Technical background

Low-carbon alkene is important Organic Chemicals, and China's consumption demand is large, but the degree of self-sufficiency is low.The method of preparing low-carbon olefins is divided by raw material and can be divided into generally 3 large classes at present: petroleum path, natural gas route and coal route.For the present situation of rich coal, oil starvation, weak breath, take coal as the raw material preparing synthetic gas, again by the synthesis gas preparing low-carbon olefins, this provides a desirable approach for be converted into the basic organic chemical industry raw material from non-oil resource.

Present industrial production low-carbon alkene adopts the method for fractional steps to carry out, and namely first produces methyl alcohol by synthesis gas, prepares low-carbon alkene by methanol dehydration again.For the methyl alcohol synthetic reaction, Britain ICI company has researched and developed the catalyst that consists of the copper Zinc-aluminium in 1966, catalyst for methanol obtains large development in recent years, by improving active component in degree of scatter and the specific area of carrier surface, improved reactivity, life-span and the mechanical strength of catalyst; For MTO(Methanol to Olefins, methanol-to-olefins) reaction, the most ripe with the research of ZSM-5 molecular sieve, its aperture is relatively large, and the primary product that obtains is propylene and C4+ hydro carbons.The synthetic SAPO-34 molecular sieve of U.S.'s union carbide corporation had the active high and high characteristics of selectivity of light olefin in 1984, was used widely.Take SAPO-34 as catalyst MTO process, methanol conversion reaches 100%, and ethylene selectivity is higher than 50%, and low-carbon alkene C2~C4 total recovery is higher than 85%, almost without the product more than the C5.

Catalyst with core-casing structure is a kind of novel reaction catalyst that two consecutive reactions better are coupled, its cardinal principle is that product is carried out first step reaction at catalyst nucleus, the process that first step product diffuses out by shell catalyst is carried out the second step reaction, the product of having guaranteed the first step all can be carried out the second step reaction, improved the selective of purpose product, simultaneously so that chemical balance constantly move to the product direction.(J.Am.Chem.Soc., 2010,132 such as Yang, p8129) having prepared cupric oxide zinc oxide aluminium oxide is that nuclear and HZSM-5 are the catalyst with core-casing structure of shell, and use it for by the direct preparation of dimethyl ether by using synthesis gas reaction, dimethyl ether selectively reaches 96%, apparently higher than the catalyst of physical mixed.The present invention proposes to adopt catalyst with core-casing structure that methyl alcohol synthetic reaction and MTO reaction is coupling in the reactor to carry out, by synthesis gas one-step synthesis low-carbon alkene.This one-step method has been simplified technical process, has improved selectivity of product.

Summary of the invention

In order to overcome the deficiencies in the prior art, the purpose of this invention is to provide a kind of catalyst with core-casing structure and by the method for one-step method from syngas preparing low-carbon olefins.

A kind of catalyst with core-casing structure by the one-step method from syngas preparing low-carbon olefins, the nuclear of this catalyst with core-casing structure are methanol synthesis catalyst; The shell of this catalyst with core-casing structure is the MTO catalysts of outer molecular screen membrane structure; The shell thickness is the 1-15 micron.

Described shell film adopts the crystal seed method preparation, and described nuclear adopts the coprecipitation preparation.

Described methanol synthesis catalyst is cupric oxide and zinc oxide, and adds in the following auxiliary agent one or more: zirconia, aluminium oxide, nickel oxide, cobalt oxide, cerium oxide, iron oxide, manganese oxide, silica, magnesia, calcium oxide, titanium oxide, vanadium oxide, chromium oxide, niobium oxide, molybdenum oxide, tin oxide.

Described MTO catalysts is modified ZSM-5 Series Molecules sieve membrane or SAPO Series Molecules sieve membrane.

A kind ofly utilize described catalyst with core-casing structure by the method for one-step method from syngas preparing low-carbon olefins, its step is as follows:

1) catalyst with core-casing structure for preparing is added in the reaction tube, with the hydrogen reducing of nitrogen dilution, wherein to account for the volume percent content of gaseous mixture be 5% to hydrogen;

2) reduction makes reaction tube be down to room temperature after finishing, and, is warming up to reaction temperature again and reacts to predetermined reaction pressure with synthesis gas booster reaction system; Predetermined reaction pressure is 1-10MPa; Synthesis gas composition: by volume, H

2: CO is 1-6:1; Reaction temperature is 200-500 ℃; Feed volume air speed 1000-10000h

-1

Regulate the mass ratio of core catalyst and lamella catalyst by changing described shell thickness, thus the conditioned reaction process.

Described step 2) utilizes gas-chromatography on-line analysis product composition in.

Beneficial effect of the present invention: adopt catalyst with core-casing structure, synthetic being coupling in the reactor with two reactions of MTO reaction of methyl alcohol reacted, simplified process route, the product of previous step reaction is as the reactant of next step reaction, can impel by the chemical reaction equilibrium of constantly breaking the methyl alcohol synthetic reaction reaction to carry out to the direction of product always, improve the selective of the conversion ratio of CO and ethene, propylene.The thickness of shell homogeneous makes the methyl alcohol that generates at catalyst nucleus all have equal chance to see through lamella catalyst and carries out the MTO reaction, has improved the purpose products collection efficiency; Shell has suppressed the alkene of generation and contacting of catalyst nucleus simultaneously, and the alkene of having avoided generating is catalyzed into alkane by catalyst nucleus; The exclusive pore passage structure of shell also has the molecule sieving actoion, reduces high carbon product and generates, thereby suppress the catalyst coking and deactivation, prolongs the service life of composite catalyst.

The specific embodiment

Below in conjunction with embodiment the present invention is further elaborated.

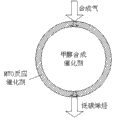

A kind of catalyst with core-casing structure by the one-step method from syngas preparing low-carbon olefins, the nuclear of this catalyst with core-casing structure are methanol synthesis catalyst; The shell of this catalyst with core-casing structure is the MTO catalysts of outer molecular screen membrane structure; The shell thickness is the 1-15 micron, and the aperture of shell film is 0.3-0.6nm.Its schematic diagram is seen Fig. 1, only represent in the drawings entering and diffusion process of a direction, in fact synthesis gas can enter the core catalyst through all directions of shell film, and the methyl alcohol of generation also can in the process that diffuse out the MTO reaction occur from all directions of shell film.

Described shell film adopts the crystal seed method preparation, and described nuclear adopts the coprecipitation preparation.

Described methanol synthesis catalyst is cupric oxide and zinc oxide, and adds in the following auxiliary agent one or more: zirconia, aluminium oxide, nickel oxide, cobalt oxide, cerium oxide, iron oxide, manganese oxide, silica, magnesia, calcium oxide, titanium oxide, vanadium oxide, chromium oxide, niobium oxide, molybdenum oxide, tin oxide.

Described MTO catalysts is modified ZSM-5 Series Molecules sieve membrane or SAPO Series Molecules sieve membrane.

Embodiment 1

1) with salpeter solution and the Na of copper zinc-aluminium

2CO

3The solution co-precipitation, suction filtration, oven dry and roasting get the copper Zinc-aluminium;

2) press Al

2O

3: P

2O

5: SiO

2: TEAOH:H

2The mol ratio of O is the synthetic liquid of 0.3:1:0.2:2:100 configuration, at 150 ℃ of hydro-thermal reaction 20h, gets the molecular sieve crystal seed.Crystal seed is coated on copper Zinc-aluminium carrier surface, the carrier that applies crystal seed is put into synthetic liquid at 170 ℃ of crystallization 100h, make the catalyst with core-casing structure of SAPO-17 molecular screen membrane coated copper Zinc-aluminium, the gained catalyst with core-casing structure is seen Fig. 2, its sectional view is seen Fig. 3,6 microns of molecular sieve thickness, the aperture of shell film are 0.4nm;

3) catalyst with core-casing structure for preparing is added in the reaction tube, with the hydrogen reducing of nitrogen dilution, wherein to account for the volume percent content of gaseous mixture be 5% to hydrogen;

4) make reaction tube be down to room temperature after reduction finishes,, be warming up to again reaction temperature and react to predetermined pressure with synthesis gas booster reaction system, and with gas-chromatography on-line analysis product composition.Reaction pressure 1MPa; Synthesis gas composition: by volume, H

2: CO is 1:1; Reaction temperature is 200 ℃; Charging air speed 1000h

-1The CO conversion ratio is 20%, and ethene and Propylene Selectivity are 96%.

Embodiment 2

1) with salpeter solution and the Na of copper zinc cobalt

2CO

3The solution co-precipitation, suction filtration, oven dry and roasting get copper zinc cobalt/cobalt oxide;

2) press Al

2O

3: SiO

2: TPAOH:EtOH:H

2The mol ratio of O is the synthetic liquid of 2:1:0.01:5:300 configuration, at 180 ℃ of hydro-thermal reaction 10h, gets the molecular sieve crystal seed.Crystal seed is coated on copper zinc cobalt/cobalt oxide carrier surface, the carrier that applies crystal seed is put into synthetic liquid at 190 ℃ of crystallization 50h, make the catalyst with core-casing structure of modified zsm-5 zeolite film coated copper zinc cobalt/cobalt oxide, 15 microns of molecular sieve thickness, the aperture of shell film is 0.5nm;

3) catalyst with core-casing structure for preparing is added in the reaction tube, with the hydrogen reducing of nitrogen dilution, wherein to account for the volume percent content of gaseous mixture be 5% to hydrogen;

4) make reaction tube be down to room temperature after reduction finishes,, be warming up to again reaction temperature and react to predetermined pressure with synthesis gas booster reaction system, and with gas-chromatography on-line analysis product composition.Reaction pressure 1MPa; Synthesis gas composition, by volume, H

2/ CO is 6; Reaction temperature is 500 ℃; Feed volume air speed 10000h

-1The CO conversion ratio is 15%, and ethene and Propylene Selectivity are 97%.

Embodiment 3

1) with the salpeter solution of copper zinc, hydrochloric acid solution and the Na of nickel manganese chromium

2CO

3The solution co-precipitation, suction filtration, oven dry and roasting get copper zinc-nickel manganese chromated oxide;

2) press Al

2O

3: P

2O

5: SiO

2: TEAOH:H

2The mol ratio of O is the synthetic liquid of 3:2:1.5:0.1:500 configuration, at 160 ℃ of hydro-thermal reaction 40h, gets the molecular sieve crystal seed.Crystal seed is coated on copper zinc-nickel manganese chromated oxide carrier surface, the carrier that applies crystal seed is put into synthetic liquid at 165 ℃ of crystallization 70h, make the catalyst with core-casing structure of SAPO-34 molecular screen membrane coated copper zinc-nickel manganese chromated oxide, 1 micron of molecular sieve thickness;

3) catalyst with core-casing structure for preparing is added in the reaction tube, with the hydrogen reducing of nitrogen dilution, wherein to account for the volume percent content of gaseous mixture be 5% to hydrogen;

4) make reaction tube be down to room temperature after reduction finishes,, be warming up to again reaction temperature and react to predetermined pressure with synthesis gas booster reaction system, and with gas-chromatography on-line analysis product composition.Reaction pressure 5MPa; Synthesis gas composition: H

2/ CO is 4; Reaction temperature is 400 ℃; Charging air speed 4000h

-1The CO conversion ratio is 25%, and ethene and Propylene Selectivity are 99%.

Embodiment 4

1) with the salpeter solution of copper zinc, sulfuric acid solution and the Na of titanium

2CO

3The solution co-precipitation, suction filtration, oven dry and roasting get copper zinc titanium oxide;

2) press Al

2O

3: P

2O

5: SiO

2: TEAOH:H

2The mol ratio of O is the synthetic liquid of 1.2:0.8:2.5:1.5:70 configuration, at 175 ℃ of hydro-thermal reaction 50h, gets the molecular sieve crystal seed.Crystal seed is coated on copper Zinc-aluminium carrier surface, the carrier that applies crystal seed is put into synthetic liquid at 190 ℃ of crystallization 30h, make the catalyst with core-casing structure of SAPO-26 molecular screen membrane coated copper zinc titanium oxide, 6 microns of molecular sieve thickness;

3) catalyst with core-casing structure for preparing is added in the reaction tube, with the hydrogen reducing of nitrogen dilution, wherein to account for the volume percent content of gaseous mixture be 5% to hydrogen;

4) make reaction tube be down to room temperature after reduction finishes,, be warming up to again reaction temperature and react to predetermined pressure with synthesis gas booster reaction system, and with gas-chromatography on-line analysis product composition.Reaction pressure 7MPa; Synthesis gas composition: H

2/ CO is 3; Reaction temperature is 300 ℃; Charging air speed 7000h

-1The CO conversion ratio is 20%, and ethene and Propylene Selectivity are 96%.

Embodiment 5

1) with salpeter solution and the Na of copper zinc cerium

2CO

3The solution co-precipitation, suction filtration, oven dry and roasting get copper zinc cerium oxide;

2) press Al

2O

3: P

2O

5: SiO

2: TEAOH:H

2The mol ratio of O is the synthetic liquid of 2.3:1.9:1:3.2:420 configuration, at 185 ℃ of hydro-thermal reaction 20h, gets the molecular sieve crystal seed.Crystal seed is coated on copper zinc cerium oxide carrier surface, the carrier that applies crystal seed is put into synthetic liquid at 195 ℃ of crystallization 50h, make the catalyst with core-casing structure of SAPO-26 molecular screen membrane coated copper zinc cerium oxide, 3 microns of molecular sieve thickness;

3) catalyst with core-casing structure for preparing is added in the reaction tube, with the hydrogen reducing of nitrogen dilution, wherein to account for the volume percent content of gaseous mixture be 5% to hydrogen;

4) make reaction tube be down to room temperature after reduction finishes,, be warming up to again reaction temperature and react to predetermined pressure with synthesis gas booster reaction system, and with gas-chromatography on-line analysis product composition.Reaction pressure 7MPa; Synthesis gas composition: H

2/ CO is 3; Reaction temperature is 300 ℃; Charging air speed 7000h

-1The CO conversion ratio is 22%, and ethene and Propylene Selectivity are 97%.

Embodiment 6

1) with salpeter solution, Ludox and the Na of copper zinc

2CO

3The solution co-precipitation, suction filtration, oven dry and roasting get copper zinc Si oxide;

2) press Al

2O

3: P

2O

5: SiO

2: TEAOH:H

2The mol ratio of O is the synthetic liquid of 2.3:1.9:1:3.2:420 configuration, at 185 ℃ of hydro-thermal reaction 20h, gets the molecular sieve crystal seed.Crystal seed is coated on copper zinc Si oxide carrier surface, the carrier that applies crystal seed is put into synthetic liquid at 195 ℃ of crystallization 50h, make the catalyst with core-casing structure of SAPO-26 molecular screen membrane coated copper zinc Si oxide, 5 microns of molecular sieve thickness;

3) catalyst with core-casing structure for preparing is added in the reaction tube, with the hydrogen reducing of nitrogen dilution, wherein to account for the volume percent content of gaseous mixture be 5% to hydrogen;

4) make reaction tube be down to room temperature after reduction finishes,, be warming up to again reaction temperature and react to predetermined pressure with synthesis gas booster reaction system, and with gas-chromatography on-line analysis product composition.Reaction pressure 3MPa; Synthesis gas composition: H

2/ CO is 5; Reaction temperature is 400 ℃; Charging air speed 4000h

-1The CO conversion ratio is 24%, and ethene and Propylene Selectivity are 96%.