JP5261717B2 - Block copolymer and method for producing the same - Google Patents

Block copolymer and method for producing the same Download PDFInfo

- Publication number

- JP5261717B2 JP5261717B2 JP2008301066A JP2008301066A JP5261717B2 JP 5261717 B2 JP5261717 B2 JP 5261717B2 JP 2008301066 A JP2008301066 A JP 2008301066A JP 2008301066 A JP2008301066 A JP 2008301066A JP 5261717 B2 JP5261717 B2 JP 5261717B2

- Authority

- JP

- Japan

- Prior art keywords

- group

- formula

- vinyl monomer

- compound represented

- organic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229920001400 block copolymer Polymers 0.000 title claims abstract description 23

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 11

- 239000000178 monomer Substances 0.000 claims abstract description 59

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 claims abstract description 34

- 229920002554 vinyl polymer Polymers 0.000 claims abstract description 34

- 125000000609 carbazolyl group Chemical group C1(=CC=CC=2C3=CC=CC=C3NC12)* 0.000 claims abstract description 13

- 150000003498 tellurium compounds Chemical class 0.000 claims description 22

- 125000000217 alkyl group Chemical group 0.000 claims description 20

- 125000004432 carbon atom Chemical group C* 0.000 claims description 18

- 239000000203 mixture Substances 0.000 claims description 16

- 125000003118 aryl group Chemical group 0.000 claims description 15

- -1 ditellurium compound Chemical class 0.000 claims description 14

- 239000007869 azo polymerization initiator Substances 0.000 claims description 13

- 125000003107 substituted aryl group Chemical group 0.000 claims description 13

- 125000006615 aromatic heterocyclic group Chemical group 0.000 claims description 9

- JPIIVHIVGGOMMV-UHFFFAOYSA-N ditellurium Chemical class [Te]=[Te] JPIIVHIVGGOMMV-UHFFFAOYSA-N 0.000 claims description 8

- 125000005740 oxycarbonyl group Chemical group [*:1]OC([*:2])=O 0.000 claims description 8

- 239000003505 polymerization initiator Substances 0.000 claims description 6

- 230000000379 polymerizing effect Effects 0.000 claims description 6

- 125000004093 cyano group Chemical group *C#N 0.000 claims description 5

- 125000004435 hydrogen atom Chemical group [H]* 0.000 claims description 5

- 125000002252 acyl group Chemical group 0.000 claims description 4

- 125000003368 amide group Chemical group 0.000 claims description 4

- 229920000642 polymer Polymers 0.000 abstract description 26

- 150000001875 compounds Chemical class 0.000 description 23

- 238000006243 chemical reaction Methods 0.000 description 21

- 238000006116 polymerization reaction Methods 0.000 description 17

- 239000000463 material Substances 0.000 description 11

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 10

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 9

- 238000000034 method Methods 0.000 description 9

- PBOISYQXIBROJD-UHFFFAOYSA-N 9-ethenylcarbazole;styrene Chemical compound C=CC1=CC=CC=C1.C1=CC=C2N(C=C)C3=CC=CC=C3C2=C1 PBOISYQXIBROJD-UHFFFAOYSA-N 0.000 description 7

- 239000012986 chain transfer agent Substances 0.000 description 7

- 239000011572 manganese Substances 0.000 description 7

- 238000001542 size-exclusion chromatography Methods 0.000 description 7

- 239000004094 surface-active agent Substances 0.000 description 7

- OZAIFHULBGXAKX-UHFFFAOYSA-N 2-(2-cyanopropan-2-yldiazenyl)-2-methylpropanenitrile Chemical compound N#CC(C)(C)N=NC(C)(C)C#N OZAIFHULBGXAKX-UHFFFAOYSA-N 0.000 description 6

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 6

- HEDRZPFGACZZDS-UHFFFAOYSA-N Chloroform Chemical compound ClC(Cl)Cl HEDRZPFGACZZDS-UHFFFAOYSA-N 0.000 description 6

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 6

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 6

- 229920001577 copolymer Polymers 0.000 description 6

- 125000005843 halogen group Chemical group 0.000 description 6

- 239000002904 solvent Substances 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- AVTLBBWTUPQRAY-UHFFFAOYSA-N 2-(2-cyanobutan-2-yldiazenyl)-2-methylbutanenitrile Chemical compound CCC(C)(C#N)N=NC(C)(CC)C#N AVTLBBWTUPQRAY-UHFFFAOYSA-N 0.000 description 4

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 4

- WYGWHHGCAGTUCH-UHFFFAOYSA-N 2-[(2-cyano-4-methylpentan-2-yl)diazenyl]-2,4-dimethylpentanenitrile Chemical compound CC(C)CC(C)(C#N)N=NC(C)(C#N)CC(C)C WYGWHHGCAGTUCH-UHFFFAOYSA-N 0.000 description 4

- VFXXTYGQYWRHJP-UHFFFAOYSA-N 4,4'-azobis(4-cyanopentanoic acid) Chemical compound OC(=O)CCC(C)(C#N)N=NC(C)(CCC(O)=O)C#N VFXXTYGQYWRHJP-UHFFFAOYSA-N 0.000 description 4

- OZAIFHULBGXAKX-VAWYXSNFSA-N AIBN Substances N#CC(C)(C)\N=N\C(C)(C)C#N OZAIFHULBGXAKX-VAWYXSNFSA-N 0.000 description 4

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- IAZDPXIOMUYVGZ-UHFFFAOYSA-N Dimethylsulphoxide Chemical compound CS(C)=O IAZDPXIOMUYVGZ-UHFFFAOYSA-N 0.000 description 4

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 4

- 238000004458 analytical method Methods 0.000 description 4

- 125000003754 ethoxycarbonyl group Chemical group C(=O)(OCC)* 0.000 description 4

- 239000003999 initiator Substances 0.000 description 4

- 125000001160 methoxycarbonyl group Chemical group [H]C([H])([H])OC(*)=O 0.000 description 4

- SFLRURCEBYIKSS-UHFFFAOYSA-N n-butyl-2-[[1-(butylamino)-2-methyl-1-oxopropan-2-yl]diazenyl]-2-methylpropanamide Chemical compound CCCCNC(=O)C(C)(C)N=NC(C)(C)C(=O)NCCCC SFLRURCEBYIKSS-UHFFFAOYSA-N 0.000 description 4

- KKFHAJHLJHVUDM-UHFFFAOYSA-N n-vinylcarbazole Chemical compound C1=CC=C2N(C=C)C3=CC=CC=C3C2=C1 KKFHAJHLJHVUDM-UHFFFAOYSA-N 0.000 description 4

- 150000003254 radicals Chemical class 0.000 description 4

- 230000035484 reaction time Effects 0.000 description 4

- 238000003756 stirring Methods 0.000 description 4

- 125000001424 substituent group Chemical group 0.000 description 4

- RYHBNJHYFVUHQT-UHFFFAOYSA-N 1,4-Dioxane Chemical compound C1COCCO1 RYHBNJHYFVUHQT-UHFFFAOYSA-N 0.000 description 3

- DLFVBJFMPXGRIB-UHFFFAOYSA-N Acetamide Chemical compound CC(N)=O DLFVBJFMPXGRIB-UHFFFAOYSA-N 0.000 description 3

- WKBOTKDWSSQWDR-UHFFFAOYSA-N Bromine atom Chemical compound [Br] WKBOTKDWSSQWDR-UHFFFAOYSA-N 0.000 description 3

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical group [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 3

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 3

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- KYIKRXIYLAGAKQ-UHFFFAOYSA-N abcn Chemical compound C1CCCCC1(C#N)N=NC1(C#N)CCCCC1 KYIKRXIYLAGAKQ-UHFFFAOYSA-N 0.000 description 3

- 229910052783 alkali metal Inorganic materials 0.000 description 3

- 150000001340 alkali metals Chemical class 0.000 description 3

- 229910052784 alkaline earth metal Inorganic materials 0.000 description 3

- 150000001342 alkaline earth metals Chemical class 0.000 description 3

- 125000003545 alkoxy group Chemical group 0.000 description 3

- GDTBXPJZTBHREO-UHFFFAOYSA-N bromine Substances BrBr GDTBXPJZTBHREO-UHFFFAOYSA-N 0.000 description 3

- 229910052794 bromium Inorganic materials 0.000 description 3

- 239000000460 chlorine Substances 0.000 description 3

- 229910052801 chlorine Inorganic materials 0.000 description 3

- 239000002270 dispersing agent Substances 0.000 description 3

- 238000000921 elemental analysis Methods 0.000 description 3

- 239000011777 magnesium Substances 0.000 description 3

- 239000000693 micelle Substances 0.000 description 3

- 238000010526 radical polymerization reaction Methods 0.000 description 3

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 3

- 125000002023 trifluoromethyl group Chemical group FC(F)(F)* 0.000 description 3

- DRAQBUIVUGPBEB-UHFFFAOYSA-N (ethylditellanyl)ethane Chemical compound CC[Te][Te]CC DRAQBUIVUGPBEB-UHFFFAOYSA-N 0.000 description 2

- ARXJGSRGQADJSQ-UHFFFAOYSA-N 1-methoxypropan-2-ol Chemical compound COCC(C)O ARXJGSRGQADJSQ-UHFFFAOYSA-N 0.000 description 2

- VUKYWZYFZZJLRZ-UHFFFAOYSA-N 2-[(1-amino-2-methyl-1-methyliminopropan-2-yl)diazenyl]-n',2-dimethylpropanimidamide;dihydrochloride Chemical compound Cl.Cl.CNC(=N)C(C)(C)N=NC(C)(C)C(=N)NC VUKYWZYFZZJLRZ-UHFFFAOYSA-N 0.000 description 2

- KWZULKIVMJKFKM-UHFFFAOYSA-N 2-[(1-amino-2-methyl-1-oxobutan-2-yl)diazenyl]-2-methylbutanamide Chemical compound CCC(C)(C(N)=O)N=NC(C)(CC)C(N)=O KWZULKIVMJKFKM-UHFFFAOYSA-N 0.000 description 2

- PFHOSZAOXCYAGJ-UHFFFAOYSA-N 2-[(2-cyano-4-methoxy-4-methylpentan-2-yl)diazenyl]-4-methoxy-2,4-dimethylpentanenitrile Chemical compound COC(C)(C)CC(C)(C#N)N=NC(C)(C#N)CC(C)(C)OC PFHOSZAOXCYAGJ-UHFFFAOYSA-N 0.000 description 2

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 2

- 102100040409 Ameloblastin Human genes 0.000 description 2

- KXDAEFPNCMNJSK-UHFFFAOYSA-N Benzamide Chemical compound NC(=O)C1=CC=CC=C1 KXDAEFPNCMNJSK-UHFFFAOYSA-N 0.000 description 2

- 0 C*CC*C(C)CC(C)C1=CC=CCC1 Chemical compound C*CC*C(C)CC(C)C1=CC=CCC1 0.000 description 2

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 2

- 101000891247 Homo sapiens Ameloblastin Proteins 0.000 description 2

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 2

- 102100020870 La-related protein 6 Human genes 0.000 description 2

- 108050008265 La-related protein 6 Proteins 0.000 description 2

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 2

- UFWIBTONFRDIAS-UHFFFAOYSA-N Naphthalene Chemical compound C1=CC=CC2=CC=CC=C21 UFWIBTONFRDIAS-UHFFFAOYSA-N 0.000 description 2

- 101100490446 Penicillium chrysogenum PCBAB gene Proteins 0.000 description 2

- WCUXLLCKKVVCTQ-UHFFFAOYSA-M Potassium chloride Chemical compound [Cl-].[K+] WCUXLLCKKVVCTQ-UHFFFAOYSA-M 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- ALBJGICXDBJZGK-UHFFFAOYSA-N [1-[(1-acetyloxy-1-phenylethyl)diazenyl]-1-phenylethyl] acetate Chemical compound C=1C=CC=CC=1C(C)(OC(=O)C)N=NC(C)(OC(C)=O)C1=CC=CC=C1 ALBJGICXDBJZGK-UHFFFAOYSA-N 0.000 description 2

- 239000003125 aqueous solvent Substances 0.000 description 2

- WPKWPKDNOPEODE-UHFFFAOYSA-N bis(2,4,4-trimethylpentan-2-yl)diazene Chemical compound CC(C)(C)CC(C)(C)N=NC(C)(C)CC(C)(C)C WPKWPKDNOPEODE-UHFFFAOYSA-N 0.000 description 2

- LWMFAFLIWMPZSX-UHFFFAOYSA-N bis[2-(4,5-dihydro-1h-imidazol-2-yl)propan-2-yl]diazene Chemical compound N=1CCNC=1C(C)(C)N=NC(C)(C)C1=NCCN1 LWMFAFLIWMPZSX-UHFFFAOYSA-N 0.000 description 2

- SWXVUIWOUIDPGS-UHFFFAOYSA-N diacetone alcohol Chemical compound CC(=O)CC(C)(C)O SWXVUIWOUIDPGS-UHFFFAOYSA-N 0.000 description 2

- LCMDQKIQBKULEI-UHFFFAOYSA-N dimethyl ditelluride Chemical compound C[Te][Te]C LCMDQKIQBKULEI-UHFFFAOYSA-N 0.000 description 2

- VRLFOXMNTSYGMX-UHFFFAOYSA-N diphenyl ditelluride Chemical group C=1C=CC=CC=1[Te][Te]C1=CC=CC=C1 VRLFOXMNTSYGMX-UHFFFAOYSA-N 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 2

- 229910052744 lithium Inorganic materials 0.000 description 2

- 229910052749 magnesium Inorganic materials 0.000 description 2

- ZQMHJBXHRFJKOT-UHFFFAOYSA-N methyl 2-[(1-methoxy-2-methyl-1-oxopropan-2-yl)diazenyl]-2-methylpropanoate Chemical compound COC(=O)C(C)(C)N=NC(C)(C)C(=O)OC ZQMHJBXHRFJKOT-UHFFFAOYSA-N 0.000 description 2

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 2

- CYTJMBLSQUBVMS-UHFFFAOYSA-N n-[[2-cyanopropan-2-yl(formyl)amino]hydrazinylidene]formamide Chemical compound N#CC(C)(C)N(C=O)NN=NC=O CYTJMBLSQUBVMS-UHFFFAOYSA-N 0.000 description 2

- 125000004108 n-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 239000003960 organic solvent Substances 0.000 description 2

- 229920003227 poly(N-vinyl carbazole) Polymers 0.000 description 2

- QLNJFJADRCOGBJ-UHFFFAOYSA-N propionamide Chemical compound CCC(N)=O QLNJFJADRCOGBJ-UHFFFAOYSA-N 0.000 description 2

- 229940080818 propionamide Drugs 0.000 description 2

- 239000003381 stabilizer Substances 0.000 description 2

- 238000006467 substitution reaction Methods 0.000 description 2

- VZGDMQKNWNREIO-UHFFFAOYSA-N tetrachloromethane Chemical compound ClC(Cl)(Cl)Cl VZGDMQKNWNREIO-UHFFFAOYSA-N 0.000 description 2

- GETTZEONDQJALK-UHFFFAOYSA-N (trifluoromethyl)benzene Chemical compound FC(F)(F)C1=CC=CC=C1 GETTZEONDQJALK-UHFFFAOYSA-N 0.000 description 1

- BSSNZUFKXJJCBG-UPHRSURJSA-N (z)-but-2-enediamide Chemical compound NC(=O)\C=C/C(N)=O BSSNZUFKXJJCBG-UPHRSURJSA-N 0.000 description 1

- BYEAHWXPCBROCE-UHFFFAOYSA-N 1,1,1,3,3,3-hexafluoropropan-2-ol Chemical compound FC(F)(F)C(O)C(F)(F)F BYEAHWXPCBROCE-UHFFFAOYSA-N 0.000 description 1

- FXEIVSYQEOJLBU-UHFFFAOYSA-N 1-$l^{1}-selanylethanimine Chemical compound CC([Se])=N FXEIVSYQEOJLBU-UHFFFAOYSA-N 0.000 description 1

- NVZWEEGUWXZOKI-UHFFFAOYSA-N 1-ethenyl-2-methylbenzene Chemical compound CC1=CC=CC=C1C=C NVZWEEGUWXZOKI-UHFFFAOYSA-N 0.000 description 1

- JZHGRUMIRATHIU-UHFFFAOYSA-N 1-ethenyl-3-methylbenzene Chemical compound CC1=CC=CC(C=C)=C1 JZHGRUMIRATHIU-UHFFFAOYSA-N 0.000 description 1

- VPIMDGCETSZFGC-UHFFFAOYSA-N 2-(propan-2-ylditellanyl)propane Chemical compound CC(C)[Te][Te]C(C)C VPIMDGCETSZFGC-UHFFFAOYSA-N 0.000 description 1

- POAOYUHQDCAZBD-UHFFFAOYSA-N 2-butoxyethanol Chemical compound CCCCOCCO POAOYUHQDCAZBD-UHFFFAOYSA-N 0.000 description 1

- UDRCRMHFHHTVSN-UHFFFAOYSA-N 2-chloro-n-(4-chlorophenyl)acetamide Chemical compound ClCC(=O)NC1=CC=C(Cl)C=C1 UDRCRMHFHHTVSN-UHFFFAOYSA-N 0.000 description 1

- ZNQVEEAIQZEUHB-UHFFFAOYSA-N 2-ethoxyethanol Chemical compound CCOCCO ZNQVEEAIQZEUHB-UHFFFAOYSA-N 0.000 description 1

- RTLBWDBZMKHPPN-UHFFFAOYSA-N 3-ethenyl-9-ethylcarbazole Chemical compound C=CC1=CC=C2N(CC)C3=CC=CC=C3C2=C1 RTLBWDBZMKHPPN-UHFFFAOYSA-N 0.000 description 1

- JLBJTVDPSNHSKJ-UHFFFAOYSA-N 4-Methylstyrene Chemical compound CC1=CC=C(C=C)C=C1 JLBJTVDPSNHSKJ-UHFFFAOYSA-N 0.000 description 1

- 125000004172 4-methoxyphenyl group Chemical group [H]C1=C([H])C(OC([H])([H])[H])=C([H])C([H])=C1* 0.000 description 1

- ZCYVEMRRCGMTRW-UHFFFAOYSA-N 7553-56-2 Chemical compound [I] ZCYVEMRRCGMTRW-UHFFFAOYSA-N 0.000 description 1

- ZECQLHQEHJJSAN-UHFFFAOYSA-N C(C1)C=Cc2c1[nH]c1c2cccc1 Chemical compound C(C1)C=Cc2c1[nH]c1c2cccc1 ZECQLHQEHJJSAN-UHFFFAOYSA-N 0.000 description 1

- NIVVALBMNHCROA-UHFFFAOYSA-N C(CCCCC(N)=[Se])(N)=[Se] Chemical compound C(CCCCC(N)=[Se])(N)=[Se] NIVVALBMNHCROA-UHFFFAOYSA-N 0.000 description 1

- OZEBSVRCCLFFHP-UHFFFAOYSA-N CS(=O)(N)=[Se] Chemical compound CS(=O)(N)=[Se] OZEBSVRCCLFFHP-UHFFFAOYSA-N 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 1

- 239000007818 Grignard reagent Substances 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- OHLUUHNLEMFGTQ-UHFFFAOYSA-N N-methylacetamide Chemical compound CNC(C)=O OHLUUHNLEMFGTQ-UHFFFAOYSA-N 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- 108091034057 RNA (poly(A)) Proteins 0.000 description 1

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 description 1

- QIOZLISABUUKJY-UHFFFAOYSA-N Thiobenzamide Chemical compound NC(=S)C1=CC=CC=C1 QIOZLISABUUKJY-UHFFFAOYSA-N 0.000 description 1

- 125000002777 acetyl group Chemical group [H]C([H])([H])C(*)=O 0.000 description 1

- XYLMUPLGERFSHI-UHFFFAOYSA-N alpha-Methylstyrene Chemical compound CC(=C)C1=CC=CC=C1 XYLMUPLGERFSHI-UHFFFAOYSA-N 0.000 description 1

- 125000003277 amino group Chemical group 0.000 description 1

- 238000000149 argon plasma sintering Methods 0.000 description 1

- 125000004104 aryloxy group Chemical group 0.000 description 1

- ZVSKZLHKADLHSD-UHFFFAOYSA-N benzanilide Chemical compound C=1C=CC=CC=1C(=O)NC1=CC=CC=C1 ZVSKZLHKADLHSD-UHFFFAOYSA-N 0.000 description 1

- 125000003236 benzoyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C(*)=O 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- SNCZNSNPXMPCGN-UHFFFAOYSA-N butanediamide Chemical compound NC(=O)CCC(N)=O SNCZNSNPXMPCGN-UHFFFAOYSA-N 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 125000002915 carbonyl group Chemical group [*:2]C([*:1])=O 0.000 description 1

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 description 1

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 1

- 125000001309 chloro group Chemical group Cl* 0.000 description 1

- YACLQRRMGMJLJV-UHFFFAOYSA-N chloroprene Chemical compound ClC(=C)C=C YACLQRRMGMJLJV-UHFFFAOYSA-N 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000007334 copolymerization reaction Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 239000004064 cosurfactant Substances 0.000 description 1

- 125000006165 cyclic alkyl group Chemical group 0.000 description 1

- 125000001995 cyclobutyl group Chemical group [H]C1([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 1

- VBWIZSYFQSOUFQ-UHFFFAOYSA-N cyclohexanecarbonitrile Chemical compound N#CC1CCCCC1 VBWIZSYFQSOUFQ-UHFFFAOYSA-N 0.000 description 1

- UKJLNMAFNRKWGR-UHFFFAOYSA-N cyclohexatrienamine Chemical group NC1=CC=C=C[CH]1 UKJLNMAFNRKWGR-UHFFFAOYSA-N 0.000 description 1

- 125000001559 cyclopropyl group Chemical group [H]C1([H])C([H])([H])C1([H])* 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 150000001993 dienes Chemical class 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000010556 emulsion polymerization method Methods 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 125000002485 formyl group Chemical group [H]C(*)=O 0.000 description 1

- 238000013467 fragmentation Methods 0.000 description 1

- 238000006062 fragmentation reaction Methods 0.000 description 1

- 125000002541 furyl group Chemical group 0.000 description 1

- 150000004795 grignard reagents Chemical class 0.000 description 1

- FBUVGICEZJFFOR-UHFFFAOYSA-N hexanedithioamide Chemical compound NC(=S)CCCCC(N)=S FBUVGICEZJFFOR-UHFFFAOYSA-N 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 239000011630 iodine Substances 0.000 description 1

- 229910052740 iodine Inorganic materials 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- WRIRWRKPLXCTFD-UHFFFAOYSA-N malonamide Chemical compound NC(=O)CC(N)=O WRIRWRKPLXCTFD-UHFFFAOYSA-N 0.000 description 1

- 229940099596 manganese sulfate Drugs 0.000 description 1

- 239000011702 manganese sulphate Substances 0.000 description 1

- 235000007079 manganese sulphate Nutrition 0.000 description 1

- SQQMAOCOWKFBNP-UHFFFAOYSA-L manganese(II) sulfate Chemical compound [Mn+2].[O-]S([O-])(=O)=O SQQMAOCOWKFBNP-UHFFFAOYSA-L 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- UQMLEZQYRFAOCA-UHFFFAOYSA-N methanesulfonothioamide Chemical compound CS(N)(=O)=S UQMLEZQYRFAOCA-UHFFFAOYSA-N 0.000 description 1

- WVFLGSMUPMVNTQ-UHFFFAOYSA-N n-(2-hydroxyethyl)-2-[[1-(2-hydroxyethylamino)-2-methyl-1-oxopropan-2-yl]diazenyl]-2-methylpropanamide Chemical compound OCCNC(=O)C(C)(C)N=NC(C)(C)C(=O)NCCO WVFLGSMUPMVNTQ-UHFFFAOYSA-N 0.000 description 1

- WMRNGPYHLQSTDL-UHFFFAOYSA-N n-cyclohexyl-2-[[1-(cyclohexylamino)-2-methyl-1-oxopropan-2-yl]diazenyl]-2-methylpropanamide Chemical compound C1CCCCC1NC(=O)C(C)(C)N=NC(C)(C)C(=O)NC1CCCCC1 WMRNGPYHLQSTDL-UHFFFAOYSA-N 0.000 description 1

- NPFIXJIFUHTLRP-UHFFFAOYSA-N n-cyclohexyl-2-methylpropanamide Chemical compound CC(C)C(=O)NC1CCCCC1 NPFIXJIFUHTLRP-UHFFFAOYSA-N 0.000 description 1

- 125000003136 n-heptyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000001280 n-hexyl group Chemical group C(CCCCC)* 0.000 description 1

- 125000000740 n-pentyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- AZTGEJBZSFKULT-UHFFFAOYSA-N n-phenylcyclohexanecarboxamide Chemical compound C1CCCCC1C(=O)NC1=CC=CC=C1 AZTGEJBZSFKULT-UHFFFAOYSA-N 0.000 description 1

- 125000004123 n-propyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 239000002105 nanoparticle Substances 0.000 description 1

- 125000001624 naphthyl group Chemical group 0.000 description 1

- 125000000449 nitro group Chemical group [O-][N+](*)=O 0.000 description 1

- 239000012788 optical film Substances 0.000 description 1

- 125000000636 p-nitrophenyl group Chemical group [H]C1=C([H])C(=C([H])C([H])=C1*)[N+]([O-])=O 0.000 description 1

- 238000005191 phase separation Methods 0.000 description 1

- 125000006678 phenoxycarbonyl group Chemical group 0.000 description 1

- 108091008695 photoreceptors Proteins 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- 239000001103 potassium chloride Substances 0.000 description 1

- 235000011164 potassium chloride Nutrition 0.000 description 1

- OTYBMLCTZGSZBG-UHFFFAOYSA-L potassium sulfate Chemical compound [K+].[K+].[O-]S([O-])(=O)=O OTYBMLCTZGSZBG-UHFFFAOYSA-L 0.000 description 1

- 229910052939 potassium sulfate Inorganic materials 0.000 description 1

- 235000011151 potassium sulphates Nutrition 0.000 description 1

- 125000004742 propyloxycarbonyl group Chemical group 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 125000004076 pyridyl group Chemical group 0.000 description 1

- 125000000168 pyrrolyl group Chemical group 0.000 description 1

- 238000001226 reprecipitation Methods 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 125000002914 sec-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- 125000005930 sec-butyloxycarbonyl group Chemical group [H]C([H])([H])C([H])([H])C([H])(OC(*)=O)C([H])([H])[H] 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 235000002639 sodium chloride Nutrition 0.000 description 1

- 229910052938 sodium sulfate Inorganic materials 0.000 description 1

- 235000011152 sodium sulphate Nutrition 0.000 description 1

- 150000003440 styrenes Chemical class 0.000 description 1

- 125000000472 sulfonyl group Chemical group *S(*)(=O)=O 0.000 description 1

- 238000010558 suspension polymerization method Methods 0.000 description 1

- 238000003786 synthesis reaction Methods 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- 229910052714 tellurium Inorganic materials 0.000 description 1

- PORWMNRCUJJQNO-UHFFFAOYSA-N tellurium atom Chemical compound [Te] PORWMNRCUJJQNO-UHFFFAOYSA-N 0.000 description 1

- 230000003797 telogen phase Effects 0.000 description 1

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 125000005931 tert-butyloxycarbonyl group Chemical group [H]C([H])([H])C(OC(*)=O)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 125000001544 thienyl group Chemical group 0.000 description 1

- YUKQRDCYNOVPGJ-UHFFFAOYSA-N thioacetamide Chemical compound CC(N)=S YUKQRDCYNOVPGJ-UHFFFAOYSA-N 0.000 description 1

- 150000003556 thioamides Chemical class 0.000 description 1

- 229920003169 water-soluble polymer Polymers 0.000 description 1

Images

Landscapes

- Graft Or Block Polymers (AREA)

- Polymerization Catalysts (AREA)

Abstract

Description

本発明は、ブロック共重合体およびその製造方法に関する。詳しくは、カルバゾール基を有するビニルモノマーの重合体ブロックと共役ビニルモノマーの重合体ブロックを含むブロック共重合体およびその製造方法に関する。 The present invention relates to a block copolymer and a method for producing the same. Specifically, the present invention relates to a block copolymer including a polymer block of a vinyl monomer having a carbazole group and a polymer block of a conjugated vinyl monomer, and a method for producing the same.

異なる種類の重合体ブロックが結合したブロック共重合体は、一般に異なるモノマーを連続して重合することにより製造される。これまでに様々な重合方法が開発され、それらを利用したブロック共重合体の製造が行われている。

リビングラジカル重合の手法のひとつであるReversible Addition-Fragmentation Chain Transfer(RAFT)重合によるブロック共重合体の合成では、チオカルボニルチオ基を有する連鎖移動剤を用い一段階目のモノマーを単独重合させることにより末端にチオカルボニルチオ基を有する高分子連鎖移動剤(マクロ連鎖移動剤:macro-chain transfer agent)を合成し、単離、精製後、二段階目で次のモノマーを重合させる手法が用いられる。

Block copolymers in which different types of polymer blocks are bonded are generally produced by successively polymerizing different monomers. Various polymerization methods have been developed so far, and block copolymers using them have been produced.

In the synthesis of block copolymers by Reversible Addition-Fragmentation Chain Transfer (RAFT) polymerization, which is one of the techniques of living radical polymerization, the first-stage monomer is homopolymerized using a chain transfer agent having a thiocarbonylthio group. A method of synthesizing a polymer chain transfer agent having a thiocarbonylthio group at the end (macro-chain transfer agent), isolating and purifying, and then polymerizing the next monomer in the second stage is used.

また、2種類のモノマーのブロック効率を考慮することも重要である。例えば、モノマーAから合成されたマクロ連鎖移動剤〔A−S−C(=S)−Z〕からモノマーBへの付加が、モノマーBから合成されたマクロ連鎖移動剤〔B−S−C(=S)−Z〕からモノマーAへの付加よりも効率が高い場合がある。実際、マクロ連鎖移動剤〔A−S−C(=S)−Z〕存在下でモノマーBを重合してpoly(A)−b−poly(B)といったブロック共重合体を合成する場合、マクロ連鎖移動剤〔A−S−C(=S)−Z〕は高い連鎖移動定数、つまり生長鎖ラジカル(A・)の脱離能がB・ラジカルより高いか、少なくても同程度である必要がある(非特許文献1)。そうでない場合は、共役モノマーと非共役モノマーのブロック共重合体は一般的に重合できないといわれている。

本発明の課題は、カルバゾール基を有するビニルモノマーの重合体ブロックと共役ビニルモノマーの重合体ブロックを含むブロック共重合体およびその製造方法を提供することにある。 The subject of this invention is providing the block copolymer containing the polymer block of the vinyl monomer which has a carbazole group, and the polymer block of a conjugated vinyl monomer, and its manufacturing method.

本発明は以下の発明に係る。

1.カルバゾール基を有するビニルモノマーの繰返し単位を含むブロック(A)と共役ビニルモノマーの繰返し単位を含むブロック(B)を含むブロック共重合体。

The present invention relates to the following inventions.

1. A block copolymer comprising a block (A) containing a repeating unit of a vinyl monomer having a carbazole group and a block (B) containing a repeating unit of a conjugated vinyl monomer.

2.カルバゾール基を有するビニルモノマーの繰返し単位を含むブロック(A)とQ−eスキームにおけるQ値が0.2以上のビニルモノマーの繰返し単位を含むブロック(B)を含むブロック共重合体であって、その重量平均分子量が2,000〜40,000である上記に記載のブロック共重合体。 2. A block copolymer comprising a block (A) containing a vinyl monomer repeating unit having a carbazole group and a block (B) containing a vinyl monomer repeating unit having a Q value of 0.2 or more in the Qe scheme, The block copolymer according to the above, having a weight average molecular weight of 2,000 to 40,000.

3.(a)式(1)で表される有機テルル化合物、

(b)式(1)で表される有機テルル化合物とアゾ系重合開始剤の混合物、

(c)式(1)で表される有機テルル化合物と式(2)で表される有機ジテルル化合物の混合物、又は

(d)式(1)で表される有機テルル化合物、アゾ系重合開始剤及び式(2)で表される有機ジテルル化合物の混合物から選ばれる有機テルル化合物系重合開始剤を用いて、

カルバゾール基を有するビニルモノマーと共役ビニルモノマーを重合するカルバゾール基を有するビニルモノマーの繰返し単位を含むブロック(A)と共役ビニルモノマーの繰返し単位を含むブロック(B)を含むブロック共重合体の製造方法。

3. (A) an organic tellurium compound represented by formula (1),

(B) a mixture of an organic tellurium compound represented by formula (1) and an azo polymerization initiator,

(C) A mixture of an organic tellurium compound represented by formula (1) and an organic ditellurium compound represented by formula (2), or (d) an organic tellurium compound represented by formula (1), an azo polymerization initiator. And an organic tellurium compound-based polymerization initiator selected from a mixture of organic ditellurium compounds represented by the formula (2):

Process for producing a block copolymer comprising a block (A) containing a vinyl monomer having a carbazole group for polymerizing a vinyl monomer having a carbazole group and a conjugated vinyl monomer, and a block (B) containing a repeating unit of the conjugated vinyl monomer .

(R1Te)2 (2)

(R1は上記に同じ)

(R 1 Te) 2 (2)

(R 1 is the same as above)

本発明によれば、カルバゾール基を有するビニルモノマーの重合体ブロックと共役ビニルモノマーの重合体ブロックを含むブロック共重合体を製造することができる。 According to the present invention, a block copolymer including a polymer block of a vinyl monomer having a carbazole group and a polymer block of a conjugated vinyl monomer can be produced.

カルバゾール基を有するビニルモノマーとしては、例えば、N−ビニルカルバゾール、N−エチル−3−ビニルカルバゾール等が挙げられる。 Examples of the vinyl monomer having a carbazole group include N-vinylcarbazole and N-ethyl-3-vinylcarbazole.

本発明に用いられる共役ビニルモノマーとしては特に制限なく使用することができるが、例えば、1949年にAlfreyとPriceにより提唱されたQ−eスキームにおけるQ値が0.2以上のモノマーが挙げられる。モノマーのQ値については種々の刊行物に記載がある。例えば、POLYMER HANDBOOK fourth editionII/309〜II/319ページのQ and e Values for Free Radical Copolymerization of Vinyl Monomers and Telogensの項に記載されている。具体的にはスチレン、α−メチルスチレン、4−メチルスチレン、2−メチルスチレン、3−メチルスチレン等のスチレン類モノマーおよびその誘導体、ブタジエン、クロロプレンなどのジエン類モノマーを例示しうる。本発明において共役ビニルモノマーは1種単独で又は2種以上で使用できる。 The conjugated vinyl monomer used in the present invention can be used without any particular limitation, and examples thereof include monomers having a Q value of 0.2 or more in the Qe scheme proposed by Alfrey and Price in 1949. The Q value of the monomer is described in various publications. For example, it is described in the section of Q and e Values for Free Radical Copolymerization of Vinyl Monomers and Telogens on the pages of POLYMER HANDBOOK fourth edition II / 309 to II / 319. Specifically styrene, alpha-methyl styrene, 4-methylstyrene, 2-methylstyrene, styrenes monomers and derivatives thereof such as 3-methylstyrene, blanking Tajien may illustrate dienes monomers such as chloroprene. In this invention, a conjugated vinyl monomer can be used individually by 1 type or 2 or more types.

本発明のカルバゾール基を有するビニルモノマーと共役ビニルモノマーを含むブロック共重合体の製造方法は、有機テルル化合物系重合開始剤を用いた重合により得ることができる。具体的には、

(a)式(1)で表される有機テルル化合物、

(b)式(1)で表される有機テルル化合物とアゾ系重合開始剤の混合物、

(c)式(1)で表される有機テルル化合物と式(2)で表される有機ジテルル化合物の混合物、又は

(d)式(1)で表される有機テルル化合物、アゾ系重合開始剤及び式(2)で表される有機ジテルル化合物の混合物

から選ばれる有機テルル化合物系重合開始剤を用いて重合する。

The method for producing a block copolymer containing a vinyl monomer having a carbazole group and a conjugated vinyl monomer according to the present invention can be obtained by polymerization using an organic tellurium compound-based polymerization initiator. In particular,

(A) an organic tellurium compound represented by formula (1),

(B) a mixture of an organic tellurium compound represented by formula (1) and an azo polymerization initiator,

(C) A mixture of an organic tellurium compound represented by formula (1) and an organic ditellurium compound represented by formula (2), or (d) an organic tellurium compound represented by formula (1), an azo polymerization initiator. And an organic tellurium compound-based polymerization initiator selected from a mixture of organic ditellurium compounds represented by formula (2).

本発明で使用する有機テルル化合物は、式(1)で表される。 The organic tellurium compound used in the present invention is represented by the formula (1).

R1で示される基は、具体的には次の通りである。

炭素数1〜8のアルキル基としては、メチル基、エチル基、n−プロピル基、イソプロピル基、シクロプロピル基、n−ブチル基、sec−ブチル基、tert−ブチル基、シクロブチル基、n−ペンチル基、n−ヘキシル基、n−ヘプチル基、n−オクチル基等の炭素数1〜8の直鎖状、分岐鎖状又は環状のアルキル基を挙げることができる。好ましいアルキル基としては、炭素数1〜4の直鎖状又は分岐鎖状のアルキル基が良い。より好ましくは、メチル基、エチル基又はn−ブチル基が良い。

アリール基としては、フェニル基、ナフチル基等を挙げることができる。好ましいアリール基としては、フェニル基が良い。置換アリールの置換基としては、例えば炭素数1〜8のアルキル基、ハロゲン原子、水酸基、アルコキシ基、アミノ基、ニトロ基、シアノ基、−CORaで示されるカルボニル含有基(Ra=炭素数1〜8のアルキル基、アリール基、炭素数1〜8のアルコキシ基、アリーロキシ基)、スルホニル基、トリフルオロメチル基等を挙げることができる。

Specific examples of the group represented by R 1 are as follows.

Examples of the alkyl group having 1 to 8 carbon atoms include methyl group, ethyl group, n-propyl group, isopropyl group, cyclopropyl group, n-butyl group, sec-butyl group, tert-butyl group, cyclobutyl group, and n-pentyl. Examples thereof include linear, branched or cyclic alkyl groups having 1 to 8 carbon atoms such as a group, n-hexyl group, n-heptyl group and n-octyl group. A preferable alkyl group is a linear or branched alkyl group having 1 to 4 carbon atoms. More preferably, a methyl group, an ethyl group, or an n-butyl group is good.

Examples of the aryl group include a phenyl group and a naphthyl group. A preferred aryl group is a phenyl group. Examples of the substituent of the substituted aryl include an alkyl group having 1 to 8 carbon atoms, a halogen atom, a hydroxyl group, an alkoxy group, an amino group, a nitro group, a cyano group, and a carbonyl-containing group represented by —COR a (R a = carbon number). 1-8 alkyl groups, aryl groups, C1-C8 alkoxy groups, aryloxy groups), sulfonyl groups, trifluoromethyl groups, and the like.

好ましい置換アリール基としては、トリフルオロメチル置換フェニル基が良い。

また、これら置換基は、1個又は2個置換しているのが良く、パラ位若しくはオルト位が好ましい。

芳香族へテロ環基としては、ピリジル基、ピロール基、フリル基、チエニル基等を挙げることができる。

A preferred substituted aryl group is a trifluoromethyl-substituted phenyl group.

These substituents may be substituted one or two, and the para position or ortho position is preferable.

Examples of the aromatic heterocyclic group include a pyridyl group, a pyrrole group, a furyl group, and a thienyl group.

R2及びR3で示される各基は、具体的には次の通りである。

炭素数1〜8のアルキル基としては、上記R1で示したアルキル基と同様のものを挙げることができる。

Each group represented by R 2 and R 3 is specifically as follows.

Examples of the alkyl group having 1 to 8 carbon atoms include the same alkyl groups as those described above for R 1 .

R4で示される各基は、具体的には次の通りである。

アリール基、置換アリール基、芳香族へテロ環基としては上記R1で示した基と同様のものを挙げることができる。

アシル基としては、ホルミル基、アセチル基、ベンゾイル基等を挙げることができる。

アミド基としては、アセトアミド、マロンアミド、スクシンアミド、マレアミド、ベンズアミド、2−フルアミド等のカルボン酸アミド、チオアセトアミド、ヘキサンジチオアミド、チオベンズアミド、メタンチオスルホンアミド等のチオアミド、セレノアセトアミド、ヘキサンジセレノアミド、セレノベンズアミド、メタンセレノスルホンアミド等のセレノアミド、N−メチルアセトアミド、ベンズアニリド、シクロヘキサンカルボキサニリド、2,4'−ジクロロアセトアニリド等のN−置換アミド等を挙げることができる。

オキシカルボニル基としては、−COORb(Rb=H、炭素数1〜8のアルキル基、アリール基)で示される基を挙げることができる。

具体的には、カルボキシル基、メトキシカルボニル基、エトキシカルボニル基、プロポキシカルボニル基、n−ブトキシカルボニル基、sec−ブトキシカルボニル基、tert−ブトキシカルボニル基、n−ペントキシカルボニル基、フェノキシカルボニル基等を挙げることができる。

Specific examples of each group represented by R 4 are as follows.

Examples of the aryl group, substituted aryl group, and aromatic heterocyclic group include the same groups as those described above for R 1 .

Examples of the acyl group include a formyl group, an acetyl group, and a benzoyl group.

Examples of the amide group include carboxylic acid amides such as acetamide, malonamide, succinamide, maleamide, benzamide, and 2-fluamide, thioamides such as thioacetamide, hexanedithioamide, thiobenzamide, and methanethiosulfonamide, selenoacetamide, hexanediselenoamide, Examples include selenoamides such as selenobenzamide and methaneselenosulfonamide, N-substituted amides such as N-methylacetamide, benzanilide, cyclohexanecarboxanilide, and 2,4′-dichloroacetanilide.

Examples of the oxycarbonyl group include a group represented by -COOR b (R b = H, an alkyl group having 1 to 8 carbon atoms, an aryl group).

Specifically, carboxyl group, methoxycarbonyl group, ethoxycarbonyl group, propoxycarbonyl group, n-butoxycarbonyl group, sec-butoxycarbonyl group, tert-butoxycarbonyl group, n-pentoxycarbonyl group, phenoxycarbonyl group, etc. Can be mentioned.

好ましいオキシカルボニル基としては、メトキシカルボニル基、エトキシカルボニル基が良い。

好ましいR4で示される各基としては、アリール基、置換アリール基、オキシカルボニル基又はシアノ基が良い。

好ましいアリール基としては、フェニル基が良い。

好ましい置換アリール基としては、ハロゲン原子置換フェニル基、トリフルオロメチル置換フェニル基が良い。

また、これらの置換基は、ハロゲン原子の場合は、1〜5個置換しているのが良い。

アルコキシ基やトリフルオロメチル基の場合は、1個又は2個置換しているのが良く、1個置換の場合は、パラ位若しくはオルト位が好ましく、2個置換の場合は、メタ位が好ましい。

好ましいオキシカルボニル基としては、メトキシカルボニル基、エトキシカルボニル基が良い。

Preferred oxycarbonyl groups are a methoxycarbonyl group and an ethoxycarbonyl group.

Each group represented by R 4 is preferably an aryl group, a substituted aryl group, an oxycarbonyl group or a cyano group.

A preferred aryl group is a phenyl group.

Preferred examples of the substituted aryl group include a halogen atom substituted phenyl group and a trifluoromethyl substituted phenyl group.

In addition, in the case of a halogen atom, these substituents are preferably substituted by 1 to 5 pieces.

In the case of an alkoxy group or a trifluoromethyl group, one or two substituents may be substituted. In the case of one substitution, the para position or the ortho position is preferable, and in the case of two substitutions, the meta position is preferable. .

Preferred oxycarbonyl groups are a methoxycarbonyl group and an ethoxycarbonyl group.

好ましい(1)で示される有機テルル化合物としては、R1が炭素数1〜4のアルキル基またはフェニル基を示し、R2及びR3が、水素原子又は炭素数1〜4のアルキル基を示し、R4が、アリール基、置換アリール基、オキシカルボニル基で示される化合物が良い。

特に好ましくは、R1が、炭素数1〜4のアルキル基またはフェニル基を示し、R2及びR3が、水素原子又は炭素数1〜4のアルキル基を示し、R4が、フェニル基、置換フェニル基、メトキシカルボニル基、エトキシカルボニル基が良い。

As the preferred organic tellurium compound represented by (1), R 1 represents an alkyl group having 1 to 4 carbon atoms or a phenyl group, and R 2 and R 3 represent a hydrogen atom or an alkyl group having 1 to 4 carbon atoms. , R 4 is preferably an aryl group, a substituted aryl group, or an oxycarbonyl group.

Particularly preferably, R 1 represents an alkyl group having 1 to 4 carbon atoms or a phenyl group, R 2 and R 3 represent a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, R 4 represents a phenyl group, A substituted phenyl group, a methoxycarbonyl group, and an ethoxycarbonyl group are preferable.

式(1)で示される有機テルル化合物は、具体的には次の通りである。

(メチルテラニルメチル)ベンゼン、(メチルテラニルメチル)ナフタレン、エチル−2−メチル−2−メチルテラニル−プロピオネート、エチル−2−メチル−2−ブチルテラニル−プロピオネートや、特許文献1及び2等に記載された有機テルル化合物の全てを例示することができる。

The organic tellurium compound represented by the formula (1) is specifically as follows.

(Methylterranylmethyl) benzene, (methylterranylmethyl) naphthalene, ethyl-2-methyl-2-methylterranyl-propionate, ethyl-2-methyl-2-butylterranyl-propionate, and

式(1)で示される有機テルル化合物の製造方法は特に限定されず、特許文献1及び2等に記載された公知の方法等により製造することができる。

例えば、式(1)の化合物は、式(3)の化合物、式(4)の化合物および金属テルルを反応させることにより製造することができる。

上記、式(3)の化合物としては、具体的には次の通りである。

For example, the compound of formula (1) can be produced by reacting a compound of formula (3), a compound of formula (4) and metal tellurium.

Specific examples of the compound of the formula (3) are as follows.

Xで示される基としては、フッ素、塩素、臭素又はヨウ素等のハロゲン原子を挙げることができる。好ましくは、塩素、臭素が良い。

M(R1)m (4)

〔R1は、上記と同じ。Mは、アルカリ金属、アルカリ土類金属又は銅原子を示す。Mがアルカリ金属の時、mは1、Mがアルカリ土類金属の時、mは2、Mが銅原子の時、mは1または2を示す。〕

Examples of the group represented by X include halogen atoms such as fluorine, chlorine, bromine and iodine. Preferably, chlorine and bromine are good.

M (R 1 ) m (4)

[R 1 is the same as above. M represents an alkali metal, alkaline earth metal or copper atom. When M is an alkali metal, m is 1, when M is an alkaline earth metal, m is 2, and when M is a copper atom, m is 1 or 2. ]

Mで示されるものとしては、リチウム、ナトリウム、カリウム等のアルカリ金属、マグネシウム、カルシウム等のアルカリ土類金属、銅を挙げることができる。好ましくは、リチウムが良い。

なお、Mがマグネシウムの時、化合物(4)はMg(R1)2でも、或いはR1MgX(Xは、ハロゲン原子)で表される化合物(グリニャール試薬)でもよい。Xは、好ましくは、塩素、臭素が良い。

Examples of M include alkali metals such as lithium, sodium and potassium, alkaline earth metals such as magnesium and calcium, and copper. Lithium is preferable.

When M is magnesium, the compound (4) may be Mg (R 1 ) 2 or a compound represented by R 1 MgX (X is a halogen atom) (Grignard reagent). X is preferably chlorine or bromine.

本発明で使用する有機ジテルル化合物は、式(2)で表される。

(R1Te)2 (2)

(R1は、炭素数1〜8のアルキル基、アリール基、置換アリール基又は芳香族ヘテロ環基を示す。)

R1で示される基は、式(1)において示した通りである。

好ましい式(2)で示される化合物としては、R1が炭素数1〜4のアルキル基、フェニル基の化合物である。

The organic ditellurium compound used in the present invention is represented by the formula (2).

(R 1 Te) 2 (2)

(R 1 represents an alkyl group having 1 to 8 carbon atoms, an aryl group, a substituted aryl group, or an aromatic heterocyclic group.)

The group represented by R 1 is as shown in Formula (1).

Preferred compounds represented by the formula (2) are compounds in which R 1 is an alkyl group having 1 to 4 carbon atoms and a phenyl group.

式(2)で示される化合物は、具体的には、ジメチルジテルリド、ジエチルジテルリド、ジ−n−プロピルジテルリド、ジイソプロピルジテルリド、ジシクロプロピルジテルリド、ジ−n−ブチルジテルリド、ジ−sec−ブチルジテルリド、ジ−tert−ブチルジテルリド、ジシクロブチルジテルリド、ジフェニルジテルリド、ビス−(p−メトキシフェニル)ジテルリド、ビス−(p−アミノフェニル)ジテルリド、ビス−(p−ニトロフェニル)ジテルリド、ビス−(p−シアノフェニル)ジテルリド、ビス−(p−スルホニルフェニル)ジテルリド、ジナフチルジテルリド、ジピリジルジテルリド等が挙げられる。好ましくは、ジメチルジテルリド、ジエチルジテルリド、ジ−n−プロピルジテルリド、ジ−n−ブチルジテルリド、ジフェニルジテルリドが良い。 Specifically, the compound represented by the formula (2) includes dimethylditelluride, diethylditelluride, di-n-propylditelluride, diisopropylditelluride, dicyclopropylditelluride, di-n- Butyl ditelluride, di-sec-butyl ditelluride, di-tert-butyl ditelluride, dicyclobutyl ditelluride, diphenyl ditelluride, bis- (p-methoxyphenyl) ditelluride, bis- (p-aminophenyl) ditelluride, bis- (p -Nitrophenyl) ditelluride, bis- (p-cyanophenyl) ditelluride, bis- (p-sulfonylphenyl) ditelluride, dinaphthylditelluride, dipyridylditelluride and the like. Preferred are dimethyl ditelluride, diethyl ditelluride, di-n-propyl ditelluride, di-n-butyl ditelluride, and diphenyl ditelluride.

また本発明では重合速度の促進を目的にアゾ系重合開始剤を使用してもよい。アゾ系重合開始剤は、通常のラジカル重合で使用するアゾ系重合開始剤であれば特に制限なく使用することができる。 In the present invention, an azo polymerization initiator may be used for the purpose of accelerating the polymerization rate. The azo polymerization initiator can be used without particular limitation as long as it is an azo polymerization initiator used in normal radical polymerization.

例えば2,2'−アゾビス(イソブチロニトリル)(AIBN)、2,2'−アゾビス(2−メチルブチロニトリル)(AMBN)、2,2'−アゾビス(2,4−ジメチルバレロニトリル)(ADVN)、1,1'−アゾビス(1−シクロヘキサンカルボニトリル)(ACHN)、ジメチル−2,2'−アゾビスイソブチレート(MAIB)、4,4'−アゾビス(4−シアノバレリアン酸)(ACVA)、1,1'−アゾビス(1−アセトキシ−1−フェニルエタン)、2,2'−アゾビス(2−メチルブチルアミド)、2,2'−アゾビス(4−メトキシ−2,4−ジメチルバレロニトリル)、2,2'−アゾビス(2−メチルアミジノプロパン)二塩酸塩、2,2'−アゾビス[2−(2−イミダゾリン−2−イル)プロパン]、2,2'−アゾビス[2−メチル−N−(2−ヒドロキシエチル)プロピオンアミド]、2,2'−アゾビス(2,4,4−トリメチルペンタン)、2−シアノ−2−プロピルアゾホルムアミド、2,2'−アゾビス(N−ブチル−2−メチルプロピオンアミド)、2,2'−アゾビス(N−シクロヘキシル−2−メチルプロピオンアミド)等が挙げられる。 For example, 2,2′-azobis (isobutyronitrile) (AIBN), 2,2′-azobis (2-methylbutyronitrile) (AMBN), 2,2′-azobis (2,4-dimethylvaleronitrile) (ADVN), 1,1′-azobis (1-cyclohexanecarbonitrile) (ACHN), dimethyl-2,2′-azobisisobutyrate (MAIB), 4,4′-azobis (4-cyanovaleric acid) (ACVA) 1,1′-azobis (1-acetoxy-1-phenylethane), 2,2′-azobis (2-methylbutyramide), 2,2′-azobis (4-methoxy-2,4- Dimethylvaleronitrile), 2,2′-azobis (2-methylamidinopropane) dihydrochloride, 2,2′-azobis [2- (2-imidazolin-2-yl) propane], 2,2′-azobis [ 2-Methyl-N- 2-hydroxyethyl) propionamide], 2,2′-azobis (2,4,4-trimethylpentane), 2-cyano-2-propylazoformamide, 2,2′-azobis (N-butyl-2-methyl) Propionamide), 2,2′-azobis (N-cyclohexyl-2-methylpropionamide) and the like.

これらのアゾ開始剤は反応条件に応じて適宜選択するのが好ましい。例えば低温重合(40℃以下)の場合は2,2'−アゾビス(2,4−ジメチルバレロニトリル)(ADVN)、2,2'−アゾビス(4−メトキシ−2,4−ジメチルバレロニトリル)、中温重合(40〜80℃)の場合は2,2'−アゾビス(イソブチロニトリル)(AIBN)、2,2'−アゾビス(2−メチルブチロニトリル)(AMBN)、ジメチル−2,2'−アゾビスイソブチレート(MAIB)、1,1'−アゾビス(1−アセトキシ−1−フェニルエタン)、4,4'−アゾビス(4−シアノバレリアン酸)(ACVA)、2,2'−アゾビス(2−メチルブチルアミド)、2,2'−アゾビス(2−メチルアミジノプロパン)二塩酸塩、2,2'−アゾビス[2−(2−イミダゾリン−2−イル)プロパン]、高温重合(80℃以上)の場合は1,1'−アゾビス(1−シクロヘキサンカルボニトリル)(ACHN)、2−シアノ−2−プロピルアゾホルムアミド、2,2'−アゾビス(N−ブチル−2−メチルプロピオンアミド)、2,2'−アゾビス(N−シクロヘキシル−2−メチルプロピオンアミド)、2,2'−アゾビス(2,4,4−トリメチルペンタン)、2,2'−アゾビス[2−メチル−N−(2−ヒドロキシエチル)プロピオンアミド]を用いるのがよい。 These azo initiators are preferably selected as appropriate according to the reaction conditions. For example, in the case of low temperature polymerization (40 ° C. or lower), 2,2′-azobis (2,4-dimethylvaleronitrile) (ADVN), 2,2′-azobis (4-methoxy-2,4-dimethylvaleronitrile), In the case of medium temperature polymerization (40-80 ° C.), 2,2′-azobis (isobutyronitrile) (AIBN), 2,2′-azobis (2-methylbutyronitrile) (AMBN), dimethyl-2,2 '-Azobisisobutyrate (MAIB), 1,1'-azobis (1-acetoxy-1-phenylethane), 4,4'-azobis (4-cyanovaleric acid) (ACVA), 2,2'- Azobis (2-methylbutyramide), 2,2′-azobis (2-methylamidinopropane) dihydrochloride, 2,2′-azobis [2- (2-imidazolin-2-yl) propane], high temperature polymerization ( 1,1'- in the case of 80 ° C or higher) Zobis (1-cyclohexanecarbonitrile) (ACHN), 2-cyano-2-propylazoformamide, 2,2′-azobis (N-butyl-2-methylpropionamide), 2,2′-azobis (N-cyclohexyl) 2-methylpropionamide), 2,2′-azobis (2,4,4-trimethylpentane), 2,2′-azobis [2-methyl-N- (2-hydroxyethyl) propionamide] Is good.

ビニルモノマーと式(1)の化合物の使用割合としては、得られる共重合体の分子量或いは分子量分布により適宜調節すればよいが、通常、式(1)の化合物1molに対して、ビニルモノマーを20〜4,000mol、好ましくは40〜400molとするのが良い。 The proportion of the vinyl monomer and the compound of formula (1) used may be appropriately adjusted depending on the molecular weight or molecular weight distribution of the copolymer to be obtained. Usually, the vinyl monomer is added to 20 mol of the compound of formula (1). ˜4,000 mol, preferably 40 to 400 mol.

式(1)の化合物とアゾ系重合開始剤の使用割合は、通常、式(1)の化合物1molに対して、アゾ系重合開始剤0.01〜100mol、好ましくは0.1〜10mol、特に好ましくは0.1〜5molとするのが良い。 The use ratio of the compound of formula (1) and the azo polymerization initiator is usually 0.01-100 mol, preferably 0.1-10 mol, particularly azo polymerization initiator, with respect to 1 mol of the compound of formula (1). Preferably it is 0.1-5 mol.

式(1)の化合物と式(2)の化合物を併用する場合、その使用量としては、通常、式(1)の化合物1molに対して、式(2)の化合物0.01〜100mol、好ましくは0.05〜10mol、特に好ましくは0.1〜5molとするのが良い。 When the compound of the formula (1) and the compound of the formula (2) are used in combination, the use amount thereof is usually 0.01 to 100 mol of the compound of the formula (2) with respect to 1 mol of the compound of the formula (1), preferably Is 0.05 to 10 mol, particularly preferably 0.1 to 5 mol.

式(1)の化合物、式(2)の化合物及びアゾ系重合開始剤を併用する場合、その使用量としては、通常、式(1)の化合物と式(2)の化合物の合計1molに対して、アゾ系重合開始剤0.01〜100mol、好ましくは0.1〜10mol、特に好ましくは0.1〜5molとするのが良い。 When the compound of the formula (1), the compound of the formula (2) and the azo polymerization initiator are used in combination, the amount used is usually 1 mol of the total of the compound of the formula (1) and the compound of the formula (2). The azo polymerization initiator may be 0.01 to 100 mol, preferably 0.1 to 10 mol, and particularly preferably 0.1 to 5 mol.

反応は、通常、無溶媒で行うが、ラジカル重合で一般に使用される有機溶媒或いは水性溶媒を使用しても構わない。使用できる有機溶媒としては、例えば、ベンゼン、トルエン、N,N−ジメチルホルムアミド(DMF)、ジメチルスルホキシド(DMSO)、アセトン、2−ブタノン(メチルエチルケトン)、ジオキサン、ヘキサフルオロイソプロパノール、クロロホルム、四塩化炭素、テトラヒドロフラン(THF)、酢酸エチル、トリフルオロメチルベンゼン等が挙げられる。また、水性溶媒としては、例えば、水、メタノール、エタノール、イソプロパノール、n−ブタノール、エチルセロソルブ、ブチルセロソルブ、1−メトキシ−2−プロパノール、ジアセトンアルコール等が挙げられる。溶媒の使用量としては適宜調節すればよいが、例えば、ビニルモノマー1gに対して、溶媒を0.01〜50ml、好ましくは、0.05〜10mlが、特に好ましくは、0.1〜1mlが良い。 The reaction is usually carried out without a solvent, but an organic solvent or an aqueous solvent generally used in radical polymerization may be used. Examples of the organic solvent that can be used include benzene, toluene, N, N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO), acetone, 2-butanone (methyl ethyl ketone), dioxane, hexafluoroisopropanol, chloroform, carbon tetrachloride, Tetrahydrofuran (THF), ethyl acetate, trifluoromethylbenzene and the like can be mentioned. Examples of the aqueous solvent include water, methanol, ethanol, isopropanol, n-butanol, ethyl cellosolve, butyl cellosolve, 1-methoxy-2-propanol, diacetone alcohol and the like. The amount of the solvent used may be adjusted as appropriate. For example, 0.01 to 50 ml, preferably 0.05 to 10 ml, particularly preferably 0.1 to 1 ml of the solvent is used per 1 g of the vinyl monomer. good.

次に、上記混合物を攪拌する。反応温度、反応時間は、得られる共重合体の分子量或いは分子量分布により適宜調節すればよいが、通常、0〜150℃で、1分〜100時間撹拌する。好ましくは、20〜100℃で、0.1〜30時間撹拌するのが良い。更に好ましくは、20〜80℃で、0.1〜15時間撹拌するのが良い。このように低い重合温度及び短い重合時間であっても高い収率と精密な分子量分布を得ることができるのが、本発明の特徴である。この時、圧力は、通常、常圧で行われるが、加圧或いは減圧しても構わない。 Next, the mixture is stirred. The reaction temperature and reaction time may be appropriately adjusted depending on the molecular weight or molecular weight distribution of the copolymer to be obtained, but are usually stirred at 0 to 150 ° C. for 1 minute to 100 hours. Preferably, stirring is performed at 20 to 100 ° C. for 0.1 to 30 hours. More preferably, stirring is performed at 20 to 80 ° C. for 0.1 to 15 hours. It is a feature of the present invention that a high yield and a precise molecular weight distribution can be obtained even at such a low polymerization temperature and a short polymerization time. At this time, the pressure is usually a normal pressure, but may be increased or decreased.

反応終了後、常法により使用溶媒や残存モノマーを減圧下除去して目的ポリマーを取り出したり、目的ポリマー不溶溶媒を使用して再沈澱処理により目的物を単離する。反応処理については、目的物に支障がなければどのような処理方法でも行う事ができる。 After completion of the reaction, the solvent or residual monomer is removed under reduced pressure by a conventional method to take out the target polymer, or the target product is isolated by reprecipitation using a target polymer insoluble solvent. The reaction treatment can be performed by any treatment method as long as there is no problem with the object.

また本発明で開始剤として用いる有機テルル化合物は水に対して安定であるため、本発明の共重合体は下記に示す特許文献3等に記載された水系での重合方法により合成できる。

即ち、エマルション重合法は界面活性剤を使用し、主にミセル中で重合する。必要に応じてポリビニルアルコール類等の水溶性高分子などの分散剤を用いても良い。これらの界面活性剤は1種類、又は2種類以上で組み合わせて使用することができる。かかる界面活性剤の使用量は、全モノマー100重量部に対して、0.3〜50重量部であることが好ましく、より好ましくは0.5〜50重量部である。又、水の使用量は、全モノマー100重量部に対して、50〜2000重量部であることが好ましく、より好ましくは70〜1500重量部である。重合温度は特に限定されないが、0〜100℃の範囲で行うことが好ましく、より好ましくは40〜90℃である。反応時間は、反応温度または用いるモノマー組成物の組成、界面活性剤や重合開始剤の種類等に応じ、重合反応が完結するように適宜設定すればよい。好ましくは24時間以内である。

Moreover, since the organic tellurium compound used as an initiator in the present invention is stable to water, the copolymer of the present invention can be synthesized by an aqueous polymerization method described in Patent Document 3 and the like shown below.

That is, the emulsion polymerization method uses a surfactant and polymerizes mainly in micelles. You may use dispersing agents, such as water-soluble polymers, such as polyvinyl alcohol, as needed. These surfactants can be used alone or in combination of two or more. The amount of the surfactant used is preferably 0.3 to 50 parts by weight, more preferably 0.5 to 50 parts by weight with respect to 100 parts by weight of the total monomers. Moreover, it is preferable that the usage-amount of water is 50-2000 weight part with respect to 100 weight part of all the monomers, More preferably, it is 70-1500 weight part. Although superposition | polymerization temperature is not specifically limited, It is preferable to carry out in the range of 0-100 degreeC, More preferably, it is 40-90 degreeC. What is necessary is just to set reaction time suitably so that a polymerization reaction may be completed according to reaction temperature or the composition of the monomer composition to be used, the kind of surfactant or a polymerization initiator, etc. Preferably within 24 hours.

懸濁重合法は分散剤を使用し、主にミセルを介さないで重合する。必要に応じてこれらの分散剤と共に、塩化ナトリウム、塩化カリウム、硫酸ナトリウム、硫酸カリウム、硫酸マンガン等の分散助剤を併用してもよい。かかる水分散安定剤の使用量は、全モノマー100重量部に対して、0.01〜30重量部であることが好ましく、より好ましくは0.05〜10重量部、特に好ましくは0.1〜5重量部である。又、水の使用量は、全モノマー100重量部に対して、50〜2000重量部であることが好ましく、より好ましくは70〜1500重量部である。重合温度は特に限定されないが、0〜100℃の範囲で行うことが好ましく、より好ましくは40〜90℃である。反応時間は、反応温度または用いるモノマー組成物の組成、水分散安定剤や重合開始剤の種類等に応じ、重合反応が完結するように適宜設定すればよい。好ましくは24時間以内である。 In the suspension polymerization method, a dispersant is used, and polymerization is mainly performed without using micelles. If necessary, a dispersing aid such as sodium chloride, potassium chloride, sodium sulfate, potassium sulfate, or manganese sulfate may be used in combination with these dispersing agents. The amount of the water dispersion stabilizer used is preferably from 0.01 to 30 parts by weight, more preferably from 0.05 to 10 parts by weight, particularly preferably from 0.1 to 100 parts by weight based on 100 parts by weight of the total monomers. 5 parts by weight. Moreover, it is preferable that the usage-amount of water is 50-2000 weight part with respect to 100 weight part of all the monomers, More preferably, it is 70-1500 weight part. Although superposition | polymerization temperature is not specifically limited, It is preferable to carry out in the range of 0-100 degreeC, More preferably, it is 40-90 degreeC. What is necessary is just to set reaction time suitably so that a polymerization reaction may be completed according to reaction temperature or the composition of the monomer composition to be used, the kind of water dispersion stabilizer, a polymerization initiator, etc. Preferably within 24 hours.

ミニエマルション重合法は界面活性剤及び共界面活性剤を使用し、ホモジナイザーや超音波装置を用いてモノマーを強制分散した後、主にミセルを介さないで重合する。かかる界面活性剤や共界面活性剤の使用量は、全モノマーに対して、0.3〜50重量部、特に好ましくは0.5〜50部である。超音波照射時間は、0.1〜10分、特に好ましくは0.2〜5分である。

該共重合体の分子量は、反応時間、式(1)の化合物の量および式(2)の化合物の量により調整可能であるが、重量平均分子量2,000〜40,000のリビングラジカルポリマーを得ることができる。

本発明において、ブロック(A)の割合が10〜90重量%、より好ましくは20〜80重量%、ブロック(B)の割合が90〜10重量%、より好ましくは80〜20重量%であるのが良い。

The molecular weight of the copolymer can be adjusted by the reaction time, the amount of the compound of the formula (1) and the amount of the compound of the formula (2), but a living radical polymer having a weight average molecular weight of 2,000 to 40,000 is used. Can be obtained.

In the present invention, the proportion of the block (A) is 10 to 90% by weight, more preferably 20 to 80% by weight, and the proportion of the block (B) is 90 to 10% by weight, more preferably 80 to 20% by weight. Is good.

該共重合体の分子量分布(PD=Mw/Mn)は、1.0〜2.0の間で制御される。更に、分子量分布1.05〜1.90、更には1.05〜1.80のより狭い分子量分布を持った共重合体を得ることができる。 The molecular weight distribution (PD = Mw / Mn) of the copolymer is controlled between 1.0 and 2.0. Furthermore, it is possible to obtain a copolymer having a narrower molecular weight distribution of 1.05 to 1.90, more preferably 1.05 to 1.80.

本発明のブロック共重合体の製造方法としては、ビニルカルバゾールを有するビニルモノマー(a)を重合し、次いで共役モノマー(b)を重合する。反応させる順番を逆にするとセグメント(b)−セグメント(a)のものも得ることができる。

上記で、各セグメントを製造後、そのまま次のブロックの反応を開始しても良いし、一度反応を終了後、精製してから次のセグメントの反応を開始しても良い。ブロック共重合体の単離は通常の方法により行うことができる。

As a method for producing the block copolymer of the present invention, a vinyl monomer (a) having vinyl carbazole is polymerized, and then a conjugated monomer (b) is polymerized. If the order of reaction is reversed, the segment (b) -segment (a) can also be obtained.

In the above, after the production of each segment, the reaction of the next block may be started as it is, or after the reaction is finished once, the reaction of the next segment may be started after purification. Isolation of the block copolymer can be performed by a usual method.

本発明のブロックポリマーは、カルバゾール骨格特有の光電導性、正孔輸送性、高屈折率および、ブロックポリマーの自己組織化によるナノサイズの相分離構造構築特性等を利用し、ホール注入材料、ホール輸送材料、発光層材料、電子輸送材料等の有機EL材料、有機トランジスタ材料、ホログラム記録材料、電子写真感光体、光学フィルム材料等での利用ができる。 The block polymer of the present invention uses a hole-injecting material, a hole-injecting material, a hole-transporting material, a hole-transporting material, a hole-transporting property, a high refractive index, and a nano-sized phase separation structure construction characteristic by self-organization of the block polymer It can be used in organic EL materials such as transport materials, light emitting layer materials, electron transport materials, organic transistor materials, hologram recording materials, electrophotographic photoreceptors, optical film materials, and the like.

以下、本発明を実施例に基づいて具体的に説明するが何らこれらに限定されるものではない。また、実施例および比較例において、各種物性測定は以下の機器により測定を行った。

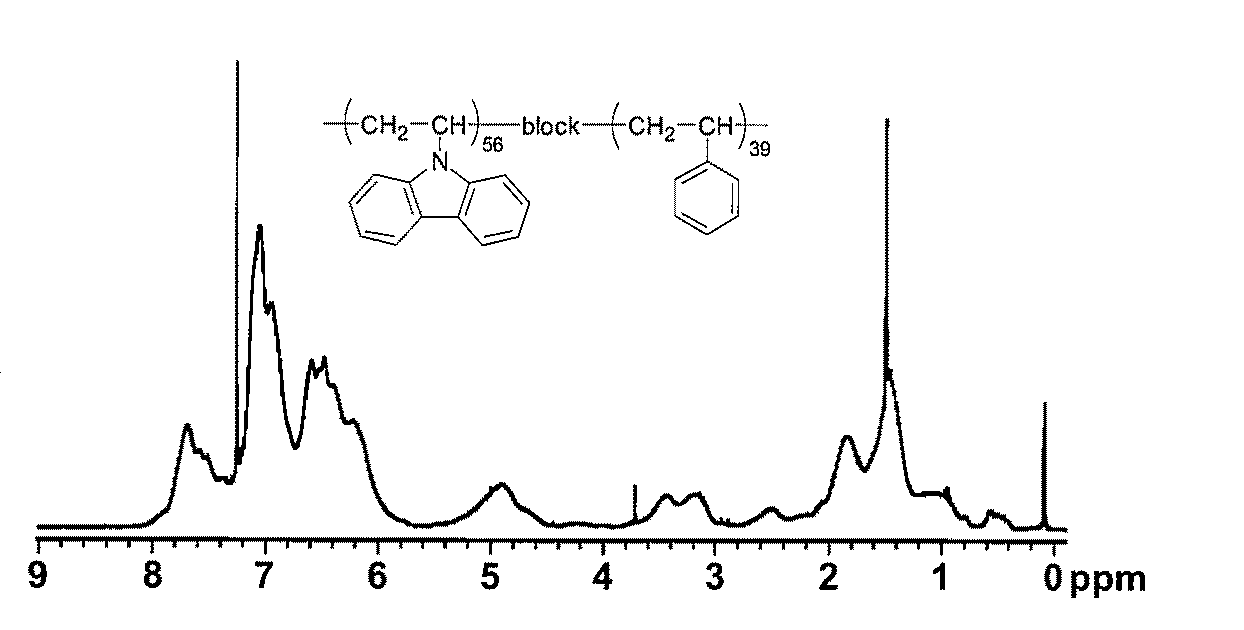

1H NMR:JNM−ECX400(400 MHz)

分子量および分子量分布:東ソー製ポンプDP−8020、Viscotek製トリプル検出器(屈折検出器、粘度検出器、光散乱検出器:630nm)TDA model−301(カラム:TSK−GEL ガードカラムHXL−HとTSK−GEL GMHXL+G4000HXL+G3000HXL+G2500HXL、ポリスチレンスタンダード:TOSOH TSK Standard)THF溶媒

元素分析:Perkin−Elmer 2400II CHNS/O analyzer

EXAMPLES Hereinafter, although this invention is demonstrated concretely based on an Example, it is not limited to these at all. In Examples and Comparative Examples, various physical properties were measured using the following equipment.

1 H NMR: JNM-ECX400 (400 MHz)

Molecular weight and molecular weight distribution: Tosoh pump DP-8020, Viscotek triple detector (refractive detector, viscosity detector, light scattering detector: 630 nm) TDA model-301 (column: TSK-GEL guard column H XL- H and TSK-GEL GMH XL + G4000H XL + G3000H XL + G2500H XL , polystyrene standard: TOSOH TSK Standard) THF solvent elemental analysis: Perkin-Elmer 2400II CHNS / O analyzer

実施例1

ポリN−ビニルカルバゾール―スチレンジブロックポリマーの合成

試験管に開始剤であるAIBN 3.0mg(0.018mmol)とN−ビニルカルバゾール0.350g(1.8mmol)、1,4−ジオキサン0.53mlを入れ、窒素置換した後にエチル−2−メチル−2−n−ブチルテラニル−プロピオネート11mg(0.036mmol)を加え、60℃で5時間反応させた。反応後、少量を取り出し1H NMRとSEC(サイズ排除クロマトグラフィー)分析を行い、転化率は98%、Mn=6700、Mn,RALLS=10800、PD=1.08であることを確認した。続けてこの反応溶液にスチレン0.17g(1.7mmol)を加え60℃で24時間反応させた。反応終了後、少量のクロロホルムで希釈した後、その溶液を攪拌しているメタノール中に滴下した。沈殿したポリマーを吸引ろ過、乾燥することによりポリN−ビニルカルバゾール―スチレンジブロックポリマー0.44g(収率86%)を得た。SEC分析よりMn=9700、Mn,RALLS=13900、PD=1.18であった。また、プレポリマーであるpoly(NVC)の絶対分子量(Mn,RALLS)およびブロック共重合体の元素分析から組成比を算出したところpoly(NVC):poly(St)=59:41であった。

Example 1

In a test tube for poly N-vinylcarbazole-styrene diblock polymer, 3.0 mg (0.018 mmol) of AIBN as an initiator and 0.350 g (1.8 mmol) of N-vinylcarbazole, 0.53 ml of 1,4-dioxane After replacing with nitrogen, 11 mg (0.036 mmol) of ethyl-2-methyl-2-n-butylterranyl-propionate was added and reacted at 60 ° C. for 5 hours. After the reaction, a small amount was taken out and subjected to 1 H NMR and SEC (size exclusion chromatography) analysis, and it was confirmed that the conversion rate was 98%, M n = 6700, M n, RALLS = 10800, PD = 1.08. . Subsequently, 0.17 g (1.7 mmol) of styrene was added to the reaction solution and reacted at 60 ° C. for 24 hours. After completion of the reaction, the reaction solution was diluted with a small amount of chloroform, and then the solution was added dropwise to stirring methanol. The precipitated polymer was suction filtered and dried to obtain 0.44 g (yield 86%) of poly N-vinylcarbazole-styrene diblock polymer. From the SEC analysis, it was Mn = 9700, Mn, RALLS = 13900, PD = 1.18. The composition ratio was calculated from the absolute molecular weight ( Mn, RALLS ) of the poly (NVC) prepolymer and the elemental analysis of the block copolymer, and it was poly (NVC): poly (St) = 59: 41. .

実施例2

ポリN−ビニルカルバゾール―スチレンジブロックポリマーの合成

試験管に開始剤であるAIBN 3.0mg(0.018mmol)とN−ビニルカルバゾール0.350g(1.8mmol)、1,4−ジオキサン0.53mlを入れ、窒素置換した後にエチル−2−メチル−2−n−ブチルテラニル−プロピオネート11mg(0.036mmol)を加え、60℃で5時間反応させた。反応後、少量を取り出し1H NMRとSEC分析を行い、転化率は97%、Mn=7100、Mn,RALLS=9500、PD=1.09であることを確認した。続けてこの反応溶液にスチレン0.37g(3.5mmol)を加え60℃で24時間反応させた。反応終了後、少量のクロロホルムで希釈した後、その溶液を攪拌しているメタノール中に滴下した。沈殿したポリマーを吸引ろ過、乾燥することによりポリN−ビニルカルバゾール―スチレンジブロックポリマー0.57g(収率79%)を得た。SEC分析よりMn=14400、Mn,RALLS=17800、PD=1.26であった。また、プレポリマーであるpoly(NVC)の絶対分子量(Mn,RALLS)およびブロック共重合体の元素分析から組成比を算出したところpoly(NVC):poly(St)=40:60であった。

Example 2

In a test tube for poly N-vinylcarbazole-styrene diblock polymer, 3.0 mg (0.018 mmol) of AIBN as an initiator and 0.350 g (1.8 mmol) of N-vinylcarbazole, 0.53 ml of 1,4-dioxane After replacing with nitrogen, 11 mg (0.036 mmol) of ethyl-2-methyl-2-n-butylterranyl-propionate was added and reacted at 60 ° C. for 5 hours. After the reaction, a small amount was taken out and subjected to 1 H NMR and SEC analysis, and it was confirmed that the conversion rate was 97%, M n = 7100, M n, RALLS = 9500, PD = 1.09. Subsequently, 0.37 g (3.5 mmol) of styrene was added to the reaction solution and reacted at 60 ° C. for 24 hours. After completion of the reaction, the reaction solution was diluted with a small amount of chloroform, and then the solution was added dropwise to stirring methanol. The precipitated polymer was suction filtered and dried to obtain 0.57 g (yield 79%) of poly N-vinylcarbazole-styrene diblock polymer. From the SEC analysis, it was Mn = 14400, Mn, RALLS = 17800, PD = 1.26. The composition ratio was calculated from the absolute molecular weight ( Mn, RALLS ) of the prepolymer poly (NVC) and the elemental analysis of the block copolymer, and it was poly (NVC): poly (St) = 40: 60. .

Claims (2)

(b)式(1)で表される有機テルル化合物とアゾ系重合開始剤の混合物、

(c)式(1)で表される有機テルル化合物と式(2)で表される有機ジテルル化合物の混合物、又は

(d)式(1)で表される有機テルル化合物、アゾ系重合開始剤及び式(2)で表される有機ジテルル化合物の混合物から選ばれる有機テルル化合物系重合開始剤を用いて、

カルバゾール基を有するビニルモノマーを重合し、次いで共役ビニルモノマーを重合することを特徴とする、カルバゾール基を有するビニルモノマーの繰返し単位を含むブロック(A)と共役ビニルモノマーの繰返し単位を含むブロック(B)を含むブロック共重合体の製造方法。

(R1Te)2 (2)

(R1は上記に同じ) (A) an organic tellurium compound represented by formula (1),

(B) a mixture of an organic tellurium compound represented by formula (1) and an azo polymerization initiator,

(C) A mixture of an organic tellurium compound represented by formula (1) and an organic ditellurium compound represented by formula (2), or (d) an organic tellurium compound represented by formula (1), an azo polymerization initiator. And an organic tellurium compound-based polymerization initiator selected from a mixture of organic ditellurium compounds represented by the formula (2):

A block containing a repeating unit of a vinyl monomer having a carbazole group (A) and a block containing a repeating unit of a conjugated vinyl monomer (B) , characterized by polymerizing a vinyl monomer having a carbazole group and then polymerizing a conjugated vinyl monomer ) Containing a block copolymer.

(R 1 Te) 2 (2)

(R 1 is the same as above)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008301066A JP5261717B2 (en) | 2008-11-26 | 2008-11-26 | Block copolymer and method for producing the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008301066A JP5261717B2 (en) | 2008-11-26 | 2008-11-26 | Block copolymer and method for producing the same |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010126583A JP2010126583A (en) | 2010-06-10 |

| JP5261717B2 true JP5261717B2 (en) | 2013-08-14 |

Family

ID=42327196

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008301066A Active JP5261717B2 (en) | 2008-11-26 | 2008-11-26 | Block copolymer and method for producing the same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5261717B2 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107209315B (en) | 2015-02-26 | 2020-11-17 | 日本瑞翁株式会社 | Transfer body for optical film, organic electroluminescent display device, and method for producing optical film |

| WO2017170455A1 (en) * | 2016-03-30 | 2017-10-05 | 日本ゼオン株式会社 | Optically anisotropic layer and production method therefor, optically anisotropic laminate and production method therefor, optically anisotropic transfer body, polarization plate, and image display device |

| CN108779193A (en) * | 2016-03-31 | 2018-11-09 | 日本瑞翁株式会社 | The manufacturing method of copolymer and the manufacturing method of latex |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1488266A (en) * | 1973-12-26 | 1977-10-12 | Xerox Corp | Xerographic imaging member and method |

| US5306586A (en) * | 1992-08-06 | 1994-04-26 | Xerox Corporation | Dual layer switch photoreceptor structures for digital imaging |

| JPH1160660A (en) * | 1997-08-11 | 1999-03-02 | Jsr Corp | Block copolymer and its production |

| AU2002313917B2 (en) * | 2002-08-06 | 2007-07-12 | Otsuka Chemical Co., Ltd. | Organic tellurium compound, process for producing the same, living radical polymerization initiator, process for producing polymer with the same, and polymer |

| US7291690B2 (en) * | 2002-08-08 | 2007-11-06 | Otsuka Chemical Co., Ltd. | Process for production of living radical polymers and polymers |

-

2008

- 2008-11-26 JP JP2008301066A patent/JP5261717B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2010126583A (en) | 2010-06-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5499477B2 (en) | Hyperbranched polymer and method for producing the same | |

| JP3542580B2 (en) | Method for synthesizing polymers by free radical polymerization controlled by halogenated xanthates | |

| JP6733807B2 (en) | Method for producing polymer | |

| JP3845109B2 (en) | Method for producing living radical polymer and polymer | |

| AU2003254890A1 (en) | Process for production of living radical polymers and polymers | |

| JP2006299278A (en) | Process for production of living radical polymer | |

| JP5193480B2 (en) | Method for producing living radical polymer and polymer | |

| JP4107996B2 (en) | Method for producing living radical polymer and polymer | |

| He et al. | Synthesis of block copolymers via the combination of RAFT and a macromolecular azo coupling reaction | |

| KR100633200B1 (en) | Process for the production of living radical polymers and polymers | |

| JP5261717B2 (en) | Block copolymer and method for producing the same | |

| JP4539843B2 (en) | Method for producing aqueous liquid using organic tellurium compound | |

| JP5380709B2 (en) | Living radical polymerization reaction promoter | |

| JP6754124B2 (en) | Method for manufacturing multi-branched polymer and multi-branched polymer | |

| TW201708186A (en) | Method for producing alkenyl ether polymer | |

| Yuan et al. | Atom transfer radical polymerization of styrene initiated by 2-(4-chloromethyl-phenyl)-benzoxazole with high activity and fluorescent property | |

| JP2007302737A (en) | Preparation of living radical polymer | |

| JP2009024162A (en) | Difunctional living radical polymerization initiator and method for producing polymer | |

| CN114402001B (en) | Method for producing fluorine-containing compound and method for producing copolymer | |

| Lu et al. | A strategy for synthesis of ion‐bonded amphiphilic miktoarm star copolymers via supramolecular macro‐RAFT agent | |

| Pizarro et al. | Amphiphilic diblock copolymers poly (2‐hydroxyethylmethacrylate)‐b‐(N‐phenylmaleimide) and poly (2‐hydroxyethylmethacrylate)‐b‐(styrene) using the macroinitiator poly (HEMA)‐Cl by ATRP: Preparation, characterization, and thermal properties | |

| JP5232986B2 (en) | Polylactic acid modifier and polylactic acid resin composition. | |

| WO2022130919A1 (en) | Tellurium-containing compound, polymer, and method for producing polymer | |

| JP2024134328A (en) | Method for producing block copolymer | |

| WO2022054547A1 (en) | Method for producing iodine-containing compound, and iodine-containing compound |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20100611 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110914 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20121128 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121225 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130206 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130402 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130404 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5261717 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |