CN1437773A - Multilayer structures as stable hole-injecting electrodes for use in high efficiency organic electronic device - Google Patents

Multilayer structures as stable hole-injecting electrodes for use in high efficiency organic electronic device Download PDFInfo

- Publication number

- CN1437773A CN1437773A CN01811439A CN01811439A CN1437773A CN 1437773 A CN1437773 A CN 1437773A CN 01811439 A CN01811439 A CN 01811439A CN 01811439 A CN01811439 A CN 01811439A CN 1437773 A CN1437773 A CN 1437773A

- Authority

- CN

- China

- Prior art keywords

- layer

- pani

- conductivity

- pedt

- polymer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 229920000767 polyaniline Polymers 0.000 claims description 129

- 239000000203 mixture Substances 0.000 claims description 85

- 239000000463 material Substances 0.000 claims description 58

- 238000002347 injection Methods 0.000 claims description 16

- 239000007924 injection Substances 0.000 claims description 16

- 239000011368 organic material Substances 0.000 claims description 16

- 229920000620 organic polymer Polymers 0.000 claims description 12

- 229920001940 conductive polymer Polymers 0.000 claims description 9

- 239000010410 layer Substances 0.000 abstract description 236

- 229920000642 polymer Polymers 0.000 abstract description 80

- 239000012044 organic layer Substances 0.000 abstract 2

- 229920001609 Poly(3,4-ethylenedioxythiophene) Polymers 0.000 description 89

- -1 poly(ethylenedioxythiophene) Polymers 0.000 description 62

- 229920002401 polyacrylamide Polymers 0.000 description 43

- 239000000243 solution Substances 0.000 description 30

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 26

- 239000010408 film Substances 0.000 description 25

- 125000000217 alkyl group Chemical group 0.000 description 24

- 239000002253 acid Substances 0.000 description 17

- 125000004432 carbon atom Chemical group C* 0.000 description 17

- 229910052751 metal Inorganic materials 0.000 description 16

- 239000002184 metal Substances 0.000 description 16

- 239000000758 substrate Substances 0.000 description 15

- 229920000547 conjugated polymer Polymers 0.000 description 14

- 229920000553 poly(phenylenevinylene) Polymers 0.000 description 13

- 125000003545 alkoxy group Chemical group 0.000 description 12

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 11

- PAYRUJLWNCNPSJ-UHFFFAOYSA-N N-phenyl amine Natural products NC1=CC=CC=C1 PAYRUJLWNCNPSJ-UHFFFAOYSA-N 0.000 description 11

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 11

- YMWUJEATGCHHMB-UHFFFAOYSA-N Dichloromethane Chemical compound ClCCl YMWUJEATGCHHMB-UHFFFAOYSA-N 0.000 description 9

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 9

- 229910052782 aluminium Inorganic materials 0.000 description 9

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 9

- 125000003118 aryl group Chemical group 0.000 description 9

- 125000000732 arylene group Chemical group 0.000 description 9

- 229920001577 copolymer Polymers 0.000 description 9

- 229910052736 halogen Inorganic materials 0.000 description 9

- 150000002739 metals Chemical class 0.000 description 9

- 238000000034 method Methods 0.000 description 9

- 239000002904 solvent Substances 0.000 description 9

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 8

- 150000007513 acids Chemical class 0.000 description 8

- 150000002367 halogens Chemical class 0.000 description 8

- 229910052709 silver Inorganic materials 0.000 description 8

- 239000004332 silver Substances 0.000 description 8

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 7

- 125000004093 cyano group Chemical group *C#N 0.000 description 7

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 7

- 238000005259 measurement Methods 0.000 description 7

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 6

- LSNNMFCWUKXFEE-UHFFFAOYSA-M Bisulfite Chemical group OS([O-])=O LSNNMFCWUKXFEE-UHFFFAOYSA-M 0.000 description 6

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 6

- 239000010949 copper Substances 0.000 description 6

- NNBZCPXTIHJBJL-UHFFFAOYSA-N decalin Chemical compound C1CCCC2CCCCC21 NNBZCPXTIHJBJL-UHFFFAOYSA-N 0.000 description 6

- 238000000151 deposition Methods 0.000 description 6

- 229920000775 emeraldine polymer Polymers 0.000 description 6

- 239000010931 gold Substances 0.000 description 6

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 5

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 5

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 5

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 5

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 5

- 125000003342 alkenyl group Chemical group 0.000 description 5

- 125000004390 alkyl sulfonyl group Chemical group 0.000 description 5

- 230000015572 biosynthetic process Effects 0.000 description 5

- 229910052802 copper Inorganic materials 0.000 description 5

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 5

- 229910052737 gold Inorganic materials 0.000 description 5

- 229910044991 metal oxide Inorganic materials 0.000 description 5

- 229920000139 polyethylene terephthalate Polymers 0.000 description 5

- 239000005020 polyethylene terephthalate Substances 0.000 description 5

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 description 5

- 229910001887 tin oxide Inorganic materials 0.000 description 5

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 4

- 239000004593 Epoxy Chemical group 0.000 description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 4

- YNAVUWVOSKDBBP-UHFFFAOYSA-N Morpholine Chemical compound C1COCCN1 YNAVUWVOSKDBBP-UHFFFAOYSA-N 0.000 description 4

- AMQJEAYHLZJPGS-UHFFFAOYSA-N N-Pentanol Chemical compound CCCCCO AMQJEAYHLZJPGS-UHFFFAOYSA-N 0.000 description 4

- UFWIBTONFRDIAS-UHFFFAOYSA-N Naphthalene Chemical compound C1=CC=CC2=CC=CC=C21 UFWIBTONFRDIAS-UHFFFAOYSA-N 0.000 description 4

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 4

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 4

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 4

- 239000004743 Polypropylene Substances 0.000 description 4

- 239000004372 Polyvinyl alcohol Substances 0.000 description 4

- 229920002125 Sokalan® Polymers 0.000 description 4

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 4

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 4

- 239000011149 active material Substances 0.000 description 4

- 125000004183 alkoxy alkyl group Chemical group 0.000 description 4

- 125000004453 alkoxycarbonyl group Chemical group 0.000 description 4

- 125000004414 alkyl thio group Chemical group 0.000 description 4

- 150000001448 anilines Chemical class 0.000 description 4

- MWPLVEDNUUSJAV-UHFFFAOYSA-N anthracene Chemical compound C1=CC=CC2=CC3=CC=CC=C3C=C21 MWPLVEDNUUSJAV-UHFFFAOYSA-N 0.000 description 4

- 125000003710 aryl alkyl group Chemical group 0.000 description 4

- 125000004391 aryl sulfonyl group Chemical group 0.000 description 4

- 229910052788 barium Inorganic materials 0.000 description 4

- 230000015556 catabolic process Effects 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- 238000006731 degradation reaction Methods 0.000 description 4

- 239000006185 dispersion Substances 0.000 description 4

- 238000005401 electroluminescence Methods 0.000 description 4

- 125000005678 ethenylene group Chemical group [H]C([*:1])=C([H])[*:2] 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 229910003437 indium oxide Inorganic materials 0.000 description 4

- 125000000449 nitro group Chemical group [O-][N+](*)=O 0.000 description 4

- 239000003960 organic solvent Substances 0.000 description 4

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 4

- 229920000573 polyethylene Polymers 0.000 description 4

- 229920001155 polypropylene Polymers 0.000 description 4

- 229920002451 polyvinyl alcohol Polymers 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- 239000004677 Nylon Substances 0.000 description 3

- 206010034972 Photosensitivity reaction Diseases 0.000 description 3

- 239000004793 Polystyrene Substances 0.000 description 3

- 125000004450 alkenylene group Chemical group 0.000 description 3

- 229920000109 alkoxy-substituted poly(p-phenylene vinylene) Polymers 0.000 description 3

- 125000002877 alkyl aryl group Chemical group 0.000 description 3

- 125000004644 alkyl sulfinyl group Chemical group 0.000 description 3

- 239000007864 aqueous solution Substances 0.000 description 3

- 238000003491 array Methods 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical group [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- DSAJWYNOEDNPEQ-UHFFFAOYSA-N barium atom Chemical compound [Ba] DSAJWYNOEDNPEQ-UHFFFAOYSA-N 0.000 description 3

- 239000000872 buffer Substances 0.000 description 3

- BTANRVKWQNVYAZ-UHFFFAOYSA-N butan-2-ol Chemical compound CCC(C)O BTANRVKWQNVYAZ-UHFFFAOYSA-N 0.000 description 3

- 229910052791 calcium Inorganic materials 0.000 description 3

- 239000011575 calcium Substances 0.000 description 3

- 238000005266 casting Methods 0.000 description 3

- 239000002131 composite material Substances 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- 125000000392 cycloalkenyl group Chemical group 0.000 description 3

- 125000000753 cycloalkyl group Chemical group 0.000 description 3

- 239000008367 deionised water Substances 0.000 description 3

- 229910021641 deionized water Inorganic materials 0.000 description 3

- 230000008021 deposition Effects 0.000 description 3

- 125000000664 diazo group Chemical group [N-]=[N+]=[*] 0.000 description 3

- 239000011263 electroactive material Substances 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 125000005843 halogen group Chemical group 0.000 description 3

- 125000005842 heteroatom Chemical group 0.000 description 3

- 229910052738 indium Inorganic materials 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 150000004706 metal oxides Chemical class 0.000 description 3

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 3

- 229910052759 nickel Inorganic materials 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 229920001778 nylon Polymers 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 230000036211 photosensitivity Effects 0.000 description 3

- 229920003023 plastic Polymers 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 229920000128 polypyrrole Polymers 0.000 description 3

- 229920002223 polystyrene Polymers 0.000 description 3

- 229920000123 polythiophene Polymers 0.000 description 3

- 238000004528 spin coating Methods 0.000 description 3

- 239000011593 sulfur Substances 0.000 description 3

- 229910052717 sulfur Inorganic materials 0.000 description 3

- RFFLAFLAYFXFSW-UHFFFAOYSA-N 1,2-dichlorobenzene Chemical compound ClC1=CC=CC=C1Cl RFFLAFLAYFXFSW-UHFFFAOYSA-N 0.000 description 2

- KBPLFHHGFOOTCA-UHFFFAOYSA-N 1-Octanol Chemical compound CCCCCCCCO KBPLFHHGFOOTCA-UHFFFAOYSA-N 0.000 description 2

- OGGKVJMNFFSDEV-UHFFFAOYSA-N 3-methyl-n-[4-[4-(n-(3-methylphenyl)anilino)phenyl]phenyl]-n-phenylaniline Chemical compound CC1=CC=CC(N(C=2C=CC=CC=2)C=2C=CC(=CC=2)C=2C=CC(=CC=2)N(C=2C=CC=CC=2)C=2C=C(C)C=CC=2)=C1 OGGKVJMNFFSDEV-UHFFFAOYSA-N 0.000 description 2

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 2

- YNQLUTRBYVCPMQ-UHFFFAOYSA-N Ethylbenzene Chemical compound CCC1=CC=CC=C1 YNQLUTRBYVCPMQ-UHFFFAOYSA-N 0.000 description 2

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- IMNFDUFMRHMDMM-UHFFFAOYSA-N N-Heptane Chemical compound CCCCCCC IMNFDUFMRHMDMM-UHFFFAOYSA-N 0.000 description 2

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 2

- URLKBWYHVLBVBO-UHFFFAOYSA-N Para-Xylene Chemical group CC1=CC=C(C)C=C1 URLKBWYHVLBVBO-UHFFFAOYSA-N 0.000 description 2

- OFBQJSOFQDEBGM-UHFFFAOYSA-N Pentane Chemical compound CCCCC OFBQJSOFQDEBGM-UHFFFAOYSA-N 0.000 description 2

- 239000005062 Polybutadiene Substances 0.000 description 2

- 229920000292 Polyquinoline Polymers 0.000 description 2

- 239000007983 Tris buffer Substances 0.000 description 2

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 2

- DZBUGLKDJFMEHC-UHFFFAOYSA-N acridine Chemical compound C1=CC=CC2=CC3=CC=CC=C3N=C21 DZBUGLKDJFMEHC-UHFFFAOYSA-N 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- 150000001335 aliphatic alkanes Chemical class 0.000 description 2

- 125000001931 aliphatic group Chemical group 0.000 description 2

- 125000006350 alkyl thio alkyl group Chemical group 0.000 description 2

- 125000002947 alkylene group Chemical group 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 2

- ROOXNKNUYICQNP-UHFFFAOYSA-N ammonium persulfate Chemical compound [NH4+].[NH4+].[O-]S(=O)(=O)OOS([O-])(=O)=O ROOXNKNUYICQNP-UHFFFAOYSA-N 0.000 description 2

- 239000003125 aqueous solvent Substances 0.000 description 2

- 150000004945 aromatic hydrocarbons Chemical class 0.000 description 2

- 125000005110 aryl thio group Chemical group 0.000 description 2

- 125000004104 aryloxy group Chemical group 0.000 description 2

- 239000004305 biphenyl Substances 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 2

- DIKBFYAXUHHXCS-UHFFFAOYSA-N bromoform Chemical compound BrC(Br)Br DIKBFYAXUHHXCS-UHFFFAOYSA-N 0.000 description 2

- 239000003990 capacitor Substances 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- MVPPADPHJFYWMZ-UHFFFAOYSA-N chlorobenzene Chemical compound ClC1=CC=CC=C1 MVPPADPHJFYWMZ-UHFFFAOYSA-N 0.000 description 2

- 239000002322 conducting polymer Substances 0.000 description 2

- MWKFXSUHUHTGQN-UHFFFAOYSA-N decan-1-ol Chemical compound CCCCCCCCCCO MWKFXSUHUHTGQN-UHFFFAOYSA-N 0.000 description 2

- 230000005611 electricity Effects 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- ZQBFAOFFOQMSGJ-UHFFFAOYSA-N hexafluorobenzene Chemical compound FC1=C(F)C(F)=C(F)C(F)=C1F ZQBFAOFFOQMSGJ-UHFFFAOYSA-N 0.000 description 2

- ZSIAUFGUXNUGDI-UHFFFAOYSA-N hexan-1-ol Chemical compound CCCCCCO ZSIAUFGUXNUGDI-UHFFFAOYSA-N 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 229910010272 inorganic material Inorganic materials 0.000 description 2

- 239000011147 inorganic material Substances 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- ZXEKIIBDNHEJCQ-UHFFFAOYSA-N isobutanol Chemical compound CC(C)CO ZXEKIIBDNHEJCQ-UHFFFAOYSA-N 0.000 description 2

- 150000002576 ketones Chemical class 0.000 description 2

- 239000011133 lead Substances 0.000 description 2

- 239000007791 liquid phase Substances 0.000 description 2

- IVSZLXZYQVIEFR-UHFFFAOYSA-N m-xylene Chemical group CC1=CC=CC(C)=C1 IVSZLXZYQVIEFR-UHFFFAOYSA-N 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 229910003455 mixed metal oxide Inorganic materials 0.000 description 2

- 239000000178 monomer Substances 0.000 description 2

- 239000012454 non-polar solvent Substances 0.000 description 2

- BKIMMITUMNQMOS-UHFFFAOYSA-N nonane Chemical compound CCCCCCCCC BKIMMITUMNQMOS-UHFFFAOYSA-N 0.000 description 2

- 229910052763 palladium Inorganic materials 0.000 description 2

- 125000000843 phenylene group Chemical group C1(=C(C=CC=C1)*)* 0.000 description 2

- 229910052697 platinum Inorganic materials 0.000 description 2

- 229920003227 poly(N-vinyl carbazole) Polymers 0.000 description 2

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 2

- 229920000412 polyarylene Polymers 0.000 description 2

- 229920002857 polybutadiene Polymers 0.000 description 2

- 229920000515 polycarbonate Polymers 0.000 description 2

- 239000004417 polycarbonate Substances 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 238000010791 quenching Methods 0.000 description 2

- 230000000171 quenching effect Effects 0.000 description 2

- 239000011541 reaction mixture Substances 0.000 description 2

- 150000003839 salts Chemical class 0.000 description 2

- 239000000523 sample Substances 0.000 description 2

- 239000004065 semiconductor Substances 0.000 description 2

- 239000004984 smart glass Substances 0.000 description 2

- 238000004544 sputter deposition Methods 0.000 description 2

- 238000003756 stirring Methods 0.000 description 2

- 125000001424 substituent group Chemical group 0.000 description 2

- 125000000547 substituted alkyl group Chemical group 0.000 description 2

- 125000000542 sulfonic acid group Chemical group 0.000 description 2

- 125000000472 sulfonyl group Chemical group *S(*)(=O)=O 0.000 description 2

- VZGDMQKNWNREIO-UHFFFAOYSA-N tetrachloromethane Chemical compound ClC(Cl)(Cl)Cl VZGDMQKNWNREIO-UHFFFAOYSA-N 0.000 description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 239000010937 tungsten Substances 0.000 description 2

- 238000007740 vapor deposition Methods 0.000 description 2

- 239000008096 xylene Substances 0.000 description 2

- 229910052725 zinc Inorganic materials 0.000 description 2

- 239000011701 zinc Substances 0.000 description 2

- ZPQOPVIELGIULI-UHFFFAOYSA-N 1,3-dichlorobenzene Chemical compound ClC1=CC=CC(Cl)=C1 ZPQOPVIELGIULI-UHFFFAOYSA-N 0.000 description 1

- OCJBOOLMMGQPQU-UHFFFAOYSA-N 1,4-dichlorobenzene Chemical compound ClC1=CC=C(Cl)C=C1 OCJBOOLMMGQPQU-UHFFFAOYSA-N 0.000 description 1

- 125000001140 1,4-phenylene group Chemical group [H]C1=C([H])C([*:2])=C([H])C([H])=C1[*:1] 0.000 description 1

- 125000004973 1-butenyl group Chemical group C(=CCC)* 0.000 description 1

- 125000006039 1-hexenyl group Chemical group 0.000 description 1

- 125000004066 1-hydroxyethyl group Chemical group [H]OC([H])([*])C([H])([H])[H] 0.000 description 1

- 125000006023 1-pentenyl group Chemical group 0.000 description 1

- 125000006017 1-propenyl group Chemical group 0.000 description 1

- MQNZNTNCDRVGFD-UHFFFAOYSA-N 2,5-dichloroaniline 3-hexylaniline Chemical compound ClC1=C(N)C=C(C=C1)Cl.C(CCCCC)C=1C=C(N)C=CC1 MQNZNTNCDRVGFD-UHFFFAOYSA-N 0.000 description 1

- STTGYIUESPWXOW-UHFFFAOYSA-N 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline Chemical compound C=12C=CC3=C(C=4C=CC=CC=4)C=C(C)N=C3C2=NC(C)=CC=1C1=CC=CC=C1 STTGYIUESPWXOW-UHFFFAOYSA-N 0.000 description 1

- QQZOPKMRPOGIEB-UHFFFAOYSA-N 2-Oxohexane Chemical compound CCCCC(C)=O QQZOPKMRPOGIEB-UHFFFAOYSA-N 0.000 description 1

- WBIQQQGBSDOWNP-UHFFFAOYSA-N 2-dodecylbenzenesulfonic acid Chemical compound CCCCCCCCCCCCC1=CC=CC=C1S(O)(=O)=O WBIQQQGBSDOWNP-UHFFFAOYSA-N 0.000 description 1

- DUIPSSGFPNDNGH-UHFFFAOYSA-N 2-methyl-2-(prop-1-enylamino)propane-1-sulfonic acid Chemical compound CC=CNC(C)(C)CS(O)(=O)=O DUIPSSGFPNDNGH-UHFFFAOYSA-N 0.000 description 1

- WMIQWIJPGVVMII-UHFFFAOYSA-N 3-butylaniline Chemical compound CCCCC1=CC=CC(N)=C1 WMIQWIJPGVVMII-UHFFFAOYSA-N 0.000 description 1

- OBNZIMFKLILQCF-UHFFFAOYSA-N 3-octylaniline Chemical compound CCCCCCCCC1=CC=CC(N)=C1 OBNZIMFKLILQCF-UHFFFAOYSA-N 0.000 description 1

- DHDHJYNTEFLIHY-UHFFFAOYSA-N 4,7-diphenyl-1,10-phenanthroline Chemical compound C1=CC=CC=C1C1=CC=NC2=C1C=CC1=C(C=3C=CC=CC=3)C=CN=C21 DHDHJYNTEFLIHY-UHFFFAOYSA-N 0.000 description 1

- KBXXZTIBAVBLPP-UHFFFAOYSA-N 4-[[4-(diethylamino)-2-methylphenyl]-(4-methylphenyl)methyl]-n,n-diethyl-3-methylaniline Chemical compound CC1=CC(N(CC)CC)=CC=C1C(C=1C(=CC(=CC=1)N(CC)CC)C)C1=CC=C(C)C=C1 KBXXZTIBAVBLPP-UHFFFAOYSA-N 0.000 description 1

- DWJXWSIJKSXJJA-UHFFFAOYSA-N 4-n-[4-(4-aminoanilino)phenyl]benzene-1,4-diamine Chemical compound C1=CC(N)=CC=C1NC(C=C1)=CC=C1NC1=CC=C(N)C=C1 DWJXWSIJKSXJJA-UHFFFAOYSA-N 0.000 description 1

- FILGCRVITUCSOH-UHFFFAOYSA-N 5-chloro-2-ethoxyaniline;4-phenoxyaniline Chemical compound CCOC1=CC=C(Cl)C=C1N.C1=CC(N)=CC=C1OC1=CC=CC=C1 FILGCRVITUCSOH-UHFFFAOYSA-N 0.000 description 1

- VFUDMQLBKNMONU-UHFFFAOYSA-N 9-[4-(4-carbazol-9-ylphenyl)phenyl]carbazole Chemical group C12=CC=CC=C2C2=CC=CC=C2N1C1=CC=C(C=2C=CC(=CC=2)N2C3=CC=CC=C3C3=CC=CC=C32)C=C1 VFUDMQLBKNMONU-UHFFFAOYSA-N 0.000 description 1

- JBRZTFJDHDCESZ-UHFFFAOYSA-N AsGa Chemical compound [As]#[Ga] JBRZTFJDHDCESZ-UHFFFAOYSA-N 0.000 description 1

- QDUHPYYPJZAZSE-UHFFFAOYSA-N C(#N)C1=C(N)C=CC=C1.C(C)OC1=C(N)C=CC=C1.C1(CCCC2=CC=CC=C12)N Chemical compound C(#N)C1=C(N)C=CC=C1.C(C)OC1=C(N)C=CC=C1.C1(CCCC2=CC=CC=C12)N QDUHPYYPJZAZSE-UHFFFAOYSA-N 0.000 description 1

- PQFGKNYGWLDLAM-UHFFFAOYSA-N C(C)C1=C(N)C=CC=C1.C(CCC)C1=C(N)C=C(C=C1)CCCC.NC1=CC(=CC=C1)C Chemical compound C(C)C1=C(N)C=CC=C1.C(CCC)C1=C(N)C=C(C=C1)CCCC.NC1=CC(=CC=C1)C PQFGKNYGWLDLAM-UHFFFAOYSA-N 0.000 description 1

- GYNWARMZSRTBIA-LNVDRNJUSA-N C1[C@H](C([C@@H](CC1(C(=O)O)OO)O)O)O Chemical compound C1[C@H](C([C@@H](CC1(C(=O)O)OO)O)O)O GYNWARMZSRTBIA-LNVDRNJUSA-N 0.000 description 1

- MRBXDGAORSRDOU-UHFFFAOYSA-N CC1=C(N)C=CC=C1C.NC=1C(=CC=CC1)C.CC1=C(N)C=C(C=C1)C.NC1=CC=CC=C1 Chemical compound CC1=C(N)C=CC=C1C.NC=1C(=CC=CC1)C.CC1=C(N)C=C(C=C1)C.NC1=CC=CC=C1 MRBXDGAORSRDOU-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 102100032373 Coiled-coil domain-containing protein 85B Human genes 0.000 description 1

- SNRUBQQJIBEYMU-UHFFFAOYSA-N Dodecane Natural products CCCCCCCCCCCC SNRUBQQJIBEYMU-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- 229910001218 Gallium arsenide Inorganic materials 0.000 description 1

- 101000868814 Homo sapiens Coiled-coil domain-containing protein 85B Proteins 0.000 description 1

- JHWNWJKBPDFINM-UHFFFAOYSA-N Laurolactam Chemical compound O=C1CCCCCCCCCCCN1 JHWNWJKBPDFINM-UHFFFAOYSA-N 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- 229920000299 Nylon 12 Polymers 0.000 description 1

- 229920002292 Nylon 6 Polymers 0.000 description 1

- 229920000144 PEDOT:PSS Polymers 0.000 description 1

- NBIIXXVUZAFLBC-UHFFFAOYSA-L Phosphate ion(2-) Chemical compound OP([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-L 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000002202 Polyethylene glycol Substances 0.000 description 1

- 229920000265 Polyparaphenylene Polymers 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 241001126918 Sycon Species 0.000 description 1

- DGEZNRSVGBDHLK-UHFFFAOYSA-N [1,10]phenanthroline Chemical compound C1=CN=C2C3=NC=CC=C3C=CC2=C1 DGEZNRSVGBDHLK-UHFFFAOYSA-N 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 229920006322 acrylamide copolymer Polymers 0.000 description 1

- 229920006397 acrylic thermoplastic Polymers 0.000 description 1

- 229910052768 actinide Inorganic materials 0.000 description 1

- 150000001255 actinides Chemical class 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 125000002723 alicyclic group Chemical group 0.000 description 1

- 229910052783 alkali metal Inorganic materials 0.000 description 1

- 150000001340 alkali metals Chemical class 0.000 description 1

- 229910052784 alkaline earth metal Inorganic materials 0.000 description 1

- 150000001342 alkaline earth metals Chemical class 0.000 description 1

- 125000003282 alkyl amino group Chemical group 0.000 description 1

- 229910001870 ammonium persulfate Inorganic materials 0.000 description 1

- YIAKBAQHIPSYRH-UHFFFAOYSA-N aniline 4-bromoaniline Chemical compound BrC1=CC=C(N)C=C1.NC1=CC=CC=C1 YIAKBAQHIPSYRH-UHFFFAOYSA-N 0.000 description 1

- 125000005160 aryl oxy alkyl group Chemical group 0.000 description 1

- 125000005135 aryl sulfinyl group Chemical group 0.000 description 1

- 125000005325 aryloxy aryl group Chemical group 0.000 description 1

- 239000002585 base Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 150000001555 benzenes Chemical class 0.000 description 1

- SRSXLGNVWSONIS-UHFFFAOYSA-N benzenesulfonic acid Chemical compound OS(=O)(=O)C1=CC=CC=C1 SRSXLGNVWSONIS-UHFFFAOYSA-N 0.000 description 1

- 229940092714 benzenesulfonic acid Drugs 0.000 description 1

- 125000001797 benzyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C([H])([H])* 0.000 description 1

- 239000003012 bilayer membrane Substances 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 235000010290 biphenyl Nutrition 0.000 description 1

- KGBXLFKZBHKPEV-UHFFFAOYSA-N boric acid Chemical compound OB(O)O KGBXLFKZBHKPEV-UHFFFAOYSA-N 0.000 description 1

- 239000004327 boric acid Substances 0.000 description 1

- 229950005228 bromoform Drugs 0.000 description 1

- 239000013590 bulk material Substances 0.000 description 1

- QDHFHIQKOVNCNC-UHFFFAOYSA-N butane-1-sulfonic acid Chemical compound CCCCS(O)(=O)=O QDHFHIQKOVNCNC-UHFFFAOYSA-N 0.000 description 1

- 125000004744 butyloxycarbonyl group Chemical group 0.000 description 1

- 125000002837 carbocyclic group Chemical group 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 150000001721 carbon Chemical group 0.000 description 1

- 125000002843 carboxylic acid group Chemical group 0.000 description 1

- 150000001735 carboxylic acids Chemical class 0.000 description 1

- 239000012876 carrier material Substances 0.000 description 1

- 239000010406 cathode material Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 150000001893 coumarin derivatives Chemical class 0.000 description 1

- 239000006059 cover glass Substances 0.000 description 1

- 150000001924 cycloalkanes Chemical class 0.000 description 1

- 125000000582 cycloheptyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 125000000596 cyclohexenyl group Chemical group C1(=CCCCC1)* 0.000 description 1

- 125000000113 cyclohexyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 125000000640 cyclooctyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C([H])([H])C1([H])[H] 0.000 description 1

- 125000002433 cyclopentenyl group Chemical group C1(=CCCC1)* 0.000 description 1

- 125000001511 cyclopentyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 1

- DIOQZVSQGTUSAI-NJFSPNSNSA-N decane Chemical compound CCCCCCCCC[14CH3] DIOQZVSQGTUSAI-NJFSPNSNSA-N 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 125000004663 dialkyl amino group Chemical group 0.000 description 1

- LVTYICIALWPMFW-UHFFFAOYSA-N diisopropanolamine Chemical compound CC(O)CNCC(C)O LVTYICIALWPMFW-UHFFFAOYSA-N 0.000 description 1

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 229940060296 dodecylbenzenesulfonic acid Drugs 0.000 description 1

- 239000002019 doping agent Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005566 electron beam evaporation Methods 0.000 description 1

- 239000012776 electronic material Substances 0.000 description 1

- 125000003700 epoxy group Chemical group 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- CCIVGXIOQKPBKL-UHFFFAOYSA-N ethanesulfonic acid Chemical group CCS(O)(=O)=O CCIVGXIOQKPBKL-UHFFFAOYSA-N 0.000 description 1

- 125000002573 ethenylidene group Chemical group [*]=C=C([H])[H] 0.000 description 1

- 125000001301 ethoxy group Chemical group [H]C([H])([H])C([H])([H])O* 0.000 description 1

- 125000003754 ethoxycarbonyl group Chemical group C(=O)(OCC)* 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 125000002541 furyl group Chemical group 0.000 description 1

- 229910052732 germanium Inorganic materials 0.000 description 1

- GNPVGFCGXDBREM-UHFFFAOYSA-N germanium atom Chemical compound [Ge] GNPVGFCGXDBREM-UHFFFAOYSA-N 0.000 description 1

- 150000004676 glycans Chemical class 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 150000008282 halocarbons Chemical class 0.000 description 1

- 125000000623 heterocyclic group Chemical group 0.000 description 1

- 230000005525 hole transport Effects 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 1

- QYHFIVBSNOWOCQ-UHFFFAOYSA-M hydrogenselenate Chemical compound O[Se]([O-])(=O)=O QYHFIVBSNOWOCQ-UHFFFAOYSA-M 0.000 description 1

- QAOWNCQODCNURD-UHFFFAOYSA-M hydrogensulfate Chemical compound OS([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-M 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- AMGQUBHHOARCQH-UHFFFAOYSA-N indium;oxotin Chemical compound [In].[Sn]=O AMGQUBHHOARCQH-UHFFFAOYSA-N 0.000 description 1

- 238000007641 inkjet printing Methods 0.000 description 1

- 229910052809 inorganic oxide Inorganic materials 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 230000001678 irradiating effect Effects 0.000 description 1

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- 229910052747 lanthanoid Inorganic materials 0.000 description 1

- 150000002602 lanthanoids Chemical class 0.000 description 1

- 229910000464 lead oxide Inorganic materials 0.000 description 1

- 229920000763 leucoemeraldine polymer Polymers 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 238000004020 luminiscence type Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 238000010128 melt processing Methods 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 125000001160 methoxycarbonyl group Chemical group [H]C([H])([H])OC(*)=O 0.000 description 1

- 125000004184 methoxymethyl group Chemical group [H]C([H])([H])OC([H])([H])* 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- 125000006216 methylsulfinyl group Chemical group [H]C([H])([H])S(*)=O 0.000 description 1

- 125000004170 methylsulfonyl group Chemical group [H]C([H])([H])S(*)(=O)=O 0.000 description 1

- 239000012046 mixed solvent Substances 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- DIOQZVSQGTUSAI-UHFFFAOYSA-N n-butylhexane Natural products CCCCCCCCCC DIOQZVSQGTUSAI-UHFFFAOYSA-N 0.000 description 1

- 125000001971 neopentyl group Chemical group [H]C([*])([H])C(C([H])([H])[H])(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 239000012457 nonaqueous media Substances 0.000 description 1

- 229910052755 nonmetal Inorganic materials 0.000 description 1

- 125000001400 nonyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- TVMXDCGIABBOFY-UHFFFAOYSA-N octane Chemical compound CCCCCCCC TVMXDCGIABBOFY-UHFFFAOYSA-N 0.000 description 1

- 125000002347 octyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- WCPAKWJPBJAGKN-UHFFFAOYSA-N oxadiazole Chemical compound C1=CON=N1 WCPAKWJPBJAGKN-UHFFFAOYSA-N 0.000 description 1

- YEXPOXQUZXUXJW-UHFFFAOYSA-N oxolead Chemical compound [Pb]=O YEXPOXQUZXUXJW-UHFFFAOYSA-N 0.000 description 1

- 125000004430 oxygen atom Chemical group O* 0.000 description 1

- 125000000636 p-nitrophenyl group Chemical group [H]C1=C([H])C(=C([H])C([H])=C1*)[N+]([O-])=O 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- CBHCDHNUZWWAPP-UHFFFAOYSA-N pecazine Chemical compound C1N(C)CCCC1CN1C2=CC=CC=C2SC2=CC=CC=C21 CBHCDHNUZWWAPP-UHFFFAOYSA-N 0.000 description 1

- XNLICIUVMPYHGG-UHFFFAOYSA-N pentan-2-one Chemical compound CCCC(C)=O XNLICIUVMPYHGG-UHFFFAOYSA-N 0.000 description 1

- 229950011087 perflunafene Drugs 0.000 description 1

- UWEYRJFJVCLAGH-IJWZVTFUSA-N perfluorodecalin Chemical compound FC1(F)C(F)(F)C(F)(F)C(F)(F)[C@@]2(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)[C@@]21F UWEYRJFJVCLAGH-IJWZVTFUSA-N 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- ZUOUZKKEUPVFJK-UHFFFAOYSA-N phenylbenzene Natural products C1=CC=CC=C1C1=CC=CC=C1 ZUOUZKKEUPVFJK-UHFFFAOYSA-N 0.000 description 1

- 229920002120 photoresistant polymer Polymers 0.000 description 1

- 239000002798 polar solvent Substances 0.000 description 1

- 229920000112 poly(2,5-bis(cholestanoxy) phenylene vinylene) Polymers 0.000 description 1

- 229920000548 poly(silane) polymer Polymers 0.000 description 1

- 229920001467 poly(styrenesulfonates) Polymers 0.000 description 1

- 229920002432 poly(vinyl methyl ether) polymer Polymers 0.000 description 1

- 229920000552 poly[2-methoxy-5-(2'-ethyl-hexyloxy)-p-phenylenevinylene] polymer Polymers 0.000 description 1

- 239000004584 polyacrylic acid Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000768 polyamine Polymers 0.000 description 1

- 229920001707 polybutylene terephthalate Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 229920001195 polyisoprene Polymers 0.000 description 1

- 238000010094 polymer processing Methods 0.000 description 1

- 239000004926 polymethyl methacrylate Substances 0.000 description 1

- 229920001282 polysaccharide Polymers 0.000 description 1

- 239000005017 polysaccharide Substances 0.000 description 1

- 229920003009 polyurethane dispersion Polymers 0.000 description 1

- 229920002717 polyvinylpyridine Polymers 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 239000002243 precursor Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 125000002924 primary amino group Chemical group [H]N([H])* 0.000 description 1

- BDERNNFJNOPAEC-UHFFFAOYSA-N propan-1-ol Chemical compound CCCO BDERNNFJNOPAEC-UHFFFAOYSA-N 0.000 description 1

- KCXFHTAICRTXLI-UHFFFAOYSA-N propane-1-sulfonic acid Chemical compound CCCS(O)(=O)=O KCXFHTAICRTXLI-UHFFFAOYSA-N 0.000 description 1

- 125000006225 propoxyethyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])OC([H])([H])C([H])([H])* 0.000 description 1

- 125000004076 pyridyl group Chemical group 0.000 description 1

- 150000003233 pyrroles Chemical class 0.000 description 1

- 125000000168 pyrrolyl group Chemical group 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 229910052761 rare earth metal Inorganic materials 0.000 description 1

- 150000002910 rare earth metals Chemical class 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 229920003252 rigid-rod polymer Polymers 0.000 description 1

- 239000010980 sapphire Substances 0.000 description 1

- 229910052594 sapphire Inorganic materials 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 125000002914 sec-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- QYHFIVBSNOWOCQ-UHFFFAOYSA-N selenic acid Chemical compound O[Se](O)(=O)=O QYHFIVBSNOWOCQ-UHFFFAOYSA-N 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- PJANXHGTPQOBST-UHFFFAOYSA-N stilbene Chemical class C=1C=CC=CC=1C=CC1=CC=CC=C1 PJANXHGTPQOBST-UHFFFAOYSA-N 0.000 description 1

- 229910052712 strontium Inorganic materials 0.000 description 1

- CIOAGBVUUVVLOB-UHFFFAOYSA-N strontium atom Chemical compound [Sr] CIOAGBVUUVVLOB-UHFFFAOYSA-N 0.000 description 1

- 125000000475 sulfinyl group Chemical group [*:2]S([*:1])=O 0.000 description 1

- BDHFUVZGWQCTTF-UHFFFAOYSA-M sulfonate Chemical compound [O-]S(=O)=O BDHFUVZGWQCTTF-UHFFFAOYSA-M 0.000 description 1

- 150000003460 sulfonic acids Chemical class 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- ISXSCDLOGDJUNJ-UHFFFAOYSA-N tert-butyl prop-2-enoate Chemical compound CC(C)(C)OC(=O)C=C ISXSCDLOGDJUNJ-UHFFFAOYSA-N 0.000 description 1

- 125000001544 thienyl group Chemical group 0.000 description 1

- 125000005556 thienylene group Chemical group 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 229910052723 transition metal Inorganic materials 0.000 description 1

- 150000003624 transition metals Chemical class 0.000 description 1

- 125000002023 trifluoromethyl group Chemical group FC(F)(F)* 0.000 description 1

- 238000007738 vacuum evaporation Methods 0.000 description 1

- PXXNTAGJWPJAGM-UHFFFAOYSA-N vertaline Natural products C1C2C=3C=C(OC)C(OC)=CC=3OC(C=C3)=CC=C3CCC(=O)OC1CC1N2CCCC1 PXXNTAGJWPJAGM-UHFFFAOYSA-N 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 229910052727 yttrium Inorganic materials 0.000 description 1

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B33/00—Electroluminescent light sources

- H05B33/12—Light sources with substantially two-dimensional radiating surfaces

- H05B33/26—Light sources with substantially two-dimensional radiating surfaces characterised by the composition or arrangement of the conductive material used as an electrode

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K59/00—Integrated devices, or assemblies of multiple devices, comprising at least one organic light-emitting element covered by group H10K50/00

- H10K59/80—Constructional details

- H10K59/805—Electrodes

- H10K59/8051—Anodes

- H10K59/80517—Multilayers, e.g. transparent multilayers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K50/00—Organic light-emitting devices

- H10K50/10—OLEDs or polymer light-emitting diodes [PLED]

- H10K50/17—Carrier injection layers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K50/00—Organic light-emitting devices

- H10K50/80—Constructional details

- H10K50/805—Electrodes

- H10K50/81—Anodes

- H10K50/816—Multilayers, e.g. transparent multilayers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K50/00—Organic light-emitting devices

- H10K50/10—OLEDs or polymer light-emitting diodes [PLED]

- H10K50/17—Carrier injection layers

- H10K50/171—Electron injection layers

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K59/00—Integrated devices, or assemblies of multiple devices, comprising at least one organic light-emitting element covered by group H10K50/00

- H10K59/10—OLED displays

- H10K59/17—Passive-matrix OLED displays

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Electroluminescent Light Sources (AREA)

- Photovoltaic Devices (AREA)

- Led Devices (AREA)

Abstract

本发明描述用于电子器件(100)如聚合物发光二极管的多层阳极结构(104)。该多层阳极包括一个与光活性层(102)邻接的高电导率有机层(114)和一个介于高电导率有机层与阳极的电连接层(110)之间的低电导率层(112)。该阳极结构使聚合物发光二极管具有高亮度、高效率和长工作寿命。本发明多层阳极结构的电阻率高到足以避免在无源寻址象素化聚合物发光显示器中发生串扰;本发明的多层阳极结构同时使象素化聚合物发光显示器具有长寿命。

The present invention describes a multilayer anode structure (104) for an electronic device (100) such as a polymer light emitting diode. The multilayer anode includes a high conductivity organic layer (114) adjacent to the photoactive layer (102) and a low conductivity layer (112) between the high conductivity organic layer and the anode's electrical connection layer (110). ). The anode structure enables the polymer light-emitting diode to have high brightness, high efficiency and long working life. The resistivity of the multilayer anode structure of the present invention is high enough to avoid crosstalk in passively addressed pixelated polymer light emitting displays; the multilayer anode structure of the present invention also enables long lifetime of the pixelated polymer light emitting displays.

Description

发明领域 field of invention

本发明涉及有机电子器件。更具体地说,它涉及用于电子器件的多层空穴-注入电极(阳极)。The present invention relates to organic electronic devices. More specifically, it relates to multilayer hole-injecting electrodes (anodes) for electronic devices.

现有技术描述 Description of prior art

有机电子器件,如发光二极管、光电探测器和光伏电池等,可以由一薄层夹在两个电接触层之间的电活性(electroactive)有机材料形成。电活性有机材料是呈现电致发光、光敏性、电荷(空穴或电子)输运和/或注入、电导率和/或激子阻塞的有机材料。这种材料可以是半导体。电接触层中至少一层对光透明,因而光可以透过电接触层到达或来自电活性有机材料层。具有类似结构的其它器件包括光电导管、光致抗蚀池、光电二极管、光控开关、晶体管、电容器、电阻器、化学电阻传感器(气/蒸气敏感电子探头、化学与生物传感器)、写入传感器和电致变色器件(智能窗)。Organic electronic devices, such as light-emitting diodes, photodetectors, and photovoltaic cells, can be formed from a thin layer of electroactive organic material sandwiched between two electrical contact layers. Electroactive organic materials are organic materials that exhibit electroluminescence, photosensitivity, charge (hole or electron) transport and/or injection, electrical conductivity and/or exciton blocking. This material can be a semiconductor. At least one of the electrical contact layers is transparent to light so that light can pass through the electrical contact layer to or from the layer of electroactive organic material. Other devices with similar structures include photoconductors, photoresist cells, photodiodes, photoswitches, transistors, capacitors, resistors, chemi-resistive sensors (gas/vapor sensitive electronic probes, chemical and biological sensors), write-in sensors and electrochromic devices (smart windows).

以共轭有机聚合物层作为发光元件的发光二极管(LED)因它们在显示技术中的潜在用途而引起了人们的关注[J.H.Burroughs,D.D.C.Bradley,A.R.Brown,R.N.Marks,K.Mackay,R.H.Friend,P.L.Burns和A.B.Holmes,Nature347,539(1990);D.Braun和A.J.Heeger,Appl.Phys.Lett.,58,1982(1991)]。有关聚合物LED的专利包括如下:R.H.Friend,J.H.Burroughs和D.D.Bradley,美国专利5,247,190;.J.Heeger和D.Braun,美国专利5,408,109和5,869,350。上述文献和本文引用的所有其它文章、专利和专利申请等都包括于此供参考。Light-emitting diodes (LEDs) with conjugated organic polymer layers as light-emitting elements have attracted attention for their potential use in display technology [J.H. Burroughs, D.D.C. Bradley, A.R. Brown, R.N. Marks, K. Mackay, R.H. Friend , P.L. Burns and A.B. Holmes, Nature 347, 539 (1990); D. Braun and A.J. Heeger, Appl. Phys. Lett., 58, 1982 (1991)]. Patents related to polymer LEDs include the following: R.H. Friend, J.H. Burroughs and D.D. Bradley, US Patent 5,247,190; J. Heeger and D. Braun, US Patents 5,408,109 and 5,869,350. The above references and all other articles, patents, patent applications, etc. cited herein are hereby incorporated by reference.

在这些二极管最基本的形式中,使用一层其一面粘结有空穴-注入电极(阳极),其另一面粘结有电子-注入电极(阴极)的共轭有机聚合物层,两极之中有一个对共轭聚合物层受电压作用时所产生的光透明。In the most basic form of these diodes, a layer of a conjugated organic polymer is used with a hole-injecting electrode (anode) bonded to one side and an electron-injecting electrode (cathode) bonded to the other, with There is a transparency to the light generated when the conjugated polymer layer is subjected to a voltage.

在许多应用中,特别在显示器中,要集成这类二极管的阵列。在这些应用中,一般有一个活性聚合物的单元体,而且电极要图形化(Patterned),以使阵列中具有所需的大量象素。利用基于活性聚合物单元体的阵列和图形化的电极,需要尽量减小相邻象素间的干扰或“串扰(cross talk)”。这一需要已通过改变活性聚合物体和电极间的接触性质而得以解决。In many applications, especially in displays, arrays of such diodes are integrated. In these applications, there is generally a unit body of the active polymer, and the electrodes are patterned so that the array has the desired number of pixels. With active polymer monomer-based arrays and patterned electrodes, there is a need to minimize interference or "cross talk" between adjacent pixels. This need has been addressed by changing the nature of the contact between the active polymer body and the electrodes.

希望提高工作寿命和效率与希望尽量减少“串扰”似乎常常相互矛盾。利用与活性材料的高电导率接触会促进高效与长工作寿命。而相邻象素间的电阻高时,能把“串扰”尽量抑制到最小。有利于高电导率从而高效与长工作寿命的结构恰好与低“串扰”所优选的条件相矛盾。The desire to increase operating life and efficiency and the desire to minimize "crosstalk" often seem to be at odds. Utilizing high conductivity contacts to the active material promotes high efficiency and long operating life. When the resistance between adjacent pixels is high, the "crosstalk" can be suppressed to a minimum. A structure that favors high conductivity and thus high efficiency and long operating life is precisely at odds with the conditions preferred for low "crosstalk".

据美国专利5,723,873公开,在空穴-注入电极与活性材料之间放置一层导电聚苯胺(PANI)有利于提高二极管的效率并降低二极管的开启电压。According to US Patent No. 5,723,873, placing a layer of conductive polyaniline (PANI) between the hole-injecting electrode and the active material is beneficial to improve the efficiency of the diode and reduce the turn-on voltage of the diode.

包括导电聚苯胺在内的空穴-注入阳极能提供足够高的电阻以避免在象素化聚合物发光显示器中发生“串扰”的缺点。但是这类高阻聚苯胺器件的寿命对许多工业应用来都不够长。而且用含聚苯胺层阳极制造的器件需要高的工作电压。Hole-injecting anodes, including conductive polyaniline, can provide sufficiently high resistance to avoid the disadvantage of "crosstalk" in pixelated polymer light-emitting displays. But the lifetime of such high-resistance polyaniline devices is not long enough for many industrial applications. Furthermore, devices fabricated with anodes containing polyaniline layers require high operating voltages.

C.Zhang,G.Yu和Y.Cao[美国专利5,798,170]在ITO和发光聚合物层之间使用一层聚苯胺或包含聚苯胺的共混物的进一步发展证明聚合物LED具有长工作寿命。Further developments by C. Zhang, G. Yu, and Y. Cao [US Patent 5,798,170] using a layer of polyaniline or a blend containing polyaniline between the ITO and light-emitting polymer layers demonstrated long operating lifetimes for polymer LEDs.

尽管有美国专利5,798,170中所述的聚合物LED的优点,但聚苯胺典型的低电阻仍阻碍聚苯胺用于象素化显示器中。为用于象素化显示器中,聚苯胺层应具有高片电阻,否则横向电导会造成相邻象素间的串扰。所造成的象素问的漏电会大大削弱功效并限制显示的分辨率和清晰度。Despite the advantages of polymer LEDs described in US Pat. No. 5,798,170, the typically low electrical resistance of polyaniline prevents polyaniline from being used in pixelated displays. For use in pixelated displays, the polyaniline layer should have a high sheet resistance, otherwise the lateral conductance will cause crosstalk between adjacent pixels. The resulting leakage between pixels can greatly impair efficacy and limit the resolution and clarity of the display.

要通过降低薄膜厚度来提高聚苯胺的片电阻并非一个良好的选择,因为较薄的膜因形成电短路而降低制造产率。这一点在图1中表达得很清楚,该图示意了在一个96×64阵列中“漏电”象素的分数与聚苯胺共混层厚度的关系。因此,为避免短路,有必要使用厚度~200nm的较厚聚苯胺层。It is not a good choice to increase the sheet resistance of polyaniline by reducing the film thickness, because the thinner film reduces the manufacturing yield due to the formation of electrical shorts. This is clearly shown in Figure 1, which shows the fraction of "leakage" pixels in a 96x64 array as a function of the polyaniline blend layer thickness. Therefore, to avoid short circuits, it is necessary to use a thicker polyaniline layer with a thickness of ~200 nm.

在聚合物发光显示器中,良好的工作寿命和较低的工作电压已通过在铟/锡氧化物(ITO)阳极层与发光聚合物层之间使用一层聚亚乙二氧基噻吩(PEDT)而实现了。PEDT,如一般制造的那样,固有地具有低电阻率。但是,为用于象素化显示器,该PEDT层需要有一个高片电阻,否则横向电导会造成相邻象素间的串扰,而所造成的象素间的漏电则会大大削弱功效并限制显示器的分辨率和清晰度。In polymer light-emitting displays, good operating lifetime and low operating voltage have been achieved by using a layer of polyethylenedioxythiophene (PEDT) between the indium/tin oxide (ITO) anode layer and the light-emitting polymer layer. And realized. PEDT, as commonly manufactured, inherently has low resistivity. However, for use in pixelated displays, the PEDT layer needs to have a high sheet resistance, otherwise the lateral conductance would cause crosstalk between adjacent pixels, and the resulting leakage between pixels would greatly impair efficacy and limit the display. resolution and clarity.

因此,目前需要有用于满足工业应用所需发光器件中的阳极结构,它能避免象素间的串扰且具有低工作电压和更长的工作寿命。Therefore, there is currently a need for an anode structure in a light emitting device meeting the requirements of industrial applications, which can avoid crosstalk between pixels and has a low operating voltage and a longer operating life.

发明概述 Summary of the invention

本发明一般地涉及一种适用于有机电子器件如二极管和象素化显示器的多层阳极结构。The present invention generally relates to a multilayer anode structure suitable for use in organic electronic devices such as diodes and pixelated displays.

所述多层阳极包括一个第一层、一个与第一层接触的第二层和一个与第二层接触的第三层,所述第一层包含一层具有第一层电导率的高电导率接触层,所述第二层包含一种具有第二层电导率的导电有机材料,所述第三层包含一种具有第三层电导率的导电有机聚合物,该第三层电导率高于第二层电导率而低于第一层电导率。The multilayer anode comprises a first layer, a second layer in contact with the first layer and a third layer in contact with the second layer, the first layer comprising a layer of high electrical conductivity having the electrical conductivity of the first layer high rate contact layer, the second layer comprising a conductive organic material having a second layer conductivity, the third layer comprising a conductive organic polymer having a third layer conductivity, the third layer having a high conductivity The conductivity of the second layer is lower than that of the first layer.

该多层结构提供足够高的电阻以避免在无源寻址象素化聚合物发光显示器中发生串扰;本发明的多层阳极结构同时还为工业应用中的象素化聚合物发光显示器提供所需的低工作电压和长工作寿命。The multilayer structure provides high enough electrical resistance to avoid crosstalk in passively addressed pixelated polymer light emitting displays; the multilayer anode structure of the present invention also provides the desired resistance for pixelated polymer light emitting displays in industrial applications. The required low working voltage and long working life.

本发明还为电子器件如象素化聚合物发光显示器提供一种改进的构型。这种构型在避免过度串扰的同时还导致高效、长工作寿命的PED。本发明一般地涉及多层阳极结构在这类器件中的应用。因此,一方面,本发明提供一种改进的聚合物发光二极管。这种改进的二极管由一层其第一面与阴极接触,第二面与透明阳极接触的活性发光聚合物层制成。所述改进包括一个由高电导率透明第一接触层制成的多层透明阳极本身、一个与第一接触层接触的透明第二层和一个与第二层和活性发光聚合物层接触的第三层。第二层含有共轭导电有机聚合物共混物并具有高电阻。第三层很薄且含有一种电阻低于第二层材料的导电有机聚合物。The present invention also provides an improved configuration for electronic devices such as pixelated polymer light emitting displays. This configuration also results in a highly efficient, long operating lifetime PED while avoiding excessive crosstalk. The present invention generally relates to the use of multilayer anode structures in such devices. Thus, in one aspect, the present invention provides an improved polymer light emitting diode. The improved diode is made from a layer of an active light-emitting polymer whose first side is in contact with the cathode and whose second side is in contact with the transparent anode. The improvement includes a multilayer transparent anode itself made of a high conductivity transparent first contact layer, a transparent second layer in contact with the first contact layer, and a third layer in contact with the second layer and the active light-emitting polymer layer. three floors. The second layer contains a conjugated conductive organic polymer blend and has high electrical resistance. The third layer is thin and contains a conductive organic polymer that has a lower electrical resistance than the material of the second layer.

虽然本发明的多层电极同时适用于非象素化和象素化电子器件,但使用这类改进的多层电极结构,在许多二极管排列成如象素化发光显示器中出现的那种阵列时特别有利,因为该阳极结构使串扰水平降到很低,同时又使寿命和效率比此前所述的阵列更长更高。Although the multilayer electrodes of the present invention are suitable for use in both non-pixelated and pixelated electronic devices, using such improved multilayer electrode structures, when many diodes are arranged in an array such as occurs in pixelated light-emitting displays This is particularly advantageous because the anode structure minimizes the level of crosstalk while allowing longer and higher efficiencies than previously described arrays.

在这一方面,本发明提供一种聚合物发光二极管的改进阵列。这种改进的二极管阵列由第一面与图形化阴极接触和第二面与图形化透明阳极接触的活性发光聚合物层制成,阳极和阴极的图形化决定发光二极管的阵列,所述改进包括一个多层透明阳极,阳极包括一层包含一层图形化高电导率透明接触层的第一层、一层与所述第一层接触的非图形化第二层以及一层与第二层和活性发光聚合物层接触的非图形化第三层,所述第二层包含一种共轭导电有机聚合物共混物并具有较高的电阻(较低的电导率),所述第三层包含一种导电有机聚合物且电阻低于(电导率高于)第二层。In this aspect, the present invention provides an improved array of polymer light emitting diodes. This improved diode array is made of an active light emitting polymer layer with a first face contacting a patterned cathode and a second face contacting a patterned transparent anode, the patterning of the anode and cathode determining the array of light emitting diodes, said modification comprising A multilayer transparent anode comprising a first layer comprising a patterned high-conductivity transparent contact layer, a non-patterned second layer in contact with said first layer, and a layer in contact with the second layer and A non-patterned third layer in contact with the active light-emitting polymer layer, the second layer comprising a conjugated conductive organic polymer blend and having higher resistance (lower conductivity), the third layer Contains a conductive organic polymer and has lower resistance (higher conductivity) than the second layer.

如本文所用,术语“有机电活性材料”是指表现出特定的电活性,如电致发光、光敏性、电荷输运和/或电荷注入、电导率和激子阻塞等,的任何有机材料。术语“溶液-加工的有机电活性材料”是指在电子器件集成中层形成期间已加进一种合适溶剂的任何有机电活性材料。术语“电荷”,当用来指电荷注入/输运时,是指空穴和电子输运/注入中的一种或两种,这取决于上下文意思。术语“光活性”有机材料是指呈现电致发光和/或光敏性等电活性的任何有机材料。术语“电导率”和“体积电导率”可交换使用,其值以每厘米西门子(S/cm)为单位表示。此外,术语“表面电阻率”和“片电阻”可互换地用来指对于给定材料是片材厚度函数的电阻值,其值以Ω/sq为单位表示。同样,术语“体积电阻率”和“电阻率”可互换地用来指电阻率,它是一种具体材料的基本性能(即不随物质尺寸而变),其值以欧姆-厘米(Ω-cm)为单位表示。电阻率是电导率的倒数。As used herein, the term "organic electroactive material" refers to any organic material that exhibits specific electroactivity, such as electroluminescence, photosensitivity, charge transport and/or charge injection, electrical conductivity, and exciton blocking, among others. The term "solution-processed organic electroactive material" refers to any organic electroactive material to which a suitable solvent has been added during the formation of layers in electronic device integration. The term "charge", when used to refer to charge injection/transport, refers to either or both hole and electron transport/injection, depending on the context. The term "photoactive" organic material refers to any organic material that exhibits electrical activity such as electroluminescence and/or photosensitivity. The terms "conductivity" and "bulk conductivity" are used interchangeably, with values expressed in units of Siemens per centimeter (S/cm). Furthermore, the terms "surface resistivity" and "sheet resistance" are used interchangeably to refer to the resistance value for a given material as a function of sheet thickness, with values expressed in units of Ω/sq. Likewise, the terms "volume resistivity" and "resistivity" are used interchangeably to refer to electrical resistivity, which is a fundamental property (i.e., invariant to size) of a particular material and is measured in ohm-centimeters (Ω- cm) as a unit. Resistivity is the inverse of conductivity.

附图简述 Brief description of the drawings

本发明将参考附图进行描述。在这些附图中,The invention will be described with reference to the accompanying drawings. In these drawings,

图1是背景技术中的参考图,它示意“漏电”象素(在一个96×64阵列中)的分数与聚苯胺层厚度的关系曲线。Figure 1 is a background art reference graph showing the fraction of "leakage" pixels (in a 96x64 array) versus the thickness of the polyaniline layer.

图2A是本发明含光活性层的有机电子器件中的象素的不按比例的剖面图。Figure 2A is a cross-sectional view, not to scale, of a pixel in an organic electronic device comprising a photoactive layer of the present invention.

图2B是图2A所示象素的放大剖面,突出多层阳极结构。Figure 2B is an enlarged cross-section of the pixel shown in Figure 2A, highlighting the multilayer anode structure.

图2C是本发明含光活性层的无源寻址象素化有机电子器件的结构示意图。Fig. 2C is a schematic structural view of a passive addressable pixelated organic electronic device containing a photoactive layer according to the present invention.

图3是示意3个器件在70℃下应力诱导降解的曲线图,一个器件有一层聚苯胺(翠绿亚胺-盐)层(PANI(ES)),一个器件有一层由聚苯胺与聚丙烯酰胺的共混物(PANI(ES)-PAM)制成的层,以及一个器件有一层聚(亚乙二氧基噻吩)(PEDT)层。实线代表工作电压,虚线代表光输出。Figure 3 is a graph illustrating the stress-induced degradation of three devices at 70 °C, one device has a polyaniline (emeraldine-salt) layer (PANI(ES)), and one device has a layer composed of polyaniline and polyacrylamide (PANI(ES)-PAM), and one device had a layer of poly(ethylenedioxythiophene) (PEDT). The solid line represents the operating voltage, and the dashed line represents the light output.

图4是示意含有不同厚度PEDT的PANI(ES)-PAM/PEDT双层的器件在70℃下应力诱导降解的曲线图。实线代表工作电压,虚线代表光输出。Figure 4 is a graph illustrating the stress-induced degradation at 70°C of devices containing PANI(ES)-PAM/PEDT bilayers with different thicknesses of PEDT. The solid line represents the operating voltage, and the dashed line represents the light output.

图5是示意一系列含有不同PANI(ES)-PAM共混物的PANI(ES)-PAM/PEDT双层的器件在80℃下应力诱导降解的曲线图。实线代表工作电压,虚线代表光输出。Figure 5 is a graph illustrating the stress-induced degradation at 80°C of a series of devices containing PANI(ES)-PAM/PEDT bilayers of different PANI(ES)-PAM blends. The solid line represents the operating voltage, and the dashed line represents the light output.

优选实施方案描述 DESCRIPTION OF THE PREFERRED EMBODIMENT

如图2A、2B和2C清楚地所示,本发明的电子器件100在一个阴极106和一个多层阳极104之间包含一层光活性层102。阳极104包括一层具有第一层电导率的导电第一层110、一层具有第二层电导率的低电导率第二层112和一层具有第三层电导率的高电导率第三层114,第三层的电导率大于第二层的电导率但低于第一层的电导率。阳极104和整个二极管结构可载在衬底108上。As best shown in FIGS. 2A , 2B and 2C, the

有机聚合物基二极管100使用一种功函较高的阳极;该高功函阳极104所起作用是将空穴注入半导体发光聚合物102中原本充满的π-带(band)。功函较低的材料优选作阴极106;该低功函阴极所起的作用是将电子注入半导体发光聚合物102中原本空的π*-带。在阳极上注入的空穴和在阴极上注入的电子在活性层中放射地重新结合,发出光线。适用于该领域的电极的判据已由I.D.Parker详述在J.Appl.Phys,75,1656(1994)中。器件构型 The organic polymer based

如图2C清楚地所示,一个有机电子器件100中的每个象素包括一个电子注入(阴极)接触106,它作为一个沉积在本发明多层阳极104上的光活性有机材料102前面的电极,起第二(透明)吸电子(阳极)电极的作用。该多层阳极(由110、112和114层构成)沉积在部分涂有第一层110的衬底108上。低电导率第二层112和高电导率第三层114沉积在第一层110之上。阴极106电连接到接触垫片80上,阳极110电连接到接触垫片82上。然后以一层密封层114将层102、106、108、110和112与环境隔开。当电子器件是发光器件时,通过在密封70以外的接触垫片80和82通电时,光线从器件朝箭头90所示方向发射出来。当电子器件是一个光电探测器时,光在与箭头90相反的方向上被器件接收(未示出)。As best seen in Figure 2C, each pixel in an organic

优选实施方案的描述按这些不同的部件组织。更具体地说,它含有下列部分:The description of the preferred embodiment is organized by these various components. More specifically, it contains the following sections:

光活性层(102)Photoactive layer(102)

多层阳极(104)Multilayer Anode(104)

导电第一层(110)Conductive first layer(110)

低电导率第二层(112) Low conductivity second layer (112)

高电导率第三层(114) High conductivity third layer(114)

阴极(106)Cathode(106)

衬底(108)Substrate(108)

接触垫片(80,90)Contact gasket (80, 90)

任选层optional layer

制造技术光活性层(102) Manufacturing Technology Photoactive Layer(102)

根据电子器件的应用,光活性层102可以是一个通过施加电压而被活化的发光层(例如在一个发光二极管或发光电化学电池中),即一层不论是否施以偏电压都能对辐照能量作出响应并产生信号的材料(例如在光电探测器中)。光电探测器的实例包括光导电管、光敏电阻器、光控开关、光电晶体管、光电管和光伏电池,这些术语在Markus,John,Electronics and Nucleonics Dict ionary,470和476(McGraw-Hill,Inc.1966)中已有所述。Depending on the application of the electronic device, the

当电子器件是一个发光器件时,光活性层102将在电接触层上施有足够的偏压时发光。合适的活性发光材料包括有机分子材料如蒽、丁二烯、香豆素衍生物、吖啶和茋衍生物,例如,见Tang的美国专利4,356,429,Van Slyke等的美国专利4,539,507,其中的相关部分包括于此供参考。或者,这类材料也可以是聚合物材料,如Friend等(美国专利5,247,190)、Heeger等(美国专利5,408,109)、Nakano等(美国专利5,317,169)所述的那些,它们的相关部分包括于此供参考。发光材料可以分散在另一种材料的基体中,加或不加添加剂均可,但优选形成单独的一层。在优选实施方案中,电致发光聚合物包含至少一种共轭聚合物或含π-共轭部分链段的共聚物。共轭聚合物是本领域内熟知的(参阅《共轭聚合物》,J.-L.Breda s和R.Silbey主编,KluwerAcademic Press,Dordrecht,1991)。典型的材料类型包括,但不限于,以下几类:When the electronic device is a light emitting device, the

(i)聚(对亚苯基亚乙烯基)及其在亚苯基部分不同位置上被取代的衍生物;(i) poly(p-phenylene vinylene) and derivatives thereof substituted at various positions on the phenylene moiety;

(ii)聚(对亚苯基亚乙烯基)及其在亚乙烯基部分不同位置上被取代的衍生物;(ii) poly(p-phenylene vinylene) and its derivatives substituted at different positions of the vinylene moiety;

(iii)聚(亚芳基亚乙烯基),其中,亚芳基可以是如萘、蒽、亚呋喃基、亚噻吩基、噁二唑之类的部分,或在不同位置有官能化取代基的这类部分之一;(iii) Poly(arylenevinylene), where the arylene group can be a moiety such as naphthalene, anthracene, furylene, thienylene, oxadiazole, or have functional substituents at various positions one of such parts of the

(iv)聚亚芳基亚乙烯基的衍生物,其中,亚芳基可以如以上(iii)在亚芳基部分的不同位置上被取代;(iv) derivatives of polyarylenevinylene, wherein the arylene group may be substituted at different positions of the arylene moiety as in (iii) above;

(v)聚亚芳基亚乙烯基的衍生物,其中亚芳基可以如以上(iii)在亚乙烯基部分的不同位置上被取代;(v) derivatives of polyarylene vinylene, wherein the arylene group may be substituted at different positions of the vinylene moiety as in (iii) above;

(vi)亚芳基亚乙烯基齐聚体与非共轭齐聚体的共聚物以及这类聚合物在亚芳基部分不同位置上被取代的衍生物、这类聚合物在亚乙烯基部分不同位置上被取代的衍生物以及这类聚合物在亚芳基和亚乙烯基部分不同位置上被取代的衍生物;(vi) Copolymers of arylene vinylidene oligomers and non-conjugated oligomers and derivatives of such polymers substituted at different positions of the arylene moiety, such polymers in the vinylene moiety Derivatives substituted at different positions and derivatives of such polymers substituted at different positions on the arylene and vinylidene moieties;

(vii)聚对亚苯基及其在亚苯基部分不同位置上被取代的衍生物,包括梯形聚合物衍生物如聚(9,9-二烷基芴)等在内;(vii) Polyparaphenylene and its derivatives substituted at different positions of the phenylene moiety, including ladder polymer derivatives such as poly(9,9-dialkylfluorene);

(viii)聚亚芳基及其在亚芳基部分不同位置上被取代的衍生物;(viii) polyarylenes and their derivatives substituted at different positions of the arylene moiety;

(ix)齐聚亚芳基与非共轭齐聚物的共聚物,以及这类聚合物在亚芳基部分不同位置上被取代的衍生物;(ix) Copolymers of oligomeric arylenes and non-conjugated oligomers, and derivatives of such polymers substituted at different positions of the arylene moiety;

(x)聚喹啉及其衍生物;(x) polyquinoline and its derivatives;

(xi)聚喹啉与对亚苯基和带有可溶性官能部分的共聚物;(xi) Copolymers of polyquinoline with p-phenylene and soluble functional moieties;

(xii)刚性棒状聚合物如聚(对-亚苯基-2,6-苯并二噻唑)、聚(对-亚苯基-2,6-苯并二噁唑)、聚(对-亚苯基-2,6-苯并咪唑)以及它们的衍生物等。(xii) Rigid rod polymers such as poly(p-phenylene-2,6-benzobithiazole), poly(p-phenylene-2,6-benzobisoxazole), poly(p-phenylene Phenyl-2,6-benzimidazole) and their derivatives.

更具体地,活性材料可以包括,但不限于,聚(亚苯基亚乙烯基)PPV和PPV的烷氧基衍生物,例如,聚(2-甲氧基-5-(2′-乙基-己氧基)-对-亚苯基亚乙烯基)或“MEH-PPV”(美国专利5,189,136)。BCHA-PPV也是一种颇具吸引力的活性材料。(C.Zhang等,J.Electron.Mater.,22,413(1993))。PPPV也适用。(C.Zhang等,Synth.Met.,62,35(1994)及其中的参考文献)优选可溶于普通有机溶剂的发光共轭聚合物,因为它们能使器件的制造相对地简单[A.Heeger和D.Braun,美国专利5,408,109和5,869,350]。More specifically, active materials may include, but are not limited to, poly(phenylene vinylene) PPV and alkoxy derivatives of PPV, for example, poly(2-methoxy-5-(2'-ethyl -hexyloxy)-p-phenylenevinylene) or "MEH-PPV" (US Patent 5,189,136). BCHA-PPV is also an attractive active material. (C. Zhang et al., J. Electron. Mater., 22, 413 (1993)). PPPV is also applicable. (C. Zhang et al., Synth. Met., 62, 35 (1994) and references therein) luminescent conjugated polymers soluble in common organic solvents are preferred because they enable relatively simple fabrication of devices [A. Heeger and D. Braun, US Patents 5,408,109 and 5,869,350].

更优选的活性发光聚合物与共聚物是H.Becker等在Adv.Mater.12,42(2000)中所述的可溶性PPV材料,本文称之为C-PPV。也可用这类聚合物与会电致发光的其它半导体聚合物和共聚物的共混物。当电子器件100是一个光电探测器时,光活性层102在受偏压或不受偏压作用时对辐照能量作出响应并产生信号。在受偏压作用时对辐照能量作出响应并能产生一个信号的材料(例如在光电导管、光敏电阻、光控开关、光电晶体管和光电管的情况下)包括,例如,许多共轭聚合物和电致发光材料。在不受偏压作用时对辐照能量作出响应并能产生一个信号的材料(例如在光电导管、光伏电池的情况下)包括与光发生化学反应并因此而产生一个信号的材料。这类化学上光敏的反应性材料包括,例如,许多共轭聚合物和电致-与光致-发光材料。具体实例包括,但不限于,MEH-PPV(“由半导体聚合物制造的光偶合器”,G.Yu,K.Pakbaz,和A.J.Heeger,Journal of ElectronicMaterials,Vol.23,925-928页(1994);以及与CN-PPV的MEH-PPV复合材料(“由互穿聚合物网络制造的高效光电二极管”,J.J.M.Ha11s等(Cambridge小组),Nature,Vol.376,498-500页,1995)。电活性有机材料可裁制成发射出不同波长的光。More preferred active light-emitting polymers and copolymers are the soluble PPV materials described by H. Becker et al. in Adv. Mater. 12, 42 (2000), referred to herein as C-PPV. Blends of such polymers with other semiconducting polymers and copolymers that will electroluminescence may also be used. When the

在某些实施方案中,聚合物光活性材料或有机分子光活性材料以0%-75%(重量,以混合物总重为基准)载体有机材料(聚合物或有机分子)混合物的形式存在于光活性层102中。选择载体有机材料的准则如下:这种材料应能在低浓度下形成机械内聚薄膜并在能分散或溶解形成薄膜的共轭聚合物的溶剂中保持稳定。为尽量减小加工难度,即过高的粘度或形成整体的均一性,优选低浓度载体材料;但是载体浓度应高到足以允许形成内聚结构。当载体是一种聚合物材料时,优选载体聚合物是高分子量(M.W>100,000)柔性链聚合物,例如,聚乙烯、全同立构聚丙烯、聚环氧乙烷、聚苯乙烯等。在本领域技术人员很容易确定的适宜条件下,这类大分子材料能从很多种液体,包括水、酸和许多极性或非极性有机溶剂,形成内聚结构。用这类载体聚合物制成的薄膜或片材,在聚合物浓度低达1体积%,甚至低达0.1体积%时,具有足够的力学强度,从而能按需进行涂布和后续加工。这类内聚结构的实例有由聚乙烯醇、聚环氧乙烷、聚对-(对苯二甲酸对苯二酯)、聚对苯甲酰胺等和其它合适的聚合物组成的那些。另一方面,如果最终聚合物的共混不能在极性环境中进行,则要选择非极性载体结构,例如,含聚乙烯、聚丙烯、聚丁二烯等的那些。In certain embodiments, the polymeric photoactive material or the organic molecular photoactive material is present in the photoactive mixture as a mixture of carrier organic materials (polymers or organic molecules) from 0% to 75% by weight, based on the total weight of the mixture. In the

光活性层的典型膜厚范围是数百埃(200)-数千埃(10,000)(1=10-8cm)。虽然活性膜厚不是非常重要,但器件性能一般能通过使用较薄的膜而得以改进。优选的厚度是300-5,000。多层阳极(104) The typical film thickness of the photoactive layer ranges from hundreds of angstroms (200 Å) to thousands of angstroms (10,000 Å) (1 Å=10 -8 cm). Although active film thickness is not critical, device performance can generally be improved by using thinner films. The preferred thickness is from 300 Å to 5,000 Å. Multilayer Anode(104)

多层阳极(104)包括导电第一层(110)、低电导率二层(112)和高电导率第三层(114)。The multilayer anode (104) includes a conductive first layer (110), a low conductivity second layer (112), and a high conductivity third layer (114).

每层110、112和114的厚度取决于这些层所需的透明度和电阻率,而透明性与电阻率因素又取决于层的组成。The thickness of each

在本发明的含有一层光活性层的器件中,一个电极是透明的,可以使光从器件发射出来或光被器件所接收。更普遍地,阳极是透明电极,虽然本发明也可用于阴极是透明电极的实施方案中。In a device of the invention comprising a photoactive layer, one electrode is transparent to allow light to be emitted from the device or received by the device. More generally, the anode is a transparent electrode, although the invention can also be used in embodiments where the cathode is a transparent electrode.

如本文所用,“透明”一词定义为“能透过至少约25%,优选至少约50%所关注的特定波长的光量”。因此即使一种材料透光的能力随波长而变,但在所关注的给定波长下的确满足25%或50%的判据时仍认为它是透明的。据薄膜领域的工作者所知,如果层非常薄,金属也能达到相当的透明度,例如在银和金的情况下,厚度小于约300,尤其约20-约250时,银具有相对无色(均匀)的透射性,金则倾向于透射黄至红色波长。同样,对于ITO,PANI和PEDT等的材料,层厚在100-10,000范围内能达到透明。As used herein, the term "transparent" is defined as "transmitting at least about 25%, preferably at least about 50%, of the amount of light of a particular wavelength of interest". So even though a material's ability to transmit light varies with wavelength, it is still considered transparent if it does meet the 25% or 50% criterion at the given wavelength of interest. As known to those working in the field of thin films, metals can achieve considerable transparency if the layers are very thin, for example in the case of silver and gold, the thickness is less than about 300 Å, especially about 20 Å to about 250 Å, silver has a relatively Colorless (uniform) transmission, gold tends to transmit yellow to red wavelengths. Similarly, for materials such as ITO, PANI and PEDT, the layer thickness can reach transparency in the range of 100 Å-10,000 Å.

除所需的透明度外,还应选择多层阳极104中各层的组成,从而使第三层的电导率小于第一层的电导率而大于第二层的电导率。因此,多层阳极中每一层材料的选择依赖于阳极中其它层的组成和这些其它层对应的电导率。决定组成的其它因素在下面涉及具体层的章节内叙述。导电第一层(110) In addition to the desired transparency, the composition of the layers in the

导电第一层具有低电阻:优选低于300Ω/sq,更优选低于100Ω/sq。The conductive first layer has a low resistance: preferably below 300Ω/sq, more preferably below 100Ω/sq.

复合阳极(104)中导电第一层(110)提供与一个外电源(未示出)的电接触,且是一层由高功函材料制成的导电层,非常典型的是一种功函在约4.5eV以上的无机材料。优选该导电第一层110由含金属、混合金属、合金、金属氧化物或混合-金属氧化物的材料组成。合适的金属包括族11的金属、族4,5和6中的金属以及族8-10的过渡金属。如果要使阳极104是透光的,则一般用族12,13和14中的混合金属氧化物,例如铟-锡-氧化物。全文采用IUPAC计数体系,其中,周期表中的族从左至右计为1-18(CRC化学与物理手册,第81版,2000)。第一层110还可包含一种有机材料,如“Flexible light-emittingdiodes made from soluble conducting polymer”,NatureVol.357,477-479页(11 June 1992)中所述的聚苯胺。The conductive first layer (110) of the composite anode (104) provides electrical contact to an external power source (not shown) and is a conductive layer made of a high work function material, very typically a work function Inorganic materials above about 4.5eV. Preferably, the conductive

起阳极作用的典型无机材料包括金属如铝、银、铂、金、钯、钨、铟、铜、铁、镍、锌、铅等;金属氧化物如氧化铅、氧化锡、铟/锡-氧化物等;石墨;掺杂的无机半导体如硅、锗、砷化镓等。当用铝、银、铂、金、钯、钨、铟、铜、铁、镍、锌、铅等金属时,阳极层应薄到足以成半透明。金属氧化物如铟/锡-氧化物一般至少是半透明的。Typical inorganic materials that function as anodes include metals such as aluminum, silver, platinum, gold, palladium, tungsten, indium, copper, iron, nickel, zinc, lead, etc.; metal oxides such as lead oxide, tin oxide, indium/tin-oxide Graphite; doped inorganic semiconductors such as silicon, germanium, gallium arsenide, etc. When using metals such as aluminum, silver, platinum, gold, palladium, tungsten, indium, copper, iron, nickel, zinc, lead, etc., the anode layer should be thin enough to be translucent. Metal oxides such as indium/tin-oxide are generally at least translucent.

当阳极透明时,导电的金属-金属氧化物混合物,在厚度最多高达2500时,在有些情况下仍能是透明的。当要求透明度时,优选金属-金属氧化物(或介电)层的厚度为约25-约1200。低电导率第二层(112) While the anode is transparent, conductive metal-metal oxide mixtures can in some cases be transparent at thicknesses up to 2500 Å. When transparency is desired, the metal-metal oxide (or dielectric) layer preferably has a thickness of from about 25 to about 1200 Å. Low Conductivity Second Layer(112)

第二层112的电阻率应高到足以防止来自多层阳极的串扰或漏电并提供足够的空穴注入/输运。优选低电导率第二层的体积电导率为约10-4S/cm-10-11S/cm。更优选第二层的体积电导率为10-5S/em-10-8S/cm。The resistivity of the

第二层112可包含聚苯胺(PANI)或一种等价的共轭导电聚合物如聚吡咯或聚噻吩,非常普遍地,在与一种或多种非导电聚合物的共混物中。聚苯胺特别有用。非常普遍地,聚苯胺以翠绿亚胺盐(ES)的形式存在。有用的导电聚苯胺包括均聚物和通常作为与本体聚合物(也称为本体聚合物)的共混物的衍生物。PANI的实例有美国专利5,232,631所述的那些。The

在另一个实施方案中,第二层可包含导电材料,如N,N′-二苯基-N,N′-双(3-甲基苯基)-[1,1′-二苯基]-4,4′-二胺(TPD)和双[4-(N,N-二乙基氨基)-2-甲基苯基](4-甲基苯基)甲烷(MPMP),以及空穴注入/输运聚合物如聚乙烯基咔唑(PVK)、(苯基甲基)聚硅烷、聚(3,4-亚乙二氧基噻吩)(PEDOT)和聚苯胺(PANI);电子和空穴注入/输运材料,如4,4′-N,N′-二咔唑联苯(BCP);或具有良好的电子和空穴输运性的发光材料,如螯合氧化型化合物,例如三(8-羟基醌酯基)铝(Alq3)。In another embodiment, the second layer may comprise a conductive material such as N,N'-diphenyl-N,N'-bis(3-methylphenyl)-[1,1'-diphenyl] -4,4′-diamine (TPD) and bis[4-(N,N-diethylamino)-2-methylphenyl](4-methylphenyl)methane (MPMP), and the hole Injection/transport polymers such as polyvinylcarbazole (PVK), (phenylmethyl)polysilane, poly(3,4-ethylenedioxythiophene) (PEDOT) and polyaniline (PANI); electronics and Hole injection/transport materials, such as 4,4'-N,N'-dicarbazole biphenyl (BCP); or light-emitting materials with good electron and hole transport properties, such as chelated oxidized compounds, For example tris(8-hydroxyquinato)aluminum (Alq 3 ).

在本文中使用术语“聚苯胺”或PANI时,一般用来包括取代与未取代的材料,以及其它等价的共轭导电聚合物如聚吡咯或聚噻吩,例如聚亚乙二氧基噻吩(“PEDT”),除非上下文中清楚表明仅指特定的非取代形式。该术语也以下述方式使用:包括任何伴随的掺杂剂,特别用来使聚苯胺导电的酸性材料。When the term "polyaniline" or PANI is used herein, it is generally taken to include substituted and unsubstituted materials, as well as other equivalent conjugated conductive polymers such as polypyrrole or polythiophene, for example polyethylenedioxythiophene ( "PEDT"), unless the context clearly indicates that only the specific unsubstituted form is being referred to. The term is also used in a manner that includes any accompanying dopants, especially acidic materials used to make polyaniline conductive.

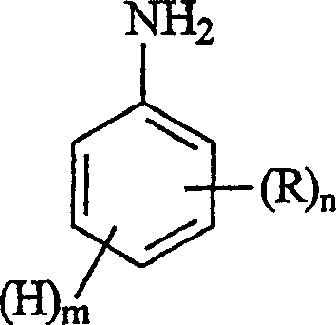

一般而言,聚苯胺是分子量能形成薄膜和纤维的聚合物与共聚物,衍生自式I的未取代与取代苯胺的聚合反应:In general, polyanilines are polymers and copolymers of molecular weight capable of forming films and fibers, derived from the polymerization of unsubstituted and substituted anilines of formula I:

式I其中,Formula I in,

n是0-4的整数;n is an integer of 0-4;

m是1-5的整数;条件是n与m之和等于5;以及m is an integer from 1 to 5; provided that the sum of n and m is equal to 5; and