CN111705682A - A construction method and equipment for demolition and reconstruction of superstructure of widened bridge across electrified railway - Google Patents

A construction method and equipment for demolition and reconstruction of superstructure of widened bridge across electrified railway Download PDFInfo

- Publication number

- CN111705682A CN111705682A CN202010267066.2A CN202010267066A CN111705682A CN 111705682 A CN111705682 A CN 111705682A CN 202010267066 A CN202010267066 A CN 202010267066A CN 111705682 A CN111705682 A CN 111705682A

- Authority

- CN

- China

- Prior art keywords

- bridge

- original

- load

- dismantling

- original bridge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000010276 construction Methods 0.000 title claims abstract description 38

- 238000000034 method Methods 0.000 claims abstract description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 4

- 238000005096 rolling process Methods 0.000 claims description 3

- 238000009435 building construction Methods 0.000 abstract description 2

- 229910000831 Steel Inorganic materials 0.000 description 8

- 239000010959 steel Substances 0.000 description 8

- 238000010586 diagram Methods 0.000 description 2

- 238000005303 weighing Methods 0.000 description 2

- 210000001367 artery Anatomy 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000009440 infrastructure construction Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 239000002893 slag Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01D—CONSTRUCTION OF BRIDGES, ELEVATED ROADWAYS OR VIADUCTS; ASSEMBLY OF BRIDGES

- E01D22/00—Methods or apparatus for repairing or strengthening existing bridges ; Methods or apparatus for dismantling bridges

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Bridges Or Land Bridges (AREA)

Abstract

本发明公开了一种跨电气化铁路加宽桥梁上部结构拆除与重建的施工方法及其设备,所述跨电气化铁路加宽桥梁为具有左幅和右幅的原桥,包括以下步骤:S1,在所述原桥的右幅外侧拼建桥梁节段;S2,将所述原桥的左幅的交通引导至所述步骤S1当中的所述原桥的右幅,拆除所述原桥的左幅;S3,在原桥的左幅拆除原址处进行重建;S4,将步骤S2中引导至所述原桥的右幅的交通引导至所述步骤S3中所述原桥的新的左幅;S5,拆除所述原桥的右幅,并在原桥右幅被拆除的原址再次新建桥梁;S6,将拼建桥梁节段朝的新建桥梁的方向横向滑移拼接。本发明具有结构稳定、施工工序优良的技术效果,本发明可广泛应用于建筑施工技术领域。

The invention discloses a construction method and equipment for dismantling and rebuilding the superstructure of a widened bridge across an electrified railway, and the widened bridge across an electrified railway is an original bridge with left width and right width, comprising the following steps: S1, in A bridge segment is constructed on the outside of the right side of the original bridge; S2, the traffic of the left side of the original bridge is guided to the right side of the original bridge in the step S1, and the left side of the original bridge is dismantled. ; S3, carry out reconstruction at the original site of the left side of the original bridge; S4, guide the traffic of the right side of the former bridge in the step S2 to the new left side of the former bridge described in the step S3; S5, Demolish the right side of the original bridge, and build a new bridge at the original site where the right side of the original bridge was removed; S6, splicing and splicing the constructed bridge segments laterally in the direction of the newly-built bridge. The invention has the technical effects of stable structure and excellent construction procedures, and can be widely used in the technical field of building construction.

Description

技术领域technical field

本发明涉及建筑施工技术领域。更具体地说,本发明涉及一种跨电气化铁路加宽桥梁上部结构拆除与重建的施工方法及其设备。The invention relates to the technical field of building construction. More specifically, the present invention relates to a construction method and equipment for dismantling and rebuilding the superstructure of a widened bridge across an electrified railway.

背景技术Background technique

几年来,我国高速公路建设取得了飞速的发展,为国民经济快速发展起到了重要的基础保障性作用。然而随着我国经济社会的快速发展,部分早期建设的高速公路,特别是部分四车道高速公路,呈现出交通量饱和、运输能力十分紧张的状况,道路通行能力和服务水平降低、安全事故逐渐增多,已不能很好的适应经济社会发展和城乡建设的需求,高速公路改扩建已成为我国交通基础设施建设中的一项重要而紧迫的任务。高速公路改扩建工程的实施,必然对现有交通流有所干扰,特别是跨既有铁路桥梁的拆除与重建,需要在最短的时间和有限的工作面内完成桥梁的拆除、运渣、防护、新建等内容。另外20世纪90年代,国家开始对原有铁路进行电气化改造,增加了铁路上部接触网,接触网电压为10~500kV,在原有建限标准条件下建造的上跨桥梁,由于下部铁路电气化改造后接触网与桥梁梁底间距较近,另由于上跨铁路交通量饱和及结构即将达到使用年限问题,急需进行拆除后重建加宽桥梁;且大部分桥梁加宽施工要在保通条件下进行。由于铁路营业线为国家运输的大动脉,营业线施工将影响营业线的正常运营,传统的施工设备及方法不适用于本类施工;Over the past few years, my country's expressway construction has achieved rapid development, which has played an important basic guarantee role for the rapid development of the national economy. However, with the rapid development of my country's economy and society, some early-constructed expressways, especially some four-lane expressways, are in a situation of saturated traffic volume and very tight transportation capacity. Road traffic capacity and service level are reduced, and safety accidents are gradually increasing. , can not well meet the needs of economic and social development and urban and rural construction, highway reconstruction and expansion has become an important and urgent task in my country's transportation infrastructure construction. The implementation of the expressway reconstruction and expansion project will inevitably interfere with the existing traffic flow, especially the demolition and reconstruction of bridges across existing railways. It is necessary to complete the demolition, slag transportation and protection of bridges in the shortest time and within a limited working face. , New, etc. In addition, in the 1990s, the state began to electrify the original railway, adding a catenary on the upper part of the railway. The catenary voltage is 10-500kV. The upper-span bridge built under the original construction limit standard conditions, due to the electrification of the lower railway. The distance between the catenary and the bottom of the bridge beam is relatively close. In addition, due to the saturation of the upper-span railway traffic and the impending service life of the structure, it is urgent to rebuild and widen the bridge after demolition; and most of the bridge widening construction must be carried out under the condition of ensuring the passage. Since the railway business line is the main artery of national transportation, the construction of the business line will affect the normal operation of the business line, and the traditional construction equipment and methods are not suitable for this type of construction;

上跨电电气化铁路桥梁的拆除与加宽重建,由于铁路电气化改造后,在先前建限标准下建设的上跨桥梁,接触网距离梁底间距较小,在营业线施工中无法增加防护措施;采用传统的施工设备与方法,不能满足工期及保通的要求,另外工序复杂要求营业线配合施工的天窗点较多,不利于施工成本控制。For the dismantling and widening and reconstruction of the electrified railway bridge on the upper span, because the upper span bridge built under the previous construction limit standard after the electrification of the railway has a small distance between the catenary and the bottom of the beam, it is impossible to add protective measures during the construction of the business line; The use of traditional construction equipment and methods cannot meet the requirements of construction period and security. In addition, the complex process requires more skylight points for the business line to cooperate with the construction, which is not conducive to the control of construction costs.

发明内容SUMMARY OF THE INVENTION

本发明的目的是提供一种结构稳定、施工工序优良的跨电气化铁路加宽桥梁上部结构拆除与重建的施工方法。The purpose of the present invention is to provide a construction method for dismantling and rebuilding the superstructure of a widened bridge across an electrified railway with stable structure and excellent construction procedures.

为了实现根据本发明的这些目的和其它优点,提供了一种跨电气化铁路加宽桥梁上部结构拆除与重建的施工方法,所述跨电气化铁路加宽桥梁为具有左幅和右幅的原桥,包括以下步骤:In order to achieve these objects and other advantages according to the present invention, there is provided a construction method for dismantling and rebuilding the superstructure of a widened bridge across an electrified railway, the widened bridge across an electrified railway being an original bridge having a left width and a right width, Include the following steps:

S1,在所述原桥的右幅外侧拼建桥梁节段;S1, build a bridge segment on the outside of the right side of the original bridge;

S2,将所述原桥的左幅的交通引导至所述步骤S1当中的所述原桥的右幅,拆除所述原桥的左幅;S2, guiding the traffic of the left side of the original bridge to the right side of the original bridge in the step S1, and removing the left side of the original bridge;

S3,将所述步骤S2中被拆除的原桥的左幅原址处进行重建,形成所述原桥的新的左幅;S3, rebuilding the original site of the left frame of the original bridge removed in the step S2 to form a new left frame of the original bridge;

S4,将所述步骤S2中引导至所述原桥的右幅的交通引导至所述步骤S3中所述原桥的新的左幅;S4, guiding the traffic directed to the right frame of the original bridge in the step S2 to the new left frame of the original bridge in the step S3;

S5,拆除所述原桥的右幅,并在原桥右幅被拆除的原址再次新建桥梁;S5, demolish the right frame of the original bridge, and build a new bridge at the original site where the right frame of the original bridge was demolished;

S6,将所述步骤S1中的拼建桥梁节段朝所述步骤S5中再次新建桥梁的方向横向滑移拼接形成所述原桥的新的右幅;S6, splicing and splicing the bridge segment constructed in the step S1 laterally towards the direction of the new bridge in the step S5 to form a new right width of the original bridge;

其中,所述步骤S4中所述原桥的新的左幅与所述步骤S6中所述原桥的新的右幅形成新桥。Wherein, the new left frame of the original bridge in the step S4 and the new right frame of the original bridge in the step S6 form a new bridge.

优选地,所述步骤S2中拆除所述原桥的左幅以及所述步骤S5中拆除所述原桥的右幅,均包括:Preferably, the removal of the left frame of the original bridge in the step S2 and the removal of the right frame of the original bridge in the step S5 include:

将所述原桥的梁板间的约束进行解除,并分割成小模块。The constraints between the beams and slabs of the original bridge are released and divided into small modules.

优选地,将所述原桥的梁板间的约束进行解除包括以下步骤:Preferably, releasing the constraints between the beams and slabs of the original bridge includes the following steps:

SS1,沿每相邻两梁板的中线长度方向间隔钻孔,形成具有数排圆孔的所述原桥的桥面;SS1, drill holes at intervals along the length direction of the midline of each adjacent two girder slabs to form the deck of the original bridge with several rows of circular holes;

S2,对所述原桥的两梁板之间的相邻钻孔之间的节段进行切割,直至切割完成所述原桥的所有相邻梁板之间相邻钻孔之间的节段后,形成若干独立的单片梁;S2, cutting the segments between the adjacent drill holes between the two girder plates of the original bridge until the segments between the adjacent drill holes between all the adjacent girder plates of the original bridge are cut After that, several independent monolithic beams are formed;

S3,安装拆除设备,对所述步骤S2中所有的单片梁进行拆除、移运。S3, install and dismantle equipment, and dismantle and move all the single-piece beams in the step S2.

优选地,所述原桥的左幅和右幅,其中任意一个桥面进行拆除工序时,另一个桥面都设置为营业线防护平台以及运输通道。Preferably, when any one of the left and right sides of the original bridge undergoes the dismantling process, the other bridge deck is set as a business line protection platform and a transportation channel.

一种跨电气化铁路加宽桥梁上部结构拆除与重建的设备,其特征在于,所述拆除设备为拆梁机,所述拆梁机横跨所述原桥的左幅和右幅、设置于原桥的正上方,用于拆除所述原桥的上部结构的所有单片梁;A device for dismantling and rebuilding the superstructure of a widened bridge across an electrified railway, characterized in that the dismantling device is a beam dismantling machine, and the beam dismantling machine spans the left and right sides of the original bridge and is arranged in the original directly above the bridge, for the removal of all monolithic beams of the superstructure of the original bridge;

所述拆梁机包括,支撑设置在所述原桥的桥面上的承重框架;The beam dismantling machine includes a load-bearing frame that supports and is arranged on the deck of the original bridge;

支撑滑动装置,其支撑设置在所述承重框架上形成悬臂;a support sliding device, which is supported and arranged on the load-bearing frame to form a cantilever;

起升机构,其可沿所述支撑梁的长度方向自由滑动悬挂于所述支撑梁的悬臂的底部,用于吊装所有所述单片梁。A hoisting mechanism, which can be freely slidably suspended on the bottom of the cantilever of the supporting beam along the length direction of the supporting beam, is used for hoisting all the single-piece beams.

优选地,所述承重框架包括:Preferably, the load-bearing frame includes:

若干对承重支腿,其沿所述原桥的横向截面方向等距设置,每一对所述承重支腿位于所述原桥上同一纵向水面截面位置;A plurality of pairs of load-bearing legs are arranged at equal distances along the transverse section direction of the original bridge, and each pair of the load-bearing legs is located at the same longitudinal water surface section position on the original bridge;

一对承重横梁,其分别对应架设于位于同一横向截面方向上的所有所述承重支腿的正上方;a pair of load-bearing beams, which are respectively erected directly above all the load-bearing legs located in the same transverse section direction;

若干承重支撑梁,其分别对应设置在位于同一纵向截面的每一对承重支腿之间;a plurality of load-bearing support beams, which are respectively arranged between each pair of load-bearing support legs located in the same longitudinal section;

若干可调支点装置,所有所述可调支点装置均分别对应设置在所有所述承重支腿的正下方,用于调节所述承重支腿的高度。A plurality of adjustable fulcrum devices, all the adjustable fulcrum devices are respectively disposed directly below all the load-bearing legs, for adjusting the height of the load-bearing legs.

优选地,所有所述承重支腿均包括,Preferably, all of said load-bearing legs comprise,

一对分腿,其上部靠拢、下部分开,且一对分腿之间还设置有若干连接梁。A pair of split legs, the upper part of which is close together and the lower part is separated, and a plurality of connecting beams are also arranged between the pair of split legs.

优选地,所述支撑滑动装置包括,Preferably, the support sliding device comprises,

一对横移天车,其对称设置在一对承重横梁上,并可沿一对所述承重横梁的长度方向自由移动;A pair of transverse cranes, which are symmetrically arranged on a pair of load-bearing beams, and can move freely along the length direction of the pair of load-bearing beams;

纵向大梁,其两端分别对应设置在一对所述横移天车上;the longitudinal beams, the two ends of which are respectively arranged on a pair of the traverse cranes;

其中,所述起升机构设置在所述纵向大梁上。Wherein, the lifting mechanism is arranged on the longitudinal beam.

优选地,还包括,转运小车,其设置在所述起升机构的自由端,用于装载所述单片梁,所述转运小车的底部设置有可自由滚动的行走轮。Preferably, it also includes a transfer trolley, which is arranged at the free end of the lifting mechanism and used for loading the single-piece beam, and the bottom of the transfer trolley is provided with freely rolling walking wheels.

本发明至少包括以下有益效果:The present invention includes at least the following beneficial effects:

(1)梁板小节段拆除,简化了桥梁拆除难度。(1) The removal of small sections of beams and slabs simplifies the difficulty of bridge removal.

(2)梁板搬移至另一幅桥面拆除,以桥梁作为营业线防护平台,杜绝了另外搭设平台。(2) The beams and slabs are moved to another bridge deck for removal, and the bridge is used as the protection platform for the business line, which prevents the erection of another platform.

(3)采用六个施工步骤进行原桥拆除与新建加宽施工,可保证施工期间不影响该施工路段的交通通行。(3) Six construction steps are adopted for the demolition of the original bridge and the new widening construction, which can ensure that the traffic of the construction section will not be affected during the construction period.

(4)拆梁机,结构稳定,刚性的支撑框架以及横跨左幅和右幅的承重横梁、以及设置与横梁上的横移天车。(4) Beam dismantling machine, stable structure, rigid support frame, load-bearing beams across the left and right beams, and traverse cranes set on the beams.

(5)拆梁机的人字形支腿设计,支撑稳定、增强了施工的安全性,适应性较强。(5) The herringbone outrigger design of the beam dismantling machine has stable support, enhances the safety of construction, and has strong adaptability.

本发明的其它优点、目标和特征将部分通过下面的说明体现,部分还将通过对本发明的研究和实践而为本领域的技术人员所理解。Other advantages, objects, and features of the present invention will appear in part from the description that follows, and in part will be appreciated by those skilled in the art from the study and practice of the invention.

附图说明Description of drawings

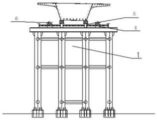

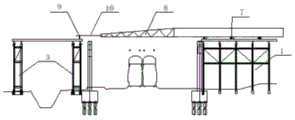

图1为本发明的拼建新桥梁节段的横断面方向的结构示意图;Fig. 1 is the structural representation of the cross-sectional direction of building a new bridge segment of the present invention;

图2为本发明拼建新桥梁节段的纵断面方向的结构示意图;Fig. 2 is the structural schematic diagram of the longitudinal section direction of the new bridge segment constructed by the present invention;

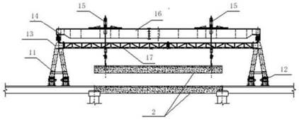

图3为本发明的拆梁机的纵断面方向的结构示意图;Fig. 3 is the structural representation of the longitudinal section direction of the beam dismantling machine of the present invention;

图4为本发明的拆梁机的横断面方向的结构示意图;Fig. 4 is the structural representation of the cross-sectional direction of the beam dismantling machine of the present invention;

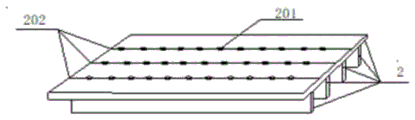

图5为本发明的单片梁的结构示意图。FIG. 5 is a schematic structural diagram of the monolithic beam of the present invention.

说明书附图标记说明:1、钢梁拼装平台,2、单片梁、3、顶推支墩,4、防护及操作平台,5、轨道梁,6、顶推防偏移装置,7、标高调节块,8、导梁,9、牵引千斤顶, 10、牵引绳,11、承重支腿,12、可调支点装置,13、承重横梁,14、横移天车,15、起升机构,16、纵向大梁,17、承重支撑梁,18、转运小车,201、圆孔,202、切缝。。Description of reference numerals in the manual: 1. Steel beam assembly platform, 2. Single-piece beam, 3. Pushing buttress, 4. Protection and operation platform, 5. Track beam, 6. Pushing and anti-excursion device, 7. Elevation Adjusting block, 8, guide beam, 9, traction jack, 10, traction rope, 11, load-bearing outrigger, 12, adjustable fulcrum device, 13, load-bearing beam, 14, traverse crane, 15, hoisting mechanism, 16 , Longitudinal beam, 17, Bearing support beam, 18, Transfer trolley, 201, Round hole, 202, Cut seam. .

具体实施方式Detailed ways

下面结合附图对本发明做进一步的详细说明,以令本领域技术人员参照说明书文字能够据以实施。The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

在本发明的描述中,术语“横向”、“纵向”、“上”、“下”、“前”、“后”、“左”、“右”、“竖直”、“水平”、“顶”、“底”、“内”、“外”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本发明和简化描述,并不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。In the description of the present invention, the terms "horizontal", "longitudinal", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", " The orientation or positional relationship indicated by "top", "bottom", "inside", "outside", etc. is based on the orientation or positional relationship shown in the accompanying drawings, and is only for the convenience of describing the present invention and simplifying the description, and is not indicated or implied. The device or element referred to must have a particular orientation, be constructed and operate in a particular orientation, and therefore should not be construed as limiting the invention.

如图1-5所示,一种跨电气化铁路加宽桥梁上部结构拆除与重建的施工方法,所述跨电气化铁路加宽桥梁为具有左幅和右幅的原桥,包括以下步骤:As shown in Figure 1-5, a construction method for dismantling and rebuilding the superstructure of a widened bridge across an electrified railway, where the widened bridge across an electrified railway is an original bridge with left and right widths, including the following steps:

S1,在所述原桥的右幅外侧拼建桥梁节段;S1, build a bridge segment on the outside of the right side of the original bridge;

S2,将所述原桥的左幅的交通引导至所述步骤S1当中的所述原桥的右幅,拆除所述原桥的左幅;S2, guiding the traffic of the left side of the original bridge to the right side of the original bridge in the step S1, and removing the left side of the original bridge;

S3,将所述步骤S2中被拆除的原桥的左幅原址处进行重建,形成所述原桥的新的左幅;S3, rebuilding the original site of the left frame of the original bridge removed in the step S2 to form a new left frame of the original bridge;

S4,将所述步骤S2中引导至所述原桥的右幅的交通引导至所述步骤S3中所述原桥的新的左幅;S4, guiding the traffic directed to the right frame of the original bridge in the step S2 to the new left frame of the original bridge in the step S3;

S5,拆除所述原桥的右幅,并在原桥右幅被拆除的原址再次新建桥梁;S5, demolish the right frame of the original bridge, and build a new bridge at the original site where the right frame of the original bridge was demolished;

S6,将所述步骤S1中的拼建桥梁节段朝所述步骤S5中再次新建桥梁的方向横向滑移拼接形成所述原桥的新的右幅;S6, splicing and splicing the bridge segment constructed in the step S1 laterally towards the direction of the new bridge in the step S5 to form a new right width of the original bridge;

其中,所述步骤S4中所述原桥的新的左幅与所述步骤S6中所述原桥的新的右幅形成新桥。Wherein, the new left frame of the original bridge in the step S4 and the new right frame of the original bridge in the step S6 form a new bridge.

在上述技术方案中,右幅外侧拼建桥梁节段施工中,新建原桥右幅外侧建1/4幅拼宽的新桥;In the above technical solution, during the construction of the bridge segment on the outer side of the right panel, a new bridge of 1/4 width is constructed on the outer side of the right panel of the original bridge;

在新桥的右幅与左幅的新建施工中,对桩基及下部结构进行分别施工,其中,上部结构采用钢箱梁形式,采用托拉法顶推施工,搭设钢梁拼装平台1、顶推支墩3、防护及操作平台4,顶推平台顶安装轨道梁5、顶推防偏移装置6与标高调节块7,拼装钢箱梁与导梁8,完成部分节段钢箱梁后在一侧顶推支墩3上安装牵引千斤顶9与牵引绳10,进行顶推施工,过程中通过顶推防偏移装置6防止钢梁偏移,通过标高调节块7调整标高,拖拉到导梁8落于一侧顶推支墩3上,停止拖拉,开始安装后节段钢梁,再重复以上步骤,直到将钢梁拖拉到设计位置;In the new construction of the right and left sides of the new bridge, the pile foundation and the lower structure are constructed separately. Among them, the upper structure is in the form of steel box girder, and the jacking method is used for construction, and a steel girder assembly platform is erected. 1. Push the support pier 3, the protection and operation platform 4, install the track beam 5 on the top of the push platform, push the anti-excursion device 6 and the elevation adjustment block 7, assemble the steel box girder and the guide beam 8, and complete the part of the segment steel box girder. A traction jack 9 and a traction rope 10 are installed on one side of the jacking pier 3 to carry out the jacking construction. During the process, the deflection prevention device 6 is used to prevent the steel beam from shifting. Beam 8 falls on one side thrust pier 3, stop dragging, start to install the back segment steel beam, and repeat the above steps until the steel beam is dragged to the design position;

在原桥的左幅和右幅拆除施工中,首先进行梁板间约束解除:先采用水磨钻沿相邻梁板中线钻孔,形成数排圆孔201,再在相邻孔内穿绳锯切割,形成数排切缝202,完全解除梁板约束,形成独立的单片梁2;在左右侧老桥桥面上安装拆梁机,首先安装可调支点装置12,再安装承重支腿11,然后安装承重横梁13,再然后安装承重支撑梁17,形成稳定的承重框架;在施工区以外预拼横移天车14,起升机构15,纵向大梁16,形成横移起重天车,采用起重装备将横移起重天车吊装至称重框架上,将起升机构15落于承重横梁13上,以上步骤就组成了拆梁机,对拆梁机进行测试及验收。起重天车横移至左侧老桥待拆除的单片梁2上方,通过起升机构15起吊单片梁2,起重天车横移至右侧老桥上,下放单片梁2至停放在右侧老桥上的转运小车18上,由转运小车18运输至制定场地;以此顺序全部拆除左侧老桥单片梁2,再拆除左侧老桥上的拆梁机,保留右侧老桥上的拆梁机。采用常规免爆工艺拆除右侧老桥下部结构。In the dismantling of the left and right sides of the original bridge, the constraints between the beams and slabs are first removed: first, use a water mill drill to drill along the center line of the adjacent beams and slabs to form several rows of

在另一种技术方案中,所述步骤S2中拆除所述原桥的左幅以及所述步骤S5中拆除所述原桥的右幅,均包括:In another technical solution, the removal of the left frame of the original bridge in the step S2 and the removal of the right frame of the original bridge in the step S5 include:

将所述原桥的梁板间的约束进行解除,并分割成小模块。The constraints between the beams and slabs of the original bridge are released and divided into small modules.

在另一种技术方案中,将所述原桥的梁板间的约束进行解除包括以下步骤:In another technical solution, releasing the constraints between the beams and slabs of the original bridge includes the following steps:

SS1,沿每相邻两梁板的中线长度方向间隔钻孔,形成具有数排圆孔201的所述原桥的桥面;SS1, drill holes at intervals along the length direction of the midline of each adjacent two girder plates to form the deck of the original bridge with several rows of

S2,对所述原桥的两梁板之间的相邻钻孔之间的节段进行切割,直至切割完成所述原桥的所有相邻梁板之间相邻钻孔之间的节段后,形成若干独立的单片梁2;S2, cutting the segments between the adjacent drill holes between the two girder plates of the original bridge until the segments between the adjacent drill holes between all the adjacent girder plates of the original bridge are cut After that, several independent

S3,安装拆除设备,对所述步骤S2中所有的单片梁2进行拆除、移运。S3, install and dismantle equipment, and dismantle and move all the single-

在另一种技术方案中,所述原桥的左幅和右幅,其中任意一个桥面进行拆除工序时,另一个桥面都设置为营业线防护平台以及运输通道。In another technical solution, when any one of the left and right panels of the original bridge undergoes the dismantling process, the other bridge deck is set as a business line protection platform and a transportation channel.

本发明的一种跨电气化铁路加宽桥梁上部结构拆除与重建的设备,所述拆除设备为拆梁机,所述拆梁机横跨所述原桥的左幅和右幅、设置于原桥的正上方,用于拆除所述原桥的上部结构的所有单片梁2;The present invention is a device for dismantling and rebuilding the superstructure of a widened bridge across an electrified railway. The dismantling device is a girder dismantling machine. The girder dismantling machine spans the left and right widths of the original bridge and is arranged on the original bridge. Right above, all

所述拆梁机包括,支撑设置在所述原桥的桥面上的承重框架;The beam dismantling machine includes a load-bearing frame that supports and is arranged on the deck of the original bridge;

支撑滑动装置,其支撑设置在所述承重框架上形成悬臂;a supporting sliding device, which is supported and arranged on the load-bearing frame to form a cantilever;

起升机构15,其可沿所述支撑梁的长度方向自由滑动悬挂于所述支撑梁的悬臂的底部,用于吊装所有所述单片梁2。A

在另一种技术方案中,所述承重框架包括:In another technical solution, the load-bearing frame includes:

若干对承重支腿11,其沿所述原桥的横向截面方向等距设置,每一对所述承重支腿 11位于所述原桥上同一纵向水面截面位置;Several pairs of load-

一对承重横梁13,其分别对应架设于位于同一横向截面方向上的所有所述承重支腿 11的正上方;A pair of load-

若干承重支撑梁17,其分别对应设置在位于同一纵向截面的每一对承重支腿11之间;A plurality of load-bearing support beams 17 are respectively arranged between each pair of load-

若干可调支点装置12,所有所述可调支点装置12均分别对应设置在所有所述承重支腿11的正下方,用于调节所述承重支腿11的高度。A plurality of

在上述技术方案中,首先安装可调支点装置12,再安装承重支腿11,然后安装承重横梁13,再然后安装承重支撑梁17,形成稳定的承重框架。In the above technical solution, the

在另一种技术方案中,所有所述承重支腿11均包括,In another technical solution, all the load-

一对分腿,其上部靠拢、下部分开,且一对分腿之间还设置有若干连接梁。A pair of split legs, the upper part of which is close together and the lower part is separated, and a plurality of connecting beams are also arranged between the pair of split legs.

在上述技术方案中,一对分腿形成“八”字形支撑结构,其稳定性和支撑性更好。In the above technical solution, a pair of split legs forms an "eight"-shaped support structure, which has better stability and support.

在另一种技术方案中,所述支撑滑动装置包括,In another technical solution, the supporting sliding device includes,

一对横移天车14,其对称设置在一对承重横梁13上,并可沿一对所述承重横梁13的长度方向自由移动;A pair of

纵向大梁16,其两端分别对应设置在一对所述横移天车14上;the

其中,所述起升机构15设置在所述纵向大梁16上。Wherein, the

在上述技术方案中,在施工区以外预拼横移天车14,起升机构15,纵向大梁16,形成横移起重天车,采用起重装备将横移起重天车吊装至称重框架上,将起升机构15落于承重横梁13上。In the above technical solution, the

在另一种技术方案中,还包括,转运小车18,其设置在所述起升机构15的自由端,用于装载所述单片梁2,所述转运小车18的底部设置有可自由滚动的行走轮。In another technical solution, it also includes a

在上述技术方案中,转运小车18用于运送拆除后的单片梁2以及将待安装的构建移运至施工现场。In the above technical solution, the

尽管本发明的实施方案已公开如上,但其并不仅仅限于说明书和实施方式中所列运用,它完全可以被适用于各种适合本发明的领域,对于熟悉本领域的人员而言,可容易地实现另外的修改,因此在不背离权利要求及等同范围所限定的一般概念下,本发明并不限于特定的细节和这里示出与描述的图例。Although the embodiment of the present invention has been disclosed as above, it is not limited to the application listed in the description and the embodiment, and it can be applied to various fields suitable for the present invention. For those skilled in the art, it can be easily Therefore, the invention is not limited to the specific details and illustrations shown and described herein without departing from the general concept defined by the appended claims and the scope of equivalents.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010267066.2A CN111705682B (en) | 2020-04-07 | 2020-04-07 | Construction method and equipment for dismantling and reconstructing upper structure of widening bridge across electrified railway |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010267066.2A CN111705682B (en) | 2020-04-07 | 2020-04-07 | Construction method and equipment for dismantling and reconstructing upper structure of widening bridge across electrified railway |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111705682A true CN111705682A (en) | 2020-09-25 |

| CN111705682B CN111705682B (en) | 2024-10-29 |

Family

ID=72537068

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010267066.2A Active CN111705682B (en) | 2020-04-07 | 2020-04-07 | Construction method and equipment for dismantling and reconstructing upper structure of widening bridge across electrified railway |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111705682B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113123248A (en) * | 2021-04-24 | 2021-07-16 | 甘肃省交通规划勘察设计院股份有限公司 | Construction process of prefabricated small box girder bridge with half-first and whole-second |

| CN113481881A (en) * | 2021-06-29 | 2021-10-08 | 中交二公局第三工程有限公司 | Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009052306A (en) * | 2007-08-28 | 2009-03-12 | Kajima Corp | Bridge girder replacement method |

| CN107268462A (en) * | 2017-06-27 | 2017-10-20 | 浙江交工集团股份有限公司 | A kind of overbridge static(al) removes the construction method in situ rebuild and its special protection net |

| CN107675636A (en) * | 2017-09-08 | 2018-02-09 | 武汉二航路桥特种工程有限责任公司 | A kind of universal bridge structure thing method for dismounting and system |

| CN109468960A (en) * | 2018-12-07 | 2019-03-15 | 武汉二航路桥特种工程有限责任公司 | Rapid replacement method and replacement system of expressway flyover |

| CN212714587U (en) * | 2020-04-07 | 2021-03-16 | 中交第二航务工程局有限公司 | Equipment for removing and rebuilding superstructure of widened bridge across electrified railway |

-

2020

- 2020-04-07 CN CN202010267066.2A patent/CN111705682B/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009052306A (en) * | 2007-08-28 | 2009-03-12 | Kajima Corp | Bridge girder replacement method |

| CN107268462A (en) * | 2017-06-27 | 2017-10-20 | 浙江交工集团股份有限公司 | A kind of overbridge static(al) removes the construction method in situ rebuild and its special protection net |

| CN107675636A (en) * | 2017-09-08 | 2018-02-09 | 武汉二航路桥特种工程有限责任公司 | A kind of universal bridge structure thing method for dismounting and system |

| CN109468960A (en) * | 2018-12-07 | 2019-03-15 | 武汉二航路桥特种工程有限责任公司 | Rapid replacement method and replacement system of expressway flyover |

| CN212714587U (en) * | 2020-04-07 | 2021-03-16 | 中交第二航务工程局有限公司 | Equipment for removing and rebuilding superstructure of widened bridge across electrified railway |

Non-Patent Citations (1)

| Title |

|---|

| 郝庆芬;: "浅谈东陵大桥加宽设计及施工工艺", 北方交通, no. 06, 28 June 2013 (2013-06-28), pages 102 - 104 * |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113123248A (en) * | 2021-04-24 | 2021-07-16 | 甘肃省交通规划勘察设计院股份有限公司 | Construction process of prefabricated small box girder bridge with half-first and whole-second |

| CN113481881A (en) * | 2021-06-29 | 2021-10-08 | 中交二公局第三工程有限公司 | Construction method for splicing, widening and dismantling reconstruction of T-shaped structure navigation bridge with hanging beams |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111705682B (en) | 2024-10-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11634877B2 (en) | Method for removal of temporary support system for road bridge pre-fabricated small box girder-type concealed bent cap, and equipment therefor | |

| JP5179804B2 (en) | Mobile suspension support | |

| US4301565A (en) | Method and system for the removal and replacement of a bridge | |

| CN101781878B (en) | Integral lifting template of main pylon of single-pylon cable-stayed bridge without dorsal cables and lifting construction method thereof | |

| CN106120787A (en) | A kind of construction method carrying out pile sinking based on pushing tow travelling platform | |

| CN106149576A (en) | On across the whole assembling and dismantling of the most wired bridge except and construction method of installation | |

| CN110468743B (en) | Movable hanging bracket for transformation of old bridge pier cap and construction method | |

| CN106284109A (en) | On across the most wired bridge main beam method for dismounting | |

| CN101481903B (en) | The method of erecting the main truss of the suspension bridge in mountainous area by reversing the cable-span crane | |

| CN111705682B (en) | Construction method and equipment for dismantling and reconstructing upper structure of widening bridge across electrified railway | |

| CN205257790U (en) | Fixed high -low leg handle portal crane | |

| CN207987749U (en) | Ride cable-styled erection crane | |

| CN110552294B (en) | Reverse girder erection construction platform of bridge girder erection machine and construction method thereof | |

| CN102535344A (en) | Concrete transportation method for bridge body of high-pier bridge in gully region | |

| CN212714587U (en) | Equipment for removing and rebuilding superstructure of widened bridge across electrified railway | |

| CN210174677U (en) | Hard crossing for changing electrified railway into moving | |

| KR20100021874A (en) | Method for removing, installing and replacing an upper structure of bridge, and lifting apparatus and transportation vehicle of the upper structure of bridge for the method | |

| CN211141349U (en) | Track panel well gantry crane foundation fixing structure | |

| CN112211112A (en) | Steel box girder installation method adopting double-guide-girder erection machine on existing bridge | |

| CN104213512B (en) | Fortune frame railway D beam one chassis and D beam installation method | |

| CN204919348U (en) | Supplementary head tower of using of self anchored suspension bridge installation | |

| CN211171638U (en) | Reverse beam erecting construction platform of bridge girder erection machine | |

| CN202466421U (en) | High-pier bridge body concrete pouring pump line grounded steel truss trestle bridge in gully areas | |

| CN107604823A (en) | It is a kind of that the construction method for shipping beam is crossed by railway | |

| CN210368664U (en) | Wide-body bridge girder erection machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |