CN202228641U - 耐磨蜗轮 - Google Patents

耐磨蜗轮 Download PDFInfo

- Publication number

- CN202228641U CN202228641U CN2011203130140U CN201120313014U CN202228641U CN 202228641 U CN202228641 U CN 202228641U CN 2011203130140 U CN2011203130140 U CN 2011203130140U CN 201120313014 U CN201120313014 U CN 201120313014U CN 202228641 U CN202228641 U CN 202228641U

- Authority

- CN

- China

- Prior art keywords

- rim

- wheel

- worm wheel

- wheel body

- abrasion resistant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Gears, Cams (AREA)

Abstract

本实用新型涉及机械传动装置技术领域,尤其是一种耐磨蜗轮。包括轮体和轮缘,轮缘呈齿状,均匀分布在轮体外圆面上,轮体和轮缘由钢基体铸成,轮缘外表面上覆有一层白口铸铁。以在钢基体表面覆盖白口铸铁耐磨层的蜗轮替代现有的全铜合金结构蜗轮,不但节约了大量的贵重铜合金,降低了成本,而且大大提高了强度和耐磨性。

Description

技术领域

本实用新型涉及机械传动装置技术领域,尤其是一种耐磨蜗轮。

背景技术

蜗轮蜗杆机构通常用来传递两交错轴之间的运动和力,蜗轮和蜗杆啮合传动时,一方面啮合齿轮间的作用力大,故摩擦损耗大;另一方面啮合齿轮间的相对滑动速度大,使齿面磨损严重、发热严重,现有的蜗轮通常采用整体式的铜合金材料制作,不但成本高,而且磨擦损耗大,效率低,发热严重。

实用新型内容

为了克服现有的蜗轮成本高,磨损大、发热严重的不足,本实用新型提供了一种耐磨蜗轮。

本实用新型解决其技术问题所采用的技术方案是:一种耐磨蜗轮,包括轮体和轮缘,轮缘呈齿状,均匀分布在轮体外圆面上,轮体和轮缘由钢基体铸成,轮缘外表面上覆有一层白口铸铁。

本实用新型的有益效果是,以在钢基体表面覆盖白口铸铁耐磨层的蜗轮替代现有的全铜合金结构蜗轮,不但节约了大量的贵重铜合金,降低了成本,而且大大提高了强度和耐磨性。

附图说明

下面结合附图和实施例对本实用新型进一步说明。

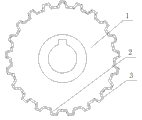

图1是本实用新型的结构示意图。

图中1. 轮体,2. 轮缘,3. 白口铸铁。

具体实施方式

如图1是本实用新型的结构示意图,一种耐磨蜗轮,包括轮体1和轮缘2,轮缘2呈齿状,均匀分布在轮体1外圆面上,轮体1和轮缘2由钢基体铸成,轮缘2外表面上覆有一层白口铸铁3。

轮体1和轮缘2由钢基体铸成,钢基体可由碳钢式合金制作,很容易满足强度要求。轮缘2外表面上覆有一层白口铸铁3,白口铸铁3具有较高的硬度,抗磨性能良好,可大大提高蜗轮的使用寿命。

Claims (1)

1.一种耐磨蜗轮,包括轮体(1)和轮缘(2),轮缘(2)呈齿状,均匀分布在轮体(1)外圆面上,其特征是,轮体(1)和轮缘(2)由钢基体铸成,轮缘(2)外表面上覆有一层白口铸铁(3)。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011203130140U CN202228641U (zh) | 2011-08-25 | 2011-08-25 | 耐磨蜗轮 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011203130140U CN202228641U (zh) | 2011-08-25 | 2011-08-25 | 耐磨蜗轮 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202228641U true CN202228641U (zh) | 2012-05-23 |

Family

ID=46079227

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011203130140U Expired - Fee Related CN202228641U (zh) | 2011-08-25 | 2011-08-25 | 耐磨蜗轮 |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202228641U (zh) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109654199A (zh) * | 2019-01-09 | 2019-04-19 | 银川威力传动技术股份有限公司 | 一种新型回转减速器 |

| CN113639010A (zh) * | 2021-07-29 | 2021-11-12 | 浙江台玖精密机械有限公司 | 减速机用复合蜗轮及复合方法 |

-

2011

- 2011-08-25 CN CN2011203130140U patent/CN202228641U/zh not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109654199A (zh) * | 2019-01-09 | 2019-04-19 | 银川威力传动技术股份有限公司 | 一种新型回转减速器 |

| CN113639010A (zh) * | 2021-07-29 | 2021-11-12 | 浙江台玖精密机械有限公司 | 减速机用复合蜗轮及复合方法 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202228641U (zh) | 耐磨蜗轮 | |

| CN102954182A (zh) | 耐磨蜗轮 | |

| CN202883150U (zh) | 一种新型活塞环 | |

| CN202028418U (zh) | 一种组合式颚板 | |

| CN201835866U (zh) | 薄煤层用刮板输送机 | |

| CN102954184A (zh) | 新型蜗轮 | |

| CN203189647U (zh) | 新型组合齿轮轴 | |

| CN201404824Y (zh) | 磨煤机耐磨复合辊套 | |

| CN201723325U (zh) | 耐磨曲轴箱体 | |

| CN202132459U (zh) | 双螺母垫片预紧滚珠丝杠副 | |

| CN201851637U (zh) | 一种平面垫片 | |

| CN202729125U (zh) | 输送链板 | |

| CN202468964U (zh) | 耐磨式拨叉 | |

| CN204164308U (zh) | 紧密型铜蜗轮 | |

| CN201461905U (zh) | 复合蜗轮 | |

| CN202238160U (zh) | 一种齿辊式破碎机齿板 | |

| CN203067734U (zh) | 一种同步带轮 | |

| CN201152355Y (zh) | 硬质合金齿轮 | |

| CN201723654U (zh) | 一种新型卧式齿轮减速机 | |

| CN202876889U (zh) | 一种铸铁锤头 | |

| CN205331365U (zh) | 发动机用正时齿轮 | |

| CN202545045U (zh) | 一种润滑性强的片环 | |

| CN203716112U (zh) | 高分子复合材料滑道 | |

| CN202992081U (zh) | 一种丝杆传动用螺母 | |

| CN202301458U (zh) | 粉末冶金滑动轴承 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120523 Termination date: 20120825 |