TWI846324B - Nanofiltration membrane and manufacturing method thereof - Google Patents

Nanofiltration membrane and manufacturing method thereof Download PDFInfo

- Publication number

- TWI846324B TWI846324B TW112105110A TW112105110A TWI846324B TW I846324 B TWI846324 B TW I846324B TW 112105110 A TW112105110 A TW 112105110A TW 112105110 A TW112105110 A TW 112105110A TW I846324 B TWI846324 B TW I846324B

- Authority

- TW

- Taiwan

- Prior art keywords

- polybenzimidazole

- nanofiltration membrane

- nanofiltration

- manufacturing

- membrane

- Prior art date

Links

- 239000012528 membrane Substances 0.000 title claims abstract description 105

- 238000001728 nano-filtration Methods 0.000 title claims abstract description 104

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 34

- 239000004693 Polybenzimidazole Substances 0.000 claims abstract description 83

- 229920002480 polybenzimidazole Polymers 0.000 claims abstract description 83

- 238000000034 method Methods 0.000 claims abstract description 36

- 238000005345 coagulation Methods 0.000 claims abstract description 29

- 230000015271 coagulation Effects 0.000 claims abstract description 29

- 239000007788 liquid Substances 0.000 claims abstract description 11

- 239000000758 substrate Substances 0.000 claims abstract description 11

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 claims description 27

- 229920002873 Polyethylenimine Polymers 0.000 claims description 24

- 239000000243 solution Substances 0.000 claims description 24

- 229920000642 polymer Polymers 0.000 claims description 23

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 claims description 15

- 230000004048 modification Effects 0.000 claims description 15

- 238000012986 modification Methods 0.000 claims description 15

- 239000007864 aqueous solution Substances 0.000 claims description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 10

- 238000005266 casting Methods 0.000 claims description 2

- TWRXJAOTZQYOKJ-UHFFFAOYSA-L Magnesium chloride Chemical compound [Mg+2].[Cl-].[Cl-] TWRXJAOTZQYOKJ-UHFFFAOYSA-L 0.000 description 28

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 description 16

- JLVVSXFLKOJNIY-UHFFFAOYSA-N Magnesium ion Chemical compound [Mg+2] JLVVSXFLKOJNIY-UHFFFAOYSA-N 0.000 description 16

- 229910001416 lithium ion Inorganic materials 0.000 description 16

- 229910001425 magnesium ion Inorganic materials 0.000 description 16

- 238000000926 separation method Methods 0.000 description 16

- 229910001629 magnesium chloride Inorganic materials 0.000 description 12

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 10

- 239000011148 porous material Substances 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 7

- 239000011777 magnesium Substances 0.000 description 7

- 229910052749 magnesium Inorganic materials 0.000 description 7

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 6

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 6

- 239000011780 sodium chloride Substances 0.000 description 6

- 238000012360 testing method Methods 0.000 description 6

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

- 239000008367 deionised water Substances 0.000 description 4

- 229910021641 deionized water Inorganic materials 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 230000014759 maintenance of location Effects 0.000 description 4

- 238000003860 storage Methods 0.000 description 4

- WEVYAHXRMPXWCK-UHFFFAOYSA-N Acetonitrile Chemical compound CC#N WEVYAHXRMPXWCK-UHFFFAOYSA-N 0.000 description 3

- 230000002378 acidificating effect Effects 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 238000001035 drying Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- FXHOOIRPVKKKFG-UHFFFAOYSA-N N,N-Dimethylacetamide Chemical compound CN(C)C(C)=O FXHOOIRPVKKKFG-UHFFFAOYSA-N 0.000 description 2

- 239000004677 Nylon Substances 0.000 description 2

- 150000001768 cations Chemical class 0.000 description 2

- 238000004146 energy storage Methods 0.000 description 2

- 238000002354 inductively-coupled plasma atomic emission spectroscopy Methods 0.000 description 2

- 150000002500 ions Chemical class 0.000 description 2

- KWGKDLIKAYFUFQ-UHFFFAOYSA-M lithium chloride Chemical compound [Li+].[Cl-] KWGKDLIKAYFUFQ-UHFFFAOYSA-M 0.000 description 2

- 229920001778 nylon Polymers 0.000 description 2

- 230000010287 polarization Effects 0.000 description 2

- 238000001223 reverse osmosis Methods 0.000 description 2

- 238000000108 ultra-filtration Methods 0.000 description 2

- 238000004483 ATR-FTIR spectroscopy Methods 0.000 description 1

- 101000827703 Homo sapiens Polyphosphoinositide phosphatase Proteins 0.000 description 1

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 102100023591 Polyphosphoinositide phosphatase Human genes 0.000 description 1

- 125000003277 amino group Chemical group 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 238000010612 desalination reaction Methods 0.000 description 1

- 238000010889 donnan-equilibrium Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000003673 groundwater Substances 0.000 description 1

- IXCSERBJSXMMFS-UHFFFAOYSA-N hcl hcl Chemical compound Cl.Cl IXCSERBJSXMMFS-UHFFFAOYSA-N 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 229910052744 lithium Inorganic materials 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 239000002048 multi walled nanotube Substances 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 231100000956 nontoxicity Toxicity 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 238000005191 phase separation Methods 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 230000009257 reactivity Effects 0.000 description 1

- 238000012827 research and development Methods 0.000 description 1

- 239000013535 sea water Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000007873 sieving Methods 0.000 description 1

- 238000002791 soaking Methods 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 230000001988 toxicity Effects 0.000 description 1

- 231100000419 toxicity Toxicity 0.000 description 1

Images

Landscapes

- Separation Using Semi-Permeable Membranes (AREA)

Abstract

Description

本發明是有關一種奈米過濾薄膜,特別是一種關於聚苯并咪唑奈米過濾薄膜及其製造方法。The present invention relates to a nano-filter membrane, in particular to a polybenzimidazole nano-filter membrane and a method for manufacturing the same.

近年來,隨著個人電子設備需求的快速增長,鋰離子電池作為儲能裝置的研究和開發不斷升級,因為它們具有重量輕、儲能高、反應活性高和無毒等優點。這帶來了從鹽水溶液(包括海水和地下水)中高效提取Li +的方法以滿足市場需求的緊迫性。然而,大多數鹽水溶液具有更高的鎂與鋰質量比,這使得將Li +與Mg 2+分離變得具有挑戰性。 迄今為止,膜技術的進步已成為離子分離應用的可行選擇。 In recent years, with the rapid growth in demand for personal electronic devices, the research and development of lithium-ion batteries as energy storage devices has been continuously upgraded because of their advantages such as light weight, high energy storage, high reactivity and non-toxicity. This has brought about the urgency of efficient methods for extracting Li + from saline solutions (including seawater and groundwater) to meet market demand. However, most saline solutions have a higher magnesium to lithium mass ratio, which makes it challenging to separate Li + from Mg2+ . To date, advances in membrane technology have become a viable option for ion separation applications.

奈米過濾(Nanofiltration,NF)是最有前途的水處理和海水淡化膜分離工藝之一。這是一個壓力驅動的過程,由於各種排斥力(例如物理篩分(physical sieving)、吉布斯-唐南效應(Gibbs-Donnan effect) 和靜電排斥)而選擇性地拒絕某些成分。這些機制有利於 Li +/Mg 2+的分離,因為大多數多價 Mg 2+的陽離子可以被排斥,同時仍允許 Li +的陽離子通過膜孔。與逆滲透法(Reverse Osmosis,RO)不同,NF可以在低壓至中等壓力下進行,同時仍然能夠提供比超濾(ultrafiltration,UF)更高的選擇性。 此外,它還可以保留水中有價值的礦物質,這些礦物質是人類所需的或用於反滲透無法實現的特定應用。 Nanofiltration (NF) is one of the most promising membrane separation processes for water treatment and desalination. It is a pressure-driven process that selectively rejects certain components due to various repulsive forces such as physical sieving, the Gibbs-Donnan effect, and electrostatic repulsion. These mechanisms favor Li + / Mg2+ separations because most multivalent Mg2 + cations can be rejected while still allowing Li + cations to pass through the membrane pores. Unlike reverse osmosis (RO), NF can be performed at low to moderate pressures while still providing higher selectivity than ultrafiltration (UF). Additionally, it can retain valuable minerals in the water that are needed by humans or for specific applications that cannot be achieved by reverse osmosis.

本發明之一態樣是提供一種能夠分離鋰離子和鎂離子的奈米過濾薄膜的製造方法。奈米過濾薄膜的製造方法包含以下操作。首先,將聚苯并咪唑溶液澆鑄於基材上,以在基材上形成聚苯并咪唑液膜。接著,調整凝固浴的pH值為1至13。再將聚苯并咪唑液膜浸泡在凝固浴中進行相轉化, 從而形成聚苯并咪唑奈米過濾薄膜。One aspect of the present invention is to provide a method for manufacturing a nanofiltration film capable of separating lithium ions and magnesium ions. The method for manufacturing the nanofiltration film comprises the following operations. First, a polybenzimidazole solution is cast on a substrate to form a polybenzimidazole liquid film on the substrate. Then, the pH value of the coagulation bath is adjusted to 1 to 13. The polybenzimidazole liquid film is then immersed in the coagulation bath for phase inversion, thereby forming a polybenzimidazole nanofiltration film.

根據本發明之某些實施方式,聚苯并咪唑溶液的濃度為15wt%至25wt%。According to certain embodiments of the present invention, the concentration of the polybenzimidazole solution is 15 wt % to 25 wt %.

根據本發明之某些實施方式,奈米過濾薄膜的製造方法更包含將聚苯并咪唑奈米過濾薄膜浸泡在甘油水溶液中。According to certain embodiments of the present invention, the method for manufacturing the nanofiltration membrane further comprises immersing the polybenzimidazole nanofiltration membrane in a glycerol aqueous solution.

根據本發明之某些實施方式,甘油水溶液中的甘油與水的體積比為1:1。According to certain embodiments of the present invention, the volume ratio of glycerol to water in the glycerol aqueous solution is 1:1.

根據本發明之某些實施方式,奈米過濾薄膜的製造方法更包含將聚苯并咪唑奈米過濾薄膜浸泡在表面改性溶液中,以形成表面改性聚苯并咪唑奈米過濾薄膜,其中表面改性溶液包含超支化聚乙烯亞胺聚合物。According to certain embodiments of the present invention, the method for manufacturing the nanofiltration membrane further comprises immersing the polybenzimidazole nanofiltration membrane in a surface modification solution to form a surface-modified polybenzimidazole nanofiltration membrane, wherein the surface modification solution comprises a hyperbranched polyethyleneimine polymer.

根據本發明之某些實施方式,超支化聚乙烯亞胺聚合物具有分子量為10000 g/mole至50000 g/mole。According to certain embodiments of the present invention, the hyperbranched polyethyleneimine polymer has a molecular weight of 10,000 g/mole to 50,000 g/mole.

根據本發明之某些實施方式,奈米過濾薄膜的製造方法更包含將表面改性聚苯并咪唑奈米過濾薄膜浸泡在異丙醇水溶液中。According to certain embodiments of the present invention, the method for manufacturing the nanofiltration membrane further comprises immersing the surface-modified polybenzimidazole nanofiltration membrane in an isopropyl alcohol aqueous solution.

本發明之另一態樣是提供一種能夠分離鋰離子和鎂離子的奈米過濾薄膜,其如由上所述之奈米過濾薄膜的製造方法所製得的奈米過濾薄膜。Another aspect of the present invention is to provide a nano-filter membrane capable of separating lithium ions and magnesium ions, such as the nano-filter membrane manufactured by the above-mentioned nano-filter membrane manufacturing method.

本發明之又一態樣是提供一種能夠分離鋰離子和鎂離子的奈米過濾薄膜。奈米過濾薄膜包含聚苯并咪唑多孔奈米過濾薄膜主體,其具有如下結構: 或 、 。 Another aspect of the present invention is to provide a nanofiltration membrane capable of separating lithium ions and magnesium ions. The nanofiltration membrane comprises a polybenzimidazole porous nanofiltration membrane body having the following structure: , .

根據本發明之某些實施方式,奈米過濾薄膜更包含超支化聚乙烯亞胺聚合物位於聚苯并咪唑多孔奈米過濾薄膜主體的多孔結構內。According to certain embodiments of the present invention, the nanofiltration membrane further comprises a hyperbranched polyethyleneimine polymer located in the porous structure of the polybenzimidazole porous nanofiltration membrane body.

為了使本揭示內容的敘述更加詳盡與完備,下文針對了本發明的實施態樣與具體實施例提出了說明性的描述;但這並非實施或運用本發明具體實施例的唯一形式。以下所揭露的各實施例,在有益的情形下可相互組合或取代,也可在一實施例中附加其他的實施例,而無須進一步的記載或說明。In order to make the description of the disclosure more detailed and complete, the following provides an illustrative description of the implementation and specific embodiments of the present invention; however, this is not the only form of implementing or using the specific embodiments of the present invention. The embodiments disclosed below can be combined or replaced with each other under beneficial circumstances, and other embodiments can be added to one embodiment without further recording or description.

為了使本揭示內容之敘述更加詳盡與完備,可參照所附之圖式及以下所述各種實施方式,圖式中相同之號碼代表相同或相似之元件。In order to make the description of the present disclosure more detailed and complete, reference may be made to the attached drawings and various embodiments described below, in which the same numbers in the drawings represent the same or similar elements.

關於本文中所使用之『約』、『大約』或『大致約』一般通常係指數值之誤差或範圍約百分之二十以內,較好地是約百分之十以內,而更佳地則是約百分五之以內。文中若無明確說明,其所提及的數值皆視作為近似值,即如『約』、『大約』或『大致約』所表示的誤差或範圍。As used herein, "about", "approximately" or "roughly" generally refers to a numerical value with an error or range of about 20%, preferably about 10%, and more preferably about 5%. If not explicitly stated in the text, the numerical values mentioned are deemed to be approximate values, that is, the error or range indicated by "about", "approximately" or "roughly".

除非內容中有其他清楚的指稱,本文所使用的單數詞包含複數的指稱對象。透過參考「一實施方式」這樣特定的指稱,在至少其中之一的本案發明的實施方式中,表示一種特定的特徵、結構或特色,因此在各處的「在一實施方式」,這樣的片語透過特別的指稱出現時,並不需要參考相同的實施方式,更進一步,在一或多實施方式中,這些特別的特徵、結構、或特色可以依合適的情況相互組合。Unless otherwise clearly indicated in the context, singular terms used herein include plural referents. By referring to a specific reference such as "one embodiment", a specific feature, structure or characteristic is indicated in at least one of the embodiments of the present invention, so that when such a phrase "in one embodiment" appears in various places by a specific reference, it is not necessary to refer to the same embodiment. Furthermore, in one or more embodiments, these specific features, structures, or characteristics can be combined with each other as appropriate.

本發明之一態樣係提供一種奈米過濾薄膜的製造方法,利用非溶劑誘導相分離(Nonsolvent Induce Phase Separation,NIPS)法來製造不對稱平板奈米過濾薄膜,因為此方法簡單、環保且能夠生產均勻的奈米過濾薄膜。第1圖繪示根據本發明多個實施方式之奈米過濾薄膜的製造方法10。第2圖繪示根據本發明多個實施方式之奈米過濾薄膜製造方法中某一階段的示意圖。第3圖繪示根據本發明多個實施方式之奈米過濾薄膜製造方法中某一階段的示意圖。如第1圖所示,方法10包含步驟110、步驟120、以及步驟130。One aspect of the present invention is to provide a method for manufacturing a nanofiltration film, which utilizes a nonsolvent induced phase separation (NIPS) method to manufacture an asymmetric flat nanofiltration film, because this method is simple, environmentally friendly and can produce uniform nanofiltration films. FIG. 1 shows a

請同時參考第1圖及第2圖,在步驟110中,將聚苯并咪唑(Polybenzimidazole,PBI)溶液210澆鑄(casting)於基材220上,以在基材220上形成聚苯并咪唑液膜230。詳細的說,可以通過澆鑄法(或稱流延法),利用澆鑄刮刀將聚苯并咪唑溶液210在基材220上澆鑄出聚苯并咪唑液膜230。Please refer to FIG. 1 and FIG. 2 at the same time. In

在一些實施例中,聚苯并咪唑溶液210的濃度為15wt%至25wt%。更詳細的說,聚苯并咪唑溶液210包含聚苯并咪唑作為溶質以及N,N-二甲基乙醯胺(Dimethylacetamide,DMAc)作為溶劑。此外,聚苯并咪唑溶液210還包含氯化鋰(LiCl)作為穩定劑。在一些實施例中,基材220包含聚醯胺(Polyamide)(或稱尼龍(nylon))。舉例來說,基材220包含非織造尼龍6,6(nonwoven 6,6-nylon)。In some embodiments, the concentration of the

請同時參考第1圖及第3圖,在步驟120中,調整凝固浴的pH值為1至13。在一些實施例中,凝固浴240主要包含去離子水(Deionized,DI)。舉例來說,可以藉由在去離子水中添加鹽酸(HCl),以調整凝固浴240至酸性(1≤pH<7),例如凝固浴240的pH值可以為1、2、3、4、5或6。再舉例來說,可以藉由在去離子水中添加氫氧化鈉(NaOH),以調整凝固浴240至鹼性(7<pH≤13),例如凝固浴240的pH值可以為8、9、10、11、12或13。Please refer to FIG. 1 and FIG. 3 at the same time. In

請同時參考第1圖及第3圖,在步驟120中,將聚苯并咪唑液膜230浸泡在凝固浴240中進行相轉化, 從而形成聚苯并咪唑奈米過濾薄膜250。在一些實施例中,步驟120係在常溫下進行,例如為25±0.5°C。可以理解的是,所生成的聚苯并咪唑奈米過濾薄膜250為一多孔性平板膜。在一些實施例中,聚苯并咪唑奈米過濾薄膜250的截留分子量(Molecular Weight Cut Off,MWCO)為1845至1911道爾頓(Dalton,Da)。Please refer to FIG. 1 and FIG. 3 at the same time. In

在一些實施例中,奈米過濾薄膜的製造方法10更包含將聚苯并咪唑奈米過濾薄膜250浸泡在甘油水溶液中。接著,再將聚苯并咪唑奈米過濾薄膜250進行乾燥製程。在一些實施例中,甘油水溶液中的甘油與水的體積比為1:1。此舉目的在於防止聚苯并咪唑奈米過濾薄膜250在後續乾燥過程中的孔隙塌陷。In some embodiments, the

在一些實施例中,奈米過濾薄膜的製造方法10更包含將聚苯并咪唑奈米過濾薄膜250浸泡在表面改性溶液中,以形成表面改性聚苯并咪唑奈米過濾薄膜。具體的說,表面改性溶液包含乙醇最為溶劑以及超支化聚乙烯亞胺(hyperbranched polyethyleneimine,HPEI)聚合物作為溶質。舉例來說,表面改性溶液中HPEI的濃度可以為1wt%。可以理解的是,超支化聚乙烯亞胺聚合物可以作為封孔劑。本揭露之奈米過濾薄膜的製造方法藉由使用超支化聚乙烯亞胺的乙醇溶液以實現綠色環保的表面改性,其原因為乙醇的毒性遠低於其他有機溶劑,諸如乙腈(acetonitrile)、N-甲基-2-吡咯烷酮(N-methyl-2-pyrrolidone,NMP)和2-丙醇(2-propanol)。

In some embodiments, the

在一些實施例中,超支化聚乙烯亞胺聚合物具有分子量為10000g/mole至50000g/mole。舉例來說,超支化聚乙烯亞胺聚合物的分子量可以為15000g/mole、20000g/mole、25000g/mole、30000g/mole、35000g/mole、40000g/mole或45000g/mole。根據多個實施例,當超支化聚乙烯亞胺聚合物的分子量大於某一數值,例如50000g/mole,則不易黏合在聚苯并咪唑奈米過濾薄膜250的表面,難以起到表面改性的效用。反之,當超支化聚乙烯亞胺聚合物的分子量小於某一數值,例如10000g/mole,則超支化聚乙烯亞胺聚合物無法有效地密封聚苯并咪唑奈米過濾薄膜250的缺陷孔。在一些實施例中,表面改性聚苯并咪唑奈米過濾薄膜的截留分子量(MWCO)為288KD。

In some embodiments, the hyperbranched polyethyleneimine polymer has a molecular weight of 10,000 g/mole to 50,000 g/mole. For example, the molecular weight of the hyperbranched polyethyleneimine polymer can be 15,000 g/mole, 20,000 g/mole, 25,000 g/mole, 30,000 g/mole, 35,000 g/mole, 40,000 g/mole or 45,000 g/mole. According to many embodiments, when the molecular weight of the hyperbranched polyethyleneimine polymer is greater than a certain value, such as 50,000 g/mole, it is difficult to adhere to the surface of the

在一些實施例中,奈米過濾薄膜的製造方法10更包含將上述的表面改性聚苯并咪唑奈米過濾薄膜浸泡在異丙醇水溶液中。此舉的目的在於將表面改性聚苯并咪唑奈米過濾薄膜表面未反應的聚合物清洗乾淨。接著,再將表面改性聚苯并咪唑奈米過濾薄膜進行乾燥製程。

In some embodiments, the

應當理解,儘管上述方法10示出了許多步驟、動作和/或特徵,但並非上述所有的操作、動作和/或特徵都是必需的,並且,也可能存在其他未示出的操作、動作和/或特徵。在一些實施方式中,上述操作和/或動作的順序可以與第1圖中所示的不同。此外,在一些實現方式中,所示出的動作可以進一步劃分為多個子動作,而在其他實現方式中,一些示出的動作可以彼此同時執行。It should be understood that although the

本發明之另一態樣係提供一種奈米過濾薄膜,其係由如上文所述之奈米過濾薄膜的製造方法10所製得的奈米過濾薄膜,此奈米過濾薄膜可以增進鋰離子與鎂離子的分離效率。更具體的說,奈米過濾薄膜包含聚苯并咪唑多孔奈米過濾薄膜主體,其具有如下結構:

或

。

Another aspect of the present invention is to provide a nanofiltration membrane, which is a nanofiltration membrane made by the nanofiltration

當奈米過濾薄膜在製造過程中係在酸性(1≤pH<7)的凝固浴中進行相變化,則生成的聚苯并咪唑多孔奈米過濾薄膜主體具有 的結構。 When the nanofiltration membrane undergoes phase change in an acidic (1≤pH<7) coagulation bath during the manufacturing process, the resulting polybenzimidazole porous nanofiltration membrane has structure.

當奈米過濾薄膜在製造過程中係在鹼性(7<pH≤13)的凝固浴中進行相變化,則生成的聚苯并咪唑多孔奈米過濾薄膜主體具有 的結構。 When the nanofiltration membrane undergoes phase change in an alkaline (7<pH≤13) coagulation bath during the manufacturing process, the resulting polybenzimidazole porous nanofiltration membrane has structure.

當奈米過濾薄膜在製造過程中係在中性(pH=7)的凝固浴中進行相變化,則生成的聚苯并咪唑多孔奈米過濾薄膜主體具有 的結構。 When the nanofiltration membrane undergoes phase change in a neutral (pH=7) coagulation bath during the manufacturing process, the resulting polybenzimidazole porous nanofiltration membrane has structure.

在一些實施例中,奈米過濾薄膜更包含超支化聚乙烯亞胺聚合物位於聚苯并咪唑多孔奈米過濾薄膜主體上及聚苯并咪唑多孔奈米過濾薄膜主體的多孔結構內。In some embodiments, the nanofiltration membrane further comprises a hyperbranched polyethyleneimine polymer located on the polybenzimidazole porous nanofiltration membrane body and in the porous structure of the polybenzimidazole porous nanofiltration membrane body.

以下實驗例用於詳細說明本揭示內容的一些態樣,以使本領域技術人員能夠實施本揭示內容。以下描述的實驗例是為使本領域技術人員能夠更好地理解本揭示內容及其技術效果。本文的實驗例和比較例不旨在限製本揭示內容。The following experimental examples are used to illustrate some aspects of the present disclosure in detail so that a person skilled in the art can implement the present disclosure. The experimental examples described below are intended to enable a person skilled in the art to better understand the present disclosure and its technical effects. The experimental examples and comparative examples herein are not intended to limit the present disclosure.

實驗例一:在凝固浴的pH值分別為2、5、7、9及12的酸鹼條件下進行相轉化所生成的聚苯并咪唑奈米過濾薄膜(分別以實施例一、二、三、四及五表示),進行溶質排斥試驗,其中溶質為氯化鎂(MgCl 2)。 Experimental Example 1: The polybenzimidazole nanofiltration membranes (represented by Examples 1, 2, 3, 4 and 5, respectively) produced by phase inversion under acid-base conditions with pH values of 2, 5, 7, 9 and 12 in the coagulation bath were subjected to a solute rejection test, wherein the solute was magnesium chloride (MgCl 2 ).

第4圖繪示根據本發明多個實施方式之在不同pH值條件下製造的各種聚苯并咪唑奈米過濾薄膜的分離性能。如第4圖所示,由圖中曲線可知,實施例一、實施例二、實施例三、實施例四及實施例五的氯化鎂排斥率分別為6.69±0.96%、5.14±0.59%、4.38±0.31%、6.63±0.88%及9.28±0.36%,其中實施例三具有最低的溶質排斥率。在酸性凝固浴下進行相轉化所生成的聚苯并咪唑奈米過濾薄膜,實施例一的氯化鎂排斥率大於實施例二的氯化鎂排斥率,且實施例二的氯化鎂排斥率大於實施例三的氯化鎂排斥率。在鹼性凝固浴下進行相轉化所生成的聚苯并咪唑奈米過濾薄膜,實施例五的氯化鎂排斥率大於實施例四的氯化鎂排斥率,且實施例四的氯化鎂排斥率大於實施例三的氯化鎂排斥率。此外,在鹼性凝固浴下進行相轉化所生成的聚苯并咪唑奈米過濾薄膜,其氯化鎂排斥率優於在酸性凝固浴下進行相轉化所生成的聚苯并咪唑奈米過濾薄膜。FIG. 4 shows the separation performance of various polybenzimidazole nanofiltration membranes manufactured under different pH conditions according to various embodiments of the present invention. As shown in FIG. 4, it can be seen from the curves in the figure that the magnesium chloride rejection rates of Example 1, Example 2, Example 3, Example 4 and Example 5 are 6.69±0.96%, 5.14±0.59%, 4.38±0.31%, 6.63±0.88% and 9.28±0.36%, respectively, among which Example 3 has the lowest solute rejection rate. For the polybenzimidazole nanofiltration membrane generated by phase inversion in an acidic coagulation bath, the magnesium chloride rejection rate of Example 1 is greater than that of Example 2, and the magnesium chloride rejection rate of Example 2 is greater than that of Example 3. The polybenzimidazole nanofilter membrane generated by phase inversion in an alkaline coagulation bath has a magnesium chloride rejection rate of Example 5 greater than that of Example 4, and the magnesium chloride rejection rate of Example 4 is greater than that of Example 3. In addition, the polybenzimidazole nanofilter membrane generated by phase inversion in an alkaline coagulation bath has a magnesium chloride rejection rate greater than that of the polybenzimidazole nanofilter membrane generated by phase inversion in an acidic coagulation bath.

此外,在本實驗例中,聚苯并咪唑奈米過濾薄膜的厚度會隨著凝固浴的pH值不同而有所變化。舉例來說,實施例一、實施例二、實施例三、實施例四及實施例五的膜厚分別為36.4±1.5微米、33.4±1.3微米、26.1±1.1微米、34.2±1.5微米、37.31±1.1微米。其原因在於聚苯并咪唑液膜在凝固浴裡進行相轉化的過程的同時發生胺基的質子化或去質子化時摻雜溶液(即,聚苯并咪唑溶液)的不穩定性。這種情形可能導致延遲分層(delayed demixing),在延長相轉化的過程中導致膜厚越來越厚。再者,聚苯并咪唑奈米過濾薄膜的表面孔隙結構也會隨著凝固浴的pH值不同而有所不同。舉例來說,實施例五的表面形成比其他實施例(實施例一至四)有更長的指狀大空隙(macrovoid),由於pH值越高的凝固浴中含有越多的OH -基團,此OH -基團會被帶正電的聚苯并咪唑奈米過濾薄膜吸引,促使非溶劑(即,凝固浴中的水)侵入從而形成較長的指狀大空隙。 In addition, in this experimental example, the thickness of the polybenzimidazole nanofiltration film varies with the pH value of the coagulation bath. For example, the film thicknesses of Example 1, Example 2, Example 3, Example 4, and Example 5 are 36.4±1.5 microns, 33.4±1.3 microns, 26.1±1.1 microns, 34.2±1.5 microns, and 37.31±1.1 microns, respectively. The reason is that the polybenzimidazole liquid film is instable when the amino groups are protonated or deprotonated during the phase inversion process in the coagulation bath. This situation may lead to delayed demixing, which causes the film thickness to become thicker and thicker during the extended phase inversion process. Furthermore, the surface pore structure of the polybenzimidazole nanofilter membrane also varies with the pH value of the coagulation bath. For example, the surface of Example 5 forms longer finger-like macrovoids than the other examples (Examples 1 to 4) because the coagulation bath with a higher pH value contains more OH - groups, which are attracted by the positively charged polybenzimidazole nanofilter membrane, causing the non-solvent (i.e., water in the coagulation bath) to invade and form longer finger-like macrovoids.

實驗例二:將實施例一、二、三、四及五的聚苯并咪唑奈米過濾薄膜使用分子量為2000 g/mole的超支化聚乙烯亞胺聚合物進行表面改性(分別以實施例六、七、八、九及十表示)後,進行溶質排斥試驗,其中溶質為氯化鎂(MgCl 2)。 Experimental Example 2: The polybenzimidazole nanofiltration membranes of Examples 1, 2, 3, 4 and 5 were surface modified with a hyperbranched polyethyleneimine polymer with a molecular weight of 2000 g/mole (represented by Examples 6, 7, 8, 9 and 10, respectively), and then subjected to a solute rejection test, wherein the solute was magnesium chloride (MgCl 2 ).

第5圖繪示根據本發明多個實施方式之各種聚苯并咪唑奈米過濾薄膜在進行表面改性後的分離性能。相較於第4圖,如第5圖所示之實施例六至實施例十的氯化鎂排斥率明顯增加,這是因為實施例六至實施例十的表面改性聚苯并咪唑奈米過濾薄膜具有不同的表面孔徑(或截留分子量)和厚度。由第5圖中曲線可知,實施例六、實施例七、實施例八、實施例九及實施例十的氯化鎂排斥率分別為97.70±4.40%、75.90±4.84%、67.91±2.95%、79.90±4.51%及89.54±4.53%,其中實施例八具有最低的溶質排斥率,且實施例六及實施例十具有最高的氯化鎂排斥率。FIG5 shows the separation performance of various polybenzimidazole nanofiltration membranes after surface modification according to various embodiments of the present invention. Compared with FIG4, the magnesium chloride rejection rate of Examples 6 to 10 as shown in FIG5 is significantly increased, because the surface-modified polybenzimidazole nanofiltration membranes of Examples 6 to 10 have different surface pore sizes (or molecular weight cutoff) and thicknesses. As can be seen from the curve in Figure 5, the magnesium chloride rejection rates of Example 6, Example 7, Example 8, Example 9 and Example 10 are 97.70±4.40%, 75.90±4.84%, 67.91±2.95%, 79.90±4.51% and 89.54±4.53%, respectively, among which Example 8 has the lowest solute rejection rate, and Example 6 and Example 10 have the highest magnesium chloride rejection rate.

實驗例三:將實施例五的聚苯并咪唑奈米過濾薄膜使用分子量為2000 g/mole、25000 g/mole及75000 g/mole的超支化聚乙烯亞胺聚合物進行表面改性(分別以實施例十一、十二及十三表示)後,進行溶質排斥試驗,其中溶質為氯化鎂(MgCl 2)。 Experimental Example 3: The polybenzimidazole nanofiltration membrane of Example 5 was surface-modified with hyperbranched polyethyleneimine polymers with molecular weights of 2000 g/mole, 25000 g/mole and 75000 g/mole (represented by Examples 11, 12 and 13, respectively), and then subjected to a solute rejection test, wherein the solute was magnesium chloride (MgCl 2 ).

第6圖繪示根據本發明多個實施方式之在pH值為12的凝固浴中生成的聚苯并咪唑奈米過濾薄膜進行不同分子量之超支化聚乙烯亞胺聚合物的表面改性後的分離性能。如第6圖所示,由圖中曲線可知,實施例五、實施例十一、實施例十二及實施例十三的氯化鎂排斥率分別為9.28%、93.25±0.71%、97.16±1.06%及96.14±0.39%,其中實施例十二的氯化鎂排斥率最高,即代表實施例十三之氯化鎂的截留性能最好。與實施例十一相比,使用分子量為25000 g/mole的超支化聚乙烯亞胺聚合物進行表面改性所得到的表面改性聚苯并咪唑奈米過濾薄膜(實施例十二)更能有效地密封聚苯并咪唑奈米過濾薄膜的表面缺陷孔。然而,由於實施例十三使用的超支化聚乙烯亞胺聚合物的分子量太大而無法進入聚苯并咪唑奈米過濾薄膜的表面孔隙中。如前文所述,未能進入聚苯并咪唑奈米過濾薄膜的表面孔隙中的超支化聚乙烯亞胺聚合物會被異丙醇水溶液帶走。FIG6 shows the separation performance of the polybenzimidazole nanofiltration membranes generated in a coagulation bath at a pH of 12 according to various embodiments of the present invention after surface modification with hyperbranched polyethyleneimine polymers of different molecular weights. As shown in FIG6, from the curves in the figure, it can be seen that the magnesium chloride rejection rates of Example 5, Example 11, Example 12 and Example 13 are 9.28%, 93.25±0.71%, 97.16±1.06% and 96.14±0.39%, respectively, among which the magnesium chloride rejection rate of Example 12 is the highest, which means that the magnesium chloride retention performance of Example 13 is the best. Compared with Example 11, the surface-modified polybenzimidazole nanofiltration membrane obtained by surface modification using a hyperbranched polyethyleneimine polymer having a molecular weight of 25000 g/mole (Example 12) can more effectively seal the surface defect holes of the polybenzimidazole nanofiltration membrane. However, since the molecular weight of the hyperbranched polyethyleneimine polymer used in Example 13 is too large, it cannot enter the surface pores of the polybenzimidazole nanofiltration membrane. As mentioned above, the hyperbranched polyethyleneimine polymer that cannot enter the surface pores of the polybenzimidazole nanofiltration membrane will be carried away by the isopropyl alcohol aqueous solution.

實驗例四:使用實施例十二進行分離濃度為500ppm、1000ppm及2000ppm鹽水溶液中鋰離子與鎂離子的奈米過濾測試,其中使用重量比為1:10的氯化鋰(LiCl)與氯化鎂(MgCl 2)來模擬鹽水溶液。 Experimental Example 4: Using Example 12, a nanofiltration test was performed to separate lithium ions and magnesium ions in saline solutions with concentrations of 500ppm, 1000ppm and 2000ppm, wherein lithium chloride (LiCl) and magnesium chloride (MgCl 2 ) with a weight ratio of 1:10 were used to simulate the saline solution.

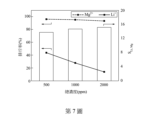

第7圖繪示根據本發明之實施例十二在不同濃度鹽水溶液中進行奈米過濾測試的排斥率。如第7圖所示,截留率隨著鹽水溶液濃度的增加而降低,這是奈米過濾薄膜常見的濃差極化(concentration polarization)效應。儘管存在濃差極化效應,但對於濃度為500 ppm至2000 ppm的鹽水溶液,鎂離子的截留率仍然保持在95.9%至93.23%的高水平。相反地,當鹽水溶液的濃度從500 ppm增加到1000 ppm,鋰離子的截留率會從43.6%顯著下降到27.44%,更進一步地當進料濃度增加至2000 ppm時,鋰離子的截留率會持續下降到13.87%。因此,雖然這兩種離子的截留率會隨著鹽水溶液濃度的增加而降低,但由於它們在尺寸和價態上的巨大差異,使得本揭露的奈米過濾薄膜提高了對鋰離子/鎂離子的分離效率。FIG. 7 shows the rejection rate of the nanofiltration test in saline solutions of different concentrations according to Example 12 of the present invention. As shown in FIG. 7 , the rejection rate decreases with the increase of the concentration of the saline solution, which is a common concentration polarization effect of nanofiltration membranes. Despite the concentration polarization effect, the rejection rate of magnesium ions is still maintained at a high level of 95.9% to 93.23% for saline solutions with a concentration of 500 ppm to 2000 ppm. On the contrary, when the concentration of the saline solution increases from 500 ppm to 1000 ppm, the retention rate of lithium ions will significantly decrease from 43.6% to 27.44%. Furthermore, when the feed concentration increases to 2000 ppm, the retention rate of lithium ions will continue to decrease to 13.87%. Therefore, although the retention rates of these two ions will decrease with the increase of the concentration of the saline solution, due to their huge differences in size and valence, the nanofiltration membrane disclosed in the present invention improves the separation efficiency of lithium ions/magnesium ions.

在本實驗例中,鋰離子相對於鎂離子的分離因子(S Li,Mg)是通過使用電感耦合等離子體-發射光譜(Inductively Coupled Plasma-Optical Emission Spectrometry,ICP-OES)(Thermo,iCAP 7000)測量並透過計算分離因子的特定公式而得。舉例來說,當S Li,Mg等於1時,則表示鋰離子和鎂離子之間沒有分離。當S Li,Mg大於1時,則表示鋰離子比鎂離子更快地通過奈米過濾薄膜。因此,S Li,Mg的值越大,對分離鋰離子與鎂離子是越理想的。 In this experimental example, the separation factor (S Li,Mg ) of lithium ions relative to magnesium ions is measured using Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES) (Thermo, iCAP 7000) and is obtained by calculating a specific formula for the separation factor. For example, when S Li,Mg is equal to 1, it means that there is no separation between lithium ions and magnesium ions. When S Li,Mg is greater than 1, it means that lithium ions pass through the nanofilter faster than magnesium ions. Therefore, the larger the value of S Li,Mg , the more ideal it is for separating lithium ions from magnesium ions.

實驗例五:比較實施例十二與八種市售膜(比較例一至八)之鋰離子相對於鎂離子的分離因子(S Li,Mg),其結果紀錄於下表一中。 Experimental Example 5: The separation factors (S Li,Mg ) of lithium ions relative to magnesium ions of Example 12 were compared with those of eight commercially available membranes (Comparative Examples 1 to 8). The results are recorded in Table 1 below.

表一

由上表一可看出,本揭露實施例十二之表面改性聚苯并咪唑奈米過濾薄膜的鋰離子與鎂離子的分離性能明顯高於其他市售膜。It can be seen from Table 1 above that the separation performance of lithium ions and magnesium ions of the surface-modified polybenzimidazole nanofiltration membrane of Example 12 of the present disclosure is significantly higher than that of other commercially available membranes.

綜上所述,本揭示之奈米過濾薄膜的製造方法具有簡單且環保的特性,且能夠生產均勻的奈米過濾薄膜。藉由此方法所生成的奈米過濾薄膜亦能增進鋰離子與鎂離子的分離效率。In summary, the manufacturing method of the nano-filter film disclosed in the present invention is simple and environmentally friendly, and can produce uniform nano-filter films. The nano-filter film produced by this method can also improve the separation efficiency of lithium ions and magnesium ions.

雖然本發明已以實施方式揭露如上,以上所述僅為本發明之較佳實施方式,並非用以限定本發明,任何熟習此技藝者,在不脫離本發明之精神和範圍內,當可作各種之均等變化與修飾,皆應屬本發明之涵蓋範圍,因此本發明之保護範圍當視後附之申請專利範圍所界定者為準。Although the present invention has been disclosed in the above embodiments, the above is only the preferred embodiment of the present invention and is not intended to limit the present invention. Any person skilled in the art can make various equivalent changes and modifications without departing from the spirit and scope of the present invention, which should all fall within the scope of the present invention. Therefore, the protection scope of the present invention shall be subject to the scope defined in the attached patent application.

10:方法10: Methods

110:步驟110: Steps

120:步驟120: Step

130:步驟130: Step

210:聚苯并咪唑溶液210:Polybenzimidazole solution

220:基材220: Base material

230:聚苯并咪唑液膜230:Polybenzimidazole liquid membrane

240:凝固浴240: Coagulation bath

250:聚苯并咪唑奈米過濾薄膜250:Polybenzimidazole nanofiltration membrane

為讓本發明之上述和其他目的、特徵、優點與實施方式能更明顯易懂,所附圖式之詳細說明如下: 第1圖繪示根據本發明多個實施方式之奈米過濾薄膜的製造方法。 第2圖繪示根據本發明多個實施方式之奈米過濾薄膜製造方法中某一階段的示意圖。 第3圖繪示根據本發明多個實施方式之奈米過濾薄膜製造方法中某一階段的示意圖。 第4圖繪示根據本發明多個實施方式之在不同pH值條件下製造的各種聚苯并咪唑奈米過濾薄膜的ATR-FTIR 光譜。 第5圖繪示根據本發明多個實施方式之各種聚苯并咪唑奈米過濾薄膜在進行表面改性後的分離性能。 第6圖繪示根據本發明多個實施方式之在pH值為12的凝固浴中生成的聚苯并咪唑奈米過濾薄膜進行不同分子量之超支化聚乙烯亞胺聚合物的表面改性後的分離性能。 第7圖繪示根據本發明之實施例十二在不同濃度鹽水溶液中進行奈米過濾測試的排斥率。 In order to make the above and other purposes, features, advantages and embodiments of the present invention more clearly understandable, the detailed description of the attached figures is as follows: Figure 1 shows a method for manufacturing a nanofiltration membrane according to multiple embodiments of the present invention. Figure 2 shows a schematic diagram of a certain stage in the method for manufacturing a nanofiltration membrane according to multiple embodiments of the present invention. Figure 3 shows a schematic diagram of a certain stage in the method for manufacturing a nanofiltration membrane according to multiple embodiments of the present invention. Figure 4 shows the ATR-FTIR spectra of various polybenzimidazole nanofiltration membranes manufactured under different pH conditions according to multiple embodiments of the present invention. Figure 5 shows the separation performance of various polybenzimidazole nanofiltration membranes after surface modification according to multiple embodiments of the present invention. FIG. 6 shows the separation performance of the polybenzimidazole nanofiltration membrane generated in a coagulation bath with a pH value of 12 according to various embodiments of the present invention after surface modification with hyperbranched polyethyleneimine polymers of different molecular weights. FIG. 7 shows the rejection rate of the nanofiltration test in saline solutions of different concentrations according to Example 12 of the present invention.

國內寄存資訊(請依寄存機構、日期、號碼順序註記) 無 國外寄存資訊(請依寄存國家、機構、日期、號碼順序註記) 無 Domestic storage information (please note in the order of storage institution, date, and number) None Foreign storage information (please note in the order of storage country, institution, date, and number) None

10:方法 10: Methods

110:步驟 110: Steps

120:步驟 120: Steps

130:步驟 130: Steps

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| TW112105110A TWI846324B (en) | 2023-02-14 | 2023-02-14 | Nanofiltration membrane and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| TW112105110A TWI846324B (en) | 2023-02-14 | 2023-02-14 | Nanofiltration membrane and manufacturing method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| TWI846324B true TWI846324B (en) | 2024-06-21 |

| TW202432234A TW202432234A (en) | 2024-08-16 |

Family

ID=92541772

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| TW112105110A TWI846324B (en) | 2023-02-14 | 2023-02-14 | Nanofiltration membrane and manufacturing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| TW (1) | TWI846324B (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103796741A (en) * | 2011-09-14 | 2014-05-14 | 新加坡国立大学 | A thin film nanofiltration membrane |

| CN105289305A (en) * | 2009-01-13 | 2016-02-03 | Ams技术Int(2012)有限公司 | Solvent and acid stable membranes, methods of manufacture thereof and methods of use thereof inter alia for separating metal ions from liquid process streams |

| CN108176258A (en) * | 2011-10-18 | 2018-06-19 | 帝国创新有限公司 | For the film of separation |

| US20210060490A1 (en) * | 2018-01-25 | 2021-03-04 | Katholieke Universiteit Leuven | Cross-linked nanofiltration membranes |

| CN112552512A (en) * | 2020-12-09 | 2021-03-26 | 华南师范大学 | Polybenzimidazole derivative, preparation method thereof and application of polybenzimidazole derivative in cyclic adsorption of metal ions |

| CN115105967A (en) * | 2021-03-17 | 2022-09-27 | 中国石油化工股份有限公司 | Acid-resistant alkali-resistant nanofiltration membrane and preparation method and application thereof |

-

2023

- 2023-02-14 TW TW112105110A patent/TWI846324B/en active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105289305A (en) * | 2009-01-13 | 2016-02-03 | Ams技术Int(2012)有限公司 | Solvent and acid stable membranes, methods of manufacture thereof and methods of use thereof inter alia for separating metal ions from liquid process streams |

| CN103796741A (en) * | 2011-09-14 | 2014-05-14 | 新加坡国立大学 | A thin film nanofiltration membrane |

| CN108176258A (en) * | 2011-10-18 | 2018-06-19 | 帝国创新有限公司 | For the film of separation |

| US20210060490A1 (en) * | 2018-01-25 | 2021-03-04 | Katholieke Universiteit Leuven | Cross-linked nanofiltration membranes |

| CN112552512A (en) * | 2020-12-09 | 2021-03-26 | 华南师范大学 | Polybenzimidazole derivative, preparation method thereof and application of polybenzimidazole derivative in cyclic adsorption of metal ions |

| CN115105967A (en) * | 2021-03-17 | 2022-09-27 | 中国石油化工股份有限公司 | Acid-resistant alkali-resistant nanofiltration membrane and preparation method and application thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| TW202432234A (en) | 2024-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6183945B2 (en) | Method for producing polyamide composite membrane | |

| KR101407445B1 (en) | Reverse osmotic membrane comprising silver nano wire layer and method of manufacturing the same | |

| EP2922617B1 (en) | A modified thin film composite reverse osmosis membrane and uses thereof | |

| CN111013391B (en) | Modified nanofiltration membrane and preparation method thereof | |

| KR101519026B1 (en) | Forward osmosis membranes based on multilayered thin films using a molecular layer-by-layer crosslinking assembly of organic monomers and method for fabricating the same | |

| KR102002917B1 (en) | Reverse osmosis or nanofiltration membranes and method for their production | |

| Ghaee et al. | Chitosan/polyethersulfone composite nanofiltration membrane for industrial wastewater treatment | |

| JP6145982B2 (en) | Method for producing composite semipermeable membrane and composite semipermeable membrane | |

| CN108187511A (en) | High flux and high retention ratio polyamide composite reverse osmosis membrane and preparation method thereof | |

| WO2017091645A1 (en) | Support layers for forward osmosis membranes | |

| TWI846324B (en) | Nanofiltration membrane and manufacturing method thereof | |

| KR101032040B1 (en) | Coating hydrophilic polymer on the surface of hydrophobic polymer and improving the performance of membrane through wet crosslinking | |

| JP5877855B2 (en) | Multilayer thin film based reverse osmosis separation membrane using cross-linking between organic monomers and method for producing the same | |

| WO2022124987A1 (en) | A thin film composite hollow fibre membrane | |

| CN113750798B (en) | Preparation method of double electric layer composite nanofiltration membrane | |

| KR101954913B1 (en) | Method for recovering multivalent metal ion from leaching solution containing sulfuric acid in which metal ions are leached, and composite membrane therefor | |

| CN115709003B (en) | Positively charged composite nanofiltration membrane and preparation method thereof | |

| Daneshvar et al. | Tris (hydroxymethyl) aminomethane-grafted polyamine nanofiltration membrane: enhanced antifouling and pH resistant properties | |

| KR102056873B1 (en) | membrane and manufacturing method thereof | |

| KR20120077997A (en) | Manufacturing method for polyamide-based reverse osmosis membrane and polyamide-based reverse osmosis membrane manufactured thereby | |

| KR20200075347A (en) | Hollow fiber type nanofiltration membrane module having high salt rejection and manufacturing method thereof | |

| KR20140065854A (en) | Fabrication method of composite membrane by pressurized-coating | |

| KR101734307B1 (en) | A polar membrane having nano-sized pores and a preparation method thereof | |

| KR102357400B1 (en) | Hollow fiber type nano-composite membrane and manufacturing method thereof | |

| KR20070013651A (en) | Manufacturing method of ultra-permeable polyamide nanocomposite membrane |