EP2615378B1 - Griddle plate - Google Patents

Griddle plate Download PDFInfo

- Publication number

- EP2615378B1 EP2615378B1 EP12151024.2A EP12151024A EP2615378B1 EP 2615378 B1 EP2615378 B1 EP 2615378B1 EP 12151024 A EP12151024 A EP 12151024A EP 2615378 B1 EP2615378 B1 EP 2615378B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plate

- central portion

- frame portion

- griddle

- griddle plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910052751 metal Inorganic materials 0.000 claims description 14

- 239000002184 metal Substances 0.000 claims description 14

- 238000010411 cooking Methods 0.000 claims description 13

- 239000000463 material Substances 0.000 claims description 9

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 6

- 229910052742 iron Inorganic materials 0.000 claims description 3

- 238000010438 heat treatment Methods 0.000 description 9

- 238000005452 bending Methods 0.000 description 6

- 239000004411 aluminium Substances 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 235000021168 barbecue Nutrition 0.000 description 2

- 230000006698 induction Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 230000005674 electromagnetic induction Effects 0.000 description 1

- 239000002241 glass-ceramic Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C15/00—Details

- F24C15/10—Tops, e.g. hot plates; Rings

Definitions

- the present invention relates to a plate, in particular for a cooking hob, according to the preamble of claim 1. Further, the present invention relates to a cooking hob including at least one griddle plate. In particular, the present invention relates to a Teppan Yaki grill.

- the griddle plate is made of a metal plate.

- the Teppan Yaki grill also includes a metal plate, in particular made of ferritic steel or iron.

- the barbecue temperatures are very high, so that the thermal expansion of the metal plate causes a bending of said metal plate.

- the temperatures in the centre of the metal plate are higher than the temperatures in the outer areas of said metal plate. The bending of the metal plate is unre-quested.

- a griddle plate in particular a Teppan Yaki grill, which may be a built-in type or a portable tabletop unit.

- the griddle plate is enclosed by the frame made at least particularly of glass ceramics.

- the material of the frame has a low thermal conductivity, so that the frame does not reach a too high temperature.

- DE 202 15 979 U1 discloses a cooking plate or griddle plate including several layers.

- the top layer and the bottom layer are metal sheets.

- the intermediate sheet is made of aluminium.

- the griddle plate is subdivided into cooking zones. Between said cooking zones are border zones. In the border zones only the top layer is present, but the intermediate layer and bottom layer lack.

- US 4,045,654 discloses an electric hot plate with a thermostat.

- a heating plate is joined to the surrounding cold zones by means of a bridge of relative thin metal.

- An actuating device for a thermostatic switch is operated by the vertical movement of the heating plate.

- the bridge acts as a hinge for the vertical movement of the heating plate.

- the heating plate includes a relative thick middle layer and thin layers on the upper and lower sides.

- the thin layers are made of stainless steel.

- the upper thin layer forms the bridge between the heating plate and the surrounding cold zones.

- the middle layer of the heating plate consists of two different materials, wherein a circular plate is surrounded by a ring.

- the coefficient of linear expansion of the circular plate is bigger than that of the ring.

- the circular plate is made of copper, while the ring is made of aluminium.

- GB 1 428 555 discloses an induction heating apparatus.

- the induction heating apparatus includes an inductor and a cover plate.

- the inductor is provided for heating a susceptor by electromagnetic induction.

- the cover plate is a non-magnetic metallic plate having a high electrical resistance.

- the cover plate includes one or more grooves in order to absorb thermal strain within said cover plate.

- the grooves are U-shaped, S-shaped or V-shaped.

- the object of the present invention is achieved by the plate according to claim 1.

- the plate is a griddle plate

- the join patch is a welded joint

- the thickness of the central portion is bigger than the thickness of the frame portion.

- the griddle plate for the cooking hob is formed as rigid body, wherein the coefficient of thermal expansion for the material of the outer portion is higher than the coefficient of thermal expansion for the material of the inner portion.

- the higher thermal expansion of the outer portion reduces or prevents the pressure from the outer portion to the inner portion, so that the bending of the inner portion and the griddle plate is reduced or completely avoided.

- the welded joint allows the rigid connection between the central portion and the frame portion of the griddle plate, so that the griddle plate forms the rigid body.

- the thickness of the central portion is bigger than the thickness of the frame portion.

- the frame portion is made of metal.

- the central portion and/or the frame portion are at least partially made of iron.

- the griddle plate is formed as a Teppan Yaki grill.

- the present invention relates to a cooking hob including at least one griddle plate mentioned above.

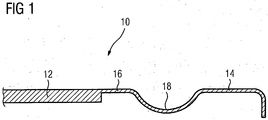

- FIG 1 illustrates a partial sectional side view of a griddle plate 10 for the cooking hob according to a preferred embodiment of the present invention.

- the griddle plate 10 is formed as a metal sheet and includes a central portion 12 and a frame portion 14.

- the partial sectional side view in FIG 1 shows the cross-sections of the complete frame portion 14 and of an outer area of the central portion 12.

- the central portion 12 of the griddle plate 10 is the preferred area provided for barbecue or broiling.

- the frame portion 14 encloses the central portion 12.

- the central portion 12 and the frame portion 14 are connected by a join patch 16.

- the join patch 16 allows a rigid connection between the central portion 12 and the frame portion 14 of the griddle plate 10.

- the griddle plate 10 forms a rigid body.

- the join patch 16 is realized by a welded joint.

- the central portion 12 and the frame portion 14 of the griddle plate 10 are made of metal. However, the materials of the central portion 12 and the frame portion 14 have different coefficients of thermal expansion.

- the coefficient of thermal expansion for the material of the frame portion 14 is higher than the coefficient of thermal expansion for the material of the central portion 12.

- the thermal expansion of the frame portion 14 is higher than the thermal expansion of the central portion 12, if the temperatures of the central portion 12 and the frame portion 14 are substantially the same.

- the higher thermal expansion of the frame portion 14 reduces or prevents the pressure from the frame portion 14 to the central portion 12.

- the bending of the central portion 12 is reduced or avoided.

- the bending of the griddle plate 10 is reduced or completely avoided.

- the frame portion 14 comprises a groove 18.

- Said groove 18 is provided for collecting fat and/or oil.

- the groove 18 is an optional element of the griddle plate 10.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Baking, Grill, Roasting (AREA)

Description

- The present invention relates to a plate, in particular for a cooking hob, according to the preamble of claim 1. Further, the present invention relates to a cooking hob including at least one griddle plate. In particular, the present invention relates to a Teppan Yaki grill.

- The griddle plate is made of a metal plate. The Teppan Yaki grill also includes a metal plate, in particular made of ferritic steel or iron. The barbecue temperatures are very high, so that the thermal expansion of the metal plate causes a bending of said metal plate. The temperatures in the centre of the metal plate are higher than the temperatures in the outer areas of said metal plate. The bending of the metal plate is unre-quested.

-

DE 20 2006 012 631 U1 discloses a griddle plate, in particular a Teppan Yaki grill, which may be a built-in type or a portable tabletop unit. The griddle plate is enclosed by the frame made at least particularly of glass ceramics. The material of the frame has a low thermal conductivity, so that the frame does not reach a too high temperature. -

DE 202 15 979 U1 discloses a cooking plate or griddle plate including several layers. The top layer and the bottom layer are metal sheets. The intermediate sheet is made of aluminium. The griddle plate is subdivided into cooking zones. Between said cooking zones are border zones. In the border zones only the top layer is present, but the intermediate layer and bottom layer lack. -

US 4,045,654 discloses an electric hot plate with a thermostat. A heating plate is joined to the surrounding cold zones by means of a bridge of relative thin metal. An actuating device for a thermostatic switch is operated by the vertical movement of the heating plate. The bridge acts as a hinge for the vertical movement of the heating plate. The heating plate includes a relative thick middle layer and thin layers on the upper and lower sides. The thin layers are made of stainless steel. The upper thin layer forms the bridge between the heating plate and the surrounding cold zones. The middle layer of the heating plate consists of two different materials, wherein a circular plate is surrounded by a ring. The coefficient of linear expansion of the circular plate is bigger than that of the ring. For example, the circular plate is made of copper, while the ring is made of aluminium. -

GB 1 428 555 - It is an object of the present invention to provide a plate for a cooking hob, wherein the bending of the griddle plate by the heat is prevented or reduced by low complexity.

- The object of the present invention is achieved by the plate according to claim 1.

- According to the present invention the plate is a griddle plate, the join patch is a welded joint, and the thickness of the central portion is bigger than the thickness of the frame portion.

- The main idea of the present invention is that the griddle plate for the cooking hob is formed as rigid body, wherein the coefficient of thermal expansion for the material of the outer portion is higher than the coefficient of thermal expansion for the material of the inner portion. The higher thermal expansion of the outer portion reduces or prevents the pressure from the outer portion to the inner portion, so that the bending of the inner portion and the griddle plate is reduced or completely avoided. The welded joint allows the rigid connection between the central portion and the frame portion of the griddle plate, so that the griddle plate forms the rigid body. The thickness of the central portion is bigger than the thickness of the frame portion.

- Preferably, the frame portion is made of metal.

- For example, the central portion and/or the frame portion are at least partially made of iron.

- In particular, the griddle plate is formed as a Teppan Yaki grill.

- At last, the present invention relates to a cooking hob including at least one griddle plate mentioned above.

- Novel and inventive features of the present invention are set forth in the appended claims.

- The present invention will be described in further detail with reference to the drawing, in which

- FIG 1

- illustrates a partial sectional side view of a griddle plate for the cooking hob according to a preferred embodiment of the present invention.

-

FIG 1 illustrates a partial sectional side view of agriddle plate 10 for the cooking hob according to a preferred embodiment of the present invention. Thegriddle plate 10 is formed as a metal sheet and includes acentral portion 12 and aframe portion 14. The partial sectional side view inFIG 1 shows the cross-sections of thecomplete frame portion 14 and of an outer area of thecentral portion 12. - The

central portion 12 of thegriddle plate 10 is the preferred area provided for barbecue or broiling. Theframe portion 14 encloses thecentral portion 12. Thecentral portion 12 and theframe portion 14 are connected by ajoin patch 16. Thejoin patch 16 allows a rigid connection between thecentral portion 12 and theframe portion 14 of thegriddle plate 10. Thus, thegriddle plate 10 forms a rigid body. Preferably, thejoin patch 16 is realized by a welded joint. - The

central portion 12 and theframe portion 14 of thegriddle plate 10 are made of metal. However, the materials of thecentral portion 12 and theframe portion 14 have different coefficients of thermal expansion. The coefficient of thermal expansion for the material of theframe portion 14 is higher than the coefficient of thermal expansion for the material of thecentral portion 12. Thus, the thermal expansion of theframe portion 14 is higher than the thermal expansion of thecentral portion 12, if the temperatures of thecentral portion 12 and theframe portion 14 are substantially the same. The higher thermal expansion of theframe portion 14 reduces or prevents the pressure from theframe portion 14 to thecentral portion 12. Thus, the bending of thecentral portion 12 is reduced or avoided. Further, also the bending of thegriddle plate 10 is reduced or completely avoided. - In this example the

frame portion 14 comprises agroove 18. Saidgroove 18 is provided for collecting fat and/or oil. Thegroove 18 is an optional element of thegriddle plate 10. - Although an illustrative embodiment of the present invention has been described herein with reference to the accompanying drawing, it is to be understood that the present invention is not limited to that precise embodiment, and that various other changes and modifications may be affected therein by one skilled in the art without departing from the scope or spirit of the invention. All such changes and modifications are intended to be included within the scope of the invention as defined by the appended claims.

-

- 10

- griddle plate

- 12

- central portion

- 14

- frame portion

- 16

- join patch

- 18

- groove

Claims (5)

- A plate (10), in particular for a cooking hob, including a central portion (12) and a frame portion (14), wherein- the central portion (12) is formed as a metal plate, and- the frame portion (14) encloses the central portion (12),- the coefficient of thermal expansion for the material of the frame portion (14) is higher than the coefficient of thermal expansion for the material of the central portion (12), and- a join patch (16) connects the central portion (12) and the frame portion (14), so that the central portion (12) and the frame portion (14) form a rigid body,characterized in, that

the plate (10) is a griddle plate (10), the join patch (16) is a welded joint, and the thickness of the central portion (12) is bigger than the thickness of the frame portion (14). - The plate according to claim 1,

characterized in that

the frame portion (14) is made of metal. - The plate according to claim 1 or 2,

characterized in, that

the central portion (12) and/or the frame portion (14) are at least partially made of iron. - The plate according to any one of the preceding claims,

characterized in, that

the griddle plate (10) is formed as a Teppan Yaki grill. - A cooking hob including at least one griddle plate (10),

characterized in, that

the cooking hob includes at least one griddle plate (10) according to any one of the claims 1 to 4.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12151024.2A EP2615378B1 (en) | 2012-01-13 | 2012-01-13 | Griddle plate |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12151024.2A EP2615378B1 (en) | 2012-01-13 | 2012-01-13 | Griddle plate |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2615378A1 EP2615378A1 (en) | 2013-07-17 |

| EP2615378B1 true EP2615378B1 (en) | 2017-03-15 |

Family

ID=45464445

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12151024.2A Active EP2615378B1 (en) | 2012-01-13 | 2012-01-13 | Griddle plate |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2615378B1 (en) |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1428555A (en) * | 1972-05-17 | 1976-03-17 | Mitsubishi Electric Corp | Induction heating apparatus |

| NO135390C (en) * | 1975-09-02 | 1977-03-30 | Rdal Og Sunndal Verk A S | ELECTRIC STOVE WITH THERMOSTAT. |

| FR2723430B1 (en) * | 1994-08-04 | 1997-01-03 | Lorraine Laminage | EXTRA-FLAT BUILT-IN COOKING ELEMENT |

| DE20215979U1 (en) | 2002-10-17 | 2004-03-04 | Eisfink Max Maier Gmbh & Co. Kg | Multi-purpose worktop for a stove or grill |

| DE202006012631U1 (en) | 2006-08-16 | 2006-10-26 | Oranier Heiz- Und Kochtechnik Gmbh | Grill device for roasting and/or cooking of e.g. Teppanyaki, has wider, metallic, heatable hob that is surrounded by frame, where frame is partially made of glass ceramic and/or glass and/or ceramic |

| US8074563B2 (en) * | 2009-01-29 | 2011-12-13 | General Electric Company | Griddle with a heat spreader |

-

2012

- 2012-01-13 EP EP12151024.2A patent/EP2615378B1/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2615378A1 (en) | 2013-07-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8074563B2 (en) | Griddle with a heat spreader | |

| US5221829A (en) | Domestic cooking apparatus | |

| US9220368B2 (en) | Electric cooking apparatus | |

| EP1946685B1 (en) | Grilling plate | |

| US20090206093A1 (en) | Non-stick cooking device | |

| EP2822357B1 (en) | Power saving induction cooking plate, cooking vessel and induction cooking arrangement | |

| KR101110498B1 (en) | Double-heated cooking vessel and its manufacturing method | |

| EP2615378B1 (en) | Griddle plate | |

| JP4302637B2 (en) | Multipurpose cooking work plate for range or grill | |

| US10257890B2 (en) | Induction cookware | |

| JP2008181675A (en) | Induction heating cooking utensil, induction heating cooker, and cooking method | |

| CN102920310B (en) | Electromagnetic heating cookware and three-dimensionally heated electromagnetic cooking appliance | |

| JP5974293B2 (en) | Cooking plate and cooking device equipped with the same | |

| JP5918276B2 (en) | kitchenware | |

| JP2011129529A (en) | Induction heating cooker and cooking method | |

| EP2133012A1 (en) | A cooking device with a hot plate and heating element | |

| KR20140048510A (en) | Cooking pot for induction range and manufacture method thereof | |

| CN110351916A (en) | Induction heating and culinary art | |

| CN202919891U (en) | Three-dimensional electromagnetic heating purpose pot and electromagnetic heating appliance | |

| US20230008372A1 (en) | Cooking Device Comprising A Multi-Layer Diffuser Base | |

| CN203000513U (en) | Pot for electromagnetic heating and electromagnetic heating electric appliance | |

| WO2024129883A1 (en) | Induction griddles | |

| EP4503854A1 (en) | Electric grill | |

| EP1980135A1 (en) | Flat radiation-heated heating element | |

| CN200996658Y (en) | Circular concave arced top plate with heat-resisting function for electromagnetic stove |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20131111 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602012029743 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: F24C0015100000 Ipc: A47J0036040000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A47J 37/06 20060101ALI20160509BHEP Ipc: A47J 36/04 20060101ALI20160509BHEP Ipc: F24C 15/16 20060101AFI20160509BHEP Ipc: F24C 15/10 20060101ALI20160509BHEP |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F24C 15/10 20060101ALI20160526BHEP Ipc: A47J 36/04 20060101AFI20160526BHEP Ipc: A47J 37/06 20060101ALI20160526BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160712 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTC | Intention to grant announced (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20161011 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 874695 Country of ref document: AT Kind code of ref document: T Effective date: 20170415 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012029743 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170315 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170616 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170615 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 874695 Country of ref document: AT Kind code of ref document: T Effective date: 20170315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170615 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170717 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170715 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012029743 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| 26N | No opposition filed |

Effective date: 20171218 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180113 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180113 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20190124 Year of fee payment: 8 Ref country code: GB Payment date: 20190121 Year of fee payment: 8 Ref country code: FR Payment date: 20190124 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170315 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170315 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200113 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200113 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230625 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240129 Year of fee payment: 13 |