CN113481881A - Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams - Google Patents

Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams Download PDFInfo

- Publication number

- CN113481881A CN113481881A CN202110727944.9A CN202110727944A CN113481881A CN 113481881 A CN113481881 A CN 113481881A CN 202110727944 A CN202110727944 A CN 202110727944A CN 113481881 A CN113481881 A CN 113481881A

- Authority

- CN

- China

- Prior art keywords

- bridge

- dismantling

- construction

- width

- rebuilding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000010276 construction Methods 0.000 title claims abstract description 61

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 26

- 239000010959 steel Substances 0.000 claims abstract description 26

- 238000000034 method Methods 0.000 claims abstract description 8

- 230000007246 mechanism Effects 0.000 claims description 6

- 238000004080 punching Methods 0.000 claims description 6

- 230000000149 penetrating effect Effects 0.000 claims description 3

- 230000008569 process Effects 0.000 abstract description 4

- 238000010586 diagram Methods 0.000 description 7

- 230000032258 transport Effects 0.000 description 7

- 230000008901 benefit Effects 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000008859 change Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000009407 construction method and process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01D—CONSTRUCTION OF BRIDGES, ELEVATED ROADWAYS OR VIADUCTS; ASSEMBLY OF BRIDGES

- E01D22/00—Methods or apparatus for repairing or strengthening existing bridges ; Methods or apparatus for dismantling bridges

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Bridges Or Land Bridges (AREA)

Abstract

The invention provides a construction method for splicing, removing and rebuilding a T-shaped structure navigation bridge of a hanging beam, which comprises the following steps: s1: newly building a spliced wide bridge, and erecting steel trestle platforms on two sides of the original high-speed navigation bridge to construct the spliced wide bridge; s2: the method comprises the following steps of (1) converting traffic and removing a half-width old bridge, changing the original high-speed half-width traffic guidance to a wide bridge spliced at two sides, and removing the half-width old bridge by adopting a disassembly and construction integrated bridge girder erection machine; s3: constructing a half-width new bridge, and constructing the new bridge at the original bridge position by using a disassembly and construction integrated bridge girder erection machine; s4: the traffic is converted and the other half of old bridge is removed, the traffic flow is guided to the split wide bridge and the newly built half of bridge, and the other half of old bridge is removed; s5: and finishing the construction of the whole bridge, newly building another half of new bridge, and finishing the width splicing, dismantling and rebuilding construction of the whole bridge. The invention not only ensures the lower navigation but also ensures the passing of high-speed vehicles, does not influence the passing vehicles in the construction process, improves the construction safety, finishes the construction of dismantling and building a new construction by using a dismantling and building integrated bridge girder erection machine, reduces the mechanical use and improves the economical efficiency.

Description

Technical Field

The invention belongs to the technical field of bridge demolition and reconstruction construction, and particularly relates to a construction method for width splicing, demolition and reconstruction of a T-shaped structure navigable bridge with a suspended beam.

Background

With the rapid development of the economic society, part of the expressways built in early stage show the conditions of saturated traffic volume and very short transport capacity, the road traffic capacity and service level are reduced, the safety accidents are gradually increased, the expressways cannot well adapt to the requirements of the economic society development and the urban and rural construction, and the reconstruction and expansion of the expressways become an important and urgent task in the construction of the national traffic infrastructure. The T-structure and hanging-beam structure type navigation bridge also meets the requirement of dismantling, rebuilding and splicing width, when the T-structure and hanging-beam structure type navigation bridge is constructed, the lower part of the T-structure and hanging-beam structure type navigation bridge is not only required to be ensured to be safely and normally navigated, but also the original high-speed vehicles on the bridge are required to be normally navigated, the construction period is short, the task is heavy, and the T-structure and hanging-beam structure type navigation bridge has high requirements on construction methods and processes.

Disclosure of Invention

The invention provides a construction method for splicing, removing and rebuilding a T-shaped suspended beam navigable bridge, which not only ensures lower navigation, but also ensures normal passing of high-speed vehicles, does not influence the passing vehicles in the construction process, improves the construction safety, completes the construction of removing and building a new bridge by using a disassembly and construction integrated bridge girder erection machine, reduces the use of machinery, and improves the economy.

The technical scheme of the invention is as follows: a construction method for splicing, widening and dismantling reconstruction of a T-beam structure navigation bridge comprises the following steps:

s1: newly building a spliced wide bridge, and erecting steel trestle platforms on two sides of the original high-speed navigation bridge to construct the spliced wide bridge;

s2: the method comprises the following steps of (1) converting traffic and removing a half-width old bridge, changing the original high-speed half-width traffic guidance to a wide bridge spliced at two sides, and removing the half-width old bridge by adopting a disassembly and construction integrated bridge girder erection machine;

s3: constructing a half-width new bridge, and constructing the new bridge at the original bridge position by using a disassembly and construction integrated bridge girder erection machine;

s4: the traffic is converted and the other half of old bridge is removed, the traffic flow is guided to the split wide bridge and the newly built half of bridge, and the other half of old bridge is removed;

s5: and finishing the construction of the whole bridge, newly building another half of new bridge, and finishing the width splicing, dismantling and rebuilding construction of the whole bridge.

Preferably, step S1 construction is pieced together the wide bridge and is included and is pieced together the wide bridge platform at the lower part of piece together, and the steel trestle platform does not communicate in the navigation hole position of former high-speed navigation bridge, guarantees the navigation under the bridge, utilizes the integrated bridge girder erection machine of building up of piecing together wide bridge beam slab, adopts the rear to feed the roof beam during erection, does not cause the influence to former high-speed traffic.

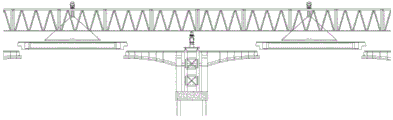

Preferably, the dismantling and building integrated bridge girder erection machine comprises supporting legs, walking wheels arranged at the bottoms of the supporting legs, transverse connecting trusses arranged on the supporting legs, and a hoisting mechanism arranged on the transverse connecting trusses, wherein the hoisting mechanism can move along the transverse connecting trusses to transport dismantled or to-be-installed piers, bearing platforms and bridge decks.

Preferably, the step S2 of dismantling the half-width old bridge includes cutting and punching holes on a bridge deck and a flange between two pier studs of the T-structure of the half-width old bridge, the cutting position avoids the position of the T-structure steel strand, the temporary support pier of the steel pipe is erected for the platform by passing through the original bearing platform from the cutting and punching position, the support platform is used as a support platform for dismantling the support leg of the integrated bridge erecting machine during bridge dismantling, the hanging beams on two sides of the T-structure are dismantled simultaneously, the joint of the hanging beams is cut by a rope saw, the dismantling integrated bridge erecting machine lifts the hanging beams to the transportation beam gun carriage at the tail part and transports the hanging beams along the bridge floor, and after the pier studs, the bearing platform and the like are cut by the rope saw, the dismantling integrated bridge erecting machine is hoisted to the tail transportation vehicle and transports the tail part.

Preferably, the two sides of the T-shaped structure are symmetrically removed when the T-shaped structure is removed and the hanging beams on the two sides of the T-shaped structure are removed.

Preferably, the temporary steel pipe buttress comprises a plurality of steel pipe piles vertically penetrating the ground, the bridge deck and the flange and perforated by cutting, transverse connecting pipes connected to the steel pipe piles and oblique cross connecting pipes.

Preferably, the step S3 of constructing the new bridge and the step S5 of newly constructing the other half of the new bridge include constructing a pile foundation, a bearing platform and a pier of the newly constructed bridge at the position of removing the original bridge, and the upper structural beam slab of the newly constructed bridge is erected by using the dismantling and constructing integrated bridge girder erection machine.

Compared with the prior art, the invention has the advantages that:

(1) the bridge erecting machine is used as a disassembly and construction integrated bridge erecting machine for bridge disassembly and construction, so that the equipment utilization rate is improved, the use of other mechanical equipment is reduced, and the economic benefit is improved;

(2) the construction is carried out by utilizing the dismantling and building integrated bridge girder erection machine, so that the navigation below the bridge girder erection machine is ensured, the normal passing of high-speed vehicles is ensured, the passing vehicles are not influenced in the construction process, and the construction safety is improved;

(3) the T-shaped structure and the hanging beams on the two sides of the T-shaped structure are symmetrically dismantled, so that the balance stability in the dismantling process is ensured, and the construction safety is enhanced;

(4) the cutting on decking and the edge of a wing is punched and original cushion cap erects the interim buttress of steel pipe when utilizing to demolish, as the supporting platform of building integral type bridging machine landing leg, has reduced the material and the preface of landing leg supporting platform construction, has practiced thrift the resource, has reduced construction rubbish, has improved the efficiency of construction.

Drawings

FIG. 1 is a schematic flow chart of a construction method for splicing, removing and rebuilding a T-shaped structure navigable bridge of a suspended beam in the invention;

FIG. 2 is a schematic diagram of a newly-built wide spliced bridge of the construction method for splicing, removing and rebuilding the T-shaped structure navigation bridge with the hanging beams;

FIG. 3 is a traffic conversion schematic diagram of step S2 of the construction method for widening, dismantling and rebuilding the T-shaped beam-hung navigable bridge of the invention;

FIG. 4 is a schematic diagram of symmetrically dismantling hanging beams on two sides of a T-shaped structure in the construction method for splicing, dismantling and rebuilding the T-shaped structure navigation bridge with the hanging beams;

FIG. 5 is a schematic diagram of two symmetrically dismantled T-shaped structures in the construction method for splicing, dismantling and rebuilding the T-shaped structure navigation bridge of the hanging beam;

FIG. 6 is a structural schematic diagram of a temporary steel pipe buttress in the construction method for widening, dismantling and rebuilding a T-shaped suspended beam navigable bridge;

FIG. 7 is a schematic diagram of the erection of a beam slab of an upper structure of a reconstruction bridge in the construction method for splicing, dismantling and reconstructing the T-shaped suspended beam navigable bridge of the invention;

FIG. 8 is a bridge widening rebuilding completion schematic diagram of the construction method for widening, dismantling and rebuilding the T-shaped suspended beam navigable bridge.

Detailed Description

The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which a person skilled in the art can, without any creative effort, fully implement the present invention.

The invention provides a construction method for splicing, removing and rebuilding a T-shaped structure navigation bridge of a hanging beam, which comprises the following steps of:

s1: newly building a spliced wide bridge, and erecting steel trestle platforms at two sides of the original high-speed navigation bridge to construct the spliced wide bridge, referring to the figure 1;

s2: the method comprises the following steps of (1) converting traffic and removing a half-width old bridge, changing the original high-speed half-width traffic guidance to a wide bridge spliced at two sides, and removing the half-width old bridge by adopting a disassembly and construction integrated bridge girder erection machine, referring to fig. 2;

s3: constructing a half-width new bridge, and constructing the new bridge at the original bridge position by using a disassembly and construction integrated bridge girder erection machine;

s4: the traffic is converted and the other half of old bridge is removed, the traffic flow is guided to the split wide bridge and the newly built half of bridge, and the other half of old bridge is removed;

s5: and finishing the construction of the whole bridge, newly building another half of new bridge, and finishing the width splicing, dismantling and rebuilding construction of the whole bridge.

Preferably, step S1 construction is pieced together the wide bridge and is included and is pieced together the wide bridge platform at the lower part of piece together, and the steel trestle platform does not communicate in the navigation hole position of former high-speed navigation bridge, guarantees the navigation under the bridge, utilizes the integrated bridge girder erection machine of building up of piecing together wide bridge beam slab, adopts the rear to feed the roof beam during erection, does not cause the influence to former high-speed traffic.

Preferably, the dismantling and building integrated bridge girder erection machine comprises supporting legs, walking wheels arranged at the bottoms of the supporting legs, transverse connecting trusses arranged on the supporting legs, and a hoisting mechanism arranged on the transverse connecting trusses, wherein the hoisting mechanism can move along the transverse connecting trusses to transport dismantled or to-be-installed piers, bearing platforms and bridge decks.

Preferably, the step S2 of removing the old half-bridge includes cutting and punching holes on a bridge deck and a flange between two T-structure pillars of the old half-bridge, the cutting position avoids the position of the T-structure steel strand, a temporary support pier of a steel pipe is erected for a platform by passing through an original bearing platform from the cutting and punching position, the temporary support pier is used as a support platform for a support leg of the integrated bridge girder erection machine when the bridge is removed, a hanging beam on two sides of the T-structure is removed at the same time, the joint of the hanging beam is cut by a wire saw, the integrated bridge girder erection machine lifts the hanging beam to a girder transporting carriage at the tail part and transports the hanging beam along the bridge floor, and after the pillars and the bearing platform are cut by the wire saw, the integrated bridge girder erection machine is lifted to the tail transport carriage and transported away, and refer to fig. 3-5.

Preferably, the two sides of the T-shaped structure are symmetrically removed when the T-shaped structure is removed and the hanging beams on the two sides of the T-shaped structure are removed.

Preferably, the temporary steel pipe buttress comprises a plurality of steel pipe piles vertically penetrating the ground, the bridge deck and the flange and perforated by cutting, transverse connecting pipes connected to the steel pipe piles and oblique cross connecting pipes.

Preferably, the step S3 of constructing the new bridge and the step S5 of newly constructing another half of the new bridge include constructing a pile foundation, a bearing platform, and a pier of the newly constructed bridge at the position of removing the original bridge, and the upper structural beam slab of the newly constructed bridge is erected by using the integrated bridge girder erection machine for dismantling and building, referring to fig. 6 to 7.

While the preferred embodiments of the invention have been described, it is to be understood that the invention is not limited to the precise embodiments described, and that equipment and structures not described in detail are understood to be practiced as commonly known in the art; any simple modification, equivalent change and modification of the above embodiments according to the technical essence of the present invention by those skilled in the art can be made without departing from the technical scope of the present invention, and still fall within the protection scope of the technical solution of the present invention.

Claims (7)

1. A construction method for splicing, widening and dismantling reconstruction of a T-beam structure navigation bridge is characterized by comprising the following steps:

s1: newly building a spliced wide bridge, and erecting steel trestle platforms on two sides of the original high-speed navigation bridge to construct the spliced wide bridge;

s2: the method comprises the following steps of (1) converting traffic and removing a half-width old bridge, changing the original high-speed half-width traffic guidance to a wide bridge spliced at two sides, and removing the half-width old bridge by adopting a disassembly and construction integrated bridge girder erection machine;

s3: constructing a half-width new bridge, and constructing the new bridge at the original bridge position by using a disassembly and construction integrated bridge girder erection machine;

s4: the traffic is converted and the other half of old bridge is removed, the traffic flow is guided to the split wide bridge and the newly built half of bridge, and the other half of old bridge is removed;

s5: and finishing the construction of the whole bridge, newly building another half of new bridge, and finishing the width splicing, dismantling and rebuilding construction of the whole bridge.

2. The construction method for assembling, dismantling and rebuilding the T-beam-hung type navigable bridge of claim 1, wherein the constructing the assembled wide bridge in the step S1 comprises erecting a steel trestle platform at the lower part of the assembled wide bridge, the steel trestle platform is not communicated at the position of a navigable hole of the original high-speed navigable bridge, the navigable under the bridge is ensured, the assembled wide bridge beam slab is erected by utilizing a dismantling and building integrated bridge erecting machine, and the rear beam feeding is adopted during the erection, so that the original high-speed navigable car is not affected.

3. The construction method for widening, dismantling and rebuilding of a T-structure navigable bridge with suspended beams according to claim 2, characterized in that the dismantling and rebuilding integrated bridge girder erection machine comprises supporting legs, traveling wheels arranged at the bottoms of the supporting legs, transverse connecting trusses arranged on the supporting legs, and hoisting mechanisms arranged on the transverse connecting trusses, wherein the hoisting mechanisms can move along the transverse connecting trusses to transport dismantled or to-be-installed piers, bearing platforms and bridge decks.

4. The construction method for widening, dismantling and rebuilding the T-frame through-pass bridge of the hanging beam as claimed in claim 3, wherein the dismantling of the half-frame old bridge in the step S2 includes cutting and punching holes on the bridge deck and the flange between the two T-frame piers of the half-frame old bridge, the cutting position avoids the T-frame steel strand position, a steel pipe temporary buttress is erected for the platform by using the original bearing platform from the cutting and punching position, the steel pipe temporary buttress is used as a supporting platform for dismantling the integral bridge erecting machine support legs during bridge dismantling, meanwhile, the hanging beam on two sides of the T-frame is dismantled, the joint of the hanging beam is cut by a rope saw, the dismantling integral bridge erecting machine lifts the hanging beam to the girder transporting gun position of the tail portion to transport along the bridge floor, and after the pier columns, the bearing platform and the like are cut by the rope saw, the dismantling integral bridge erecting machine is lifted to the tail transport vehicle to transport away.

5. The construction method for splicing, dismantling and reconstructing the T-shaped structure navigable bridge of the hanging beam according to claim 4, characterized in that the T-shaped structure and the hanging beam at the two sides of the T-shaped structure are dismantled symmetrically at two sides.

6. The construction method for widening, dismantling and rebuilding of a T-beam navigable bridge according to claim 5, wherein the temporary steel pipe buttresses comprise a plurality of steel pipe piles vertically penetrating the ground, the bridge deck and the flanges and perforated by cutting, transverse connecting pipes connected to the steel pipe piles and oblique cross connecting pipes.

7. The construction method for widening, dismantling and rebuilding of a T-shaped suspended girder navigable bridge according to claim 6, wherein the step S3 of constructing the new bridge and the step S5 of constructing the other half of the new bridge comprise constructing pile foundations, bearing platforms and piers of the rebuilt new bridge at the position of dismantling the original bridge, and the erection of the upper structural beam slab of the rebuilt bridge is performed by using a dismantling and building integrated bridge girder erection machine.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110727944.9A CN113481881A (en) | 2021-06-29 | 2021-06-29 | Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110727944.9A CN113481881A (en) | 2021-06-29 | 2021-06-29 | Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN113481881A true CN113481881A (en) | 2021-10-08 |

Family

ID=77936445

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110727944.9A Pending CN113481881A (en) | 2021-06-29 | 2021-06-29 | Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113481881A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114000444A (en) * | 2021-11-30 | 2022-02-01 | 中铁二十二局集团第三工程有限公司 | Urban navigation large-span bridge dismantling and building integrated supporting structure and construction method |

| CN114875804A (en) * | 2022-06-14 | 2022-08-09 | 保利长大工程有限公司 | Erection construction method for prefabricated box girder of spliced wide bridge |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104060545A (en) * | 2014-07-10 | 2014-09-24 | 中交二航局第四工程有限公司 | Overwater suspension cable trestle capable of being used for pumping concrete and construction method and application thereof |

| CN107268463A (en) * | 2017-08-18 | 2017-10-20 | 中铁二局集团有限公司 | A kind of continuous beam method for dismounting |

| CN107386128A (en) * | 2017-09-15 | 2017-11-24 | 中铁第五勘察设计院集团有限公司 | Double-T shaped beam bridge changes beam construction system |

| CN110184950A (en) * | 2019-05-21 | 2019-08-30 | 宁波市政工程建设集团股份有限公司 | The construction method of bridge former address reorganization and expansion new bridge under a kind of guarantor's gating condition |

| CN110331675A (en) * | 2019-07-02 | 2019-10-15 | 中交二公局东萌工程有限公司 | A kind of construction method of reorganization and expansion bridge |

| CN110904868A (en) * | 2019-12-19 | 2020-03-24 | 贵州大成恒通建设工程有限公司 | Bridge dismantling construction method for reverse segment hoisting of bridge girder erection machine |

| CN111560864A (en) * | 2020-01-17 | 2020-08-21 | 广东冠粤路桥有限公司 | Method for dismantling old bridge |

| CN111705682A (en) * | 2020-04-07 | 2020-09-25 | 中交第二航务工程局有限公司 | A construction method and equipment for demolition and reconstruction of superstructure of widened bridge across electrified railway |

| CN112211112A (en) * | 2020-09-03 | 2021-01-12 | 宁波市政工程建设集团股份有限公司 | Steel box girder installation method adopting double-guide-girder erection machine on existing bridge |

-

2021

- 2021-06-29 CN CN202110727944.9A patent/CN113481881A/en active Pending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104060545A (en) * | 2014-07-10 | 2014-09-24 | 中交二航局第四工程有限公司 | Overwater suspension cable trestle capable of being used for pumping concrete and construction method and application thereof |

| CN107268463A (en) * | 2017-08-18 | 2017-10-20 | 中铁二局集团有限公司 | A kind of continuous beam method for dismounting |

| CN107386128A (en) * | 2017-09-15 | 2017-11-24 | 中铁第五勘察设计院集团有限公司 | Double-T shaped beam bridge changes beam construction system |

| CN110184950A (en) * | 2019-05-21 | 2019-08-30 | 宁波市政工程建设集团股份有限公司 | The construction method of bridge former address reorganization and expansion new bridge under a kind of guarantor's gating condition |

| CN110331675A (en) * | 2019-07-02 | 2019-10-15 | 中交二公局东萌工程有限公司 | A kind of construction method of reorganization and expansion bridge |

| CN110904868A (en) * | 2019-12-19 | 2020-03-24 | 贵州大成恒通建设工程有限公司 | Bridge dismantling construction method for reverse segment hoisting of bridge girder erection machine |

| CN111560864A (en) * | 2020-01-17 | 2020-08-21 | 广东冠粤路桥有限公司 | Method for dismantling old bridge |

| CN111705682A (en) * | 2020-04-07 | 2020-09-25 | 中交第二航务工程局有限公司 | A construction method and equipment for demolition and reconstruction of superstructure of widened bridge across electrified railway |

| CN112211112A (en) * | 2020-09-03 | 2021-01-12 | 宁波市政工程建设集团股份有限公司 | Steel box girder installation method adopting double-guide-girder erection machine on existing bridge |

Non-Patent Citations (2)

| Title |

|---|

| 刘水: "浅谈旧桥改造施工组织与精细化管理", 山东工业技术, no. 9 * |

| 叶显亮: "预应力混凝土T型刚构桥旧桥拆除分析", 山西建筑, vol. 42, no. 22, pages 157 - 158 * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114000444A (en) * | 2021-11-30 | 2022-02-01 | 中铁二十二局集团第三工程有限公司 | Urban navigation large-span bridge dismantling and building integrated supporting structure and construction method |

| CN114875804A (en) * | 2022-06-14 | 2022-08-09 | 保利长大工程有限公司 | Erection construction method for prefabricated box girder of spliced wide bridge |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN106120787A (en) | A kind of construction method carrying out pile sinking based on pushing tow travelling platform | |

| CN110886187B (en) | Cable crane system installation system and construction method thereof | |

| CN211340473U (en) | Steel guide beam for large-span steel beam pushing construction | |

| CN211947993U (en) | Support for large-span cast-in-situ bridge construction | |

| CN113481881A (en) | Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams | |

| CN104790297A (en) | Flexible arch splicing method for steel trussed beams | |

| CN111593665B (en) | Bridge construction method integrating dismantling and construction | |

| CN111608086A (en) | A kind of steel composite beam lateral flat roof construction structure and method | |

| CN114457668A (en) | Large-span spatial special-shaped arch rib flying-swallow type basket steel box arch bridge and rapid construction method | |

| CN105544409B (en) | Double guide beam bridge erecting machine sets up combination beam and now spells a section girder steel construction technology | |

| CN110093863A (en) | A kind of double face integration Bridge Erector being not provided with front leg strut | |

| CN113774822B (en) | Dismantling method of old reinforced concrete bridge | |

| CN215629392U (en) | Wide equipment is pieced together to prefabricated case roof beam | |

| JP2020002778A (en) | Bridge pier construction method | |

| CN114808772A (en) | Method for decomposing, reinforcing and dismantling beam lattice over existing railway continuous beam bridge | |

| CN102535344A (en) | Concrete transportation method for bridge body of high-pier bridge in gully region | |

| CN111705682A (en) | A construction method and equipment for demolition and reconstruction of superstructure of widened bridge across electrified railway | |

| CN111851307A (en) | Construction method of large-span prefabricated corrugated web composite box girder transport frame | |

| CN214695701U (en) | Pile foundation hinders to clear away with two system conversion pile foundation underpinning structures | |

| CN114961338A (en) | Temporary support method for top plate of PC (polycarbonate) assembly type engineering basement | |

| CN214328478U (en) | Three-tower self-anchored suspension bridge | |

| CN115478486A (en) | Erecting method of pier-beam integrated construction bridge girder erection machine | |

| CN211848997U (en) | Semi-span pier beam-lifting machine for bridge on high pier column prefabricated T beam in limited space | |

| CN101886370A (en) | Bridge pier steel column girder | |

| CN219972971U (en) | Hollow slab reinforced structure system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20211008 |