルム(F)と結合すること。 - 積層ガラスペイン(1)のヘッドアップディスプレイ領域を照らすためのプロジェクター(3)と、請求項12に記載の積層ガラスペイン(1)とを含むヘッドアップディスプレイ装置(5)であって、操作時に、前記プロジェクター(3)が、前記規定領域(K)を実質的に照らす、ヘッドアップディスプレイ装置(5)。

- カメラ(7)と、請求項12に記載の積層ガラスペイン(1)とを含むカメラ装置(6)であって、前記カメラ(7)が、前記規定領域(K)を向いており、かつ前記積層ガラスペイン(1)を通過する光線を記録する、カメラ装置(6)。

- 水上、陸上、及び空中の移動手段における、ヘッドアップディスプレイ及び/又はカメラウィンドウを有するフロントペインとしての、請求項12に記載の積層ガラスペイン(1)の使用。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP17183444 | 2017-07-27 | ||

| EP17183444.3 | 2017-07-27 | ||

| PCT/EP2018/069372 WO2019020432A1 (de) | 2017-07-27 | 2018-07-17 | Thermoplastische kunststofffolie für eine verbundglasscheibe |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2020528039A JP2020528039A (ja) | 2020-09-17 |

| JP6898510B2 true JP6898510B2 (ja) | 2021-07-07 |

Family

ID=59506070

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020502266A Active JP6898510B2 (ja) | 2017-07-27 | 2018-07-17 | 積層ガラスペインのための熱可塑性フィルム |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US11052639B2 (ja) |

| EP (1) | EP3658371B1 (ja) |

| JP (1) | JP6898510B2 (ja) |

| KR (1) | KR102398542B1 (ja) |

| CN (1) | CN109562606B (ja) |

| BR (1) | BR112019021726A2 (ja) |

| CA (1) | CA3065668A1 (ja) |

| ES (1) | ES2887851T3 (ja) |

| HU (1) | HUE055545T2 (ja) |

| MA (1) | MA49672B1 (ja) |

| PL (1) | PL3658371T3 (ja) |

| RU (1) | RU2738173C1 (ja) |

| WO (1) | WO2019020432A1 (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11524799B2 (en) * | 2018-08-08 | 2022-12-13 | Rangel Fernandez | Aerospace-grade sensor replacement method |

| JP7624991B2 (ja) * | 2019-11-29 | 2025-01-31 | エージーシー グラス ユーロップ | ヘッドアップディスプレイ(hud)からの画像を投射するための積層されたグレージング |

| CN113858730B (zh) * | 2021-10-08 | 2023-04-28 | 福耀玻璃工业集团股份有限公司 | 夹层玻璃及抬头显示系统 |

| TW202402521A (zh) * | 2022-04-15 | 2024-01-16 | 日商積水化學工業股份有限公司 | 層合玻璃用中間膜及其製造方法、以及層合玻璃及其製造方法 |

| DE102022114785B3 (de) * | 2022-06-13 | 2023-09-21 | Cariad Se | Verfahren zur Herstellung einer Verbundscheibe für ein Kraftfahrzeug |

Family Cites Families (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5013134A (en) | 1989-09-28 | 1991-05-07 | Hughes Aircraft Company | Ghost-free automotive head-up display employing a wedged windshield |

| US5812332A (en) | 1989-09-28 | 1998-09-22 | Ppg Industries, Inc. | Windshield for head-up display system |

| JPH03264184A (ja) | 1990-03-13 | 1991-11-25 | Mitsubishi Electric Corp | パルスレーザによる分解除去方法 |

| WO1994000787A1 (en) | 1992-06-25 | 1994-01-06 | E.I. Du Pont De Nemours And Company | Shaped interlayers for head-up display windshields and process for preparing the same |

| US5639538A (en) * | 1992-06-25 | 1997-06-17 | E. I. Du Pont De Nemours And Company | Shaped interlayers for head-up display windshields and process for preparing the same |

| DE19535053A1 (de) | 1994-10-04 | 1996-04-11 | Volkswagen Ag | Gekrümmte Verbundscheibe |

| DE19611483A1 (de) | 1995-09-21 | 1997-10-02 | Volkswagen Ag | Gekrümmte Verbundscheibe |

| BR9908628A (pt) | 1998-03-11 | 2000-12-05 | Sekisui Chemical Co Ltd | Pelìcula intermediária para vidro laminado |

| EP1093006A4 (en) * | 1998-06-03 | 2005-06-29 | Nippon Sheet Glass Co Ltd | HEAD VISUALIZATION DEVICE |

| WO2002103434A1 (en) | 2001-06-15 | 2002-12-27 | E.I. Du Pont De Nemours And Company | Shaped interlayer for heads-up display windshields and process for preparing same |

| JP4371654B2 (ja) | 2002-12-25 | 2009-11-25 | 積水化学工業株式会社 | 合わせガラス用中間膜及び合わせガラス。 |

| US20070009714A1 (en) * | 2005-05-11 | 2007-01-11 | Lee David J | Polymeric interlayers having a wedge profile |

| JP2007223883A (ja) | 2005-12-26 | 2007-09-06 | Asahi Glass Co Ltd | 車両用合せガラス |

| JP2008201667A (ja) * | 2007-01-24 | 2008-09-04 | Asahi Glass Co Ltd | 車両用合わせガラス |

| KR101325662B1 (ko) | 2007-12-07 | 2013-11-05 | 쌩-고벵 글래스 프랑스 | 적층된 유리로 만들어진 굴곡된 차량용 앞유리 |

| JP2010105016A (ja) | 2008-10-30 | 2010-05-13 | Toray Advanced Film Co Ltd | レーザー加工方法およびレーザー加工装置 |

| EA032590B1 (ru) | 2013-12-12 | 2019-06-28 | Сэн-Гобэн Гласс Франс | Термопластичная пленка для многослойного стекла с нелинейным непрерывным клиновидным вкладышем на некоторых участках в вертикальном направлении |

| ES2834128T3 (es) * | 2013-12-12 | 2021-06-16 | Saint Gobain | Película termoplástica para una hoja de vidrio laminado con inserto de cuña continuo no lineal en dirección vertical y horizontal |

| ES2710026T3 (es) * | 2013-12-12 | 2019-04-22 | Saint Gobain | Procedimiento para producir una lámina combinada termoplástica para un panel de vidrio compuesto |

| KR20170093892A (ko) * | 2014-12-08 | 2017-08-16 | 쌩-고벵 글래스 프랑스 | 헤드업 디스플레이 (hud)를 위한 감소된 두께를 갖는 적층 유리 |

| US10678050B2 (en) * | 2015-06-11 | 2020-06-09 | Saint-Gobain Glass France | Projection arrangement for a contact analog head-up display (HUD) |

| JPWO2016208370A1 (ja) | 2015-06-25 | 2018-04-26 | 日本板硝子株式会社 | ウインドシールド |

| US20170015082A1 (en) * | 2015-07-16 | 2017-01-19 | Solutia Inc. | Polymeric interlayers having enhanced surface roughness |

| US10703253B2 (en) * | 2016-11-14 | 2020-07-07 | Saint-Gobain Glass France | Vehicle window with light guide body for a sensor |

| US10338400B2 (en) * | 2017-07-03 | 2019-07-02 | Holovisions LLC | Augmented reality eyewear with VAPE or wear technology |

| DE102019002986A1 (de) * | 2018-05-07 | 2019-11-07 | AGC Inc. | Laminiertes glas |

-

2018

- 2018-07-17 EP EP18740234.2A patent/EP3658371B1/de active Active

- 2018-07-17 ES ES18740234T patent/ES2887851T3/es active Active

- 2018-07-17 MA MA49672A patent/MA49672B1/fr unknown

- 2018-07-17 WO PCT/EP2018/069372 patent/WO2019020432A1/de active Application Filing

- 2018-07-17 BR BR112019021726A patent/BR112019021726A2/pt not_active Application Discontinuation

- 2018-07-17 JP JP2020502266A patent/JP6898510B2/ja active Active

- 2018-07-17 PL PL18740234T patent/PL3658371T3/pl unknown

- 2018-07-17 CN CN201880001386.4A patent/CN109562606B/zh active Active

- 2018-07-17 CA CA3065668A patent/CA3065668A1/en not_active Abandoned

- 2018-07-17 HU HUE18740234A patent/HUE055545T2/hu unknown

- 2018-07-17 US US16/609,663 patent/US11052639B2/en active Active

- 2018-07-17 KR KR1020207002075A patent/KR102398542B1/ko active IP Right Grant

- 2018-07-17 RU RU2020102862A patent/RU2738173C1/ru active

Also Published As

| Publication number | Publication date |

|---|---|

| CN109562606A (zh) | 2019-04-02 |

| MA49672B1 (fr) | 2021-07-29 |

| KR102398542B1 (ko) | 2022-05-25 |

| JP2020528039A (ja) | 2020-09-17 |

| PL3658371T3 (pl) | 2021-11-02 |

| CN109562606B (zh) | 2022-06-24 |

| EP3658371A1 (de) | 2020-06-03 |

| HUE055545T2 (hu) | 2021-12-28 |

| WO2019020432A1 (de) | 2019-01-31 |

| BR112019021726A2 (pt) | 2020-05-05 |

| KR20200019988A (ko) | 2020-02-25 |

| US20200147934A1 (en) | 2020-05-14 |

| EP3658371B1 (de) | 2021-07-14 |

| CA3065668A1 (en) | 2019-01-31 |

| RU2738173C1 (ru) | 2020-12-09 |

| MA49672A (fr) | 2021-04-28 |

| ES2887851T3 (es) | 2021-12-28 |

| US11052639B2 (en) | 2021-07-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6898510B2 (ja) | 積層ガラスペインのための熱可塑性フィルム | |

| KR102401304B1 (ko) | 광학 성능이 강화된 중간층 | |

| US10234681B2 (en) | Thermoplastic film for a laminated-glass pane having a non-linear continuous wedge insert in the vertical and horizontal direction in some sections | |

| JP6570660B2 (ja) | ヘッドアップディスプレイ(hud)用の投影システム | |

| JP6717093B2 (ja) | 合わせガラス | |

| JP6951466B2 (ja) | 熱可塑性結合フィルムの製造方法 | |

| JP2018518713A (ja) | コンタクトアナログヘッドアップディスプレイ(hud)用の投影システム | |

| EP3441375B1 (en) | Laminated glass | |

| CN108973608A (zh) | 夹层玻璃 | |

| JP2019534470A (ja) | ヘッドアップディスプレイ用複合ペイン | |

| JP7059780B2 (ja) | 合わせガラス | |

| US20230288699A1 (en) | Interlayers having enhanced optical performance | |

| WO2022026290A1 (en) | Interlayers having enhanced optical performance in transmission | |

| JP7624991B2 (ja) | ヘッドアップディスプレイ(hud)からの画像を投射するための積層されたグレージング | |

| EA045130B1 (ru) | Многослойное остекление для проецирования изображения с индикаторной панели на ветровом стекле (hud) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200117 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20201225 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210112 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20210511 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20210610 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6898510 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |