JP5503121B2 - Insulating paint and insulated wires - Google Patents

Insulating paint and insulated wires Download PDFInfo

- Publication number

- JP5503121B2 JP5503121B2 JP2008174082A JP2008174082A JP5503121B2 JP 5503121 B2 JP5503121 B2 JP 5503121B2 JP 2008174082 A JP2008174082 A JP 2008174082A JP 2008174082 A JP2008174082 A JP 2008174082A JP 5503121 B2 JP5503121 B2 JP 5503121B2

- Authority

- JP

- Japan

- Prior art keywords

- weight

- polyamide

- imide

- insulating

- polyamideimide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Formation Of Insulating Films (AREA)

- Insulated Conductors (AREA)

- Paints Or Removers (AREA)

Description

本発明は、絶縁塗料および絶縁電線に関するものである。特に、ポリアミドイミド系絶縁塗料およびその絶縁塗料が導体上に塗布焼付けされて成るポリアミドイミド系絶縁電線に関するものである。 The present invention relates to an insulating paint and an insulated wire. In particular, the present invention relates to a polyamide-imide insulating wire and a polyamide-imide insulating wire formed by applying and baking the insulating coating on a conductor.

電気絶縁塗料を導体上に塗布焼付した絶縁電線は各種の電気機器に組み込まれたコイルの用途に大量に使用されている。電気絶縁塗料は各種の用途、要求性能によって耐熱温度が105℃〜250℃等の耐熱クラスに分かれており、中でもポリアミドイミド系絶縁塗料は優れた耐熱性、機械的特性、耐冷媒性を有しており、近年耐熱温度が180〜200℃以上の耐熱クラスのモータに広く使用されるようになってきている。また、ポリアミドイミド系絶縁塗料を塗布焼付けした絶縁電線の生産合理化のため絶縁塗料には焼付け工程の生産合理化に対応した高温、高速焼付け性が強く要求されるようになってきている。 Insulated electric wires obtained by applying and baking electrical insulating paints on conductors are used in large quantities for coils used in various electric devices. Electrical insulation paints are divided into heat-resistant classes with a heat-resistant temperature of 105 ° C to 250 ° C depending on various applications and required performance. Among them, polyamide-imide insulating paints have excellent heat resistance, mechanical properties, and refrigerant resistance. In recent years, it has been widely used in motors of a heat resistance class having a heat resistance temperature of 180 to 200 ° C. or higher. In addition, in order to rationalize the production of insulated wires coated and baked with polyamide-imide insulating paint, the insulating paint is strongly required to have high temperature and high-speed bakeability corresponding to the production rationalization of the baking process.

しかし、従来のポリアミドイミド系絶縁塗料は、耐熱グレードが155〜180℃の耐熱クラスのポリエステル系絶縁塗料およびポリエステルイミド系絶縁塗料に比べ、高温高速焼付け性で劣り、絶縁皮膜の仕上げ外観において発泡やシワなどの異常が出やすいという欠点があった。特に、導体との密着性を改良したポリアミドイミド系絶縁塗料は高温高速焼付けが困難であり、焼付け工程において、シワ不良を防止するために低温低速とし、1回当たりの塗布量を少なくし、塗装回数を増やして絶縁電線を製造するなど、コスト面において不利な条件での製造を余儀なくされている。 However, conventional polyamide-imide insulating coatings are inferior in high-temperature and high-speed bakeability compared to polyester-based insulating coatings and polyesterimide-based insulating coatings having a heat resistance grade of 155 to 180 ° C. There was a drawback that wrinkles and other abnormalities were likely to occur. In particular, polyamideimide insulation coatings with improved adhesion to conductors are difficult to be baked at high temperature and high speed. In the baking process, low temperature and low speed are used to prevent wrinkle defects, and the amount of coating per application is reduced. For example, an insulated wire is manufactured by increasing the number of times, and it is forced to manufacture under a disadvantageous condition in terms of cost.

以上のような問題において、焼付け時の発泡は、ポリアミドイミド樹脂の硬化反応時に発生する炭酸ガスの発生と焼付け時の溶剤蒸発挙動に依存している。また、皮膜のシワは硬化反応の速度に依存している。 In the above problems, foaming during baking depends on the generation of carbon dioxide gas generated during the curing reaction of the polyamideimide resin and the solvent evaporation behavior during baking. The wrinkle of the film depends on the speed of the curing reaction.

そこで、特許文献1では、炭酸ガスの発生を少なくして皮膜の泡を防止するために、ポリアミドイミド樹脂に特定のエポキシ樹脂を配合することが記載されている。これによりポリアミドイミド樹脂の末端イソシアネート基とエポキシ環が優先的に反応することで本来のアミドイミド樹脂の硬化反応である末端カルボキシル基と末端イソシアネート基およびアミド基とカルボキシル基の反応が弱められるため、発泡が抑えられる。また、特許文献1の類似提案として、特許文献2には、ポリアミドイミド絶縁塗料中にエポキシ当量400以下のエポキシ樹脂を配合することで高速焼付け時の発泡を抑え電線特性も低下しないことが記載されている。

Therefore,

特許文献3では、硬化反応速度の調節により皮膜のシワを防止するために、ポリアミドイミド絶縁塗料中に特定元素の金属塩を配合する提案がなされている。これは有機溶剤としてフェノール系溶媒(代表例クレゾール)を使用しているため、ポリアミドイミド樹脂の末端イソシアネート基による硬化反応が非プロトン系溶剤(代表例N−メチル−2−ピロリドン)使用の場合よりも起こりにくいという欠点を改善するための提案である。この提案によれば、金属塩がフェノール系溶媒で安定化されている末端イソシアネート基を活性化させる触媒の役目を果たし、硬化速度を向上させることにより皮膜のシワ、荒れは無くなる。 In Patent Document 3, in order to prevent wrinkling of the film by adjusting the curing reaction rate, a proposal has been made to mix a metal salt of a specific element in a polyamide-imide insulating coating. This is because a phenolic solvent (representative example cresol) is used as the organic solvent, so that the curing reaction by the terminal isocyanate group of the polyamide-imide resin is more than when an aprotic solvent (representative example N-methyl-2-pyrrolidone) is used. It is a proposal to improve the disadvantage that it is difficult to occur. According to this proposal, the metal salt serves as a catalyst for activating the terminal isocyanate group stabilized with the phenol solvent, and the wrinkle and roughness of the film are eliminated by improving the curing rate.

また、特許文献4には、溶剤蒸発速度を調整することで皮膜の泡を防止するために、絶縁塗料中に特定の高沸点炭化水素を配合することが記載されており、これにより、溶剤蒸発過程で高沸点溶剤が残留することで皮膜表面硬化が抑えられて発泡が減少する。 In addition, Patent Document 4 describes that a specific high-boiling hydrocarbon is blended in the insulating paint in order to prevent the foam of the film by adjusting the solvent evaporation rate. The high boiling point solvent remains in the process, so that the film surface hardening is suppressed and foaming is reduced.

しかし、特許文献1、2に記載されている技術では、焼付け後の絶縁皮膜の耐熱性が従来のポリアミドイミド絶縁塗料より劣り、特に絶縁電線の軟化特性が低下するという問題があった。また、特許文献3の技術では、金属塩の種類によってはポリアミドイミド樹脂と反応し絶縁塗料の粘度が上昇するので焼付け作業性が低下するという問題があり、特許文献4の技術をポリアミドイミド樹脂に適用した場合には、樹脂との相溶性が低いため配合量が制限され、かつ、塗装時の樹脂の流動性が低いため本来の効果である表面硬化防止を発揮できないという問題があった。

However, the techniques described in

本発明は、このような従来の問題点に鑑みて為されたもので、その目的は、導体との密着性が良く、高温高速焼付けしても外観の良好な、絶縁塗料および絶縁電線を提供することにある。 The present invention has been made in view of such conventional problems, and an object thereof is to provide an insulating paint and an insulated wire having good adhesion to a conductor and good appearance even when baked at high temperature and high speed. There is to do.

上記課題を解決するため、本発明の第1の態様は、1,3−ジメチル−2−イミダゾリジノンを含有する有機溶剤にポリアミドイミド樹脂が溶解されたことを特徴とする絶縁塗料を提供する。 In order to solve the above-mentioned problems, a first aspect of the present invention provides an insulating paint characterized in that a polyamide-imide resin is dissolved in an organic solvent containing 1,3-dimethyl-2-imidazolidinone. .

本発明における第1の態様は、以下の(1)および(2)である。The first aspect of the present invention is the following (1) and (2).

(1)ポリアミドイミド樹脂が有機溶剤に溶解された絶縁塗料であって、(1) An insulating paint in which a polyamideimide resin is dissolved in an organic solvent,

前記有機溶剤がN−メチル−2−ピロリドンと1,3−ジメチル−2−イミダゾリジノンからなり、 The organic solvent comprises N-methyl-2-pyrrolidone and 1,3-dimethyl-2-imidazolidinone;

前記1,3−ジメチル−2−イミダゾリジノンの前記有機溶剤中の含有量が10質量%〜30質量%であり、The content of the 1,3-dimethyl-2-imidazolidinone in the organic solvent is 10% by mass to 30% by mass,

前記ポリアミドイミド樹脂の重量平均分子量が20000以上かつ30000以下であることを特徴とする絶縁塗料。A weight average molecular weight of the polyamideimide resin is 20000 or more and 30000 or less.

(2)前記ポリアミドイミド樹脂100重量部に対して、(2) For 100 parts by weight of the polyamideimide resin,

(i)アルコキシ化メラミン樹脂5〜20重量部、(I) 5-20 parts by weight of alkoxylated melamine resin,

(ii)トリアルキルアミン0.05〜1.0重量部、または、(Ii) 0.05 to 1.0 part by weight of a trialkylamine, or

(iii)トリアルキルアミン0.05〜1.0重量部およびアルコキシ化メラミン樹脂5〜20重量部、(Iii) 0.05 to 1.0 part by weight of a trialkylamine and 5 to 20 parts by weight of an alkoxylated melamine resin,

が更に含有されていることを特徴とする(1)に記載の絶縁塗料。Is further contained, The insulating paint as described in (1) characterized by the above-mentioned.

本発明の第2の態様は、以下の(3)である。

(3)前記(1)または(2)に記載の絶縁塗料が導体上に又は他の絶縁層を介して塗布焼付けされてなることを特徴とする絶縁電線。

The second aspect of the present invention is the following (3).

(3) (1) or insulated electric wire insulating paint, characterized in that formed by coating baked or via another insulating layer on a conductor according to (2).

本発明によれば、導体との密着性が良く、高温高速焼付けしても外観の良好な、絶縁塗料および絶縁電線を提供することができる。 According to the present invention, it is possible to provide an insulating paint and an insulated wire having good adhesion to a conductor and good appearance even when baked at high temperature and high speed.

本発明の絶縁塗料は、ポリアミドイミド樹脂を有機溶剤に溶解した絶縁塗料であって、前記有機溶剤中に1,3−ジメチル−2−イミダゾリジノンを含有することを特徴とする。有機溶剤中に1,3−ジメチル−2−イミダゾリジノンを含有することで、発泡およびシワの無い平滑な絶縁皮膜が得られる。 The insulating paint of the present invention is an insulating paint obtained by dissolving a polyamideimide resin in an organic solvent, and is characterized in that 1,3-dimethyl-2-imidazolidinone is contained in the organic solvent. By containing 1,3-dimethyl-2-imidazolidinone in the organic solvent, a smooth insulating film free from foaming and wrinkles can be obtained.

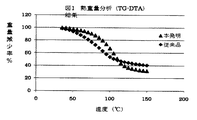

図1に、本発明の絶縁塗料と従来品の絶縁塗料に関する熱重量分析結果を示す。縦軸が絶縁塗料の重量減少率であり、横軸が加熱雰囲気の温度である。この結果より、焼付炉内で溶剤が蒸発する線温と推定される50〜120℃温度領域では、本発明の絶縁塗料(▲で示す)の溶剤蒸発速度が従来品の絶縁材料(◆で示す)より遅いことがわかる。このような挙動を示す塗料は皮膜の表面硬化が著しく妨げられ、発泡が抑えられる。つまり、1,3−ジメチル−2−イミダゾリジノンが高沸点で、かつ、樹脂との相溶性が良好であるために、絶縁塗料の溶剤が揮発する過程で、皮膜中に高沸点の1,3−ジメチル−2−イミダゾリジノンが残留し、これが皮膜の表面硬化を防止していると考えられる。

FIG. 1 shows the results of thermogravimetric analysis regarding the insulating paint of the present invention and the conventional insulating paint. The vertical axis represents the weight reduction rate of the insulating paint, and the horizontal axis represents the temperature of the heating atmosphere. From this result, in the temperature range of 50 to 120 ° C., which is estimated as the linear temperature at which the solvent evaporates in the baking furnace, the solvent evaporation rate of the insulating paint of the present invention (indicated by ▲) is the conventional insulating material (indicated by ◆). ) You can see it is slower. The paint exhibiting such a behavior remarkably hinders the surface hardening of the film and suppresses foaming. In other words, since 1,3-dimethyl-2-imidazolidinone has a high boiling point and good compatibility with the resin, a

上述のように、1,3−ジメチル−2−イミダゾリジノンは発泡を抑えるのに主要な役割を果たしており、本発明における絶縁塗料の全溶剤量に対して10質量%〜30質量%の間であることが好ましく、本発明では、10質量%〜30質量%使用する。

As described above, 1,3-dimethyl-2-imidazolidinone plays a major role in suppressing foaming, and is between 10% by mass and 30% by mass with respect to the total amount of solvent of the insulating paint in the present invention. rather it preferably is at, in the present invention, use 10% to 30% by weight.

1,3−ジメチル−2−イミダゾリジノンが10質量%未満では発泡、ツブが発生しやすくなり、30質量%を超えると、絶縁塗料の粘度が上がるため、焼付け時の作業性が低下してエナメル線の品質不良が発生しやすくなる。 When 1,3-dimethyl-2-imidazolidinone is less than 10% by mass, foaming and tubing are likely to occur, and when it exceeds 30% by mass, the viscosity of the insulating paint increases, so the workability during baking is reduced. Enamel wire quality defects are likely to occur.

本発明におけるポリアミドイミド樹脂の製造方法は、特に制限はなく、既に公知の製造方法(特公昭44−19274公報等)により製造することができる。具体的には、芳香族トリカルボン酸無水物と芳香族ジイソシアネートを非プロトン性極性溶剤中で反応させて得られる。芳香族トリカルボン酸無水物の代表例としてはトリメリット酸無水物が挙げられる。 There is no restriction | limiting in particular in the manufacturing method of the polyamide-imide resin in this invention, It can manufacture by an already well-known manufacturing method (Japanese Patent Publication 44-19274 etc.). Specifically, it can be obtained by reacting an aromatic tricarboxylic acid anhydride and an aromatic diisocyanate in an aprotic polar solvent. A representative example of the aromatic tricarboxylic acid anhydride is trimellitic acid anhydride.

また、必要に応じて、この芳香族トリカルボン酸無水物の一部をピロメリット酸二無水物、ベンゾフェノンテトラカルボン酸二無水物等の芳香族テトラカルボン酸二無水物またはテレフタル酸、イソフタル酸等の芳香族二塩基酸に置き換えてもよい。 In addition, if necessary, a part of this aromatic tricarboxylic anhydride may be an aromatic tetracarboxylic dianhydride such as pyromellitic dianhydride or benzophenone tetracarboxylic dianhydride or terephthalic acid or isophthalic acid. An aromatic dibasic acid may be substituted.

なお、1,3−ジメチル−2−イミダゾリジノンの配合時期に制限はなく、ポリアミドイミド絶縁塗料の樹脂合成溶剤として反応開始時に仕込んでもよく、また反応終了時の希釈剤として用いてもよい。 In addition, there is no restriction | limiting in the mixing | blending time of 1, 3- dimethyl-2- imidazolidinone, You may charge at the time of the reaction start as a resin synthetic | combination solvent of a polyamide-imide insulation coating material, and you may use as a diluent at the time of completion | finish of reaction.

芳香族ジイソシアネートとしては4,4’−ジフェニルメタンジイソシアネート、トリレンジイソシアネート、4,4’−ジフェニルエーテルジイソシアネート等を使用することができるがコストと入手の容易さから4,4’−ジフェニルメタンジイソシアネートが好ましい。 As the aromatic diisocyanate, 4,4'-diphenylmethane diisocyanate, tolylene diisocyanate, 4,4'-diphenyl ether diisocyanate and the like can be used, but 4,4'-diphenylmethane diisocyanate is preferable from the viewpoint of cost and availability.

芳香族トリカルボン酸無水物と芳香族ジイソシアネートの反応においては、芳香族トリカルボン酸無水物1モルに対して芳香族ジイソシアネートを0.9モル〜1.1モルの間に設定することが好ましい。より好ましくは、芳香族ジイソシアネートのモル数を1.0モル〜1.05モルの間に設定すると良い。このように設定することで本発明の高分子量のポリアミドイミド樹脂が得られる。反応は80℃〜150℃の間で非プロトン性極性溶剤の存在下にて遊離してくる炭酸ガスを系外に除去しながら加熱縮合を進める。 In the reaction of the aromatic tricarboxylic acid anhydride and the aromatic diisocyanate, the aromatic diisocyanate is preferably set between 0.9 mol and 1.1 mol with respect to 1 mol of the aromatic tricarboxylic acid anhydride. More preferably, the number of moles of the aromatic diisocyanate is set between 1.0 mole and 1.05 mole. By setting in this way, the high molecular weight polyamideimide resin of the present invention is obtained. The reaction proceeds with heat condensation while removing carbon dioxide gas liberated in the presence of an aprotic polar solvent between 80 ° C. and 150 ° C. out of the system.

非プロトン性極性溶剤としてはN−メチル−2−ピロリドン(NMP)、N,N−ジメチルホルムアミド、N,N−ジメチルアセトアミド、ジメチルスルホキシド等が使用でき、本発明では、N−メチル−2−ピロリドンを使用する。

As the aprotic polar solvent, N-methyl-2-pyrrolidone (NMP), N, N-dimethylformamide, N, N-dimethylacetamide, dimethyl sulfoxide and the like can be used . In the present invention, N-methyl-2-pyrrolidone is used. that use.

また、本発明において用いるポリアミドイミド樹脂の重量平均分子量は、20000以上かつ30000以下であることが好ましく、本発明では、20000以上かつ30000以下である。

The weight average molecular weight of the polyamide-imide resin used in the present invention, rather preferably be 20,000 or more and 30,000 or less, the present invention is 20,000 or more and 30000 or less.

ポリアミドイミド樹脂の分子量の制御は、塗料の粘度が時間の進行とともに上昇するので、粘度および攪拌機のモータトルク値に置き換えて実施する。本発明においては、重量平均分子量が20000から30000の間に入ったところで加熱を止め、希釈溶剤を投入して反応を停止させることで、ポリアミドイミド樹脂の好ましい重量平均分子量とすることができる。なお、反応停止材として樹脂末端のイソシアネート基を保護するアルコール、フェノール、ラクタム等を加えることもできる。 The molecular weight of the polyamideimide resin is controlled by replacing the viscosity and the motor torque value of the stirrer with each other because the viscosity of the paint increases with time. In the present invention, when the weight average molecular weight falls between 20,000 and 30,000, heating is stopped, and the reaction is stopped by adding a diluting solvent, whereby the preferred weight average molecular weight of the polyamideimide resin can be obtained. In addition, alcohol, phenol, lactam, etc. which protect the isocyanate group of the resin terminal can also be added as a reaction terminator.

ポリアミドイミド樹脂の重量平均分子量を20000より小さくすると、単位重量に対する樹脂末端のイソシアネート基が多くなり、樹脂末端のカルボキシル基との反応により発生する炭酸ガス量が多くなることから、高温高速焼付け時に皮膜に発泡が発生しやすくなってしまう。また、分子量が30000を超えると、単位重量に対する樹脂末端のイソシアネート基が少なくなりすぎ、焼付け時の硬化が十分に進まず、絶縁性等の電線特性が低下しやすくなってしまう。更に、絶縁塗料の粘度が高くなりすぎて焼付け作業性が低下するといった問題が生じる。 If the weight average molecular weight of the polyamide-imide resin is smaller than 20000, the number of isocyanate groups at the end of the resin per unit weight will increase, and the amount of carbon dioxide generated by the reaction with the carboxyl group at the end of the resin will increase. Foaming is likely to occur. On the other hand, if the molecular weight exceeds 30000, the number of isocyanate groups at the end of the resin relative to the unit weight will be too small, curing during baking will not proceed sufficiently, and electrical characteristics such as insulation will tend to be reduced. Furthermore, there arises a problem that the viscosity of the insulating paint becomes too high and the baking workability is lowered.

発泡やシワが発生しない範囲内で絶縁塗料の粘度やコストを下げるために助溶剤として、N,N−ジメチルホルムアミド(DMF)や高沸点炭化水素(例えば、丸善石油化学株式会社製ハイゾール1000、ハイゾール1500(商品名))やキシレン等を使用することもできる。特に、DMFは絶縁塗料の粘度を下げることができるので、助溶剤としては汎用的に使用することができる。 N, N-dimethylformamide (DMF) or high-boiling hydrocarbons (for example, Hysol 1000, Hysol manufactured by Maruzen Petrochemical Co., Ltd.) are used as cosolvents to reduce the viscosity and cost of insulating coatings within the range where foaming and wrinkles do not occur. 1500 (trade name)) and xylene can also be used. In particular, since DMF can lower the viscosity of the insulating paint, it can be used for a general purpose as a co-solvent.

また、トリアルキルアミンおよび/またはアルコキシ化メラミン樹脂を配合することができる。トリアルキルアミンとしては、好ましくはトリメチルアミン、トリエチルアミン、トリプロピルアミン、トリブチルアミン等の低級アルキルのトリアルキルアミンが使用できる。この中でも可とう性および密着性の点でトリメチルアミン、トリエチルアミンがより好ましい。また、アルコキシ化メラミン樹脂としては、例えばブトキシ化メラミン樹脂、メトキシ化メラミン樹脂等の低級アルコキシ基で置換されたメラミン樹脂を用いることができ、樹脂の相溶性の点でメトキシ化メラミン樹脂が好ましい。これらはポリアミドイミド樹脂と銅との密着性を向上させる効果を有する。 Moreover, a trialkylamine and / or alkoxylated melamine resin can be mix | blended. The trialkylamine is preferably a lower alkyl trialkylamine such as trimethylamine, triethylamine, tripropylamine or tributylamine. Among these, trimethylamine and triethylamine are more preferable in terms of flexibility and adhesion. In addition, as the alkoxylated melamine resin, for example, a melamine resin substituted with a lower alkoxy group such as a butoxylated melamine resin or a methoxylated melamine resin can be used, and a methoxylated melamine resin is preferable in terms of compatibility of the resin. These have the effect of improving the adhesion between the polyamideimide resin and copper.

ここで、トリアルキルアミンはポリアミドイミド樹脂100重量部に対して、0.05〜1.0重量部であることが好ましい。0.05重量部未満の場合には、密着性が十分得られず、1.0重量部を超えた場合には、塗料としての安定性が低下する。また、アルコキシ化メラミン樹脂はポリアミドイミド樹脂100重量部に対して、5〜20重量部であることが好ましい。5重量部未満の場合には、密着性が十分得られず、20重量部を超えた場合には、得られる絶縁電線の耐熱性が低下する。 Here, it is preferable that a trialkylamine is 0.05-1.0 weight part with respect to 100 weight part of polyamideimide resins. When the amount is less than 0.05 part by weight, sufficient adhesion cannot be obtained, and when it exceeds 1.0 part by weight, the stability as a coating is lowered. Moreover, it is preferable that an alkoxylated melamine resin is 5-20 weight part with respect to 100 weight part of polyamideimide resins. When the amount is less than 5 parts by weight, sufficient adhesion cannot be obtained. When the amount exceeds 20 parts by weight, the heat resistance of the obtained insulated wire is lowered.

以下本発明を実施例により具体的に説明するが、本発明は以下の実施例に限定されるものではない。 EXAMPLES Hereinafter, the present invention will be specifically described with reference to examples, but the present invention is not limited to the following examples.

なお、得られた絶縁塗料および絶縁電線について、下記の各種特性評価を行った。 In addition, the following various characteristic evaluation was performed about the obtained insulating coating material and the insulated wire.

[絶縁塗料]

(a)重量平均分子量

島津製作所(株)製CR型高速液体クロマトグラフを用いて、N−メチル−ピロリドンを展開溶媒として測定した分子量分布曲線から標準ポリスチレンを基準として算出した。

(b)塗料粘度

JISC 2351(エナメル線用ワニス)の粘度測定に準じて測定した。なお粘度計の回転コーンはNO3を使用した。

[Insulating paint]

(A) Weight average molecular weight Using a CR type high performance liquid chromatograph manufactured by Shimadzu Corporation, the weight average molecular weight was calculated based on standard polystyrene from a molecular weight distribution curve measured using N-methyl-pyrrolidone as a developing solvent.

(B) Paint viscosity It measured according to the viscosity measurement of JISC 2351 (varnish for enameled wire). The rotating cone of the viscometer used NO3.

[絶縁電線]

(c)外観

JIS C3003(1984年版).4に示す方法にて皮膜の発泡およびシワの有無の観察を行った。その評価判定基準を以下に示す。

○:発泡、シワが全く見られない

△:発泡、シワが部分的に発生する

×:発泡、シワが線に連続して発生する

(d)絶縁破壊電圧

JIS C3003(1984年版).11(2)に準拠して行った。

(e)上昇軟化

JIS C3003(1984年版).12(2)に準拠して行った。

(f)可とう性

線を20%伸長した後、導体径に相当する直径のマンドレルに巻付け、亀裂の有無を観察した。

(g)密着性(捻回剥離回数)

JIS C3003(1999年版)密着性、ねじり法に準拠して行った。なお、線の長さを15cmとした。

(h)作業性

絶縁電線の作製中に塗装ダイスの状態を観察し、塗装しているダイスの総数のうち、ダイスホルダーに設置しているバーに接触しているダイス数を測定した。その評価判定基準を以下に示す。

○:バーに接触しているダイス数の割合が全体の10%未満

△:バーに接触しているダイス数の割合が全体の10%以上60%未満

×:バーに接触しているダイス数の割合が全体の60%以上

[Insulated wire]

(C) Appearance JIS C3003 (1984 version). The film was observed for foaming and wrinkles by the method shown in FIG. The evaluation criteria are shown below.

○: Foaming and wrinkles are not observed Δ: Foaming and wrinkles are partially generated ×: Foaming and wrinkles are continuously generated in the line (d) Dielectric breakdown voltage JIS C3003 (1984 version). 11 (2).

(E) Ascending softening JIS C3003 (1984 version). 12 (2).

(F) Flexibility After extending the wire by 20%, it was wound around a mandrel having a diameter corresponding to the conductor diameter, and the presence or absence of cracks was observed.

(G) Adhesiveness (number of twist peels)

This was performed in accordance with JIS C3003 (1999 edition) adhesion and torsion method. The length of the line was 15 cm.

(H) Workability The state of the coated dies was observed during the production of the insulated wire, and the number of dies in contact with the bar installed in the dies holder was measured out of the total number of dies coated. The evaluation criteria are shown below.

○: The ratio of the number of dies in contact with the bar is less than 10% of the whole. △: The ratio of the number of dies in contact with the bar is 10% or more and less than 60% of the whole. More than 60% of the total

本発明の実施例として、絶縁塗料および絶縁電線を次のように得た。 As an example of the present invention, an insulating paint and an insulated wire were obtained as follows.

(実施例1−1)

2リットル容の4つ口フラスコに攪拌機、冷却管、塩化カルシウム管を取り付けた装置を用いる。まず、芳香族トリカルボン酸無水物として無水トリメリット酸192gを、芳香族ジイソシアネートとして4,4’−ジフェニルメタンジイソシアネート250gを、非プロトン性極性溶剤としてN−メチル−2−ピロリドン(NMP)540gを、4つ口フラスコに仕込み、80℃で2時間、昇温して140℃で5時間反応させ、系内の粘度が上昇し、重量平均分子量が21000に到達したところで加熱を止め、内温を80℃になるまで冷却した。

その後、希釈溶剤として1,3−ジメチル−2−イミダゾリジノン(DMI)を231g投入して約1時間攪拌し、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

(Example 1-1)

Use a 2-liter 4-neck flask equipped with a stirrer, cooling tube, and calcium chloride tube. First, 192 g of trimellitic anhydride as an aromatic tricarboxylic acid anhydride, 250 g of 4,4′-diphenylmethane diisocyanate as an aromatic diisocyanate, and 540 g of N-methyl-2-pyrrolidone (NMP) as an aprotic polar solvent Charged to a three-necked flask, heated at 80 ° C. for 2 hours and reacted at 140 ° C. for 5 hours. When the viscosity in the system increased and the weight average molecular weight reached 21000, the heating was stopped and the internal temperature was increased to 80 ° C. Cooled until.

Thereafter, 231 g of 1,3-dimethyl-2-imidazolidinone (DMI) as a diluting solvent was added and stirred for about 1 hour to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(実施例1−2)

非プロトン性極性溶剤としてNMPを115g、希釈溶剤としてDMIを116g投入した他は実施例1−1と同様に合成し、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

(Example 1-2)

Synthesis was carried out in the same manner as in Example 1-1 except that 115 g of NMP as an aprotic polar solvent and 116 g of DMI as a diluting solvent were added to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(実施例1−3)

実施例1−1の絶縁塗料を使用し、焼付け塗装回数を6回にした他は実施例1と同様にして皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.3倍とした。

(Example 1-3)

A polyamide-imide insulated wire having a film thickness of 0.030 mm was obtained in the same manner as in Example 1 except that the insulating paint of Example 1-1 was used and the number of baking coatings was six. The baking speed was 1.3 times that of Comparative Example 1 shown later.

(実施例1−4)

実施例1−2の絶縁塗料を使用し、焼付け塗装回数を6回にした他は実施例2と同様にして皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.3倍とした。

(Example 1-4)

A polyamide-imide insulated wire having a film thickness of 0.030 mm was obtained in the same manner as in Example 2 except that the insulating paint of Example 1-2 was used and the number of baking coatings was changed to 6. The baking speed was 1.3 times that of Comparative Example 1 shown later.

(実施例1−5、1−6)

実施例1−1と同様の手順で合成し、重量平均分子量が25000、29000にそれぞれ到達したところで加熱を止め、内温を80℃になるまで冷却し、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

(Examples 1-5 and 1-6)

The synthesis was carried out in the same procedure as in Example 1-1, and when the weight average molecular weight reached 25000 and 29000, the heating was stopped and the internal temperature was cooled to 80 ° C. to obtain the intended polyamideimide insulating paint. . Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(実施例1−7)

非プロトン性極性溶剤としてNMPを617g、希釈溶剤として1,3−ジメチル−2−イミダゾリジノン(DMI)を154g投入した他は実施例1−1と同様に合成し、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

(Example 1-7)

The target polyamideimide insulation was synthesized in the same manner as in Example 1-1 except that 617 g of NMP was added as an aprotic polar solvent and 154 g of 1,3-dimethyl-2-imidazolidinone (DMI) was added as a diluent solvent. A paint was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(実施例1−8)

非プロトン性極性溶剤としてNMPを578g、希釈溶剤として1,3−ジメチル−2−イミダゾリジノン(DMI)を193g投入した他は実施例1−1と同様に合成し、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

(Example 1-8)

The target polyamideimide insulation was synthesized in the same manner as in Example 1-1 except that 578 g of NMP as an aprotic polar solvent and 193 g of 1,3-dimethyl-2-imidazolidinone (DMI) as a diluting solvent were added. A paint was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(参考例 a)

2リットル容の4つ口フラスコに攪拌機、冷却管、塩化カルシウム管を取り付けた装置を用いる。まず、芳香族トリカルボン酸無水物として無水トリメリット酸192gを、芳香族ジイソシアネートとして4,4’−ジフェニルメタンジイソシアネート250gを、非プロトン性極性溶剤としてNMP40gを4つ口フラスコに仕込み、80℃で2時間、昇温して140℃で5時間反応させ、系内の粘度が上昇し重量平均分子量が15000〜18000の間に到達したところで加熱を止め、内温を80℃になるまで冷却した。

その後、希釈溶剤としてDMIを231g投入して約1時間攪拌し、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

( Reference example a )

An apparatus equipped with a stirrer, a condenser tube, and a calcium chloride tube in a two-liter four-necked flask is used. First, 192 g of trimellitic anhydride as an aromatic tricarboxylic acid anhydride, 250 g of 4,4′-diphenylmethane diisocyanate as an aromatic diisocyanate, and 40 g of NMP as an aprotic polar solvent were charged into a four-necked flask and heated at 80 ° C. for 2 hours. The temperature was raised and the reaction was carried out at 140 ° C. for 5 hours. When the viscosity in the system increased and the weight average molecular weight reached between 15000 and 18000, the heating was stopped and the internal temperature was cooled to 80 ° C.

Thereafter, 231 g of DMI was added as a diluent solvent and stirred for about 1 hour to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(参考例 b)

参考例 aのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して6回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.3倍とした。

( Reference example b )

The polyamideimide insulating paint of Reference Example a was applied 6 times using a vertical baking machine having a furnace length of 8 m to obtain a polyamideimide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.3 times that of Comparative Example 1 shown later.

(参考例 c)

2リットル容の4つ口フラスコに攪拌機、冷却管、塩化カルシウム管を取り付けた装置を用いる。まず、芳香族トリカルボン酸無水物として無水トリメリット酸192gを、芳香族ジイソシアネートとして4,4’−ジフェニルメタンジイソシアネート250g、非プロトン性極性溶剤としてNMP540gを仕込み、80℃で2時間、昇温して140℃で5時間反応させ、系内の粘度が上昇し重量平均分子量が30000〜40000の間に到達したところで加熱を止め、内温を80℃になるまで冷却した。希釈溶剤としてDMIを231g投入して約1時間攪拌し、目的とするポリアミドイミド絶縁塗料を得た。1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して6回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.3倍とした。

( Reference example c )

An apparatus equipped with a stirrer, a condenser tube, and a calcium chloride tube in a two-liter four-necked flask is used. First, 192 g of trimellitic anhydride as an aromatic tricarboxylic acid anhydride, 250 g of 4,4′-diphenylmethane diisocyanate as an aromatic diisocyanate, and 540 g of NMP as an aprotic polar solvent were charged and heated at 80 ° C. for 2 hours to 140 The reaction was carried out at 5 ° C. for 5 hours. When the viscosity in the system increased and the weight average molecular weight reached between 30,000 and 40,000, the heating was stopped and the internal temperature was cooled to 80 ° C. 231 g of DMI was added as a diluting solvent and stirred for about 1 hour to obtain a target polyamideimide insulating paint. This polyamide-imide insulating paint was applied six times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.3 times that of Comparative Example 1 shown later.

(参考例 d)

2リットル容の4つ口フラスコに攪拌機、冷却管、塩化カルシウム管を取り付けた装置を用いる。まず、芳香族トリカルボン酸無水物として無水トリメリット酸192gを、芳香族ジイソシアネートとして4,4’−ジフェニルメタンジイソシアネート250gを、非プロトン性極性溶剤としてNMP463g、DMI77gを仕込み、80℃で2時間、昇温して140℃で5時間反応させ、系内の粘度が上昇し重量平均分子量が20000〜30000の間に到達したところで加熱を止め、内温を80℃なるまで冷却した。希釈溶剤としてDMIを231g投入して約1時間攪拌し、目的とするポリアミドイミド絶縁塗料を得た。1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

( Reference example d )

An apparatus equipped with a stirrer, a condenser tube, and a calcium chloride tube in a two-liter four-necked flask is used. First, 192 g of trimellitic anhydride as aromatic tricarboxylic acid anhydride, 250 g of 4,4′-diphenylmethane diisocyanate as aromatic diisocyanate, NMP463 g and 77 g of DMI as aprotic polar solvents were charged, and the temperature was raised at 80 ° C. for 2 hours. Then, the reaction was carried out at 140 ° C. for 5 hours. When the viscosity in the system increased and the weight average molecular weight reached between 20000 and 30000, the heating was stopped and the internal temperature was cooled to 80 ° C. 231 g of DMI was added as a diluting solvent and stirred for about 1 hour to obtain a target polyamideimide insulating paint. This polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(参考例 e)

非プロトン性極性溶剤としてNMPを540g、希釈溶剤としてDMIを38.55g、NMPを192.45g投入した他は実施例1−12と同様に合成し、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.7倍とした。

( Reference example e )

Synthesis was carried out in the same manner as in Example 1-12 except that 540 g of NMP was added as an aprotic polar solvent, 38.55 g of DMI and 192.45 g of NMP were added as diluent solvents, to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1 shown later.

(実施例2−1)

実施例1−1と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販の株式会社三和ケミカル社製ニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して7重量部添加して、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-1)

To the polyamideimide insulating paint synthesized in the same manner as in Example 1-1, commercially available Nikalac MX-10 (trade name) manufactured by Sanwa Chemical Co., Ltd. as an alkoxylated melamine resin was added to 7 parts by weight of polyamideimide resin. By adding parts by weight, the desired polyamide-imide insulating coating was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−2)

アルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して10重量部添加した他は実施例2−1と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-2)

Synthesis was carried out in the same manner as in Example 2-1, except that 10 parts by weight of commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin was added to 100 parts by weight of the polyamideimide resin. A paint was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−3)

アルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して18重量部添加した他は実施例2−1と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-3)

Synthesis was performed in the same manner as in Example 2-1, except that 18 parts by weight of commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin was added to 100 parts by weight of polyamideimide resin, and the target polyamideimide insulation was obtained. A paint was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−4)

実施例1−1と同様に合成したポリアミドイミド絶縁塗料に、更にポリアミドイミド樹脂100重量部に対してトリアルキルアミンの代表例であるトリメチルアミンを0.08重量部添加して、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-4)

0.08 parts by weight of trimethylamine, which is a typical example of trialkylamine, is added to 100 parts by weight of the polyamideimide resin to the polyamideimide insulating paint synthesized in the same manner as in Example 1-1, and the target polyamideimide is added. An insulating paint was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−5)

トリアルキルアミンとしてトリメチルアミンをポリアミドイミド樹脂100重量部に対して0.5重量部添加した他は実施例2−4と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-5)

Synthesis was performed in the same manner as in Example 2-4 except that 0.5 part by weight of trimethylamine as a trialkylamine was added to 100 parts by weight of the polyamideimide resin to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−6)

トリアルキルアミンとしてトリメチルアミンをポリアミドイミド樹脂100重量部に対して0.9重量部添加した他は実施例2−4と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-6)

Synthesis was performed in the same manner as in Example 2-4 except that 0.9 part by weight of trimethylamine as a trialkylamine was added to 100 parts by weight of the polyamideimide resin, to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−7)

実施例1−1と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して10重量部、トリアルキルアミンとしてトリメチルアミンを0.5重量部添加して、目的とする密着性改良型であるポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-7)

In addition to the polyamide-imide insulating paint synthesized in the same manner as in Example 1-1, 10 parts by weight of a commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin with respect to 100 parts by weight of the polyamide-imide resin as a trialkylamine 0.5 parts by weight of trimethylamine was added to obtain a polyamideimide insulating paint which is the target adhesion improving type. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−8)

実施例1−1と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して18重量部、トリアルキルアミンとしてトリメチルアミンを0.5重量部添加して、目的とする密着性改良型であるポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-8)

In addition to the polyamideimide insulating paint synthesized in the same manner as in Example 1-1, 18 parts by weight of a commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin with respect to 100 parts by weight of the polyamideimide resin as a trialkylamine 0.5 parts by weight of trimethylamine was added to obtain a polyamideimide insulating paint which is the target adhesion improving type. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−9)

実施例1−1と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して10重量部、トリアルキルアミンとしてトリメチルアミンを0.9重量部添加して、目的とする密着性改良型であるポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-9)

In addition to the polyamide-imide insulating paint synthesized in the same manner as in Example 1-1, 10 parts by weight of a commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin with respect to 100 parts by weight of the polyamide-imide resin as a trialkylamine 0.9 parts by weight of trimethylamine was added to obtain a polyamideimide insulating coating which is the target improved adhesion type. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−10)

実施例2と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して10重量部、トリアルキルアミンとしてトリメチルアミンを0.5重量部添加して、目的とする密着性改良型であるポリアミドイミド絶縁塗料を得た。1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-10)

To the polyamide-imide insulating paint synthesized in the same manner as in Example 2, 10 parts by weight of commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin with respect to 100 parts by weight of polyamide-imide resin, and trimethylamine as trialkylamine. 0.5 part by weight was added to obtain a polyamideimide insulating paint which is a target adhesion improving type. This polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−11)

アルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名) をポリアミドイミド樹脂100重量部に対して3重量部添加した他は実施例2−1と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-11)

Synthesis was performed in the same manner as in Example 2-1, except that 3 parts by weight of commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin was added to 100 parts by weight of polyamideimide resin. A paint was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−12)

アルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名) をポリアミドイミド樹脂100重量部に対して25重量部添加した他は実施例2−1と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-12)

Synthesis was carried out in the same manner as in Example 2-1, except that 25 parts by weight of commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin was added to 100 parts by weight of the polyamideimide resin. A paint was obtained. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−13)

トリアルキルアミンとしてトリメチルアミンをポリアミドイミド樹脂100重量部に対して0.02重量部添加した他は実施例2−4と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-13)

Synthesis was performed in the same manner as in Example 2-4 except that 0.02 part by weight of trimethylamine as a trialkylamine was added with respect to 100 parts by weight of the polyamideimide resin, to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−14)

トリアルキルアミンとしてトリメチルアミンをポリアミドイミド樹脂100重量部に対して1.5重量部添加した他は実施例2−4と同様の合成を行い、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-14)

Synthesis was performed in the same manner as in Example 2-4 except that 1.5 parts by weight of trimethylamine as a trialkylamine was added with respect to 100 parts by weight of the polyamideimide resin, to obtain a target polyamideimide insulating paint. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−15)

実施例1−1と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して25重量部、トリアルキルアミンとしてトリメチルアミンを0.9重量部添加して、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-15)

In addition to the polyamide-imide insulating paint synthesized in the same manner as Example 1-1, 25 parts by weight of a commercially available Nicarak MX-10 (trade name) as an alkoxylated melamine resin with respect to 100 parts by weight of the polyamide-imide resin as a trialkylamine 0.9 parts by weight of trimethylamine was added to obtain a target polyamideimide insulating coating. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(実施例2−16)

実施例1−1と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名) をポリアミドイミド樹脂100重量部に対して7重量部、トリアルキルアミンとしてトリメチルアミンを0.07重量部添加して、目的とするポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

(Example 2-16)

In addition to the polyamideimide insulating paint synthesized in the same manner as in Example 1-1, 7 parts by weight of a commercially available Nicarak MX-10 (trade name) as an alkoxylated melamine resin with respect to 100 parts by weight of the polyamideimide resin as a trialkylamine Trimethylamine was added in an amount of 0.07 parts by weight to obtain a target polyamideimide insulating coating. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(参考例 f)

参考例 aと同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して10重量部、トリアルキルアミンとしてトリメチルアミンを0.5重量部添加し、目的とする密着性改良型であるポリアミドイミド絶縁塗料を得た。1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

( Reference example f )

Reference Example A polyamideimide insulating paint synthesized in the same manner as in a . Further, commercially available Nicalak MX-10 (trade name) as an alkoxylated melamine resin is 10 parts by weight with respect to 100 parts by weight of polyamideimide resin, and trimethylamine as trialkylamine. 0.5 part by weight was added to obtain a polyamideimide insulating paint which is a target adhesion improving type. This polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

(参考例 g)

参考例 cと同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して10重量部、トリアルキルアミンとしてトリメチルアミンを0.5重量部添加し、目的とする密着性改良型であるポリアミドイミド絶縁塗料を得た。1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお焼付け速度は後に示す比較例1の1.5倍とした。

( Reference example g )

Reference Example In addition to the polyamideimide insulating paint synthesized in the same manner as c , 10 parts by weight of commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin with respect to 100 parts by weight of polyamideimide resin, and trimethylamine as trialkylamine. 0.5 part by weight was added to obtain a polyamideimide insulating paint which is a target adhesion improving type. This polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1 shown later.

また、比較例としての絶縁塗料および絶縁電線を、次のように得た。 Moreover, the insulating paint and the insulated wire as a comparative example were obtained as follows.

(比較例1)

反応溶剤としてNMPを540g投入し、所定の分子量に到達するまで重合反応を継続させ、希釈溶剤としてNMPを231g投入した他は実施例1と同様にしてポリアミドイミド絶縁塗料を得た。更に、1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。

(Comparative Example 1)

A polyamideimide insulating paint was obtained in the same manner as in Example 1 except that 540 g of NMP was added as a reaction solvent, the polymerization reaction was continued until a predetermined molecular weight was reached, and 231 g of NMP was added as a dilution solvent. Further, this polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulating wire having a one-side film thickness of 0.030 mm.

(比較例2)

比較例1のポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお、焼付け速度は比較例1の1.3倍とした。

(Comparative Example 2)

The polyamide-imide insulating paint of Comparative Example 1 was applied 8 times using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.3 times that of Comparative Example 1.

(比較例3)

比較例1のポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお、焼付け速度は比較例1の1.7倍とした。

(Comparative Example 3)

The polyamide-imide insulating paint of Comparative Example 1 was applied 8 times using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.7 times that of Comparative Example 1.

(比較例4)

比較例1と同様に合成したポリアミドイミド絶縁塗料に、更にアルコキシ化メラミン樹脂として市販のニカラックMX−10(商品名)をポリアミドイミド樹脂100重量部に対して10重量部、トリアルキルアミンとしてトリメチルアミンを0.5重量部添加して、目的とする密着性改良型であるポリアミドイミド絶縁塗料を得た。1.0mmφの銅線上にこのポリアミドイミド絶縁塗料を炉長8mの縦型焼付機を使用して8回塗装し、片側皮膜厚さ0.030mmのポリアミドイミド絶縁電線を得た。なお、焼付け速度は比較例1の1.5倍とした。

(Comparative Example 4)

To the polyamideimide insulating paint synthesized in the same manner as in Comparative Example 1, further commercially available Nicalac MX-10 (trade name) as an alkoxylated melamine resin is 10 parts by weight with respect to 100 parts by weight of the polyamideimide resin, and trimethylamine as trialkylamine. 0.5 part by weight was added to obtain a polyamideimide insulating paint which is a target adhesion improving type. This polyamide-imide insulating coating was applied eight times on a 1.0 mmφ copper wire using a vertical baking machine having a furnace length of 8 m to obtain a polyamide-imide insulated wire having a one-side film thickness of 0.030 mm. The baking speed was 1.5 times that of Comparative Example 1.

以上の実施例および比較例のポリアミドイミド絶縁電線を製造したときの焼付け速度比は比較例1の適正焼付け速度を1.0とした場合の速度比として示したものである。 The baking speed ratio when the polyamideimide insulated wires of the above Examples and Comparative Examples are manufactured is shown as a speed ratio when the proper baking speed of Comparative Example 1 is 1.0.

このようにして得られた絶縁塗料および絶縁電線の特性調査を行い、得られた結果を表1〜3に示す。 The characteristics of the insulating paint and the insulated wire thus obtained were investigated, and the results obtained are shown in Tables 1 to 3.

表3の比較例1〜4に示すように、絶縁塗料中に1,3−ジメチル−2−イミダゾリジノン(DMI)が含有されていない場合には、全体的に外観が好ましくない。具体的には、比較例1、2のように、線速が遅い場合には、外観は比較的好ましい状態となるが、絶縁破壊電圧の値が低くなり、絶縁性が悪くなっていることが分かる。また、線速を上げた場合には、外観が悪くなってしまうことが分かる。 As shown in Comparative Examples 1 to 4 in Table 3, when 1,3-dimethyl-2-imidazolidinone (DMI) is not contained in the insulating coating, the overall appearance is not preferable. Specifically, as in Comparative Examples 1 and 2, when the linear velocity is low, the appearance is relatively favorable, but the value of the dielectric breakdown voltage is low, and the insulation property is poor. I understand. It can also be seen that when the linear velocity is increased, the appearance deteriorates.

一方、1,3−ジメチル−2−イミダゾリジノンを含有している表1の実施例1−1〜1−8、表2の実施例2−1〜2−16では、線速を上げた場合でも、外観は良好であることが分かる。

On the other hand, 1,3-dimethyl-2 Example 1-1~1- 8 of Table 1 containing imidazolidinone, Example 2-1~2- 16 in Table 2, raised linear velocity Even in this case, it can be seen that the appearance is good.

また、参考例 a、bのように、絶縁塗料の重量平均分子量が20000未満の場合には、外観があまり好ましくなく、参考例 cのように絶縁塗料の重量平均分子量が30000を超えた場合には、作業性がよくないことが分かる。このことから、実施例1−1〜1−8のように重量平均分子量が20000〜30000の間であれば、外観が最も好ましい状態であり、作業性においても好適であると言える。

In addition, when the weight average molecular weight of the insulating paint is less than 20000 as in Reference Examples a and b , the appearance is not very preferable, and when the weight average molecular weight of the insulating paint exceeds 30000 as in Reference Example c. Shows that workability is not good. From this, when the weight average molecular weight is between 20000 and 30000 as in Examples 1-1 to 1-8, it can be said that the appearance is the most preferable state and the workability is also preferable.

更に、表2では、1,3−ジメチル−2−イミダゾリジノンの他に、アルコキシ化メラミン樹脂および/またはトリアルキルアミンを含有した場合の評価を行っている。更にアルコキシ化メラミン樹脂および/またはトリアルキルアミンを含有することで、1,3−ジメチル−2−イミダゾリジノンのみが添加された表1の場合に比べて、密着性が向上していることが分かる。実施例2−11のように、アルコキシ化メラミン樹脂の含有量がポリアミドイミド樹脂100重量部に対して、5重量部未満となると、密着性が低くなっていることが分かる。また、20重量部を超えると、上昇軟化温度が低くなっており、塗料としての安定性が低下していることが分かる。 Furthermore, in Table 2, the evaluation in the case of containing an alkoxylated melamine resin and / or a trialkylamine in addition to 1,3-dimethyl-2-imidazolidinone is performed. Furthermore, by containing an alkoxylated melamine resin and / or a trialkylamine, the adhesion is improved as compared with the case of Table 1 to which only 1,3-dimethyl-2-imidazolidinone is added. I understand. As in Example 2-11, it can be seen that when the content of the alkoxylated melamine resin is less than 5 parts by weight with respect to 100 parts by weight of the polyamideimide resin, the adhesion is low. Moreover, when it exceeds 20 weight part, it turns out that the raise softening temperature is low and the stability as a coating material is falling.

また、実施例2−13、2−14のように、トリアルキルアミンの含有量がポリアミドイミド樹脂100重量部に対して、0.05重量部未満の場合には、アルコキシ化メラミン樹脂の場合と同様に、密着性が低くなり、1.0重量部を超えた場合には、塗料としての安定性が低下し、作業性が低下していることが分かる。アルコキシ化メラミン樹脂及びトリアルキルアミンの両者を含有している場合についても、実施例2−15、2−16のように上述した範囲外となると、少ない場合には密着性が低下し、多い場合には塗料としての安定性が低下していることが分かる。実施例2−1〜2−3のように、ポリアミドイミド樹脂100重量部に対して、5〜20重量部のアルコキシ化メラミン樹脂および/または0.05〜1.0重量部のトリアルキルアミンが含有されている場合には、密着性および塗料としての安定性がよいことが分かる。 Further, as in Examples 2-13 and 2-14, when the trialkylamine content is less than 0.05 parts by weight with respect to 100 parts by weight of the polyamideimide resin, the case of the alkoxylated melamine resin Similarly, when adhesiveness becomes low and exceeds 1.0 weight part, it turns out that the stability as a coating material falls and workability | operativity falls. When both the alkoxylated melamine resin and the trialkylamine are contained, when the amount is outside the above-described range as in Examples 2-15 and 2-16, the adhesiveness is reduced in the case of a small amount, and the case is large. It can be seen that the stability as a paint is reduced. As in Examples 2-1 to 2-3, 5 to 20 parts by weight of the alkoxylated melamine resin and / or 0.05 to 1.0 part by weight of the trialkylamine are based on 100 parts by weight of the polyamideimide resin. When it is contained, it can be seen that adhesion and stability as a coating are good.

参考例 f、gのように、アルコキシ化メラミン樹脂および/またはトリアルキルアミンを含有している場合でも、参考例 a、bと同様に、絶縁塗料の重量平均分子量が20000未満の場合には、外観があまり好ましくなく、参考例 cのように絶縁塗料の重量平均分子量が30000を超えた場合には、作業性がよくないことが分かる。 Even when the alkoxylated melamine resin and / or trialkylamine is contained as in Reference Examples f and g , as in Reference Examples a and b , when the weight average molecular weight of the insulating coating is less than 20000, When the weight average molecular weight of the insulating coating exceeds 30000 as in Reference Example c , it is understood that the workability is not good.

Claims (3)

前記有機溶剤がN−メチル−2−ピロリドンと1,3−ジメチル−2−イミダゾリジノンからなり、

前記1,3−ジメチル−2−イミダゾリジノンの前記有機溶剤中の含有量が10質量%〜30質量%であり、

前記ポリアミドイミド樹脂の重量平均分子量が20000以上かつ30000以下であることを特徴とする絶縁塗料。 An insulating paint in which a polyamide-imide resin is dissolved in an organic solvent,

The organic solvent comprises N-methyl-2-pyrrolidone and 1,3-dimethyl-2-imidazolidinone ;

The content of the 1,3-dimethyl-2-imidazolidinone in the organic solvent is 10% by mass to 30% by mass,

A weight average molecular weight of the polyamideimide resin is 20000 or more and 30000 or less .

(i)アルコキシ化メラミン樹脂5〜20重量部、

(ii)トリアルキルアミン0.05〜1.0重量部、または、

(iii)トリアルキルアミン0.05〜1.0重量部およびアルコキシ化メラミン樹脂5〜20重量部、

が更に含有されていることを特徴とする請求項1に記載の絶縁塗料。 For 100 parts by weight of the polyamideimide resin,

(I) 5-20 parts by weight of alkoxylated melamine resin,

(Ii) 0.05 to 1.0 part by weight of a trialkylamine, or

(Iii) 0.05 to 1.0 part by weight of a trialkylamine and 5 to 20 parts by weight of an alkoxylated melamine resin,

The insulating paint according to claim 1, further comprising:

Claim 1 or 2 insulated wires insulating paint, characterized in that formed by coating baked or via another insulating layer on a conductor according to.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008174082A JP5503121B2 (en) | 2008-07-03 | 2008-07-03 | Insulating paint and insulated wires |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008174082A JP5503121B2 (en) | 2008-07-03 | 2008-07-03 | Insulating paint and insulated wires |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010013546A JP2010013546A (en) | 2010-01-21 |

| JP5503121B2 true JP5503121B2 (en) | 2014-05-28 |

Family

ID=41699950

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008174082A Active JP5503121B2 (en) | 2008-07-03 | 2008-07-03 | Insulating paint and insulated wires |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5503121B2 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150166924A1 (en) * | 2012-08-02 | 2015-06-18 | Dow Corning Tory Co., Ltd. | Coating composition containing polyamide-imide resin |

| CN103409030B (en) * | 2013-07-02 | 2015-11-18 | 安徽联硕实业有限公司 | A kind of high temperature resistant aminoresin impregnating varnish and preparation method thereof |

| JP6798154B2 (en) * | 2016-06-15 | 2020-12-09 | 富士ゼロックス株式会社 | Endless belt, image forming device, and endless belt unit |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3582122B2 (en) * | 1994-03-25 | 2004-10-27 | チッソ株式会社 | Varnish composition |

| JP3717297B2 (en) * | 1996-12-25 | 2005-11-16 | 古河電気工業株式会社 | Insulated wire |

| JP2007270074A (en) * | 2006-03-31 | 2007-10-18 | Sumitomo Electric Ind Ltd | Work-resistant polyamide-imide resin varnish and insulated wire |

| JP5250959B2 (en) * | 2006-10-19 | 2013-07-31 | 東洋紡株式会社 | Method for producing polyimide resin and polyimide resin varnish |

-

2008

- 2008-07-03 JP JP2008174082A patent/JP5503121B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010013546A (en) | 2010-01-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5626530B2 (en) | Insulating paint, method for producing the same, insulated wire using the same, and method for producing the same | |

| JP4584014B2 (en) | Partially discharge-resistant insulating paint, insulated wire, and method for producing the same | |

| JP5609732B2 (en) | Insulating paint and insulated wire using the same | |

| WO2012102121A1 (en) | Polyimide resin varnish, and insulated electrical wire, electrical coil, and motor using same | |

| JP2009149757A (en) | Polyamide imide and production method thereof, polyamide imide-based insulating coating, and insulated wire | |

| WO2012153636A1 (en) | Polyimide resin varnish, insulated electric wire using same, electric coil, and motor | |

| JP2013253124A (en) | Polyimide resin vanish, and insulated electric wire, electric coil and motor using the same | |

| JP5503121B2 (en) | Insulating paint and insulated wires | |

| JP2007270074A (en) | Work-resistant polyamide-imide resin varnish and insulated wire | |

| JP5351011B2 (en) | Insulated wire, electric coil and motor | |

| JP2012234625A (en) | Insulated wire and electric coil and motor using the same | |

| JP3724922B2 (en) | Polyimide-based insulating paint and insulated wire | |

| JP2012046619A (en) | Insulated wire, electric appliance coil using the same, and motor | |

| JP5104706B2 (en) | Polyesterimide resin varnish and insulated wire using the same | |

| JP5837397B2 (en) | Insulated wire and electric coil and motor using the same | |

| JP2010031101A (en) | Polyamideimide resin coating and insulated electric wire using it | |

| JP2008243677A (en) | Resin composition for electric insulation, and coating and enamel wire using it | |

| JP5329121B2 (en) | Insulated wire | |

| JP2009091509A (en) | Resin composition for electric insulation and enamel wire | |

| JP4482857B2 (en) | Resin composition for electrical insulation and enameled wire | |

| JP2001319526A (en) | Insulated cable | |

| JP7179132B2 (en) | insulated wire | |

| JPH07316425A (en) | Varnish for enameled wire and enameled wire | |

| JP2011178965A (en) | Insulated wire and electric coil and motor using the same | |

| JP5364939B2 (en) | Insulated wire |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110509 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130205 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130308 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130507 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20130507 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140218 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140314 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5503121 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |