JP4841516B2 - 空気入りタイヤ及びその製造方法 - Google Patents

空気入りタイヤ及びその製造方法 Download PDFInfo

- Publication number

- JP4841516B2 JP4841516B2 JP2007207858A JP2007207858A JP4841516B2 JP 4841516 B2 JP4841516 B2 JP 4841516B2 JP 2007207858 A JP2007207858 A JP 2007207858A JP 2007207858 A JP2007207858 A JP 2007207858A JP 4841516 B2 JP4841516 B2 JP 4841516B2

- Authority

- JP

- Japan

- Prior art keywords

- tire

- rubber

- carcass ply

- bead

- buttress portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title description 15

- 229920001971 elastomer Polymers 0.000 claims description 64

- 239000011324 bead Substances 0.000 claims description 28

- 239000000945 filler Substances 0.000 claims description 6

- 238000000465 moulding Methods 0.000 description 13

- 238000004073 vulcanization Methods 0.000 description 10

- 238000000034 method Methods 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 7

- 238000004804 winding Methods 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 230000037303 wrinkles Effects 0.000 description 2

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 239000006229 carbon black Substances 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 230000001012 protector Effects 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/72—Side-walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/30—Applying the layers; Guiding or stretching the layers during application

- B29D30/3028—Applying the layers; Guiding or stretching the layers during application by feeding a continuous band and winding it helically, i.e. the band is fed while being advanced along the drum axis, to form an annular element

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/52—Unvulcanised treads, e.g. on used tyres; Retreading

- B29D30/58—Applying bands of rubber treads, i.e. applying camel backs

- B29D30/60—Applying bands of rubber treads, i.e. applying camel backs by winding narrow strips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C11/00—Tyre tread bands; Tread patterns; Anti-skid inserts

- B60C11/01—Shape of the shoulders between tread and sidewall, e.g. rounded, stepped or cantilevered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C13/00—Tyre sidewalls; Protecting, decorating, marking, or the like, thereof

- B60C13/02—Arrangement of grooves or ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C11/00—Tyre tread bands; Tread patterns; Anti-skid inserts

- B60C11/0008—Tyre tread bands; Tread patterns; Anti-skid inserts characterised by the tread rubber

- B60C2011/0016—Physical properties or dimensions

- B60C2011/0025—Modulus or tan delta

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Tyre Moulding (AREA)

- Tires In General (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Heating, Cooling, Or Curing Plastics Or The Like In General (AREA)

Description

トレッドゴムのショルダー部はスクエア形状であって、

バッドレス部に突起を備え、前記トレッドゴム及び前記突起の抗張積は15000〜18000(MPa・%)であり、前記サイドウォールゴムの抗張積は10000〜12000(MPa・%)であることを特徴とする。

成形ドラムにインナーライナーを貼り付け、前記インナーライナーの外側にカーカスプライを貼り付け、ビードコアとビードフィラーを備えた一対のビードを前記カーカスプライの両端に載置し、前記カーカスプライの端部が各ビードを巻き上げるように前記カーカスプライの両端を折り返し、

前記カーカスプライの外側に、加硫後の抗張積が10000〜12000(MPa・%)であるサイドウォールゴムを貼り付け、

前記成形ドラムを拡径した後、前記カーカスプライのクラウン部に相当する位置の外側にベルト層及び加硫後の抗張積が15000〜18000(MPa・%)であるトレッドゴムを貼り付けて、生タイヤを成形し、

前記生タイヤのバットレス部に、加硫後の抗張積が15000〜18000(MPa・%)である帯状ゴム部材を貼り付けて環状突起部を形成し、前記生タイヤを金型で加硫成型することで製造される。

成形ドラムにインナーライナーを貼り付け、前記インナーライナーの外側にカーカスプライを貼り付け、ビードコアとビードフィラーを備えた一対のビードを前記カーカスプライの両端に載置し、前記カーカスプライの端部が各ビードを巻き上げるように前記カーカスプライの両端を折り返し、

前記カーカスプライの外側に、加硫後の抗張積が10000〜12000(MPa・%)であるサイドウォールゴムを貼り付け、

前記成形ドラムを拡径した後、前記カーカスプライのクラウン部に相当する位置の外側にベルト層及び加硫後の抗張積が15000〜18000(MPa・%)であるトレッドゴムを貼り付けて、生タイヤを成形し、

前記生タイヤのバットレス部に、加硫後の抗張積が15000〜18000(MPa・%)であるリボン状ゴム部材を複数回巻きつけて環状突起部を形成し、前記生タイヤを金型で加硫成型することで製造される。

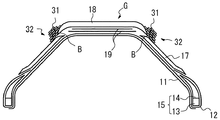

11 インナーライナー

12 カーカスプライ

13 ビードコア

14 ビードフィラー

15 ビード

17 サイドウォールゴム

18 トレッドゴム

19 ベルト層

30 突起

Claims (1)

- ビードコアとビードフィラーを備えた一対のビードと、端部が各ビードを巻き上げるように折り返されてトロイダル状に成形されたカーカスプライと、前記カーカスプライのサイド部を覆うサイドウォールゴムと、前記カーカスプライのクラウン部を覆うトレッドゴムとを備えた空気入りタイヤであって、

トレッドゴムのショルダー部はスクエア形状であって、

バッドレス部に突起を備え、前記トレッドゴム及び前記突起の抗張積は15000〜18000(MPa・%)であり、前記サイドウォールゴムの抗張積は10000〜12000(MPa・%)であることを特徴とする空気入りタイヤ。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007207858A JP4841516B2 (ja) | 2007-08-09 | 2007-08-09 | 空気入りタイヤ及びその製造方法 |

| PCT/JP2008/057722 WO2009019912A1 (ja) | 2007-08-09 | 2008-04-22 | 空気入りタイヤ及びその製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007207858A JP4841516B2 (ja) | 2007-08-09 | 2007-08-09 | 空気入りタイヤ及びその製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009040237A JP2009040237A (ja) | 2009-02-26 |

| JP4841516B2 true JP4841516B2 (ja) | 2011-12-21 |

Family

ID=40341149

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007207858A Active JP4841516B2 (ja) | 2007-08-09 | 2007-08-09 | 空気入りタイヤ及びその製造方法 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP4841516B2 (ja) |

| WO (1) | WO2009019912A1 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013177065A (ja) * | 2012-02-28 | 2013-09-09 | Sumitomo Rubber Ind Ltd | 空気入りタイヤ |

| US11724547B2 (en) * | 2018-06-19 | 2023-08-15 | Sumitomo Rubber Industries, Ltd. | Heavy duty pneumatic tire |

| JP2021041666A (ja) * | 2019-09-13 | 2021-03-18 | Toyo Tire株式会社 | 空気入りタイヤの製造方法 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2915409B2 (ja) * | 1987-10-27 | 1999-07-05 | 株式会社ブリヂストン | 2輪車用扁平空気入りラジアルタイヤ |

| JP3207885B2 (ja) * | 1991-08-28 | 2001-09-10 | 株式会社ブリヂストン | ゴム組成物 |

| JPH10217717A (ja) * | 1997-02-10 | 1998-08-18 | Bridgestone Corp | 重荷重用空気入りラジアルタイヤ |

| JPH11321229A (ja) * | 1998-05-12 | 1999-11-24 | Yokohama Rubber Co Ltd:The | 空気入りラジアルタイヤ及びその製造方法 |

| JP4202168B2 (ja) * | 2003-03-28 | 2008-12-24 | 東洋ゴム工業株式会社 | 空気入りラジアルタイヤ |

| JP2006182179A (ja) * | 2004-12-27 | 2006-07-13 | Yokohama Rubber Co Ltd:The | 空気入りタイヤ |

| JP4912645B2 (ja) * | 2005-09-06 | 2012-04-11 | 東洋ゴム工業株式会社 | 空気入りタイヤ |

-

2007

- 2007-08-09 JP JP2007207858A patent/JP4841516B2/ja active Active

-

2008

- 2008-04-22 WO PCT/JP2008/057722 patent/WO2009019912A1/ja active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| JP2009040237A (ja) | 2009-02-26 |

| WO2009019912A1 (ja) | 2009-02-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6085940B2 (ja) | 更生タイヤ | |

| JP2006062518A (ja) | 重荷重用空気入りタイヤ及びその製造方法 | |

| CN110001308B (zh) | 充气轮胎 | |

| JP4780796B2 (ja) | 空気入りタイヤの製造方法 | |

| JP5211707B2 (ja) | 更生タイヤ及びタイヤ更生方法 | |

| JP2005225278A (ja) | 空気入りタイヤ | |

| JP7482622B2 (ja) | 空気入りタイヤ | |

| KR102132667B1 (ko) | 공기입 타이어 및 그 제조 방법 | |

| JP4841516B2 (ja) | 空気入りタイヤ及びその製造方法 | |

| CN100348405C (zh) | 充气轮胎及其制造方法 | |

| JP2013184534A (ja) | 空気入りタイヤ及びその製造方法 | |

| JP6056360B2 (ja) | 更生タイヤ | |

| JP2008168807A (ja) | 空気入りタイヤおよびその製造方法 | |

| JP2007001105A (ja) | 空気入りラジアルタイヤの製造方法 | |

| JP6943275B2 (ja) | 空気入りタイヤ | |

| JP3845514B2 (ja) | 空気入りタイヤ | |

| JP3876270B2 (ja) | 乗用車用空気入りタイヤ | |

| JP6136131B2 (ja) | 更生タイヤ | |

| JP6147650B2 (ja) | 空気入りタイヤの製造方法 | |

| JP2018192658A (ja) | 空気入バイアスタイヤ、及びその製造方法 | |

| JP4577005B2 (ja) | 小型トラック用空気入りタイヤ | |

| JP2004058823A (ja) | 空気入りタイヤ | |

| JP2006151327A (ja) | 空気入りタイヤ及びその製造方法 | |

| JP2009018553A (ja) | 空気入りタイヤの製造方法及び空気入りタイヤ | |

| KR101582049B1 (ko) | 실리카 적용 공기입 타이어 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100312 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110407 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110606 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110701 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111003 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111004 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 4841516 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141014 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |