JP6637200B2 - 圧延接合体及びその製造方法 - Google Patents

圧延接合体及びその製造方法 Download PDFInfo

- Publication number

- JP6637200B2 JP6637200B2 JP2018567449A JP2018567449A JP6637200B2 JP 6637200 B2 JP6637200 B2 JP 6637200B2 JP 2018567449 A JP2018567449 A JP 2018567449A JP 2018567449 A JP2018567449 A JP 2018567449A JP 6637200 B2 JP6637200 B2 JP 6637200B2

- Authority

- JP

- Japan

- Prior art keywords

- thickness

- rolled

- plate

- metal layer

- rolled joint

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 13

- 229910052751 metal Inorganic materials 0.000 claims description 89

- 239000002184 metal Substances 0.000 claims description 89

- 238000005304 joining Methods 0.000 claims description 41

- 238000000992 sputter etching Methods 0.000 claims description 17

- 230000009467 reduction Effects 0.000 claims description 16

- 238000000034 method Methods 0.000 claims description 15

- 229910052802 copper Inorganic materials 0.000 claims description 13

- 238000003825 pressing Methods 0.000 claims description 9

- 229910052782 aluminium Inorganic materials 0.000 claims description 8

- 229910052719 titanium Inorganic materials 0.000 claims description 6

- 230000008569 process Effects 0.000 claims description 5

- 229910045601 alloy Inorganic materials 0.000 claims description 4

- 239000000956 alloy Substances 0.000 claims description 4

- 229910052742 iron Inorganic materials 0.000 claims description 3

- 229910052749 magnesium Inorganic materials 0.000 claims description 3

- 239000010410 layer Substances 0.000 description 114

- 239000010949 copper Substances 0.000 description 26

- 238000005096 rolling process Methods 0.000 description 25

- 229910000838 Al alloy Inorganic materials 0.000 description 14

- 239000000463 material Substances 0.000 description 14

- 229910001220 stainless steel Inorganic materials 0.000 description 13

- 239000010935 stainless steel Substances 0.000 description 13

- 238000010438 heat treatment Methods 0.000 description 11

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 9

- 229910001069 Ti alloy Inorganic materials 0.000 description 9

- 238000005259 measurement Methods 0.000 description 9

- 239000010936 titanium Substances 0.000 description 9

- 239000011888 foil Substances 0.000 description 7

- 230000017525 heat dissipation Effects 0.000 description 6

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 5

- 239000007769 metal material Substances 0.000 description 5

- 230000003287 optical effect Effects 0.000 description 5

- 229910000861 Mg alloy Inorganic materials 0.000 description 4

- 238000005452 bending Methods 0.000 description 4

- 230000008859 change Effects 0.000 description 4

- 238000005097 cold rolling Methods 0.000 description 4

- 229910000881 Cu alloy Inorganic materials 0.000 description 3

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 3

- 239000011261 inert gas Substances 0.000 description 3

- 229910000765 intermetallic Inorganic materials 0.000 description 3

- 239000011241 protective layer Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 238000003466 welding Methods 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 2

- 229910052786 argon Inorganic materials 0.000 description 2

- 229910000963 austenitic stainless steel Inorganic materials 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 238000006243 chemical reaction Methods 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 238000005098 hot rolling Methods 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 238000000879 optical micrograph Methods 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 230000003014 reinforcing effect Effects 0.000 description 2

- 238000001179 sorption measurement Methods 0.000 description 2

- QPLDLSVMHZLSFG-UHFFFAOYSA-N Copper oxide Chemical compound [Cu]=O QPLDLSVMHZLSFG-UHFFFAOYSA-N 0.000 description 1

- 239000005751 Copper oxide Substances 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 1

- 238000007743 anodising Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000001680 brushing effect Effects 0.000 description 1

- ZCDOYSPFYFSLEW-UHFFFAOYSA-N chromate(2-) Chemical compound [O-][Cr]([O-])(=O)=O ZCDOYSPFYFSLEW-UHFFFAOYSA-N 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 229910000431 copper oxide Inorganic materials 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000004649 discoloration prevention Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 229910052743 krypton Inorganic materials 0.000 description 1

- DNNSSWSSYDEUBZ-UHFFFAOYSA-N krypton atom Chemical compound [Kr] DNNSSWSSYDEUBZ-UHFFFAOYSA-N 0.000 description 1

- 230000013011 mating Effects 0.000 description 1

- 229910052754 neon Inorganic materials 0.000 description 1

- GKAOGPIIYCISHV-UHFFFAOYSA-N neon atom Chemical compound [Ne] GKAOGPIIYCISHV-UHFFFAOYSA-N 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 238000001953 recrystallisation Methods 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

- 229910052724 xenon Inorganic materials 0.000 description 1

- FHNFHKCVQCLJFQ-UHFFFAOYSA-N xenon atom Chemical compound [Xe] FHNFHKCVQCLJFQ-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B1/00—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations

- B21B1/38—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling sheets of limited length, e.g. folded sheets, superimposed sheets, pack rolling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/01—Layered products comprising a layer of metal all layers being exclusively metallic

- B32B15/013—Layered products comprising a layer of metal all layers being exclusively metallic one layer being formed of an iron alloy or steel, another layer being formed of a metal other than iron or aluminium

- B32B15/015—Layered products comprising a layer of metal all layers being exclusively metallic one layer being formed of an iron alloy or steel, another layer being formed of a metal other than iron or aluminium the said other metal being copper or nickel or an alloy thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B1/00—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations

- B21B1/22—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling plates, strips, bands or sheets of indefinite length

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B38/00—Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/04—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating by means of a rolling mill

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/22—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating taking account of the properties of the materials to be welded

- B23K20/227—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating taking account of the properties of the materials to be welded with ferrous layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/22—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating taking account of the properties of the materials to be welded

- B23K20/227—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating taking account of the properties of the materials to be welded with ferrous layer

- B23K20/2275—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating taking account of the properties of the materials to be welded with ferrous layer the other layer being aluminium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/01—Layered products comprising a layer of metal all layers being exclusively metallic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/18—Sheet panels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/02—Iron or ferrous alloys

- B23K2103/04—Steel or steel alloys

- B23K2103/05—Stainless steel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/18—Dissimilar materials

- B23K2103/20—Ferrous alloys and aluminium or alloys thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/18—Dissimilar materials

- B23K2103/22—Ferrous alloys and copper or alloys thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/732—Dimensional properties

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

- Laminated Bodies (AREA)

- Metal Rolling (AREA)

Description

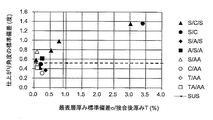

(1)2層以上の金属層からなる圧延接合体であって、

最表層の厚みの標準偏差σと、前記圧延接合体の厚みTとの比σ/Tが0〜4.0%であり、且つ前記厚みTが2mm以内であり、前記厚みTの偏差が4.0%以内である、前記圧延接合体。

(2)最表層の厚みの標準偏差σが、4.0μm未満である、上記(1)に記載の圧延接合体。

(3)2層以上の金属層が、それぞれ独立して、Al、Cu、Mg、Fe及びTiからなる群から選択される金属又はその合金である、上記(1)又は(2)に記載の圧延接合体。

(4)上記(1)に記載の圧延接合体の製造方法であって、

2層以上の金属層のうち、最も硬質である金属層の接合前後におけるビッカース硬さ(JIS Z 2244、荷重50gf)の変化量が80以内になるように前記2層以上の金属層を接合する工程を含み、

接合前の前記2層以上の金属層の総厚みT0に対する圧下量ΔTの比ΔT/T0が1.0未満である、前記製造方法。

(5)2層以上の金属層を接合する工程が、接合する金属層の表面をスパッタエッチングし、前記スパッタエッチングした表面同士を圧接することにより行われる、上記(4)に記載の圧延接合体の製造方法。

(6)上記(1)〜(3)のいずれかに記載の圧延接合体からなる成型品。

例2:厚み50μmのSUS板/厚み102μmのCu板/厚み50μmのSUS板

例3:厚み102μmのSUS板/厚み204μmのCu板/厚み102μmのSUS板

例4:厚み102μmのSUS板/厚み204μmのCu板/厚み102μmのSUS板

例5:厚み102μmのSUS板/厚み204μmのCu板/厚み102μmのSUS板

例6:厚み50μmのSUS板/厚み52μmのCu板

例7:厚み201μmのSUS板/厚み195μmのCu板

例8:厚み15μmのSUS板/厚み74μmのAl板/厚み15μmのSUS板

例9:厚み51μmのAl板/厚み198μmのSUS板/厚み51μmのAl板

例10:厚み0.25mmのSUS板(SUS304)/厚み0.8mmのAl合金板(A5052)

例11:厚み200μmのCu板(C1020)/厚み200μmのAl合金板(A5052)

例12:厚み200μmの純Ti板(TP270)/厚み600μmのAl合金板(A5052)

例13:厚み200μmのTi合金板(Ti15−3−3−3)/厚み600μmのAl合金板(A5052)

t1 最表層の厚み

T 圧延接合体の厚み

Claims (6)

- 2層以上の金属層からなる圧延接合体であって、

最表層の厚みの標準偏差σと、前記圧延接合体の厚みTとの比σ/Tが0〜4.0%であり、且つ前記厚みTが2mm以内であり、前記厚みTの偏差が4.0%以内であり、前記標準偏差σが4.0μm未満であり、

前記2層以上の金属層が、それぞれ独立して、Al、Cu、Mg、Fe及びTiからなる群から選択される金属又はその合金である、前記圧延接合体。 - 標準偏差σと圧延接合体の厚みTとの比σ/Tが0〜1.2%である、請求項1に記載の圧延接合体。

- 標準偏差σが1.8μm未満である、請求項1又は2に記載の圧延接合体。

- 請求項1に記載の圧延接合体の製造方法であって、

2層以上の金属層のうち、最も硬質である金属層の接合前後におけるビッカース硬さ(JIS Z 2244、荷重50gf)の変化量が80以内になるように前記2層以上の金属層を接合する工程を含み、

接合前の前記2層以上の金属層の総厚みT0に対する圧下量ΔTの比ΔT/T0が1.0未満である、前記製造方法。 - 2層以上の金属層を接合する工程が、接合する金属層の表面をスパッタエッチングし、前記スパッタエッチングした表面同士を圧接することにより行われる、請求項4に記載の圧延接合体の製造方法。

- 請求項1〜3のいずれか1項に記載の圧延接合体からプレス加工により作製された成型品。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017020551 | 2017-02-07 | ||

| JP2017020551 | 2017-02-07 | ||

| PCT/JP2018/004105 WO2018147297A1 (ja) | 2017-02-07 | 2018-02-07 | 圧延接合体及びその製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2018147297A1 JPWO2018147297A1 (ja) | 2019-06-27 |

| JP6637200B2 true JP6637200B2 (ja) | 2020-01-29 |

Family

ID=63108322

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018567449A Active JP6637200B2 (ja) | 2017-02-07 | 2018-02-07 | 圧延接合体及びその製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11453203B2 (ja) |

| JP (1) | JP6637200B2 (ja) |

| KR (1) | KR102306045B1 (ja) |

| CN (2) | CN117798187A (ja) |

| WO (1) | WO2018147297A1 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7085419B2 (ja) * | 2018-03-14 | 2022-06-16 | 東洋鋼鈑株式会社 | 圧延接合体及びその製造方法 |

| JP7162960B2 (ja) * | 2018-08-06 | 2022-10-31 | 東洋鋼鈑株式会社 | 圧延接合体及びその製造方法、並びに電子機器用の放熱補強部材 |

| WO2024029299A1 (ja) * | 2022-08-02 | 2024-02-08 | 株式会社プロテリアル | クラッド材およびクラッド材の製造方法 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5410646B1 (ja) | 1969-05-19 | 1979-05-09 | ||

| DE3664588D1 (en) * | 1985-04-05 | 1989-08-31 | Nippon Steel Corp | Method for producing a clad plate by hot-rolling |

| JP3168930B2 (ja) | 1996-12-24 | 2001-05-21 | 住友金属工業株式会社 | 銅−ステンレス鋼クラッド板の製造方法 |

| JP4447762B2 (ja) | 2000-10-18 | 2010-04-07 | 東洋鋼鈑株式会社 | 多層金属積層板及びその製造方法 |

| JP3862737B1 (ja) * | 2005-10-18 | 2006-12-27 | 栄樹 津島 | クラッド材およびその製造方法、クラッド材の成型方法、クラッド材を用いた放熱基板 |

| WO2011152478A1 (ja) * | 2010-06-02 | 2011-12-08 | 住友金属工業株式会社 | クラッド材 |

| JP3168930U (ja) | 2011-03-28 | 2011-07-07 | 明弘 澤田 | 組み合わせ仏具 |

| US9421741B2 (en) * | 2012-07-10 | 2016-08-23 | Neomax Materials Co., Ltd. | Chassis and method for manufacturing chassis |

| TW201427827A (zh) * | 2012-12-06 | 2014-07-16 | Mitsubishi Gas Chemical Co | 覆金屬箔疊層板之製造方法 |

| JP6100605B2 (ja) | 2013-05-17 | 2017-03-22 | 昭和電工株式会社 | 多層クラッド材の製造方法 |

| JP6543439B2 (ja) | 2014-04-01 | 2019-07-10 | 東洋鋼鈑株式会社 | 金属積層材の製造方法 |

| CN104588646A (zh) * | 2014-12-30 | 2015-05-06 | 天龙钨钼(天津)有限公司 | 一种制备cpc层状复合材料的方法及一种cpc层状复合材料 |

| CN105170652B (zh) | 2015-08-31 | 2017-03-01 | 东北大学 | 一种多层异种金属复合极薄带的制备方法 |

| CN105543649B (zh) * | 2015-12-14 | 2017-10-31 | 宝山钢铁股份有限公司 | 一种三层复合钢板及其制造方法 |

-

2018

- 2018-02-07 JP JP2018567449A patent/JP6637200B2/ja active Active

- 2018-02-07 CN CN202410061726.XA patent/CN117798187A/zh active Pending

- 2018-02-07 KR KR1020197009179A patent/KR102306045B1/ko active IP Right Grant

- 2018-02-07 US US16/483,623 patent/US11453203B2/en active Active

- 2018-02-07 WO PCT/JP2018/004105 patent/WO2018147297A1/ja active Application Filing

- 2018-02-07 CN CN201880009902.8A patent/CN110234443B/zh active Active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2018147297A1 (ja) | 2018-08-16 |

| CN110234443B (zh) | 2024-01-26 |

| KR20190116243A (ko) | 2019-10-14 |

| CN117798187A (zh) | 2024-04-02 |

| CN110234443A (zh) | 2019-09-13 |

| JPWO2018147297A1 (ja) | 2019-06-27 |

| US20200031096A1 (en) | 2020-01-30 |

| US11453203B2 (en) | 2022-09-27 |

| KR102306045B1 (ko) | 2021-09-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6865172B2 (ja) | 金属積層材及びその製造方法 | |

| JP6637200B2 (ja) | 圧延接合体及びその製造方法 | |

| KR102573723B1 (ko) | 압연 접합체 및 그 제조 방법 | |

| WO2018181717A1 (ja) | 電子機器用圧延接合体及び電子機器用筐体 | |

| JP7375131B2 (ja) | 圧延接合体及び圧延接合体の製造方法 | |

| JP7060468B2 (ja) | 圧延接合体及びその製造方法 | |

| WO2019176937A1 (ja) | 圧延接合体及びその製造方法 | |

| JP6813961B2 (ja) | 銅及びマグネシウムからなる金属積層材及びその製造方法 | |

| WO2018181721A1 (ja) | 圧延接合体 | |

| JP7162960B2 (ja) | 圧延接合体及びその製造方法、並びに電子機器用の放熱補強部材 | |

| WO2018181702A1 (ja) | 電子機器用圧延接合体及び電子機器用筐体 | |

| JP2019112718A (ja) | 積層薄板の製造方法及び積層薄板 | |

| JP2019002052A (ja) | クラッド材の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190228 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190228 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20190228 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20190314 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190521 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190722 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190924 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191101 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20191203 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20191219 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6637200 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |