CN109492602B - Process timing method and system based on human body language - Google Patents

Process timing method and system based on human body language Download PDFInfo

- Publication number

- CN109492602B CN109492602B CN201811393385.7A CN201811393385A CN109492602B CN 109492602 B CN109492602 B CN 109492602B CN 201811393385 A CN201811393385 A CN 201811393385A CN 109492602 B CN109492602 B CN 109492602B

- Authority

- CN

- China

- Prior art keywords

- worker

- body language

- production process

- video data

- time

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims abstract description 291

- 238000004519 manufacturing process Methods 0.000 claims abstract description 146

- 230000005856 abnormality Effects 0.000 claims description 33

- 230000000737 periodic effect Effects 0.000 claims description 22

- 238000010586 diagram Methods 0.000 claims description 20

- 238000004458 analytical method Methods 0.000 claims description 9

- 230000009466 transformation Effects 0.000 claims description 8

- 238000009958 sewing Methods 0.000 description 14

- 238000005516 engineering process Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 210000000707 wrist Anatomy 0.000 description 4

- 230000002159 abnormal effect Effects 0.000 description 3

- 230000008878 coupling Effects 0.000 description 3

- 238000010168 coupling process Methods 0.000 description 3

- 238000005859 coupling reaction Methods 0.000 description 3

- 238000004891 communication Methods 0.000 description 2

- 238000013527 convolutional neural network Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000001568 sexual effect Effects 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 210000003857 wrist joint Anatomy 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06V—IMAGE OR VIDEO RECOGNITION OR UNDERSTANDING

- G06V40/00—Recognition of biometric, human-related or animal-related patterns in image or video data

- G06V40/20—Movements or behaviour, e.g. gesture recognition

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06V—IMAGE OR VIDEO RECOGNITION OR UNDERSTANDING

- G06V20/00—Scenes; Scene-specific elements

- G06V20/40—Scenes; Scene-specific elements in video content

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07C—TIME OR ATTENDANCE REGISTERS; REGISTERING OR INDICATING THE WORKING OF MACHINES; GENERATING RANDOM NUMBERS; VOTING OR LOTTERY APPARATUS; ARRANGEMENTS, SYSTEMS OR APPARATUS FOR CHECKING NOT PROVIDED FOR ELSEWHERE

- G07C1/00—Registering, indicating or recording the time of events or elapsed time, e.g. time-recorders for work people

- G07C1/10—Registering, indicating or recording the time of events or elapsed time, e.g. time-recorders for work people together with the recording, indicating or registering of other data, e.g. of signs of identity

-

- G—PHYSICS

- G06—COMPUTING; CALCULATING OR COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2218/00—Aspects of pattern recognition specially adapted for signal processing

- G06F2218/08—Feature extraction

- G06F2218/10—Feature extraction by analysing the shape of a waveform, e.g. extracting parameters relating to peaks

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Multimedia (AREA)

- Theoretical Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Computer Vision & Pattern Recognition (AREA)

- General Health & Medical Sciences (AREA)

- Psychiatry (AREA)

- Social Psychology (AREA)

- Human Computer Interaction (AREA)

- General Factory Administration (AREA)

Abstract

本发明公开了一种基于人体肢体语言的工序计时方法及系统。其中,所述方法包括:获取一个工人生产过程中的视频数据,进而从该视频数据中识别出该工人生产过程中的肢体语言信息,进而根据该视频数据和该肢体语言信息,建立基于该视频数据的视频帧与该肢体语言信息的二维坐标图,进而对该二维坐标图进行图像去噪,进而对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值,进而根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。通过上述方式,能够实现无需人工参与可以自动对工人生产过程中的工序进行计时,使得工序计时更加客观和准确。

The invention discloses a process timing method and system based on human body language. Wherein, the method includes: acquiring video data of a worker in the production process, and then identifying the body language information of the worker in the production process from the video data, and then according to the video data and the body language information. The video frame of the data and the two-dimensional coordinate map of the body language information, and then perform image denoising on the two-dimensional coordinate map, and then label the coordinate data representing the body language information in the two-dimensional coordinate map after image denoising. , mark the peak value, and then according to the marked peak value, take two peak intervals as a process cycle, count the process time in the production process of the worker, and obtain the process timing in the production process of the worker. Through the above method, it is possible to automatically time the processes in the production process of workers without manual participation, so that the process timing is more objective and accurate.

Description

技术领域technical field

本发明涉及工序计时技术领域,尤其涉及一种基于人体肢体语言的工序计时方法及系统。The invention relates to the technical field of process timing, in particular to a process timing method and system based on human body language.

背景技术Background technique

随着计算机科学技术的发展,缝制品工业可以利用现代计算机科学技术,将缝制行业的一般车缝时间的应用信息化,使企业方拥有一个智能,友好,便捷的工作环境。通过计算机系统软件可以建立强大的静态资料库,资料库具有图文并茂,检索方便的特点,可以使普通管理人员轻松完成资料的选择、复制等其他操作,最终达到快速实现款式的方法分析及时间分析的目的。计算机系统软件能将分析出来的结果通过图形,表格等方式描述出来,且能通过计算机进行工艺平衡,人员分配,机器分配,生产排位,产能分析等数据运算,为车缝行业管理提供巨大的支持。With the development of computer science and technology, the sewing products industry can use modern computer science and technology to informatize the application of general sewing time in the sewing industry, so that enterprises have a smart, friendly and convenient working environment. Through the computer system software, a powerful static database can be established. The database has the characteristics of both pictures and texts and easy retrieval. It can enable ordinary managers to easily complete the selection, copying and other operations of data, and finally achieve the method analysis and time analysis of the style quickly. Purpose. The computer system software can describe the results of the analysis through graphics, tables, etc., and can perform data operations such as process balance, personnel allocation, machine allocation, production ranking, capacity analysis, etc. through the computer, providing huge management for the sewing industry. support.

在目前的缝制品工业中,所使用的计算机管理系统还只是基于传统的计算机软件技术。使用范围和可靠性都很有限,尤其是对车缝每道工序计时,目前主要的方法采用工人刷卡的方法,在工序开始和结束时分别刷卡进而进行身份的验证和时序的计数。这些操作需要大量人工参与操作,容易造成人员的浪费,同时因人工参与因素易导致计时结果不够客观和不够准确。In the current sewing industry, the computer management system used is only based on traditional computer software technology. The scope of use and reliability are very limited, especially for timing each process of sewing. At present, the main method is to use the method of workers swiping cards, and swiping cards at the beginning and end of the process to verify the identity and count the sequence. These operations require a large number of manual operations, which is easy to cause waste of personnel, and at the same time, the timing results are not objective and accurate due to the factors of manual participation.

发明内容SUMMARY OF THE INVENTION

有鉴于此,本发明的目的在于提出一种基于人体肢体语言的工序计时方法及系统,能够实现无需人工参与可以自动对工人生产过程中的工序进行计时,避免了工序计时中的人工参与因素,使得工序计时更加客观和准确。In view of this, the purpose of the present invention is to propose a process timing method and system based on human body language, which can realize the automatic timing of the processes in the production process of workers without manual participation, and avoid the manual participation factor in the process timing, Make the process timing more objective and accurate.

根据本发明的一个方面,提供一种基于人体肢体语言的工序计时方法,包括:According to one aspect of the present invention, there is provided a process timing method based on human body language, comprising:

获取一个工人生产过程中的视频数据;Get the video data of a worker's production process;

根据所述获取的视频数据,从所述视频数据中识别出所述工人生产过程中的肢体语言信息;According to the acquired video data, identify the body language information of the worker in the production process from the video data;

根据所述获取的视频数据和所述识别出的肢体语言信息,建立基于所述视频数据的视频帧与所述识别出的肢体语言信息的二维坐标图;According to the acquired video data and the identified body language information, establish a two-dimensional coordinate diagram based on the video frame of the video data and the identified body language information;

对所述建立的二维坐标图进行图像去噪;performing image denoising on the established two-dimensional coordinate map;

对所述经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值;其中,所述峰值包括最大峰值和最小峰值;Marking the coordinate data representing body language information in the two-dimensional coordinate graph after image denoising, and marking the peak value; wherein, the peak value includes a maximum peak value and a minimum peak value;

根据所述标注出的峰值,取两个峰值区间为一个工序周期,对所述工人生产过程中的工序时间进行统计,得到所述工人生产过程中的工序计时。According to the marked peaks, two peak intervals are taken as a process cycle, and the process time in the production process of the worker is counted to obtain the process timing in the production process of the worker.

其中,所述获取一个工人生产过程中的视频数据,包括:Wherein, the described acquisition of video data in a worker's production process includes:

采用摄像方式,获取一个工人生产过程中的视频数据。The video data of a worker's production process is obtained by means of camera.

其中,所述根据所述获取的视频数据,从所述视频数据中识别出所述工人生产过程中的肢体语言信息,包括:Wherein, identifying the body language information of the worker in the production process from the video data according to the acquired video data includes:

据所述获取的视频数据,采用肢体语言识别方式,从所述视频数据中识别出所述工人生产过程中的肢体语言信息。According to the acquired video data, the body language information in the production process of the worker is identified from the video data by adopting a body language recognition method.

其中,所述根据所述标注出的峰值,取两个峰值区间为一个工序周期,对所述工人生产过程中的工序时间进行统计,得到所述工人生产过程中的工序计时,包括:Wherein, according to the marked peaks, two peak intervals are taken as a process cycle, and the process time in the production process of the worker is counted to obtain the process timing in the production process of the worker, including:

根据所述标注出的峰值包括最大峰值最小峰值,取相邻两个峰值区间作为一个工序周期,对所述标注出的峰值区间进行坐标转换,将所述峰值区间转换为同一计时标准的时间数据,得到所述相邻最大峰值区间或相邻最小峰值区间分别对应的时间数据,根据所述得到的最大峰值区间和最小峰值区间分别对应的时间数据,对所述工人生产过程中的工序时间进行统计,得到所述工人生产过程中的工序计时。According to the marked peak including the maximum peak and minimum peak, take two adjacent peak intervals as a process cycle, perform coordinate transformation on the marked peak interval, and convert the peak interval into time data of the same timing standard , obtain the time data corresponding to the adjacent maximum peak interval or the adjacent minimum peak interval, respectively, according to the obtained time data corresponding to the maximum peak interval and the minimum peak interval, respectively, perform the process time in the production process of the worker. According to statistics, the process timing in the production process of the worker is obtained.

其中,在所述根据所述标注出的峰值,取两个峰值区间为一个工序周期,对所述工人生产过程中的工序时间进行统计,得到所述工人生产过程中的工序计时之后,还包括:Wherein, according to the marked peaks, two peak intervals are taken as a process cycle, the process time in the production process of the worker is counted, and after the process timing in the production process of the worker is obtained, the process further includes: :

根据所述得到的所述工人生产过程中的工序计时,对所述得到的所述工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较所述统计出的所述各个相同周期性工序的工序时间,比较出工序时间异常情况,根据所述工序时间异常情况,自动对工人进行工序时间异常的提示。According to the obtained process timing in the production process of the worker, make statistics on the same periodic process time in the obtained process timing in the production process of the worker, and compare the respective identical cycles obtained by the statistics. The process time of the sexual process is compared, and the abnormality of the process time is compared, and according to the abnormality of the process time, the worker is automatically prompted for the abnormality of the process time.

根据本发明的一个方面,提供一种基于人体肢体语言的工序计时系统,包括:According to one aspect of the present invention, a process timing system based on human body language is provided, comprising:

视频获取单元、肢体语言识别单元、坐标建立单元、图像去噪单元、取峰值单元和时间统计单元;Video acquisition unit, body language recognition unit, coordinate establishment unit, image denoising unit, peak value unit and time statistics unit;

所述视频获取单元,用于获取一个工人生产过程中的视频数据;The video acquisition unit is used to acquire video data in a worker's production process;

所述肢体语言识别单元,用于根据所述获取的视频数据,从所述视频数据中识别出所述工人生产过程中的肢体语言信息;The body language recognition unit is used for identifying the body language information in the production process of the worker from the video data according to the acquired video data;

所述坐标建立单元,用于根据所述获取的视频数据和所述识别出的肢体语言信息,建立基于所述视频数据的视频帧与所述识别出的肢体语言信息的二维坐标图;The coordinate establishment unit is used to establish a two-dimensional coordinate diagram based on the video frame of the video data and the identified body language information according to the obtained video data and the identified body language information;

所述图像去噪单元,用于对所述建立的二维坐标图进行图像去噪;the image denoising unit, configured to perform image denoising on the established two-dimensional coordinate map;

所述取峰值单元,用于对所述经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值;其中,所述峰值包括最大峰值和最小峰值;The peak taking unit is used to mark the coordinate data representing body language information in the two-dimensional coordinate graph after image denoising, and mark the peak value; wherein, the peak value includes a maximum peak value and a minimum peak value;

所述时间统计单元,用于根据所述标注出的峰值,取两个峰值区间为一个工序周期,对所述工人生产过程中的工序时间进行统计,得到所述工人生产过程中的工序计时。The time statistics unit is configured to, according to the marked peaks, take two peak intervals as a process cycle, perform statistics on the process time in the worker's production process, and obtain the process timing in the worker's production process.

其中,所述视频获取单元,具体用于:Wherein, the video acquisition unit is specifically used for:

采用摄像方式,获取一个工人生产过程中的视频数据。The video data of a worker's production process is obtained by means of camera.

其中,所述肢体语言识别单元,具体用于:Wherein, the body language recognition unit is specifically used for:

据所述获取的视频数据,采用肢体语言识别方式,从所述视频数据中识别出所述工人生产过程中的肢体语言信息。According to the acquired video data, the body language information in the production process of the worker is identified from the video data by adopting a body language recognition method.

其中,所述时间统计单元,具体用于:Wherein, the time statistics unit is specifically used for:

根据所述标注出的峰值包括最大峰值最小峰值,取相邻两个峰值区间作为一个工序周期,对所述标注出的峰值区间进行坐标转换,将所述峰值区间转换为同一计时标准的时间数据,得到所述相邻最大峰值区间或相邻最小峰值区间分别对应的时间数据,根据所述得到的最大峰值区间和最小峰值区间分别对应的时间数据,对所述工人生产过程中的工序时间进行统计,得到所述工人生产过程中的工序计时。According to the marked peak including the maximum peak and minimum peak, take two adjacent peak intervals as a process cycle, perform coordinate transformation on the marked peak interval, and convert the peak interval into time data of the same timing standard , obtain the time data corresponding to the adjacent maximum peak interval or the adjacent minimum peak interval, respectively, according to the obtained time data corresponding to the maximum peak interval and the minimum peak interval, respectively, perform the process time in the production process of the worker. According to statistics, the process timing in the production process of the worker is obtained.

其中,所述基于人体肢体语言的工序计时系统,还包括:Wherein, the process timing system based on human body language also includes:

工序计时分析单元,用于根据所述得到的所述工人生产过程中的工序计时,对所述得到的所述工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较所述统计出的所述各个相同周期性工序的工序时间,比较出工序时间异常情况,根据所述工序时间异常情况,自动对工人进行工序时间异常的提示。A process timing analysis unit, configured to perform statistics on the same periodic process time in the obtained process timing in the worker's production process according to the obtained process timing in the worker's production process, and compare the statistics The process time of each of the same periodic processes is obtained, and the abnormality of the process time is compared, and according to the abnormality of the process time, the worker is automatically prompted for the abnormality of the process time.

可以发现,以上方案,可以获取一个工人生产过程中的视频数据,进而根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息,进而根据该获取的视频数据和该识别出的肢体语言信息,建立基于该视频数据的视频帧与该识别出的肢体语言信息的二维坐标图,进而对该建立的二维坐标图进行图像去噪,进而对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值,进而根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时,能够实现无需人工参与可以自动对工人生产过程中的工序进行计时,避免了工序计时中的人工参与因素,使得工序计时更加客观和准确。It can be found that the above scheme can obtain the video data of a worker in the production process, and then according to the obtained video data, identify the body language information of the worker in the production process from the video data, and then according to the obtained video data and The identified body language information, establishes a two-dimensional coordinate map based on the video frame of the video data and the identified body language information, and then performs image denoising on the established two-dimensional coordinate map, and then denoises the processed image. The coordinate data representing body language information in the two-dimensional coordinate graph after noise is marked, and the peak value is marked, and then according to the marked peak value, two peak intervals are taken as a process cycle, and the process time in the production process of the worker is carried out. According to statistics, the process timing in the production process of the worker can be obtained, which can realize the automatic timing of the process in the production process of the worker without manual participation, avoid the manual participation factor in the process timing, and make the process timing more objective and accurate.

进一步的,以上方案,可以根据该得到的该工人生产过程中的工序计时,对该得到的该工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较该统计出的该各个相同周期性工序的工序时间,比较出工序时间异常情况,根据该工序时间异常情况,自动对工人进行工序时间异常的提示,能够实现在生产过程中能及时对工作效率异常的工人进行提示,提高生产过程中的工作效率。Further, the above scheme, according to the obtained process timing in the production process of the worker, the same periodic process time in the obtained process timing in the production process of the worker can be counted, and the statistics obtained are compared. The process time of the periodic process is compared, and the abnormality of the process time is compared. According to the abnormality of the process time, the workers are automatically prompted for the abnormality of the process time, which can prompt the workers with abnormal work efficiency in time during the production process and improve production. efficiency in the process.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without creative efforts.

图1是本发明基于人体肢体语言的工序计时方法一实施例的流程示意图;1 is a schematic flowchart of an embodiment of a process timing method based on human body language of the present invention;

图2是本发明基于人体肢体语言的工序计时方法一实施例中建立基于一个工人生产过程中的视频数据的视频帧与识别出的基于一个工人生产过程中的肢体语言信息的二维坐标图的一举例示意图;Fig. 2 is a process timing method based on human body language of the present invention to establish a two-dimensional coordinate diagram based on a video frame of video data in a worker's production process and a recognized two-dimensional coordinate diagram based on body language information in a worker's production process an example schematic diagram;

图3是本发明基于人体肢体语言的工序计时方法一实施例中经图像去噪后的一个工人生产过程中的视频数据的视频帧与识别出的基于一个工人生产过程中的肢体语言信息的二维坐标的二维波形图的一举例示意图;Fig. 3 is the video frame of the video data of a worker's production process after image denoising in an embodiment of the process timing method based on human body language of the present invention and the identified two images based on the body language information of a worker's production process. A schematic diagram of an example of a two-dimensional waveform diagram of dimensional coordinates;

图4是本发明基于人体肢体语言的工序计时方法另一实施例的流程示意图;4 is a schematic flowchart of another embodiment of a process timing method based on human body language of the present invention;

图5是本发明基于人体肢体语言的工序计时系统一实施例的结构示意图;5 is a schematic structural diagram of an embodiment of a process timing system based on human body language of the present invention;

图6是本发明基于人体肢体语言的工序计时系统另一实施例的结构示意图;6 is a schematic structural diagram of another embodiment of the process timing system based on human body language of the present invention;

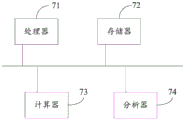

图7是本发明基于人体肢体语言的工序计时系统又一实施例的结构示意图。7 is a schematic structural diagram of another embodiment of the process timing system based on human body language of the present invention.

具体实施方式Detailed ways

下面结合附图和实施例,对本发明作进一步的详细描述。特别指出的是,以下实施例仅用于说明本发明,但不对本发明的范围进行限定。同样的,以下实施例仅为本发明的部分实施例而非全部实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其它实施例,都属于本发明保护的范围。The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It is particularly pointed out that the following examples are only used to illustrate the present invention, but do not limit the scope of the present invention. Likewise, the following embodiments are only some rather than all embodiments of the present invention, and all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

本发明提供一种基于人体肢体语言的工序计时方法,能够实现无需人工参与可以自动对工人生产过程中的工序进行计时,避免了工序计时中的人工参与因素,使得工序计时更加客观和准确。The invention provides a process timing method based on human body language, which can automatically time the processes in the production process of workers without manual participation, avoids the manual participation factor in the process timing, and makes the process timing more objective and accurate.

请参见图1,图1是本发明基于人体肢体语言的工序计时方法一实施例的流程示意图。需注意的是,若有实质上相同的结果,本发明的方法并不以图1所示的流程顺序为限。如图1所示,该方法包括如下步骤:Please refer to FIG. 1 . FIG. 1 is a schematic flowchart of an embodiment of a process timing method based on human body language of the present invention. It should be noted that, if there is substantially the same result, the method of the present invention is not limited to the sequence of the processes shown in FIG. 1 . As shown in Figure 1, the method includes the following steps:

S101:获取一个工人生产过程中的视频数据。S101: Acquire video data of a worker in the production process.

其中,该获取一个工人生产过程中的视频数据,可以包括:Among them, the video data of a worker's production process should be obtained, which may include:

采用摄像方式,获取一个工人生产过程中的视频数据。The video data of a worker's production process is obtained by means of camera.

S102:根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息。S102: According to the acquired video data, identify the body language information of the worker in the production process from the video data.

其中,该根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息,可以包括:Wherein, identifying the body language information of the worker in the production process from the video data according to the acquired video data may include:

据该获取的视频数据,采用OpenPose(肢体语言识别)方式,从该视频数据中识别出该工人生产过程中的肢体语言信息。According to the acquired video data, the OpenPose (body language recognition) method is used to identify the body language information of the worker in the production process from the video data.

S103:根据该获取的视频数据和该识别出的肢体语言信息,建立基于该视频数据的视频帧与该识别出的肢体语言信息的二维坐标图。S103: According to the acquired video data and the identified body language information, establish a two-dimensional coordinate map of the video frame based on the video data and the identified body language information.

请参见图2,图2是本发明基于人体肢体语言的工序计时方法一实施例中建立基于一个工人生产过程中的视频数据的视频帧与识别出的基于一个工人生产过程中的肢体语言信息的二维坐标图的一举例示意图。如图2所示,是以车缝工序为例,在现实操作中,大部分车缝工序要经过工人取料、车缝、放料等一系列操作,且容易发现正常工序时,工人总是用左手来取料,然后在缝纫机下进行车缝,车缝完毕之后再将成品放到完品区。Please refer to Fig. 2, Fig. 2 is a process timing method based on human body language in an embodiment of the present invention to establish a video frame based on video data in a worker's production process and the identified image based on body language information in a worker's production process. An example schematic diagram of a two-dimensional coordinate graph. As shown in Figure 2, taking the sewing process as an example, in actual operation, most of the sewing processes have to go through a series of operations such as worker picking, sewing, and unwinding, and it is easy to find that in normal processes, workers always Use the left hand to pick up the material, and then sew it under the sewing machine. After the sewing is completed, the finished product is placed in the finished product area.

如图2所示,当工人用左手拿料时,在视频帧的画面中,工人此刻的左手手腕X方向距离原点最远,所以在视频帧中该工人左手手腕X方向上坐标为最大值,绘制出如图2所示的频帧X方向值与视频帧帧数的二维图。如图2所示,X轴表示频帧的帧数,Y轴表示工人左手手腕在视频帧X方向的坐标,则则X方向上的最大值对应的是其峰值点,即峰值点表示工人在取料的时刻。后续根据生产过程中的特点和该二维图,自动对一个工人生产过程中的工序进行计时。As shown in Figure 2, when the worker takes the material with his left hand, in the picture of the video frame, the X direction of the worker's left wrist is the farthest from the origin, so in the video frame, the coordinate of the worker's left wrist in the X direction is the maximum value, Draw a two-dimensional diagram of the X-direction value of the frequency frame and the number of video frames as shown in Figure 2. As shown in Figure 2, the X axis represents the number of frames of the frequency frame, and the Y axis represents the coordinates of the worker's left wrist in the X direction of the video frame, then the maximum value in the X direction corresponds to its peak point, that is, the peak point indicates that the worker is in the video frame. The time to take the material. Subsequently, according to the characteristics of the production process and the two-dimensional map, the process in the production process of a worker is automatically timed.

S104:对该建立的二维坐标图进行图像去噪。S104: Perform image denoising on the established two-dimensional coordinate map.

S105:对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值;其中,该峰值包括最大峰值和最小峰值。S105: Mark the coordinate data representing body language information in the two-dimensional coordinate graph after denoising the image, and mark a peak value; wherein, the peak value includes a maximum peak value and a minimum peak value.

请参见图3,图3是本发明基于人体肢体语言的工序计时方法一实施例中经图像去噪后的一个工人生产过程中的视频数据的视频帧与识别出的基于一个工人生产过程中的肢体语言信息的二维坐标的二维波形图的一举例示意图。如图3所示,是以车缝工序为例,由上往下的第一段曲线表示一个工人在生产过程中的肢体语言例如人体手腕关节点X坐标和该工人在生产过程中的视频数据的帧数的二维波形图,由上往下的第二段曲线表示该工人在生产过程中的肢体语言例如人体手腕关节点Y坐标和该工人在生产过程中的视频数据的帧数的二维波形图,圆点标注出峰值,可以表示该工人左手取料的时刻。该采用圆点形式标注的峰值点下有两条散点连线图,是可以通过GoogleNet(卷积神经网络)构建的一个二分类分类器,对当前工作台是否为空进行分类,当工作台非空则为高阈值,此时可取工序阈值取值为600的散点图,反之,为下面低阈值,此时可取工序阈值取值为580的散点图。如图3所示,显然可以看到当峰值点处,高阈值例如上述阈值为600的散点有较大间断,表示此刻工作台有一段时间为空。Please refer to FIG. 3, FIG. 3 is a video frame of video data in a worker's production process after image denoising in an embodiment of the process timing method based on human body language of the present invention and the identified video frame based on a worker's production process An example schematic diagram of a two-dimensional waveform of two-dimensional coordinates of body language information. As shown in Figure 3, taking the sewing process as an example, the first curve from top to bottom represents the body language of a worker during the production process, such as the X coordinate of the human wrist joint point and the video data of the worker during the production process The two-dimensional waveform diagram of the number of frames, the second curve from top to bottom represents the body language of the worker during the production process, such as the Y coordinate of the joint point of the human wrist and the second of the frame number of the video data of the worker during the production process. Dimensional waveform diagram, the dots mark the peak value, which can indicate the moment when the worker takes material with his left hand. The peak point marked in the form of dots has two scatter-point connection graphs. It is a binary classifier that can be constructed by GoogleNet (convolutional neural network) to classify whether the current workbench is empty. When the workbench If it is not empty, it is a high threshold. At this time, a scatter plot with a process threshold value of 600 can be selected. On the contrary, it is a low threshold value below. At this time, a scatter plot with a process threshold value of 580 can be selected. As shown in Figure 3, it can be clearly seen that at the peak point, the scatter points with a high threshold value, such as the above threshold value of 600, have large discontinuities, indicating that the workbench is empty for a period of time at this moment.

S106:根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。S106: According to the marked peak value, two peak intervals are taken as a process cycle, and the process time in the production process of the worker is counted to obtain the process timing in the production process of the worker.

其中,该根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时,可以包括:Wherein, according to the marked peak value, two peak intervals are taken as a process cycle, the process time in the production process of the worker is counted, and the process timing in the production process of the worker is obtained, which may include:

根据该标注出的峰值包括最大峰值最小峰值,取相邻两个峰值区间作为一个工序周期,对该标注出的峰值区间进行坐标转换,将该峰值区间转换为同一计时标准的时间数据,得到该相邻最大峰值区间或相邻最小峰值区间分别对应的时间数据,根据该得到的最大峰值区间和最小峰值区间分别对应的时间数据,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。According to the marked peak including the maximum peak and the minimum peak, take two adjacent peak intervals as a process cycle, perform coordinate transformation on the marked peak interval, and convert the peak interval into the time data of the same timing standard to obtain the The time data corresponding to the adjacent maximum peak interval or the adjacent minimum peak interval respectively, according to the obtained time data corresponding to the maximum peak interval and the minimum peak interval respectively, the process time in the production process of the worker is counted, and the production of the worker is obtained. The timing of the steps in the process.

其中,在该根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时之后,还可以包括:Wherein, according to the marked peak value, two peak intervals are taken as a process cycle, the process time in the production process of the worker is counted, and after the process timing in the production process of the worker is obtained, it can also include:

根据该得到的该工人生产过程中的工序计时,对该得到的该工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较该统计出的该各个相同周期性工序的工序时间,比较出工序时间异常情况,根据该工序时间异常情况,自动对工人进行工序时间异常的提示。According to the obtained process timing in the production process of the worker, make statistics on the same periodic process time in the obtained process timing in the production process of the worker, and compare the calculated process time of each of the same periodic processes, The abnormality of the process time is compared, and according to the abnormality of the process time, the worker is automatically prompted for the abnormality of the process time.

在本实施例中,该基于人体肢体语言的工序计时方法可以应用于缝制品行业中,可以利用视觉摄像方式来对生产过程中的工序进行工序计时,可以避免工序计时中的人工因素。In this embodiment, the process timing method based on human body language can be applied to the sewing product industry, and the visual camera method can be used to time the process in the production process, which can avoid artificial factors in the process timing.

在本实施例中,该基于人体肢体语言的工序计时方法可以利用计算机视觉技术,特别是人体姿态估计技术,对生产过程中的工人的工作时间即工序时间进行分析,自动提取生产每件产品的时间周期,为后续的管理和工作效率分析等提供核心的数据。In this embodiment, the process timing method based on human body language can use computer vision technology, especially human body posture estimation technology, to analyze the working time of the workers in the production process, that is, the process time, and automatically extract the production time of each product. The time period provides core data for subsequent management and work efficiency analysis.

在本实施例中,该基于人体肢体语言的工序计时方法无需人工手拿秒表进行计时或工人自己计时,可以通过例如摄像的方式进行视频拍摄,可以自动分析该视频内容得出工序时间结果,能够实现主动无人工因素的工序计时过程,可以填补市场上例如基于视觉的缝制品工序计时系统的空白。In this embodiment, the process timing method based on human body language does not require manual timekeeping with a stopwatch or workers themselves, and video recording can be performed by, for example, videography, and the content of the video can be automatically analyzed to obtain process time results. Achieving an active process timing process without artificial factors can fill the gap in the market such as vision-based sewing process timing systems.

可以发现,以上方案,可以获取一个工人生产过程中的视频数据,进而根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息,进而根据该获取的视频数据和该识别出的肢体语言信息,建立基于该视频数据的视频帧与该识别出的肢体语言信息的二维坐标图,进而对该建立的二维坐标图进行图像去噪,进而对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值,进而根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时,能够实现无需人工参与可以自动对工人生产过程中的工序进行计时,避免了工序计时中的人工参与因素,使得工序计时更加客观和准确。It can be found that the above scheme can obtain the video data of a worker in the production process, and then according to the obtained video data, identify the body language information of the worker in the production process from the video data, and then according to the obtained video data and The identified body language information, establishes a two-dimensional coordinate map based on the video frame of the video data and the identified body language information, and then performs image denoising on the established two-dimensional coordinate map, and then denoises the processed image. The coordinate data representing body language information in the two-dimensional coordinate graph after noise is marked, and the peak value is marked, and then according to the marked peak value, two peak intervals are taken as a process cycle, and the process time in the production process of the worker is carried out. According to statistics, the process timing in the production process of the worker can be obtained, which can realize the automatic timing of the process in the production process of the worker without manual participation, avoid the manual participation factor in the process timing, and make the process timing more objective and accurate.

请参见图4,图4是本发明基于人体肢体语言的工序计时方法另一实施例的流程示意图。本实施例中,该方法包括以下步骤:Please refer to FIG. 4 . FIG. 4 is a schematic flowchart of another embodiment of the process timing method based on human body language of the present invention. In this embodiment, the method includes the following steps:

S401:获取一个工人生产过程中的视频数据。S401: Acquire video data of a worker in the production process.

可如上S101所述,在此不作赘述。It can be described in S101 above, and details are not repeated here.

S402:根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息。S402: Identify the body language information of the worker in the production process from the video data according to the acquired video data.

可如上S102所述,在此不作赘述。It can be described in the above S102, which is not repeated here.

S403:根据该获取的视频数据和该识别出的肢体语言信息,建立基于该视频数据的视频帧与该识别出的肢体语言信息的二维坐标图。S403: According to the acquired video data and the identified body language information, establish a two-dimensional coordinate map based on the video frame of the video data and the identified body language information.

可如上S103所述,在此不作赘述。It can be described in the above S103, which is not repeated here.

S404:对该建立的二维坐标图进行图像去噪。S404: Perform image denoising on the established two-dimensional coordinate map.

S405:对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值;其中,该峰值包括最大峰值和最小峰值。S405: Mark the coordinate data representing body language information in the two-dimensional coordinate graph after denoising the image, and mark a peak value; wherein, the peak value includes a maximum peak value and a minimum peak value.

可如上S105所述,在此不作赘述。It can be described in the above S105, which is not repeated here.

S406:根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。S406: According to the marked peak value, two peak intervals are taken as a process cycle, and the process time in the production process of the worker is counted to obtain the process timing in the production process of the worker.

可如上S106所述,在此不作赘述。It can be described in the above S106, which is not repeated here.

S407:根据该得到的该工人生产过程中的工序计时,对该得到的该工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较该统计出的该各个相同周期性工序的工序时间,比较出工序时间异常情况,根据该工序时间异常情况,自动对工人进行工序时间异常的提示。S407: According to the obtained process timing in the production process of the worker, perform statistics on the same periodic process time in the obtained process timing in the production process of the worker, and compare the counted processes of the same periodic process Time, compare the abnormality of the process time, and automatically prompt the worker of the abnormality of the process time according to the abnormality of the process time.

可以发现,在本实施例中,可以根据该得到的该工人生产过程中的工序计时,对该得到的该工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较该统计出的该各个相同周期性工序的工序时间,比较出工序时间异常情况,根据该工序时间异常情况,自动对工人进行工序时间异常的提示,能够实现在生产过程中能及时对工作效率异常的工人进行提示,提高生产过程中的工作效率。It can be found that, in this embodiment, according to the obtained process timing in the production process of the worker, the same periodic process time in the obtained process timing in the production process of the worker can be counted, and the statistics obtained can be compared. The process time of each of the same periodic processes is compared, and the abnormality of the process time is compared. According to the abnormality of the process time, the worker is automatically prompted for the abnormality of the process time, which can realize the prompt of the abnormal work efficiency in the production process. , improve the work efficiency in the production process.

本发明还提供一种基于人体肢体语言的工序计时系统,能够实现无需人工参与可以自动对工人生产过程中的工序进行计时,避免了工序计时中的人工参与因素,使得工序计时更加客观和准确。The invention also provides a process timing system based on human body language, which can automatically time the processes in the production process of workers without manual participation, avoids the manual participation factor in the process timing, and makes the process timing more objective and accurate.

请参见图5,图5是本发明基于人体肢体语言的工序计时系统一实施例的结构示意图。本实施例中,该基于人体肢体语言的工序计时系统50包括视频获取单元51、肢体语言识别单元52、坐标建立单元53、图像去噪单元54、取峰值单元55和时间统计单元56。Please refer to FIG. 5 , which is a schematic structural diagram of an embodiment of a process timing system based on human body language of the present invention. In this embodiment, the

该视频获取单元51,用于获取一个工人生产过程中的视频数据。The

该肢体语言识别单元52,用于根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息。The body

该坐标建立单元53,用于根据该获取的视频数据和该识别出的肢体语言信息,建立基于该视频数据的视频帧与该识别出的肢体语言信息的二维坐标图。The coordinate establishing

该图像去噪单元54,用于对该建立的二维坐标图进行图像去噪。The

该取峰值单元55,用于对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值;其中,该峰值包括最大峰值和最小峰值。The

该时间统计单元56,用于根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。The time

可选地,该视频获取单元51,可以具体用于:Optionally, the

采用摄像方式,获取一个工人生产过程中的视频数据。The video data of a worker's production process is obtained by means of camera.

可选地,该肢体语言识别单元52,可以具体用于:Optionally, the body

据该获取的视频数据,采用肢体语言识别OpenPose方式,从该视频数据中识别出该工人生产过程中的肢体语言信息。According to the obtained video data, the body language information of the worker in the production process is identified from the video data by using the method of body language recognition OpenPose.

可选地,该时间统计单元56,可以具体用于:Optionally, the

根据该标注出的峰值包括最大峰值最小峰值,取相邻两个峰值区间作为一个工序周期,对该标注出的峰值区间进行坐标转换,将该峰值区间转换为同一计时标准的时间数据,得到该相邻最大峰值区间或相邻最小峰值区间分别对应的时间数据,根据该得到的最大峰值区间和最小峰值区间分别对应的时间数据,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。According to the marked peak including the maximum peak and the minimum peak, take two adjacent peak intervals as a process cycle, perform coordinate transformation on the marked peak interval, and convert the peak interval into the time data of the same timing standard to obtain the The time data corresponding to the adjacent maximum peak interval or the adjacent minimum peak interval respectively, according to the obtained time data corresponding to the maximum peak interval and the minimum peak interval respectively, the process time in the production process of the worker is counted, and the production of the worker is obtained. The timing of the steps in the process.

在本实施例中,该视频获取单元51可以是任意可采用摄像方式获取一个工人生产过程中的视频数据的终端,例如摄像机、相机、手机等,本发明不加以限定。In this embodiment, the

请参见图6,图6是本发明基于人体肢体语言的工序计时系统另一实施例的结构示意图。区别于上一实施例,本实施例所述基于人体肢体语言的工序计时系统60还包括:工序计时分析单元61。Please refer to FIG. 6 , which is a schematic structural diagram of another embodiment of the process timing system based on human body language of the present invention. Different from the previous embodiment, the

该工序计时分析单元61,用于根据该得到的该工人生产过程中的工序计时,对该得到的该工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较该统计出的该各个相同周期性工序的工序时间,比较出工序时间异常情况,根据该工序时间异常情况,自动对工人进行工序时间异常的提示。The process

该基于人体肢体语言的工序计时系统50/60的各个单元模块可分别执行上述方法实施例中对应步骤,故在此不对各单元模块进行赘述,详细请参见以上对应步骤的说明。Each unit module of the

请参见图7,图7是本发明基于人体肢体语言的工序计时系统又一实施例的结构示意图。该基于人体肢体语言的工序计时系统的各个单元模块可以分别执行上述方法实施例中对应步骤。相关内容请参见上述方法中的详细说明,在此不再赘叙。Please refer to FIG. 7 , which is a schematic structural diagram of another embodiment of the process timing system based on human body language of the present invention. Each unit module of the process timing system based on human body language can respectively execute the corresponding steps in the above method embodiments. For related content, please refer to the detailed description in the above method, which will not be repeated here.

本实施例中,该基于人体肢体语言的工序计时系统包括:处理器71、与处理器71耦合的存储器72、计算器73及分析器74。In this embodiment, the process timing system based on human body language includes: a

该处理器71,用于获取一个工人生产过程中的视频数据,和根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息,和根据该获取的视频数据和该识别出的肢体语言信息,建立基于该视频数据的视频帧与该识别出的肢体语言信息的二维坐标图,和对该建立的二维坐标图进行图像去噪,以及对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值;其中,该峰值包括最大峰值和最小峰值。The

该存储器72,用于存储操作系统、处理器71执行的指令等。The

该计算器73,用于根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。The

该分析器74,用于根据该得到的该工人生产过程中的工序计时,对该得到的该工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较该统计出的该各个相同周期性工序的工序时间,比较出工序时间异常情况,根据该工序时间异常情况,自动对工人进行工序时间异常的提示。The

可选地,该处理器71,可以具体用于:Optionally, the

采用摄像方式,获取一个工人生产过程中的视频数据。The video data of a worker's production process is obtained by means of camera.

可选地,该处理器71,可以具体用于:Optionally, the

据该获取的视频数据,采用肢体语言识别OpenPose方式,从该视频数据中识别出该工人生产过程中的肢体语言信息。According to the obtained video data, the body language information of the worker in the production process is identified from the video data by using the method of body language recognition OpenPose.

可选地,该计算器73,可以具体用于:Optionally, the

根据该标注出的峰值包括最大峰值最小峰值,取相邻两个峰值区间作为一个工序周期,对该标注出的峰值区间进行坐标转换,将该峰值区间转换为同一计时标准的时间数据,得到该相邻最大峰值区间或相邻最小峰值区间分别对应的时间数据,根据该得到的最大峰值区间和最小峰值区间分别对应的时间数据,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时。According to the marked peak including the maximum peak and the minimum peak, take two adjacent peak intervals as a process cycle, perform coordinate transformation on the marked peak interval, and convert the peak interval into the time data of the same timing standard to obtain the The time data corresponding to the adjacent maximum peak interval or the adjacent minimum peak interval respectively, according to the obtained time data corresponding to the maximum peak interval and the minimum peak interval respectively, the process time in the production process of the worker is counted, and the production of the worker is obtained. The timing of the steps in the process.

可以发现,以上方案,可以获取一个工人生产过程中的视频数据,进而根据该获取的视频数据,从该视频数据中识别出该工人生产过程中的肢体语言信息,进而根据该获取的视频数据和该识别出的肢体语言信息,建立基于该视频数据的视频帧与该识别出的肢体语言信息的二维坐标图,进而对该建立的二维坐标图进行图像去噪,进而对该经图像去噪后的二维坐标图中表示肢体语言信息的坐标数据进行标注,标注出峰值,进而根据该标注出的峰值,取两个峰值区间为一个工序周期,对该工人生产过程中的工序时间进行统计,得到该工人生产过程中的工序计时,能够实现无需人工参与可以自动对工人生产过程中的工序进行计时,避免了工序计时中的人工参与因素,使得工序计时更加客观和准确。It can be found that the above scheme can obtain the video data of a worker in the production process, and then according to the obtained video data, identify the body language information of the worker in the production process from the video data, and then according to the obtained video data and The identified body language information, establishes a two-dimensional coordinate map based on the video frame of the video data and the identified body language information, and then performs image denoising on the established two-dimensional coordinate map, and then denoises the processed image. The coordinate data representing body language information in the two-dimensional coordinate graph after noise is marked, and the peak value is marked, and then according to the marked peak value, two peak intervals are taken as a process cycle, and the process time in the production process of the worker is carried out. According to statistics, the process timing in the production process of the worker can be obtained, which can realize the automatic timing of the process in the production process of the worker without manual participation, avoid the manual participation factor in the process timing, and make the process timing more objective and accurate.

进一步的,以上方案,可以根据该得到的该工人生产过程中的工序计时,对该得到的该工人生产过程中的工序计时中的相同周期性工序时间进行统计,比较该统计出的该各个相同周期性工序的工序时间,比较出工序时间异常情况,根据该工序时间异常情况,自动对工人进行工序时间异常的提示,能够实现在生产过程中能及时对工作效率异常的工人进行提示,提高生产过程中的工作效率。Further, the above scheme, according to the obtained process timing in the production process of the worker, the same periodic process time in the obtained process timing in the production process of the worker can be counted, and the statistics obtained are compared. The process time of the periodic process is compared, and the abnormality of the process time is compared. According to the abnormality of the process time, the workers are automatically prompted for the abnormality of the process time, which can prompt the workers with abnormal work efficiency in time during the production process and improve production. efficiency in the process.

在本发明所提供的几个实施方式中,应该理解到,所揭露的系统,装置和方法,可以通过其它的方式实现。例如,以上所描述的装置实施方式仅仅是示意性的,例如,模块或单元的划分,仅仅为一种逻辑功能划分,实际实现时可以有另外的划分方式,例如多个单元或组件可以结合或者可以集成到另一个系统,或一些特征可以忽略,或不执行。另一点,所显示或讨论的相互之间的耦合或直接耦合或通信连接可以是通过一些接口,装置或单元的间接耦合或通信连接,可以是电性,机械或其它的形式。In the several embodiments provided by the present invention, it should be understood that the disclosed system, apparatus and method may be implemented in other manners. For example, the apparatus implementations described above are only illustrative, for example, the division of modules or units is only a logical function division, and there may be other divisions in actual implementation, for example, multiple units or components may be combined or Can be integrated into another system, or some features can be ignored, or not implemented. On the other hand, the shown or discussed mutual coupling or direct coupling or communication connection may be through some interfaces, indirect coupling or communication connection of devices or units, and may be in electrical, mechanical or other forms.

作为分离部件说明的单元可以是或者也可以不是物理上分开的,作为单元显示的部件可以是或者也可以不是物理单元,即可以位于一个地方,或者也可以分布到多个网络单元上。可以根据实际的需要选择其中的部分或者全部单元来实现本实施方式方案的目的。Units described as separate components may or may not be physically separated, and components shown as units may or may not be physical units, that is, may be located in one place, or may be distributed to multiple network units. Some or all of the units may be selected according to actual needs to achieve the purpose of the solution in this implementation manner.

另外,在本发明各个实施方式中的各功能单元可以集成在一个处理单元中,也可以是各个单元单独物理存在,也可以两个或两个以上单元集成在一个单元中。上述集成的单元既可以采用硬件的形式实现,也可以采用软件功能单元的形式实现。In addition, each functional unit in each embodiment of the present invention may be integrated into one processing unit, or each unit may exist physically alone, or two or more units may be integrated into one unit. The above-mentioned integrated units may be implemented in the form of hardware, or may be implemented in the form of software functional units.

集成的单元如果以软件功能单元的形式实现并作为独立的产品销售或使用时,可以存储在一个计算机可读取存储介质中。基于这样的理解,本发明的技术方案本质上或者说对现有技术做出贡献的部分或者该技术方案的全部或部分可以以软件产品的形式体现出来,该计算机软件产品存储在一个存储介质中,包括若干指令用以使得一台计算机设备(可以是个人计算机,服务器,或者网络设备等)或处理器(processor)执行本发明各个实施方式方法的全部或部分步骤。而前述的存储介质包括:U盘、移动硬盘、只读存储器(ROM,Read-Only Memory)、随机存取存储器(RAM,Random Access Memory)、磁碟或者光盘等各种可以存储程序代码的介质。The integrated unit, if implemented as a software functional unit and sold or used as a stand-alone product, may be stored in a computer-readable storage medium. Based on this understanding, the technical solution of the present invention is essentially or the part that contributes to the prior art, or all or part of the technical solution can be embodied in the form of a software product, and the computer software product is stored in a storage medium , including several instructions to make a computer device (which may be a personal computer, a server, or a network device, etc.) or a processor (processor) to execute all or part of the steps of the methods in the various embodiments of the present invention. The aforementioned storage medium includes: U disk, mobile hard disk, Read-Only Memory (ROM, Read-Only Memory), Random Access Memory (RAM, Random Access Memory), magnetic disk or optical disk and other media that can store program codes .

以上所述仅为本发明的部分实施例,并非因此限制本发明的保护范围,凡是利用本发明说明书及附图内容所作的等效装置或等效流程变换,或直接或间接运用在其他相关的技术领域,均同理包括在本发明的专利保护范围内。The above descriptions are only part of the embodiments of the present invention, and are not intended to limit the protection scope of the present invention. Any equivalent device or equivalent process transformation made by using the contents of the description and drawings of the present invention, or directly or indirectly applied to other related All technical fields are similarly included in the scope of patent protection of the present invention.

Claims (8)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811393385.7A CN109492602B (en) | 2018-11-21 | 2018-11-21 | Process timing method and system based on human body language |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811393385.7A CN109492602B (en) | 2018-11-21 | 2018-11-21 | Process timing method and system based on human body language |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109492602A CN109492602A (en) | 2019-03-19 |

| CN109492602B true CN109492602B (en) | 2020-11-03 |

Family

ID=65697282

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811393385.7A Active CN109492602B (en) | 2018-11-21 | 2018-11-21 | Process timing method and system based on human body language |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN109492602B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111507231B (en) * | 2020-04-10 | 2023-06-23 | 盛景智能科技(嘉兴)有限公司 | Automatic detection method and system for correctness of process steps |

| US11348355B1 (en) | 2020-12-11 | 2022-05-31 | Ford Global Technologies, Llc | Method and system for monitoring manufacturing operations using computer vision for human performed tasks |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8718337B1 (en) * | 2010-06-30 | 2014-05-06 | Imdb.Com, Inc. | Identifying an individual for a role |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105469073A (en) * | 2015-12-16 | 2016-04-06 | 安徽创世科技有限公司 | Kinect-based call making and answering monitoring method of driver |

| CN108062533A (en) * | 2017-12-28 | 2018-05-22 | 北京达佳互联信息技术有限公司 | Analytic method, system and the mobile terminal of user's limb action |

-

2018

- 2018-11-21 CN CN201811393385.7A patent/CN109492602B/en active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8718337B1 (en) * | 2010-06-30 | 2014-05-06 | Imdb.Com, Inc. | Identifying an individual for a role |

Non-Patent Citations (1)

| Title |

|---|

| 采用共享空间稀疏表示的单幅图像超分辨率方法;张建,彭佳林,杜吉祥;《华侨大学学报(自然科学版)》;20180331;第39卷(第2期);第268-273页 * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109492602A (en) | 2019-03-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11386717B2 (en) | Fingerprint inputting method and related device | |

| CN108154105B (en) | Underwater biological detection and identification method and device, server and terminal equipment | |

| CN110610127B (en) | Face recognition method and device, storage medium and electronic equipment | |

| CN110197116B (en) | Human behavior recognition method, device and computer readable storage medium | |

| CN108269333A (en) | Face identification method, application server and computer readable storage medium | |

| CN110472082B (en) | Data processing method, data processing device, storage medium and electronic equipment | |

| CN110866469B (en) | Facial five sense organs identification method, device, equipment and medium | |

| CN109886162A (en) | Fingerprint verification method and related device | |

| CN110533654A (en) | The method for detecting abnormality and device of components | |

| CN109726678B (en) | License plate recognition method and related device | |

| CN113723157B (en) | Crop disease identification method and device, electronic equipment and storage medium | |

| EP4160473A1 (en) | Method and device for capturing information, and method, device, and system for measuring level of attention | |

| CN109492602B (en) | Process timing method and system based on human body language | |

| CN111767912A (en) | Mark point identification method, device, equipment and storage medium | |

| CN105825228A (en) | Image identification method and apparatus | |

| CN115330824A (en) | Box body grabbing method and device and electronic equipment | |

| CN115601811B (en) | Face acne detection method and device | |

| CN109598201B (en) | Action detection method and device, electronic equipment and readable storage medium | |

| EP3200092A1 (en) | Method and terminal for implementing image sequencing | |

| CN102783174B (en) | Image processing equipment, content delivery system, image processing method and program | |

| CN104978583A (en) | Person action recognition method and person action recognition device | |

| CN112348112A (en) | Training method and device for image recognition model and terminal equipment | |

| CN112581444A (en) | Anomaly detection method, device and equipment | |

| CN108334602B (en) | Data annotation method and device, electronic equipment and computer storage medium | |

| CN112418357A (en) | Image classification method based on artificial intelligence |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |