JP2009248506A - Decorative sheet and decorative material - Google Patents

Decorative sheet and decorative material Download PDFInfo

- Publication number

- JP2009248506A JP2009248506A JP2008101456A JP2008101456A JP2009248506A JP 2009248506 A JP2009248506 A JP 2009248506A JP 2008101456 A JP2008101456 A JP 2008101456A JP 2008101456 A JP2008101456 A JP 2008101456A JP 2009248506 A JP2009248506 A JP 2009248506A

- Authority

- JP

- Japan

- Prior art keywords

- layer

- decorative

- decorative sheet

- resin

- transparent

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000463 material Substances 0.000 title claims abstract description 50

- 229920005989 resin Polymers 0.000 claims abstract description 35

- 239000011347 resin Substances 0.000 claims abstract description 35

- 239000002023 wood Substances 0.000 claims abstract description 29

- 239000000758 substrate Substances 0.000 claims abstract description 23

- 230000005540 biological transmission Effects 0.000 claims abstract description 7

- 229920000747 poly(lactic acid) Polymers 0.000 claims abstract description 7

- 239000004626 polylactic acid Substances 0.000 claims abstract description 7

- 238000000691 measurement method Methods 0.000 claims abstract description 6

- 239000010410 layer Substances 0.000 claims description 36

- 239000012790 adhesive layer Substances 0.000 claims description 22

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 13

- 238000001035 drying Methods 0.000 claims description 11

- 239000000853 adhesive Substances 0.000 claims description 10

- 230000001070 adhesive effect Effects 0.000 claims description 10

- 239000000839 emulsion Substances 0.000 claims description 9

- 239000004745 nonwoven fabric Substances 0.000 claims description 9

- 239000002537 cosmetic Substances 0.000 claims description 3

- 239000002585 base Substances 0.000 description 11

- 241000196324 Embryophyta Species 0.000 description 5

- 229910000831 Steel Inorganic materials 0.000 description 5

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 5

- 238000000034 method Methods 0.000 description 5

- 239000011241 protective layer Substances 0.000 description 5

- 239000010959 steel Substances 0.000 description 5

- 229920002803 thermoplastic polyurethane Polymers 0.000 description 5

- 230000037303 wrinkles Effects 0.000 description 5

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- -1 polybutylene succinate Polymers 0.000 description 4

- 241000894007 species Species 0.000 description 4

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- 239000000654 additive Substances 0.000 description 3

- 239000003795 chemical substances by application Substances 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 239000011121 hardwood Substances 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000002028 Biomass Substances 0.000 description 2

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 229920002978 Vinylon Polymers 0.000 description 2

- 239000004840 adhesive resin Substances 0.000 description 2

- 229920006223 adhesive resin Polymers 0.000 description 2

- 229920006167 biodegradable resin Polymers 0.000 description 2

- 239000004566 building material Substances 0.000 description 2

- 239000000378 calcium silicate Substances 0.000 description 2

- 229910052918 calcium silicate Inorganic materials 0.000 description 2

- OYACROKNLOSFPA-UHFFFAOYSA-N calcium;dioxido(oxo)silane Chemical compound [Ca+2].[O-][Si]([O-])=O OYACROKNLOSFPA-UHFFFAOYSA-N 0.000 description 2

- 235000013339 cereals Nutrition 0.000 description 2

- 239000003822 epoxy resin Substances 0.000 description 2

- 125000000816 ethylene group Chemical group [H]C([H])([*:1])C([H])([H])[*:2] 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 239000003112 inhibitor Substances 0.000 description 2

- 230000035699 permeability Effects 0.000 description 2

- 239000004631 polybutylene succinate Substances 0.000 description 2

- 229920002961 polybutylene succinate Polymers 0.000 description 2

- 229920000647 polyepoxide Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 239000006097 ultraviolet radiation absorber Substances 0.000 description 2

- JYEUMXHLPRZUAT-UHFFFAOYSA-N 1,2,3-triazine Chemical compound C1=CN=NN=C1 JYEUMXHLPRZUAT-UHFFFAOYSA-N 0.000 description 1

- RNFJDJUURJAICM-UHFFFAOYSA-N 2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-triene Chemical compound N=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1 RNFJDJUURJAICM-UHFFFAOYSA-N 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- 241000167854 Bourreria succulenta Species 0.000 description 1

- 241000218631 Coniferophyta Species 0.000 description 1

- 229910001335 Galvanized steel Inorganic materials 0.000 description 1

- 240000007049 Juglans regia Species 0.000 description 1

- 235000009496 Juglans regia Nutrition 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- 229920000331 Polyhydroxybutyrate Polymers 0.000 description 1

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 1

- OFOBLEOULBTSOW-UHFFFAOYSA-N Propanedioic acid Natural products OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 1

- 244000086363 Pterocarpus indicus Species 0.000 description 1

- 235000009984 Pterocarpus indicus Nutrition 0.000 description 1

- 241000219492 Quercus Species 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- 240000002871 Tectona grandis Species 0.000 description 1

- 239000006096 absorbing agent Substances 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000003522 acrylic cement Substances 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- QRUDEWIWKLJBPS-UHFFFAOYSA-N benzotriazole Chemical compound C1=CC=C2N[N][N]C2=C1 QRUDEWIWKLJBPS-UHFFFAOYSA-N 0.000 description 1

- 239000012964 benzotriazole Substances 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 235000019693 cherries Nutrition 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000003851 corona treatment Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 238000001723 curing Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 238000004049 embossing Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000011094 fiberboard Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 239000008397 galvanized steel Substances 0.000 description 1

- 238000007646 gravure printing Methods 0.000 description 1

- 229910052602 gypsum Inorganic materials 0.000 description 1

- 239000010440 gypsum Substances 0.000 description 1

- 239000012760 heat stabilizer Substances 0.000 description 1

- 239000012943 hotmelt Substances 0.000 description 1

- 230000007062 hydrolysis Effects 0.000 description 1

- 238000006460 hydrolysis reaction Methods 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 description 1

- 239000011976 maleic acid Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000013008 moisture curing Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 239000002667 nucleating agent Substances 0.000 description 1

- 239000012466 permeate Substances 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 239000011120 plywood Substances 0.000 description 1

- 239000005015 poly(hydroxybutyrate) Substances 0.000 description 1

- 229920001610 polycaprolactone Polymers 0.000 description 1

- 239000004632 polycaprolactone Substances 0.000 description 1

- 229920006149 polyester-amide block copolymer Polymers 0.000 description 1

- 229920013716 polyethylene resin Polymers 0.000 description 1

- 229920005672 polyolefin resin Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 239000005871 repellent Substances 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 description 1

- 238000009834 vaporization Methods 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- 235000020234 walnut Nutrition 0.000 description 1

Images

Landscapes

- Laminated Bodies (AREA)

Abstract

Description

本発明は、建築用材料・屋内消費財用材料に使用する化粧材であり、特に木材基板のもつエンボス(導管凹凸模様)や照り感を生かしつつ意匠性を向上させ、更に透湿性の高い透明樹脂層を用いた化粧シート及びそのシートを積層した化粧材に関する。

The present invention is a decorative material used for building materials and materials for indoor consumer goods. In particular, it improves design while taking advantage of embossing (conduit unevenness pattern) and shine of wood substrates, and is transparent with high moisture permeability. The present invention relates to a decorative sheet using a resin layer and a decorative material in which the sheets are laminated.

従来、内装や家具の表面材として使用される化粧板としては、基材の表面に木材単板を貼り合わせた突板化粧板が広く用いられてきた。しかし近年、天然資源、特に桜、楢、チーク、ウォールナット等の広葉樹材の枯渇により、これらを用いた突板化粧板の代替として、合板・MDF(Medium Density Fiberboard)等の基材にこれらの模様を印刷した化粧シートを貼り合わせた化粧板が多く使用されている。 Conventionally, as a decorative plate used as a surface material for interior and furniture, a veneer decorative plate in which a single wood plate is bonded to the surface of a base material has been widely used. However, due to the depletion of natural resources, especially hardwood materials such as cherry, oak, teak, and walnut, these patterns have been applied to substrates such as plywood and MDF (Medium Density Fiberboard) as an alternative to veneer veneer using these materials. A decorative board in which a printed decorative sheet is bonded is often used.

しかしこの方法では、本来木材が有するいわゆる照り感、木質感や導管形状の表現性に限界があった。そこで照り感、木質感を表現する方法として、比較的入手のしやすい針葉樹材を薄く平坦にした木材基板の上に、裏面に広葉樹材の木目模様を印刷した透明ポリオレフィン系樹脂からなる化粧シートを貼り合わせることにより、本来木材が有するいわゆる照り感や木質感を反映した意匠性に優れた化粧材とする方法が考えられた。 However, with this method, there is a limit to the expression of so-called shine, wood texture, and conduit shape inherent to wood. Therefore, as a method of expressing the feeling of shine and wood texture, a decorative sheet made of transparent polyolefin resin with a hardwood wood grain pattern printed on the back of a thin and flat wood substrate made of relatively easy-to-obtain coniferous wood is used. The method of making the decorative material excellent in the design property reflecting the so-called shine feeling and the wood texture that the wood originally has was considered.

しかし、上記のような化粧材を壁面に施工するとき、化粧材を鋼板に接着してからフックを取り付け施工すると、化粧板の表面の化粧シートと鋼板に挟まれるため、木質基材に由来する水分や水性エマルジョン接着剤の水分が乾燥しにくくなる。すると木質基材に黴が生えることがあった。

本発明はこれらの問題点を解決するためになされたものであり、すなわちその課題とするところは、木材基板の上に透明性を有する絵柄模様層、透明樹脂層を少なくともこの順に設けてなる化粧シートにおいて、黴の発生を抑制した化粧シートおよび化粧材を提供することにある。 The present invention has been made in order to solve these problems. That is, the object of the present invention is a makeup in which a transparent pattern layer and a transparent resin layer are provided at least in this order on a wood substrate. An object of the present invention is to provide a decorative sheet and a decorative material in which generation of wrinkles is suppressed in the sheet.

本発明はこの課題を解決したものであり、すなわちその請求項1記載の発明は、木材基板の上に、絵柄模様層、透明樹脂層を少なくともこの順に設けてなる化粧シートにおいて、前記透明樹脂層の水蒸気透過率が60.0g/(m2・24h)(測定方法はJIS−K−7129−1992に準じる)以上であることを特徴とする化粧シートである。 The present invention solves this problem, that is, the invention according to claim 1 is a decorative sheet in which a picture pattern layer and a transparent resin layer are provided in this order on a wood substrate. Is a decorative sheet characterized by having a water vapor transmission rate of 60.0 g / (m 2 · 24 h) (measurement method conforms to JIS-K-7129-1992) or more.

また、請求項2記載の発明は前記透明樹脂層の樹脂がポリ乳酸からなることを特徴とする請求項1に記載の化粧シートである。 The invention according to claim 2 is the decorative sheet according to claim 1, wherein the resin of the transparent resin layer is made of polylactic acid.

また、請求項3記載の発明は、前記木材基板と絵柄模様層の間に、乾燥後に透明性を有する水性エマルジョン接着剤からなる接着剤層を設けてなることを特徴とする請求項1または2のいずれかに記載の化粧シートである。 The invention described in claim 3 is characterized in that an adhesive layer made of an aqueous emulsion adhesive having transparency after drying is provided between the wood substrate and the pattern layer. The decorative sheet according to any one of the above.

また、請求項4記載の発明は、化粧材基材の上に、水性接着剤層、不織布、水性接着剤層を少なくともこの順に設けてなり、その上に請求項1〜3のいずれか記載の化粧シートを設けてなることを特徴とする化粧材である。 Moreover, invention of Claim 4 provides an aqueous | water-based adhesive layer, a nonwoven fabric, and an aqueous | water-based adhesive layer in this order at least on this on a decorative material base material, The Claims 1-3 of Claim 1 is provided on it in that order. A cosmetic material comprising a decorative sheet.

本発明により、化粧材を壁面に施工するとき、化粧材を鋼板に接着してからフックを取り付け施工しても、化粧板の表面の化粧シートと鋼板に挟まれた、木質基材に由来する水分や水性エマルジョン接着剤の水分が化粧シートを透過して蒸発する。よって木質基材に黴が生えることがないという効果が得られる。 According to the present invention, when the decorative material is applied to the wall surface, even if the decorative material is bonded to the steel plate and then attached to the hook, the hook is attached to the surface of the decorative plate and is derived from the wooden base material sandwiched between the decorative sheet and the steel plate. Moisture and moisture in the aqueous emulsion adhesive permeate the decorative sheet and evaporate. Therefore, the effect that wrinkles do not grow on a wooden base material is acquired.

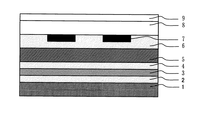

以下、本発明を図面に基づき詳細に説明する。図1に本発明の化粧シート及び化粧材の一実施例の断面の構造を示す。化粧材基材1、接着剤層A2、不織布3、接着剤層B4、木材基板5、接着剤層C6、絵柄模様層7、透明樹脂層8、そして適宜設ける表面保護層9が、この順に積層されてなる。 Hereinafter, the present invention will be described in detail with reference to the drawings. FIG. 1 shows a cross-sectional structure of an embodiment of the decorative sheet and the decorative material of the present invention. The decorative material substrate 1, the adhesive layer A2, the nonwoven fabric 3, the adhesive layer B4, the wood substrate 5, the adhesive layer C6, the pattern layer 7, the transparent resin layer 8, and the surface protective layer 9 provided as appropriate are laminated in this order. Being done.

本発明における化粧材基材1としては、特に限定するものではないが、その目的とするところから不燃性を有するものであることが好適である。具体的には厚み6〜12mm程度の珪酸カルシウム板、厚み9〜12.5mmの石膏ボード、厚み3〜28mmの火山性ガラス質複層基材、厚み0.8〜1.2mmの鋼板、窯業系セメント板等が使用可能である。なお、厚みは上記以外でも使用できる。なお、図示しないが、アルカリ留めとしてウレタン樹脂シーラーを乾燥後の塗布量で5から30g/m2程度塗工、乾燥しておくのが望ましい。 Although it does not specifically limit as the decorative material base material 1 in this invention, It is suitable that it has a nonflammability from the target place. Specifically, a calcium silicate plate having a thickness of about 6 to 12 mm, a gypsum board having a thickness of 9 to 12.5 mm, a volcanic glassy multilayer substrate having a thickness of 3 to 28 mm, a steel plate having a thickness of 0.8 to 1.2 mm, and a ceramic industry A cement board or the like can be used. In addition, thickness can use other than the above. Although not shown, it is desirable that the urethane resin sealer is applied and dried in an amount of 5 to 30 g / m 2 after drying as an alkali stopper.

接着剤層A2は、前記化粧材基材1と後述する不織布3の層間を接着する。乾燥後に透明になるウレタン変性エチレン・酢酸ビニル重合体の水性エマルジョン接着剤(固形分54重量%、粘度10,000mPa・S程度)や、2液ウレタン樹脂系水性エマルジョンや酢酸ビニル樹脂系水性エマルジョン、1液湿気硬化型ウレタン系ホットメルト樹脂、エポキシ樹脂接着剤、アクリル樹脂粘着剤等が接着力の点で好適である。乾燥後の塗布量は10〜120g/m2程度が望ましい。 The adhesive layer A2 adheres between the decorative material base 1 and a non-woven fabric 3 described later. Urethane modified ethylene / vinyl acetate polymer aqueous emulsion adhesive (solid content 54 wt%, viscosity around 10,000 mPa · S), two-component urethane resin aqueous emulsion, vinyl acetate resin aqueous emulsion, which becomes transparent after drying, One-component moisture-curing urethane hot melt resin, epoxy resin adhesive, acrylic resin pressure-sensitive adhesive, and the like are preferable in terms of adhesive strength. The coating amount after drying is preferably about 10 to 120 g / m 2 .

不織布3としては、ビニロン繊維製の米坪量10〜60g程度のものが好ましい。この不織布3は後述する木材基板5の割れを防ぎ、取り扱いを容易にする役目をもつ。 The nonwoven fabric 3 is preferably made of vinylon fiber having a basis weight of about 10 to 60 g. The nonwoven fabric 3 has a role of preventing cracking of the wood substrate 5 described later and facilitating handling.

接着剤層B4は、前記不織布3と後述する木材基板5の層間を接着するものであり、接着剤層A2と同様の物、塗布量で使える。 Adhesive layer B4 adheres between the nonwoven fabric 3 and the wood substrate 5 described later, and can be used with the same material and coating amount as adhesive layer A2.

本発明における木材基板5としては、その表面の模様が化粧材として好適となるものであれば良く、後述する絵柄模様層7と重ね合わせることで効果のある導管模様に乏しい広葉樹材を使用することが出来るが、針葉樹材からなるものであっても良いし、不法伐採されていない、植林にて生産したアユース樹種等からなる人工突板でも良い。具体的には厚み0.3mm程度にスライスした植林にて生産した樹種アユース(アフリカ産 トリプロチトン属アオギリ科)の突板や他の樹種の針葉樹、ローズウッド等も使える。また、人工突板も使うことができる。 The wood substrate 5 according to the present invention may be any material as long as its surface pattern is suitable as a decorative material, and use a hardwood material that lacks an effective conduit pattern by overlapping with a pattern layer 7 described later. However, it may be made of coniferous wood, or an artificial veneer made of a use tree species that has not been illegally harvested and is produced by afforestation. Specifically, the veneer of the tree species youth (African triprochiton genus Aogiriaceae) produced by afforestation sliced to a thickness of about 0.3 mm, conifers of other tree species, rosewood, etc. can be used. Artificial veneers can also be used.

接着剤層C6は、前記木材基板と透明樹脂層8の層間を接着するものであり、接着剤層A2、接着剤層B4と同様の物、塗布量で使える。 The adhesive layer C6 is for bonding the wood substrate and the transparent resin layer 8, and can be used with the same material and application amount as the adhesive layer A2 and the adhesive layer B4.

絵柄模様層7としては、2液ウレタン樹脂バインダー(マトリックス)に顔料などを添加したインキが好適に用いられるが、特にこれに限定するものではなく、積層する各層との接着性等を考慮して適宜選択すればよい。絵柄模様層7は表面側から前記木材基板の表面の意匠との兼ね合いで意匠性を向上させるのを目的とするものであり、全体にわたり透視可能な色合いを有するものや、部分的に透明な部分と不透明な部分を設けることなどにより目的を達成することができるものであるが、特に限定するものではなく、意匠性を向上させることができるものであればよい。 As the pattern layer 7, an ink obtained by adding a pigment or the like to a two-component urethane resin binder (matrix) is preferably used. However, the ink is not particularly limited, and the adhesiveness with each layer to be laminated is considered. What is necessary is just to select suitably. The pattern layer 7 is intended to improve the design properties in consideration of the design of the surface of the wood substrate from the surface side, and has a color that can be seen through, or a partially transparent portion. The object can be achieved by providing an opaque part, but is not particularly limited as long as the design can be improved.

透明樹脂層8としては、水蒸気透過率が60.0g/(m2・24h)(測定方法はJIS−K−7129−1992に準じる)以上となるように樹脂、添加剤、層厚を調整してなる。水蒸気透過率が10g/m2・24h程度であれば耐水、耐湿性の化粧シートと同等であり、40g/(m2・24h)程度であっても水性接着剤等の水分の蒸発の実現は困難である。コスト対効果を考えれば上限は300g/(m2・24h)程度が好適な範囲である。層厚としては10〜120μm程度が好適であり、最も好ましくは20〜90μmである。 As the transparent resin layer 8, the resin, additives, and layer thickness are adjusted so that the water vapor transmission rate is 60.0 g / (m 2 · 24 h) (measurement method conforms to JIS-K-7129-1992) or more. It becomes. If the water vapor transmission rate is about 10 g / m 2 · 24 h, it is equivalent to a waterproof and moisture-resistant decorative sheet. Even if it is about 40 g / (m 2 · 24 h), the water vaporization of the water-based adhesive etc. can be realized. Have difficulty. Considering the cost effectiveness, the upper limit is preferably about 300 g / (m 2 · 24 h). The layer thickness is preferably about 10 to 120 μm, and most preferably 20 to 90 μm.

透明樹脂層8に用いる樹脂としては特に限定しないが、近年の環境対応から屋内消費財用材料用途などにあっては、植物由来のポリ乳酸(Poly Lactic Acid)樹脂が好ましい。ポリ乳酸樹脂の他、その物性や植物由来性に影響を与えない範囲で他のバイオマス材料や生分解性樹脂、着色剤、酸化防止剤、紫外線吸収剤、熱安定剤、可塑剤、滑剤、帯電防止剤、難燃剤、充填剤、加水分解抑止剤、核剤など従来公知の各種の添加剤の1種以上を添加しても良い。 Although it does not specifically limit as resin used for the transparent resin layer 8, For the use for indoor consumer goods material etc. from recent environmental measures, a plant-derived polylactic acid (Poly Lactic Acid) resin is preferable. In addition to polylactic acid resin, other biomass materials and biodegradable resins, colorants, antioxidants, UV absorbers, heat stabilizers, plasticizers, lubricants, charging, as long as they do not affect their physical properties and plant origin You may add 1 or more types of conventionally well-known various additives, such as an inhibitor, a flame retardant, a filler, a hydrolysis inhibitor, and a nucleating agent.

バイオマス材料や生分解性樹脂は耐熱性向上の為に適宜添加されるものであり、具体的には、ポリヒドロキシブチレート系、ポリブチレンサクシネート系、ポリブチレンサクシネート系、ポリカプロラクトン系、酢酸セルロース系、ポリエステルアミド系、酢酸ビニル系、デンプン系のものから適宜選択が可能で、単一でも複数種の混合でも構わない。 Biomass materials and biodegradable resins are added as appropriate to improve heat resistance. Specifically, polyhydroxybutyrate, polybutylene succinate, polybutylene succinate, polycaprolactone, acetic acid Cellulose-based, polyesteramide-based, vinyl acetate-based, and starch-based materials can be appropriately selected, and a single type or a mixture of plural types may be used.

紫外線吸収剤としては、ベンゾトリアゾール系、トリアジン系、ベンゾイミン系などが挙げられる。また、適宜、ヒンダードアミンやヒンダードフェノール系の光安定剤などを添加しても良い。これにより、本発明の植物由来化粧シート貼り化粧材に耐候性が付与される。 Examples of the ultraviolet absorber include benzotriazole, triazine, and benzoimine. In addition, a hindered amine or a hindered phenol light stabilizer may be added as appropriate. Thereby, weather resistance is provided to the plant-derived decorative sheet-attached decorative material of the present invention.

透明樹脂層8の上には、その上に適宜設ける表面保護層9との接着性を向上させるために酸変性、特にマレイン酸変性したポリエチレン樹脂やポリプロピレン樹脂などの接着性樹脂層(図示せず)を適宜設けても良い。この接着性樹脂層は、透明植物由来樹脂基材8と共押出成形などで設けるのが好適であるが、特にこの方法に限定するものではない。 On the transparent resin layer 8, an adhesive resin layer (not shown) such as polyethylene resin or polypropylene resin modified with acid, in particular maleic acid, in order to improve adhesion with the surface protective layer 9 appropriately provided thereon. ) May be provided as appropriate. The adhesive resin layer is preferably provided by coextrusion molding with the transparent plant-derived resin base material 8, but is not particularly limited to this method.

適宜設ける表面保護層9としては、各種表面物性を強化するために適宜設けることができ、具体的には2液ウレタン樹脂、紫外線硬化型樹脂、電子線硬化型樹脂などが使用可能である。また、紫外線吸収剤、光開始剤等の添加剤を適宜添加してもよい。 The surface protective layer 9 provided as appropriate can be provided as appropriate in order to enhance various surface properties. Specifically, a two-component urethane resin, an ultraviolet curable resin, an electron beam curable resin, or the like can be used. Moreover, you may add additives, such as a ultraviolet absorber and a photoinitiator, suitably.

木材基板5として縦横300mm、厚み0.3mmにスライスした植林にて生産した樹種アユース(アフリカ産 トリプロチトン属(アオギリ科))の突板を用いた。

不織布3としてビニロン繊維(米坪量30g)を用い、この両面に乾燥後に透明になるウレタン変性エチレン・酢酸ビニル重合体の水性エマルジョン接着剤(固形分 54重量%、粘度10,000mPa・S)を、乾燥前60g/m2として塗布して接着剤層A2と接着剤層B4とした。その後、接着剤層B4側を木材基板5の裏面と貼り合せた。

As the wood substrate 5, a veneer of a tree species Ayous (African triprositone genus (Aogiriaceae)) produced by afforestation sliced in length and width of 300 mm and thickness of 0.3 mm was used.

A vinylon fiber (rice basis weight 30 g) is used as the nonwoven fabric 3, and an urethane-modified ethylene / vinyl acetate polymer aqueous emulsion adhesive (solid content 54 wt%, viscosity 10,000 mPa · S) that becomes transparent after drying on both sides. Then, it was applied as 60 g / m 2 before drying to form an adhesive layer A2 and an adhesive layer B4. Thereafter, the adhesive layer B4 side was bonded to the back surface of the wood substrate 5.

透明樹脂層8として、厚み20μmのポリ乳酸樹脂フィルム(東セロ(株)製「パルグリーンLC」)を用いた。この水蒸気透過率は250.0g/(m2・24h)(測定方法はJIS−K−7129−1992に準じる)であった。 As the transparent resin layer 8, a 20 μm-thick polylactic acid resin film (“Palgreen LC” manufactured by Tosero Co., Ltd.) was used. The water vapor transmission rate was 250.0 g / (m 2 · 24 h) (measurement method conforming to JIS-K-7129-1992).

前記透明樹脂層8の両面にコロナ処理を施したあと、その表面側に、2液硬化型ウレタン系トップコート剤100重量部にシリコーン樹脂系發液剤0.5重量部を配合したものをグラビアコート法にて乾燥後の塗布量が3g/m2になるように施し、乾燥、硬化させて表面保護層9とした。

そして、前記透明樹脂層8の裏面側に、透明性インキにてグラビア印刷法により木目柄を形成して絵柄模様層7とした。

After corona treatment is applied to both surfaces of the transparent resin layer 8, a gravure coat is formed by blending 100 parts by weight of a two-part curable urethane topcoat agent with 0.5 parts by weight of a silicone resin-type liquid-repellent on the surface side. The surface protective layer 9 was prepared by applying the coating amount after drying by the method to 3 g / m 2 , drying and curing.

Then, on the back side of the transparent resin layer 8, a wood grain pattern was formed by a gravure printing method with a transparent ink to obtain a picture pattern layer 7.

そして、前記木材基板5の表面側に、ウレタン変性エチレン・酢酸ビニル重合体の水性エマルジョン接着剤(固形分 54重量%、粘度10,000mPa・S)を乾燥前60g/m2として塗布して接着剤層C6として設け、これと前記透明樹脂層8の前記絵柄模様層7を設けた側とを貼り合せ、化粧シートを得た。 Then, an aqueous emulsion adhesive of urethane-modified ethylene / vinyl acetate polymer (solid content 54 wt%, viscosity 10,000 mPa · S) is applied to the surface side of the wood substrate 5 as 60 g / m 2 before drying. It provided as agent layer C6, this was bonded together the side in which the said pattern layer 7 of the said transparent resin layer 8 was provided, and the decorative sheet was obtained.

化粧材基材1として厚み6mmの市販の珪酸カルシウム板を用い、図示しないがこの表面に目止め剤として水性ウレタン樹脂シーラーを乾燥後の塗布量が10g/m2になるように塗布した。この表面と前記化粧シートの接着剤層A2とを貼り合わせ、全体を30〜50℃でプレス機を用いて圧締し(40N/cm2)、化粧材を得た。 A commercially available calcium silicate plate having a thickness of 6 mm was used as the decorative material base 1, and although not shown, an aqueous urethane resin sealer was applied to this surface as a sealing agent so that the coating amount after drying was 10 g / m 2 . This surface was bonded to the adhesive layer A2 of the decorative sheet, and the whole was pressed (30 N / cm 2 ) with a press at 30 to 50 ° C. to obtain a decorative material.

<比較例1>

前記透明樹脂層8として、2軸延伸ポリプロピレン樹脂(水蒸気透過率は10.0g/(m2・24h)(測定方法はJIS−K−7129−1992に準じる)であった。)を用いた以外は実施例1と同様にして化粧シート、化粧材を得た。

<Comparative Example 1>

As the transparent resin layer 8, a biaxially stretched polypropylene resin (water vapor transmission rate was 10.0 g / (m 2 · 24h) (measurement method conforming to JIS-K-7129-1992)) was used. Obtained a decorative sheet and a decorative material in the same manner as in Example 1.

<性能評価・結果>

実施例1、比較例1を厚み0.5mmの亜鉛メッキ鋼板に塗布量20g/m2の2液エポキシ樹脂接着剤にて積層した。その後、40℃90%RH(相対湿度)の恒温恒湿槽に1ヶ月放置した所、実施例1では黴は生えなかったが、比較例1では黴がはえた。

<Performance evaluation and results>

Example 1 and Comparative Example 1 were laminated on a galvanized steel sheet having a thickness of 0.5 mm with a two-part epoxy resin adhesive having an application amount of 20 g / m 2 . Then, when left in a constant temperature and humidity chamber at 40 ° C. and 90% RH (relative humidity) for 1 month, no wrinkles were formed in Example 1, but wrinkles were produced in Comparative Example 1.

建築用材料・屋内消費財用材料に使用する化粧材であり、特に木材基板のもつエンボス(導管凹凸模様)や照り感を生かしつつ意匠性を向上させ、更に透湿性の高い植物由来材料を使用した化粧シート及びそのシートを積層した化粧材として利用可能である。 It is a decorative material used for building materials and indoor consumer goods materials. In particular, it uses the embossed (concavity and convexity pattern) and shine of the wood substrate to improve design, and uses plant-derived materials with high moisture permeability. And can be used as a decorative material in which the sheets are laminated.

1…化粧材基材

2…接着剤層A

3…不織布

4…接着剤層B

5…木材基板

6…接着剤層C

7…絵柄模様層

8…透明樹脂層

9…表面保護層

DESCRIPTION OF SYMBOLS 1 ... Cosmetic material base material 2 ... Adhesive layer A

3 ... Nonwoven fabric 4 ... Adhesive layer B

5 ... wood substrate 6 ... adhesive layer C

7 ... Pattern pattern layer 8 ... Transparent resin layer 9 ... Surface protective layer

Claims (4)

A water-based adhesive layer, a nonwoven fabric, and a water-based adhesive layer are provided at least in this order on the decorative material base material, and the decorative sheet according to any one of claims 1 to 3 is provided thereon. Make up cosmetics.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008101456A JP2009248506A (en) | 2008-04-09 | 2008-04-09 | Decorative sheet and decorative material |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008101456A JP2009248506A (en) | 2008-04-09 | 2008-04-09 | Decorative sheet and decorative material |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2009248506A true JP2009248506A (en) | 2009-10-29 |

Family

ID=41309630

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008101456A Pending JP2009248506A (en) | 2008-04-09 | 2008-04-09 | Decorative sheet and decorative material |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2009248506A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011052243A1 (en) | 2009-10-29 | 2011-05-05 | 株式会社イノアックコーポレーション | Fiber-reinforced molded product and method for producing same |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62264945A (en) * | 1986-05-13 | 1987-11-17 | ロンシール工業株式会社 | decorative sheet |

| JPS6393132A (en) * | 1986-10-07 | 1988-04-23 | Nec Corp | Semiconductor device |

| JPH0387251A (en) * | 1989-06-16 | 1991-04-12 | Dainippon Printing Co Ltd | Veneer decorative material |

| JPH04182127A (en) * | 1989-01-16 | 1992-06-29 | Toppan Printing Co Ltd | Manufacture of decorative metallic plate |

| JPH0985897A (en) * | 1995-09-28 | 1997-03-31 | Toppan Printing Co Ltd | Decorative board and manufacturing method thereof |

| JPH10119187A (en) * | 1996-10-16 | 1998-05-12 | Toppan Printing Co Ltd | Artificial components |

| JP2001270017A (en) * | 2000-03-22 | 2001-10-02 | K S T:Kk | Air permeable interior material |

| JP2001323155A (en) * | 2000-05-11 | 2001-11-20 | Sanyo Chem Ind Ltd | Humidity control material for cosmetic material and cosmetic material using the same |

| JP2006131798A (en) * | 2004-11-08 | 2006-05-25 | Mitsubishi Plastics Ind Ltd | Polylactic acid composition and polylactic acid film |

| JP2009226869A (en) * | 2008-03-25 | 2009-10-08 | Toppan Printing Co Ltd | Decorative sheet, decorative material, and method for production of decorative sheet |

-

2008

- 2008-04-09 JP JP2008101456A patent/JP2009248506A/en active Pending

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62264945A (en) * | 1986-05-13 | 1987-11-17 | ロンシール工業株式会社 | decorative sheet |

| JPS6393132A (en) * | 1986-10-07 | 1988-04-23 | Nec Corp | Semiconductor device |

| JPH04182127A (en) * | 1989-01-16 | 1992-06-29 | Toppan Printing Co Ltd | Manufacture of decorative metallic plate |

| JPH0387251A (en) * | 1989-06-16 | 1991-04-12 | Dainippon Printing Co Ltd | Veneer decorative material |

| JPH0985897A (en) * | 1995-09-28 | 1997-03-31 | Toppan Printing Co Ltd | Decorative board and manufacturing method thereof |

| JPH10119187A (en) * | 1996-10-16 | 1998-05-12 | Toppan Printing Co Ltd | Artificial components |

| JP2001270017A (en) * | 2000-03-22 | 2001-10-02 | K S T:Kk | Air permeable interior material |

| JP2001323155A (en) * | 2000-05-11 | 2001-11-20 | Sanyo Chem Ind Ltd | Humidity control material for cosmetic material and cosmetic material using the same |

| JP2006131798A (en) * | 2004-11-08 | 2006-05-25 | Mitsubishi Plastics Ind Ltd | Polylactic acid composition and polylactic acid film |

| JP2009226869A (en) * | 2008-03-25 | 2009-10-08 | Toppan Printing Co Ltd | Decorative sheet, decorative material, and method for production of decorative sheet |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011052243A1 (en) | 2009-10-29 | 2011-05-05 | 株式会社イノアックコーポレーション | Fiber-reinforced molded product and method for producing same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| ES2538470T3 (en) | Light panel printed directly | |

| KR100951163B1 (en) | Flame-retardant board and manufacturing method therof | |

| JP5247645B2 (en) | Adhesive wallpaper and wallpaper construction method | |

| BR112014026478B1 (en) | PROCESS FOR PRODUCTION OF A DECORATED SHEET AND ITS USE | |

| JPH08207012A (en) | Wooden surface decorative sheet | |

| JP5125665B2 (en) | Decorative sheet, decorative material, and method for producing decorative sheet | |

| JP2009248506A (en) | Decorative sheet and decorative material | |

| CN204112664U (en) | A kind of environment-friendly waterproof solid wooden compound floor | |

| CN207808670U (en) | Electric wire cured film multi-layer composite floor | |

| JP2008155460A (en) | Facing sheet and decorative plate using it | |

| JP2009297896A (en) | Decorative flooring material | |

| CN101323193A (en) | Surface recombination technique of veneer and plaster tablets | |

| FI20065497A7 (en) | Coated wood board, method for its manufacture and use | |

| CN101666146A (en) | Composite decorative board | |

| ATE392452T1 (en) | COMPOSITION FOR PRODUCING A BARRIER LAYER ON LAMINATED PACKAGING MATERIAL | |

| RU2007127838A (en) | SURFACE SEALING METHOD | |

| JP2007031958A (en) | Construction plate | |

| JP2009113261A (en) | Decorative material | |

| FI20095493L (en) | Digitally printed product and its manufacturing method and use | |

| CN205046784U (en) | Fire -retardant artistic board | |

| JP2001293703A (en) | Three-dimensional wooden building materials | |

| JP2001129958A (en) | Decorative sheet and decorative material | |

| EP3034320B1 (en) | Method for producing scented decorative laminates and scented faced panels | |

| JP7268778B2 (en) | Decorative sheet and board | |

| JP2008290349A (en) | Decorative sheet having inlay pattern |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110408 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120517 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120626 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20121120 |