KR100746917B1 - 다결정 실리콘 연마용 cmp 슬러리 조성물 - Google Patents

다결정 실리콘 연마용 cmp 슬러리 조성물 Download PDFInfo

- Publication number

- KR100746917B1 KR100746917B1 KR1020060003406A KR20060003406A KR100746917B1 KR 100746917 B1 KR100746917 B1 KR 100746917B1 KR 1020060003406 A KR1020060003406 A KR 1020060003406A KR 20060003406 A KR20060003406 A KR 20060003406A KR 100746917 B1 KR100746917 B1 KR 100746917B1

- Authority

- KR

- South Korea

- Prior art keywords

- polycrystalline silicon

- slurry composition

- polishing

- cmp slurry

- metal oxide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000005498 polishing Methods 0.000 title claims abstract description 55

- 239000002002 slurry Substances 0.000 title claims abstract description 40

- 239000000203 mixture Substances 0.000 title claims abstract description 28

- 229910021420 polycrystalline silicon Inorganic materials 0.000 title claims abstract description 28

- 229910044991 metal oxide Inorganic materials 0.000 claims abstract description 19

- 150000004706 metal oxides Chemical class 0.000 claims abstract description 19

- 150000001875 compounds Chemical class 0.000 claims abstract description 14

- 125000001453 quaternary ammonium group Chemical group 0.000 claims abstract description 12

- WGTYBPLFGIVFAS-UHFFFAOYSA-M tetramethylammonium hydroxide Chemical compound [OH-].C[N+](C)(C)C WGTYBPLFGIVFAS-UHFFFAOYSA-M 0.000 claims description 16

- 238000000034 method Methods 0.000 claims description 14

- VDZOOKBUILJEDG-UHFFFAOYSA-M tetrabutylammonium hydroxide Chemical compound [OH-].CCCC[N+](CCCC)(CCCC)CCCC VDZOOKBUILJEDG-UHFFFAOYSA-M 0.000 claims description 10

- LPSKDVINWQNWFE-UHFFFAOYSA-M tetrapropylazanium;hydroxide Chemical compound [OH-].CCC[N+](CCC)(CCC)CCC LPSKDVINWQNWFE-UHFFFAOYSA-M 0.000 claims description 6

- 229920000642 polymer Polymers 0.000 claims description 5

- 239000011164 primary particle Substances 0.000 claims description 5

- 229940073455 tetraethylammonium hydroxide Drugs 0.000 claims description 5

- LRGJRHZIDJQFCL-UHFFFAOYSA-M tetraethylazanium;hydroxide Chemical compound [OH-].CC[N+](CC)(CC)CC LRGJRHZIDJQFCL-UHFFFAOYSA-M 0.000 claims description 5

- 229910018072 Al 2 O 3 Inorganic materials 0.000 claims description 4

- 229910010413 TiO 2 Inorganic materials 0.000 claims description 4

- 229910004298 SiO 2 Inorganic materials 0.000 claims description 3

- 229910020203 CeO Inorganic materials 0.000 claims description 2

- 229920000831 ionic polymer Polymers 0.000 abstract description 11

- 239000000654 additive Substances 0.000 abstract description 7

- 230000000996 additive effect Effects 0.000 abstract description 7

- 239000000126 substance Substances 0.000 abstract description 5

- 239000002245 particle Substances 0.000 abstract description 4

- 229910021642 ultra pure water Inorganic materials 0.000 abstract description 3

- 239000012498 ultrapure water Substances 0.000 abstract description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical group O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 14

- 239000000463 material Substances 0.000 description 6

- 239000004065 semiconductor Substances 0.000 description 5

- 239000000377 silicon dioxide Substances 0.000 description 5

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 4

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 4

- 229920002125 Sokalan® Polymers 0.000 description 3

- 150000001412 amines Chemical class 0.000 description 3

- CETPSERCERDGAM-UHFFFAOYSA-N ceric oxide Chemical compound O=[Ce]=O CETPSERCERDGAM-UHFFFAOYSA-N 0.000 description 3

- 229910000422 cerium(IV) oxide Inorganic materials 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 125000000524 functional group Chemical group 0.000 description 3

- 239000004584 polyacrylic acid Substances 0.000 description 3

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 125000000129 anionic group Chemical group 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- -1 hydroxyl ions Chemical class 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 239000011976 maleic acid Substances 0.000 description 2

- 229920005591 polysilicon Polymers 0.000 description 2

- 238000003756 stirring Methods 0.000 description 2

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- LHIJANUOQQMGNT-UHFFFAOYSA-N aminoethylethanolamine Chemical compound NCCNCCO LHIJANUOQQMGNT-UHFFFAOYSA-N 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 150000001735 carboxylic acids Chemical class 0.000 description 1

- 125000002091 cationic group Chemical group 0.000 description 1

- 238000000975 co-precipitation Methods 0.000 description 1

- 239000008119 colloidal silica Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000008367 deionised water Substances 0.000 description 1

- 229910021641 deionized water Inorganic materials 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 235000013399 edible fruits Nutrition 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 229910017053 inorganic salt Inorganic materials 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000001459 lithography Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 229920002120 photoresistant polymer Polymers 0.000 description 1

- 229920001446 poly(acrylic acid-co-maleic acid) Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 150000003242 quaternary ammonium salts Chemical class 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000002210 silicon-based material Substances 0.000 description 1

- QEMXHQIAXOOASZ-UHFFFAOYSA-N tetramethylammonium Chemical class C[N+](C)(C)C QEMXHQIAXOOASZ-UHFFFAOYSA-N 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09G—POLISHING COMPOSITIONS; SKI WAXES

- C09G1/00—Polishing compositions

- C09G1/02—Polishing compositions containing abrasives or grinding agents

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B33/00—Silicon; Compounds thereof

- C01B33/02—Silicon

- C01B33/021—Preparation

- C01B33/023—Preparation by reduction of silica or free silica-containing material

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01F—COMPOUNDS OF THE METALS BERYLLIUM, MAGNESIUM, ALUMINIUM, CALCIUM, STRONTIUM, BARIUM, RADIUM, THORIUM, OR OF THE RARE-EARTH METALS

- C01F7/00—Compounds of aluminium

- C01F7/02—Aluminium oxide; Aluminium hydroxide; Aluminates

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01G—COMPOUNDS CONTAINING METALS NOT COVERED BY SUBCLASSES C01D OR C01F

- C01G23/00—Compounds of titanium

- C01G23/04—Oxides; Hydroxides

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01G—COMPOUNDS CONTAINING METALS NOT COVERED BY SUBCLASSES C01D OR C01F

- C01G25/00—Compounds of zirconium

- C01G25/02—Oxides

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

- C09K3/14—Anti-slip materials; Abrasives

- C09K3/1454—Abrasive powders, suspensions and pastes for polishing

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Environmental & Geological Engineering (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

Abstract

Description

Claims (7)

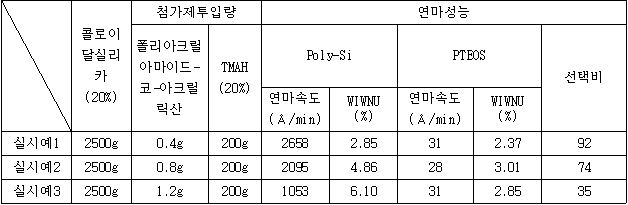

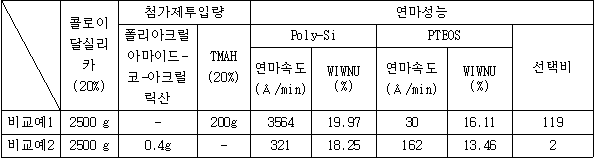

- 금속산화물, 4급암모늄염기화합물을 포함하는 다결정 실리콘 연마용 CMP 슬러리 조성물에 있어서, 양쪽 이온성 고분자를 더 포함하는 것을 특징으로 하는 다결정 실리콘 연마용 CMP 슬러리 조성물.

- 제 1항에 있어서, 상기 양쪽 이온성 고분자를 전체 CMP 슬러리 조성물에 대하여 0.001 내지 1중량% 포함하는 것을 특징으로 하는 다결정 실리콘 연마용 CMP 슬러리 조성물.

- 제 1항에 있어서, 상기 양쪽 이온성 고분자가 폴리아크릴아마이드-코-아크릴릭산 (poly(acylamide-co-acrylic acid))인 것을 특징으로 하는 다결정 실리콘 연마용 CMP 슬러리 조성물.

- 제 1항에 있어서, 상기 4급암모늄염기화합물은 테트라메틸암모늄하이드록사이드(Tetramethylammoniumhydroxide), 테트라에틸암모늄하이드록사이드(Tetraethylammoniumhydroxide), 테트라프로필암모늄하이드록사이드(Tetrapropylammoniumhydroxide), 테트라부틸암모늄하이드록사이드(Tetrabutylammoniumhydroxide) 중의 하나 이상인 것을 특징으로 하는 다결정 실리콘 연마용 CMP 슬러리 조성물.

- 제 1항에 있어서, 상기 4급암모늄염기화합물을 전체 CMP 슬러리 조성물에 대하여 0.01 내지 5중량% 포함하는 것을 특징으로 하는 다결정 실리콘 연마용 CMP 슬러리 조성물.

- 제 1항에 있어서, 상기 금속산화물은 SiO2, Al2O3, CeO2, ZrO2 및 TiO2 중의 하나 이상이고, 금속산화물의 일차입자크기는 10 내지 200nm, 비표면적은 10 내지 300㎡/g인 것을 특징으로 하는 다결정 실리콘 연마용 CMP 슬러리 조성물.

- 제 1항에 있어서, 상기 금속산화물을 전체 CMP 슬러리 조성물에 대하여 0.1 내지 30중량% 포함하는 것을 특징으로 하는 다결정 실리콘 연마용 CMP 슬러리 조성물.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020060003406A KR100746917B1 (ko) | 2006-01-12 | 2006-01-12 | 다결정 실리콘 연마용 cmp 슬러리 조성물 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020060003406A KR100746917B1 (ko) | 2006-01-12 | 2006-01-12 | 다결정 실리콘 연마용 cmp 슬러리 조성물 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20070075075A KR20070075075A (ko) | 2007-07-18 |

| KR100746917B1 true KR100746917B1 (ko) | 2007-08-07 |

Family

ID=38500277

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020060003406A Active KR100746917B1 (ko) | 2006-01-12 | 2006-01-12 | 다결정 실리콘 연마용 cmp 슬러리 조성물 |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR100746917B1 (ko) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190063678A (ko) | 2017-11-30 | 2019-06-10 | 김성호 | 기능성 아스콘 플랜트 시스템 |

| KR102638342B1 (ko) * | 2021-04-20 | 2024-02-21 | 주식회사 케이씨텍 | 연마 슬러리 조성물 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20040038882A (ko) * | 2002-10-31 | 2004-05-08 | 제이에스알 가부시끼가이샤 | 화학 기계 연마용 수계 분산체, 화학 기계 연마 방법 및반도체 장치의 제조 방법 및 화학 기계 연마용 수계분산체 제조용 재료 |

| KR20050096014A (ko) * | 2004-03-29 | 2005-10-05 | 한화석유화학 주식회사 | 반도체 얕은 트렌치 소자 분리 공정용 화학적 기계적 연마슬러리 |

-

2006

- 2006-01-12 KR KR1020060003406A patent/KR100746917B1/ko active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20040038882A (ko) * | 2002-10-31 | 2004-05-08 | 제이에스알 가부시끼가이샤 | 화학 기계 연마용 수계 분산체, 화학 기계 연마 방법 및반도체 장치의 제조 방법 및 화학 기계 연마용 수계분산체 제조용 재료 |

| KR20050096014A (ko) * | 2004-03-29 | 2005-10-05 | 한화석유화학 주식회사 | 반도체 얕은 트렌치 소자 분리 공정용 화학적 기계적 연마슬러리 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20070075075A (ko) | 2007-07-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4537010B2 (ja) | 化学機械的ポリシングスラリー及びこれを用いた化学機械的研磨方法 | |

| US7708900B2 (en) | Chemical mechanical polishing slurry compositions, methods of preparing the same and methods of using the same | |

| US20080081542A1 (en) | Slurry compositions and methods of polishing a layer using the slurry compositions | |

| JP2015147938A (ja) | 誘電性CMPスラリーにおけるCsOHの使用 | |

| KR20200132756A (ko) | 강화된 결함 억제를 나타내고 산성 환경에서 실리콘 이산화물 위의 실리콘 질화물을 선택적으로 연마하는 화학 기계적 연마 조성물 및 방법 | |

| KR100827594B1 (ko) | 다결정 실리콘 연마용 cmp 슬러리 조성물 및 이의 제조방법 | |

| US8512593B2 (en) | Chemical mechanical polishing slurry compositions, methods of preparing the same and methods of using the same | |

| KR100746917B1 (ko) | 다결정 실리콘 연마용 cmp 슬러리 조성물 | |

| KR100660767B1 (ko) | 다결정 실리콘 연마용 cmp 슬러리 및 이의 제조 방법 | |

| KR20000074300A (ko) | 연마용 조성물 | |

| KR100497410B1 (ko) | 연마성능이 개선된 산화막 연마용 슬러리 조성물 | |

| JP2008182181A (ja) | 研磨用組成物 | |

| KR100627589B1 (ko) | 결함 발생률이 낮은 cmp 슬러리 조성물 및 그 제조방법 | |

| KR101178716B1 (ko) | 다결정 실리콘 연마용 cmp 슬러리 조성물 및 이를 이용한 연마 방법 | |

| KR20150053048A (ko) | 연마 슬러리용 첨가제 및 이를 포함하는 슬러리 조성물 | |

| JP2006128689A (ja) | 化学的機械的平坦化用の水性スラリー組成物 | |

| KR101178717B1 (ko) | 다결정 실리콘 연마용 cmp 슬러리 조성물 및 이를 이용한 연마 방법 | |

| KR100367830B1 (ko) | Cmp용 조성물 | |

| KR100740898B1 (ko) | 절연막 연마 속도를 증가시킨 cmp 연마용 슬러리 조성물 | |

| KR100565419B1 (ko) | 연마용 조성물 | |

| KR100366304B1 (ko) | 반도체 웨이퍼 절연층의 화학적 기계적 연마용 조성물 | |

| KR20020008933A (ko) | Cmp용 조성물 | |

| KR20020004425A (ko) | Cmp용 슬러리 및 이의 제조 방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20060112 |

|

| PA0201 | Request for examination | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20070130 Patent event code: PE09021S01D |

|

| PG1501 | Laying open of application | ||

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

Patent event code: PE07011S01D Comment text: Decision to Grant Registration Patent event date: 20070731 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 20070801 Patent event code: PR07011E01D |

|

| PR1002 | Payment of registration fee |

Payment date: 20070801 End annual number: 3 Start annual number: 1 |

|

| PG1601 | Publication of registration | ||

| G170 | Re-publication after modification of scope of protection [patent] | ||

| PG1701 | Publication of correction | ||

| PR1001 | Payment of annual fee |

Payment date: 20100622 Start annual number: 4 End annual number: 4 |

|

| PR1001 | Payment of annual fee |

Payment date: 20110711 Start annual number: 5 End annual number: 5 |

|

| PR1001 | Payment of annual fee |

Payment date: 20120724 Start annual number: 6 End annual number: 6 |

|

| FPAY | Annual fee payment |

Payment date: 20130607 Year of fee payment: 7 |

|

| PR1001 | Payment of annual fee |

Payment date: 20130607 Start annual number: 7 End annual number: 7 |

|

| FPAY | Annual fee payment |

Payment date: 20140605 Year of fee payment: 8 |

|

| PR1001 | Payment of annual fee |

Payment date: 20140605 Start annual number: 8 End annual number: 8 |

|

| FPAY | Annual fee payment |

Payment date: 20150721 Year of fee payment: 9 |

|

| PR1001 | Payment of annual fee |

Payment date: 20150721 Start annual number: 9 End annual number: 9 |

|

| FPAY | Annual fee payment |

Payment date: 20160721 Year of fee payment: 10 |

|

| PR1001 | Payment of annual fee |

Payment date: 20160721 Start annual number: 10 End annual number: 10 |

|

| FPAY | Annual fee payment |

Payment date: 20170720 Year of fee payment: 11 |

|

| PR1001 | Payment of annual fee |

Payment date: 20170720 Start annual number: 11 End annual number: 11 |

|

| FPAY | Annual fee payment |

Payment date: 20180718 Year of fee payment: 12 |

|

| PR1001 | Payment of annual fee |

Payment date: 20180718 Start annual number: 12 End annual number: 12 |

|

| FPAY | Annual fee payment |

Payment date: 20190801 Year of fee payment: 13 |

|

| PR1001 | Payment of annual fee |

Payment date: 20190801 Start annual number: 13 End annual number: 13 |

|

| PR1001 | Payment of annual fee |

Payment date: 20200803 Start annual number: 14 End annual number: 14 |

|

| PR1001 | Payment of annual fee |

Payment date: 20210728 Start annual number: 15 End annual number: 15 |

|

| PR1001 | Payment of annual fee |

Payment date: 20220801 Start annual number: 16 End annual number: 16 |

|

| PR1001 | Payment of annual fee |

Payment date: 20230801 Start annual number: 17 End annual number: 17 |

|

| PR1001 | Payment of annual fee |

Payment date: 20240730 Start annual number: 18 End annual number: 18 |